AUTOFLAME Mk7 D.T.I. Setup Manual

Hide thumbs

Also See for Mk7 D.T.I.:

- Setup manual (153 pages) ,

- Manual (86 pages) ,

- Setup manual (116 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AUTOFLAME Mk7 D.T.I.

- Page 1 ...

- Page 3 Department: This manual and all the information contained herein is copyright of Autoflame Engineering Ltd. It may not be copied in the whole or part without the consent of the Managing Director. Autoflame Engineering Ltd’s policy is one of continuous improvement in both design and manufacture.

- Page 5 Autoflame product range, i.e. combustion, electrical and control. The sale of Autoflame’s systems and equipment referred to in this Manual assume that the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high...

-

Page 6: Table Of Contents

Contents MK7 DATA TRANSFER INTERFACE MODULE ............. 1 Overview of the Mk7 D.T.I......................1 1.1.1 Introduction to the Mk7 D.T.I................... 1 1.1.2 Information Available from Mk7 D.T.I................1 Fixing Holes and Dimensions ....................4 SET-UP AND CONNECTIONS ..................5 Wiring ............................ - Page 7 Information, Errors and Lockouts ..................62 4.5.1 Digital Inputs (1x Reference) ..................62 4.5.2 Analogue Inputs (3x References) ................. 63 4.5.3 Error and Lockout Codes ....................64 4.5.4 Water Level ........................68 INTERACTING WITH THE MK7 D.T.I................ 69 Burner Information ........................ 69 M.M.

-

Page 9: Mk7 Data Transfer Interface Module

Modbus communications. Typical remote B.M.S. information and operational facilities are subject to the particular site and management system requirements. The Autoflame network operates using a two core screened cable and features dedicated data ports for RS422 and Ethernet connections. The Mk7 D.T.I. poles each item on the network periodically, storing up-to-date information every 2 seconds. - Page 10 1 Mk7 Data Transfer Interface Module Fuel flow metering values Load detector type (temperature/pressure) 16 lockout and error history with date and conditions Auto/hand/low flame hold operation Number of channels used Channe1, 2, 3, 4, 7, servomotor angle ...

- Page 11 1 Mk7 Data Transfer Interface Module Mini Mk 8 M.M. Actual boiler temperature (deg. C/F) or pressure (Bar/PSI) Required setpoint i.e. required boiler temperature (deg. C/F) or pressure (Bar/PSI) Burner on/off status Burner firing rate (%) ...

-

Page 12: Fixing Holes And Dimensions

1 Mk7 Data Transfer Interface Module Fixing Holes and Dimensions Page 4 Mk7 D.T.I. Set-Up Guide 10.08.2015... -

Page 13: Set-Up And Connections

2 Set-Up and Connections SET-UP AND CONNECTIONS Wiring 2.1.1 Mk7 D.T.I. Wiring Diagram Figure 2.1.1.i Mk7 D.T.I. Wiring Diagram Electrical Specifications: Max power for the Mk7 D.T.I. power supply is 184W. Figure 2.1.1.ii Mk7 D.T.I. Board 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 5... -

Page 14: System Schematic

2 Set-Up and Connections 2.1.2 System Schematic Page 6 Mk7 D.T.I. Set-Up Guide 10.08.2015... -

Page 15: Modules Connection

2 Set-Up and Connections 2.1.3 M.M. Modules Connection 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 7... -

Page 16: Mk7 M.m. And Mk8 E.g.a. With Mk7 D.t.i

2 Set-Up and Connections 2.1.4 Mk7 M.M. and Mk8 E.G.A. with Mk7 D.T.I. Page 8 Mk7 D.T.I. Set-Up Guide 10.08.2015... -

Page 17: Mk7 D.t.i. Set-Up

2 Set-Up and Connections Mk7 D.T.I. Set-Up 2.2.1 Mk7 M.M. Options and Parameters To get the Mk7 D.T.I. to communicate with the Mk7 M.M., the right communication settings need to be set on the Mk7 M.M. The following options and parameters need to be set. 10.08.2015 Mk7 D.T.I. - Page 18 2 Set-Up and Connections DTI Comms Mode Mk6 DTI - 9600bps Mk7 DTI - 19200bps Lead/Lag (IBS) and DTI: A lead boiler can be selected by connecting a line voltage to terminal 88 on the appropriate MM. Only 1 MM may be selected as lead boiler at a time, or the sequencing will not operate.

- Page 19 2 Set-Up and Connections 0 - 10 Sequencing: Highest MM ID. This parameter speeds up communications between MM's when sequening. Shuffle sequencing: Disabled Sequence order changed from DTI. 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 11...

-

Page 20: Mini Mk8 M.m. Options And Parameters

2 Set-Up and Connections 2.2.2 Mini Mk8 M.M. Options and Parameters To get the Mk7 D.T.I. to communicate with the Mini Mk8 M.M., the right communication settings need to be set on the Mini Mk8 M.M. The following options and parameters need to be set. Page 12 Mk7 D.T.I. - Page 21 2 Set-Up and Connections Sequencing and D.T.I Enable: A lead boiler can be selected by press Lead Boiler in the IBS screen or via the D.T.I. if optioned. Only 1 M.M. may be selected as lead boiler at a time, or the sequencing will not operate.The Lead Boiler button on the M.M.

- Page 22 2 Set-Up and Connections Sequencing - Highest M.M. ID: This sets the number of M.M.s in that sequencing loop for improved comms. 1 - 10 Shuffle Sequencing: This allows the sequence order to be changed remotely through the D.T.I. or Modbus. Disabled.

-

Page 23: Configuring The Boiler Room

2 Set-Up and Connections 2.2.3 Configuring the Boiler Room The Mk7 D.T.I. is a gateway for communicating with the Autoflame range of products. Through the D.T.I. touchscreen, you can configure the boiler room with the following features: Modbus Read/Write ability ... - Page 24 2 Set-Up and Connections Figure 2.2.3.ii Password Screen You will be presented with a password screen. The same password that is used on the D.T.I. is used to connect to that D.T.I. through the CEMS Audit Software. Once the password is entered you can now configure the boilers, D.T.I.

- Page 25 2 Set-Up and Connections Figure 2.2.3.iii From the Boiler Configuration, boilers can be added or deleted; up to 10 boilers can be configured for communication with the Mk7 D.T.I. To add a boiler, press 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 17...

- Page 26 2 Set-Up and Connections Figure 2.2.3.iv Add Boiler Select an empty boiler position to add a boiler, and then press Page 18 Mk7 D.T.I. Set-Up Guide 10.08.2015...

- Page 27 2 Set-Up and Connections Figure 2.2.3.v Boiler Setup In the Boiler Setup screen, the type of burner can be configured, whether it is a standalone D.T.I. or with the M.M., and also if it taking data from the E.G.A. If an E.G.A. is being used together with the M.M., than the D.T.I. will receive the E.G.A. data from the M.M.

- Page 28 2 Set-Up and Connections Figure 2.2.3.vi Boiler I/O Configuration Once the Boiler Setup has been saved, press to add an analogue or digital I/O module for that boiler. Page 20 Mk7 D.T.I. Set-Up Guide 10.08.2015...

- Page 29 2 Set-Up and Connections Figure 2.2.3.vii Add IO Unit Select the ID number required for the analogue or digital I/O module and press . Once the I/O modules have been added, please see section 3 for full configuration. 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 21...

-

Page 30: Setup

2 Set-Up and Connections 2.2.4 D.T.I. Setup Figure 2.2.4.i D.T.I. Setup Screen 1 To set up the D.T.I., press the button in the Boiler Configuration screen. On the first screen you are able to change the date, time and time formats, as well as the D.T.I. password and display name. - Page 31 2 Set-Up and Connections Figure 2.2.4.ii D.T.I Setup Screen 2 Pressing the button on the screen in figure 2.2.4.i will take you to the next screen to set up the D.T.I. shown in figure 2.2.4.ii. To set the units, press on the ‘Metric’ or ‘Imperial’ button as appropriate. ...

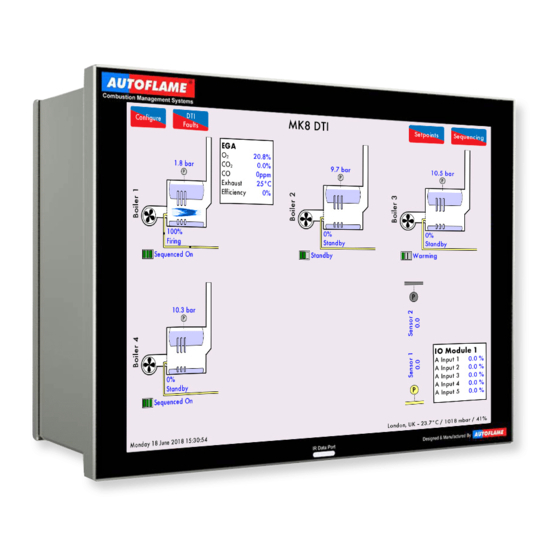

- Page 32 2 Set-Up and Connections Figure 2.2.4.iii Home Screen Once the D.T.I. has been set up press . To enter the D.T.I. setup screen once the D.T.I. has been fully configured, press on the Home screen. Page 24 Mk7 D.T.I. Set-Up Guide 10.08.2015...

-

Page 33: Deleting Boilers And I/O Modules

2 Set-Up and Connections 2.2.5 Deleting Boilers and I/O Modules Figure 2.2.5.i Edit/Delete Boiler To edit or delete a boiler, press on the Home screen and then as required. 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 25... - Page 34 2 Set-Up and Connections Figure 2.2.5.ii Delete Boiler Select the boiler to delete, and then press Page 26 Mk7 D.T.I. Set-Up Guide 10.08.2015...

- Page 35 2 Set-Up and Connections Figure 2.2.5.iii Delete Boiler The next screen will display an option to delete or keep the stored logged data for that boiler. Once the required selection has been made, press 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 27...

- Page 36 2 Set-Up and Connections Figure 2.2.5.iv Delete Boiler Press Yes or No to confirm whether or not to delete that boiler, and press . Once the boiler (and its data) has been deleted, the D.T.I. will go back to the Boiler Configuration screen. Page 28 Mk7 D.T.I.

- Page 37 2 Set-Up and Connections Figure 2.2.5.v Delete I/O Module 1 To delete an analogue or digital I/O module once it has been added, go to the Boiler I/O Configuration screen Figure 2.2.5.i press Press either as required. Similar to deleting a boiler from the D.T.I., the next screen gives an option to delete or keep the stored logged data for that I/O module.

-

Page 38: Network Set-Up

2 Set-Up and Connections 2.2.6 Network Set-Up The Mk7 D.T.I. is a gateway for communications between the Autoflame system and PC or Building Management System. Enter the Network setup screen by pressing ‘Configure’ on the DTI home screen, and then ‘Network Setup.’... - Page 39 Domain Name Server (DNS) that may be configured in this Network Setup screen. [For example, if the DNS name is set to ‘demo,’ and is connected to the Autoflame network, a connection to the DTI may be established by connecting to ‘demo.autoflame.com.’] Port Number A default port number of 80 is used for the DTI (default webserver port).

-

Page 40: Mk7 D.t.i. Connections

2.3.1 PC Connection The DTI can be connected directly to a PC through the Ethernet. The Autoflame CEMS Audit software displays information on all the boilers in the boiler room, just as on the Mk7 D.T.I. This monitoring and control software can be customised with uploaded boiler images, electrical and mechanical drawings, and site names. -

Page 41: Network Connection

20. If you using Plant Manager version of the PC DTI software, to activate the software, go to the ‘Help’ tab on the taskbar and select ‘Licence…’ Then contact Autoflame Sales on + 44 (0) 845 872 2000, with the licence code and we will you send you an activation key to be typed into this dialogue box. -

Page 42: Pinging The D.t.i

2 Set-Up and Connections 2.3.3 Pinging the D.T.I. To determine the cause of communication failure, pinging the D.T.I. checks that a connection has definitely been established between the computer and the D.T.I. 1. Go to the ‘Start Menu’ on the computer. 2. -

Page 43: Rs422 Connection

Once this has been set on the BMS, communications will be established with the D.T.I. If this doesn’t connect, please request Modscan 32 software from Autoflame Technical Support, to check that the comms from the D.T.I. For a full list of Modbus addresses, please Section 4. -

Page 44: Analogue And Digital Inputs/Outputs

10 Mk7 I/O modules. The data gathered by the Autoflame Mk7 D.T.I. for the Mk7 I/O modules is logged for 2 years, and can be viewed using the CEMS Audit Software. -

Page 45: Wiring And Dimensions

3 Analogue and Digital Inputs/Outputs 3.1.2 Wiring and Dimensions Figure 3.1.2.i Wiring 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 37... - Page 46 3 Analogue and Digital Inputs/Outputs Mk7 Universal I/O Module Dimensions Figure 3.1.2.ii Dimensions Page 38 Mk7 D.T.I. Set-Up Guide 10.08.2015...

-

Page 47: Set-Up I/O Modules On Mk7 D.t.i

3 Analogue and Digital Inputs/Outputs 3.1.3 Set-Up I/O Modules on Mk7 D.T.I. The Mk7 D.T.I. is capable of communications with up to 10 analogue and 10 digital, or 10 Universal input/ output (IO) modules. Once the I/O modules have been configured through the I/O Board Configurator for the Mk7 Universal I/O module (please refer to the PC Software Guide). - Page 48 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.ii Digital I/O Screen The digital I/O screens display both inputs and outputs as instantaneous values. The Mk7 D.T.I. can have up to 16 digital inputs. Page 40 Mk7 D.T.I. Set-Up Guide 10.08.2015...

- Page 49 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.iii Digital I/O Label To rename a digital input or output, press ‘Please enter a label,’ or the label text if it is already setup. 10.08.2015 Mk7 D.T.I. Set-Up Guide Page 41...

- Page 50 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.iv Digital I/O Screen – Alarms Each I/O input can be set to monitor/ alarm. To enable the I/O module alarms, press the digital I/O screen. From this screen, you can set the I/O module to either Alarm, or display a fault when a digital input is gained or lost.

- Page 51 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.v Digital I/O Log Screen The data for digital input and output is stored on the D.T.I. To view this information, press on the press on each of the inputs at the top of the D.T.I. screen. To zoom into data, press on two dates/ time on the x-axis to zoom between the two.

- Page 52 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.vi Analogue I/O Screen If an analogue I/O module has been selected, the screen in Figure 3.1.3.vi will appear. The analogue I/O screen displays both inputs and outputs as instantaneous values. The Mk7 D.T.I. can have up to 6 4-20mA signals.

- Page 53 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.vii Analogue I/O Label To edit the label that is seen on the screen, press ‘Please enter a label,’ or the label text if already setup. To set the units, minimum value and maximum valve, press on the relevant boxes. If a rate is set on the analogue unit, a totalised value is stored both on the DTI and on the IO module.

- Page 54 3 Analogue and Digital Inputs/Outputs Figure 3.1.3.viii Analogue I/O Screen – Alarms Each I/O input can be set to monitor/alarm. To enable the I/O module alarms, press on the button. From this screen, you can set the I/O module to either Alarm, or display a fault when an analogue signal drops below or rises above a set value.

- Page 55 3 Analogue and Digital Inputs/Outputs Dosing Pump Figure 3.1.3.ix Analogue I/O Log The data from each input and output is stored on the D.T.I. and logged for 2 years, and can be viewed by pressing the button, and then pressing on each of the inputs at the top of the D.T.I. screen.

-

Page 56: Modbus

4 Modbus MODBUS Through the Modbus protocol, the Mk7 D.T.I. data can be read from the boiler room information. The D.T.I. accepts Read and Read/Write commands. The 0x and 4x addresses are the Read/Write commands, and the 1x and the 3x addresses are the Read commands. The Read/Write commands are those which allow you to control certain aspect of the burners remotely. - Page 57 4 Modbus M.M. ID 1x Read Low Flame 10234 10314 10394 10474 10554 10634 10714 10794 10874 10954 Hold MM Comms 10239 10319 10399 10479 10559 10639 10719 10799 10879 10959 Bus Driver Input 88 10240 10320 10400 10480 10560 10640 10720 10800...

- Page 58 4 Modbus The 3x addresses are analogue inputs ready only addresses, which will give a number from a range. Refer to section 4.5.2 for relevance of these addresses. For example, if Modbus address 30160 outputs 42.1, this means that the channel 2 servomotor is at 42.1 M.M.

- Page 59 4 Modbus M.M. ID 3x Read Comm. 30125 30175 30225 30275 30325 30375 30425 30475 30525 30575 Exhaust Temp. Comm. 30126 30176 30226 30276 30326 30376 30426 30476 30526 30576 Efficiency Comm. NO 30127 30177 30227 30277 30327 30377 30427 30477 30527 30577...

- Page 60 4 Modbus M.M. ID 3x Read Ch6 Input 0- 30807 30857 30907 30957 31007 31057 31107 31157 31207 31257 Option 1 30808 30858 30908 30958 31008 31058 31108 31158 31208 31258 Option 77 30809 30859 30909 30959 31009 31059 31109 31159 31209 31259...

- Page 61 4 Modbus M.M. ID 3x Read Option 62 fuel 30836 30886 30936 30986 31036 30186 31136 31186 31236 31286 2 flow units Option 63 fuel 30837 30887 30937 30987 31037 30187 31137 31187 31237 31287 3 flow units Option 64 fuel 30838 30888 30938...

- Page 62 4 Modbus M.M. ID 3x Read Feedwater 32015 32115 32215 32315 32415 32515 32615 32715 32815 32915 Temp Deg.C Steam rate 32016 32116 32216 32316 32416 32516 32616 32716 32816 32916 lb/hr Heat to steam 32017 32117 32217 32317 32417 32517 32617 32717...

- Page 63 4 Modbus M.M. ID 3x Read Draft Servo 32045 32145 32245 32345 32445 32545 32645 32745 32945 32945 Angle Draft Actual* 32046 32146 32246 32346 32446 32546 32646 32746 32946 32946 Pressure Draft Com* 32047 32147 32247 32347 32447 32547 32647 32747 32947...

-

Page 64: Read Addresses

4 Modbus E.G.A. Read Addresses The Modbus addresses in this section are used when a standalone E.G.A. communicates a D.T.I. The 1x E.G.A. Read addresses give digital inputs. Refer to section 4.5.1 for relevance of these addresses. For example if Modbus address 11002 reads 1, then E.G.A. with ID 1 has an NO cell optioned. - Page 65 4 Modbus The 2x Read addresses give analogue inputs. Refer to section 4.5.2 for relevance of these addresses. For example if Modbus address 30602 outputs reads as 2.0 then E.G.A. ID 1 has online O value of E.G.A. ID 3x Read Fuel Selected 30601 30621...

-

Page 66: Input/ Output Modules Read Addresses

4 Modbus Input/ Output Modules Read Addresses The 1x Read addresses are digital inputs. Digital I/O Module ID Input 1 10001 10017 10033 10049 10065 10081 10097 10113 10129 10145 Input 2 10002 10018 10034 10050 10066 10082 10098 10114 10130 10146 Input 3... - Page 67 4 Modbus Analogue I/O Module ID Input 5 30021 30029 30037 30045 30053 30061 30069 30077 30085 30093 Input 6 30022 30030 30038 30046 30054 30062 30070 30078 30086 30094 Analogue I/O Channel ID Module ID Byte 7/6 31324 31328 31332 31336 31340...

- Page 68 4 Modbus Analogue I/O Channel ID Module ID Byte 7/6 31468 31472 31476 31480 31484 31488 Byte 5/4 31467 31471 31475 31479 31483 31487 Byte 3/2 31466 31470 31474 31478 31482 31486 Byte 1/0 31465 31469 31473 31477 31481 31485 Byte 7/6 31492 31496...

-

Page 69: Read/Write Addresses

4 Modbus Read/Write Addresses 4.4.1 M.M. Read/Write Addresses These Modbus addresses can be used to remotely control the M.M.s M.M. ID Enable/ 00001 00002 00003 00004 00005 00006 00007 00008 00009 00010 Disable Individual 40001 40002 40003 40004 40005 40006 40007 40008 40009... -

Page 70: Information, Errors And Lockouts

4 Modbus Information, Errors and Lockouts Each M.M./ E.G.A. can provide the following information and updates the D.T.I. approximately once every 5-10 seconds. 4.5.1 Digital Inputs (1x Reference) CR1 Relay Status Boiler Temperature/ Pressure Temperature Pressure Flow Metering On CO off/on fuel 2 (fuel 1 CO always on) Deg C or Deg F Deg C Deg F... -

Page 71: Analogue Inputs (3X References)

4 Modbus 4.5.2 Analogue Inputs (3x References) Firing Rate % 0 – 100 Burner Rating 0 – 250 Actual Value Deg C/ Deg F/ PSI 0 – 999 0.0 – 99.9 Required Value Deg C/ Deg F/ PSI 0 – 999 0.0 –... -

Page 72: Error And Lockout Codes

4 Modbus 4.5.3 Error and Lockout Codes Firing Status The following table lists the start-up/firing status for the below Modbus addresses: MM ID Start-up/ 30102 30152 30202 30252 30302 30352 30402 30452 30502 30552 Firing Status Code Explanation Waiting for stat circuit to complete Waiting for command to drive air damper to purge position Driving air damper to purge position Purging –... - Page 73 4 Modbus Code Mk7 M.M. Mini Mk8 M.M. Commission data fault Ch2 gain error RAM memory fault Ch4 gain error Ch3 positioning error Ch4 positioning error Ch1 movement error Ch2 movement error Ch3 movement error Analogue power supply error Digital power supply error EEProm error ADC Error Watchdog timeout...

- Page 74 4 Modbus Lockout Codes The following table lists the lockout codes for the below Modbus addresses: MM ID Lockout Direct 30830 30880 30930 30980 31030 31080 31130 31180 31230 31280 31311 31312 31313 31314 31315 31316 31317 31318 31319 31320 D.T.I.

- Page 75 4 Modbus Lockout Mk7 M.M. Mini Mk8 M.M. Freeze timeout Freeze timeout Purge air pressure low Option 141 incorrect Terminal 86 inverse Terminal 85-86 fault Prove cct fail No prove cct set No prove cct reset Option 118 incorrect Ion. internal failsafe fault Ion.

-

Page 76: Water Level

4 Modbus 4.5.4 Water Level The following lists show the various codes for the water level Modbus addresses: WL control type 0 – Modulating Standard 1 – On/Off 2 – Modulating High High 3 – Modulating Pre 1 Low/Pre High Level status 0 –... -

Page 77: Interacting With The Mk7 D.t.i

Once the D.T.I. has been successfully configured, it is possible to view the information on each of the M.M.s, E.G.A.s, Analogue and Digital Input/ Output Modules connected in the Autoflame system. By pressing on the boiler images, it is possible to display information on the M.M. units and the associated E.G.As. - Page 78 5 Interacting with the Mk7 D.T.I. Figure 5.1.ii Select M.M. Screen Pressing on the Digital I/O or the Analogue I/O will show the input and output information of the I/O associated with that boiler only. Pressing on the Mechanical Data Logs, Electrical Data Logs, or Technical Specifications will go to the screens showing all the additional bitmap files that were uploaded to the D.T.I via the CEMS PC Software (see PC Software Guide).

-

Page 79: Display Screen

5 Interacting with the Mk7 D.T.I. M.M. Display Screen Figure 5.2.i M.M. Home Screen Pressing on the M.Ms on the D.T.I. will bring up an emulation of the M.M. home screen. This home screen provides access to view information on the information logged just as on the M.M. screen. 10.08.2015 Mk7 D.T.I. - Page 80 5 Interacting with the Mk7 D.T.I. Figure 5.2.ii M.M. Setpoint Screen Pressing on the flame will display the Setpoint screen, providing the following information: 1. Burner rating 2. Fuel selected 3. Firing rate 4. Actual temperature/ pressure 5. Required setpoint temperature/ pressure 6.

- Page 81 5 Interacting with the Mk7 D.T.I. Figure 5.2.iii Global Setpoint Screen To change the global setpoint i.e. on all the M.M.s in that sequence loop, the ‘Global Setpoint’ must button must be selected on each of the M.M.s. then go to the home screen and press on Global Setpoint to change it as you require.

-

Page 82: Fault Logs

5 Interacting with the Mk7 D.T.I. Fault Logs Figure 5.3.i Errors Screen Pressing on the ‘Fault Logs’ button will display the lockouts and errors as recorded by the D.T.I. from the M.M. There is a maximum of 100 that will be recorded for each of the burner lockouts, M.M. errors and expansion errors, while connected to the D.T.I. -

Page 83: Screen

5 Interacting with the Mk7 D.T.I. M.M. I.B.S Screen Figure 5.4.i Boiler Sequencing Screen Pressing on the IBS box will emulate the sequencing screen shown on the M.M., showing which burner is in lead, and which ones are in lag, and their respective firing rates and status. 10.08.2015 Mk7 D.T.I. -

Page 84: Display Logs

5 Interacting with the Mk7 D.T.I. Display Logs By pressing the Display Logs button, this will give access to the logged M.M. data such as the setpoint history and the servomotor position history. Figure 5.5.i Setpoint Log Screen Pressing will display the Setpoint Log screen; the actual setpoint, required setpoint and firing rate are stored for up to 2 years. - Page 85 5 Interacting with the Mk7 D.T.I. Figure 5.5.ii Water Level Log Screen If an expansion board is used together with the M.M. for Autoflame water level control, in addition to the display log buttons in Figure 5.5.i, these water level control screens will be shown.

-

Page 86: Display Screen

5 Interacting with the Mk7 D.T.I. E.G.A. Display Screen Figure 5.6.i E.G.A. Display Screen Once you have selected the M.M. on the D.T.I. home screen, if there is an E.G.A. in the system, you can access the E.G.A. screen via 2 ways: ... -

Page 87: Information

5 Interacting with the Mk7 D.T.I. I.B.S Information If the D.T.I. has been setup so that some actions through the M.M. can be remotely controlled by the D.T.I., the sequencing order can be changed. Figure 5.7.i Lead Boiler Select Screen The lead boiler can be selected by pressing on the Lead Boiler Select button on the D.T.I. - Page 88 5 Interacting with the Mk7 D.T.I. Figure 5.7.ii Lag Boiler Sequence Screen The lag boiler order can be changed by pressing on the Lag Boiler Sequence button on the D.T.I. home screen. Select two lag boilers to swap them around in the lag sequence order. Note: D.T.I.

- Page 90 Notes...

- Page 94 Autoflame Engineering Ltd Unit1-2 Concorde Business Centre Airport Industrial Estate, Wireless Road Biggin Hill, Kent TN16 3YN United Kingdom +44 (0) 845 872 2000 www.autoflame.com...

Need help?

Do you have a question about the Mk7 D.T.I. and is the answer not in the manual?

Questions and answers