Advertisement

Quick Links

Advertisement

Summary of Contents for VWR Mini Shaker

- Page 1 Instruction Manual Mini Shaker Microplate Shaker...

-

Page 2: Table Of Contents

Mini Shaker or Microplate Shaker Manufacturer warrants this product to be free from defects in material and workmanship when used Non-skid rubber mat (Mini Shaker only) under normal conditions for five (5) years. Register your equipment or instrument online at www. -

Page 3: Installation

Upon receiving the VWR Mini/Microplate Shaker, check to ensure that no dam- operating Conditions: Indoor use only. age has occurred during shipment. It is important that any damage that occurred * For use in CO environments, incubators or cold rooms. - Page 4 & r afety nstructIons tandards egulatIons Please read the entire instruction manual before operating the Mini/ Henry Troemner LLC hereby declares under it’s sole responsibility that the con- Microplate Shaker. struction of this product conforms in accordance with the following standards: WArning! do not use the Mini/Microplate Shaker in a hazardous Safety standards: atmosphere or with hazardous materials for which the unit was not...

- Page 5 ontrol anel The front panel of the Mini/Microplate Shaker contains all the controls and dis- E. time display: Displays accumulated time (continuous mode) or how much plays needed to operate the unit. time is remaining (timed mode). The display range is from 0 to 9,999 minutes in one (1) second increments.

-

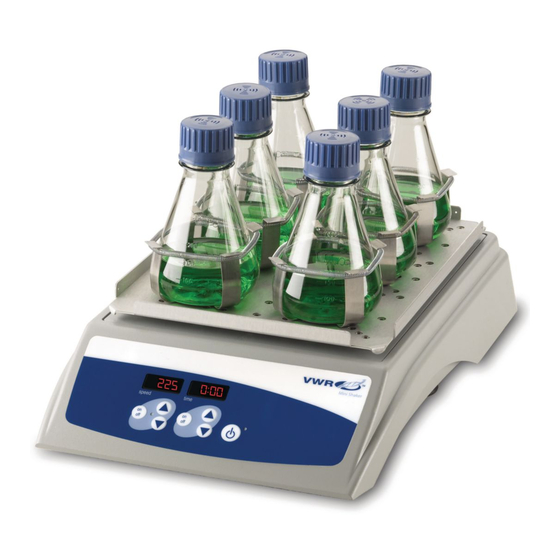

Page 6: Mini Shaker

1 second to 9999 minutes (increased in 1 second increments) orbit: 0.125” (3mm) Maximum weight capacity: ~ 8lbs (3.6kg), up to 1000rpm ~ 5lbs (2.3kg), over 1000rpm Controls: see page 4 tray material: aluminum Ship weight: 25lbs (11.4kg) Mini Shaker with plasticware... -

Page 7: Mini Shaker

The Mini Shaker is supplied with a tray designed to hold a variety of accessories. 1. Flat containers can be shaken by placing them on the non-skid mat provided with the unit. 2. The tray also has mounting holes ready for use with flask/media bottle clamps or test tube racks. See below for tray configurations. -

Page 8: Microplate Shaker

IcroPlate haker PecIfIcatIons overall dimensions (L x W x H): 17 x 11 x 4” (43.2 x 27.9 x 10.2cm) tray dimensions (L x W): 11 x 7.75” (27.9 x 19.7cm) Electrical (50/60 Hz): 120 volts, 5 amps, 25 watts 230 volts, 5 amps, 25 watts Fuses: 5mm x 20mm, 5 amp quick acting... -

Page 9: Microplate Shaker

IcroPlate haker The Microplate Shaker is designed to hold two (2) or four (4) microplates, or two (2) Micro-Tube Racks. 1. Place two (2) microplates or deep well blocks diagonally on the tray, or place four (4) microplates or deep well blocks on the tray. The plates/blocks do not have to be filled. - Page 10 PeratIng nstructIons The Mini/Microplate Shakers have been designed for the speed and time func- 3. Setting time to zero (0:00) and continuous mode: Accumulated time. tions to work independently of one another. The speed can be reset without a. Press and hold the on/off button below the time display. After three resetting the timer and the timer can be stopped and started without interrupting (3) seconds the display will indicate the previous set time.

-

Page 11: Troubleshooting

(0:00), you will hear the four (4) audible beeps that mum load capacity before restarting the unit. If the E04 error code persists, switch indicate the count down function is complete and the shaking the unit off and contact your VWR representative for repairs. function will cease. Error Code... - Page 12 haker ePlaceMent arts dESCriPtion PArt nuMBEr 1. Front panel membrane switch 380704-00 2. Tray 580050-00 3. Display board 380780-00 4. Belt 580019-00 5. Motor 380712-00 6. Motor transition board 380715-00 7. Connection cable 380720-00 8. IEC power entry module 386122-00 9.

- Page 13 IcroPlate haker ePlaceMent arts dESCriPtion PArt nuMBEr 1. Front panel membrane switch 380703-00 2. Tray assembly 880761-00 3. Display board 380780-00 4. Belt 580019-00 5. Motor 380712-00 6. Motor transition board 380715-00 7. Connection cable 380720-00 8. IEC power entry module 386122-00 9.

-

Page 14: Accessories

12620-952 500mL Media Bottle Clamp stainless steel 14215-236 125mL Erlenmeyer Flask Clamp 97003-576 installation of test tube racks - Mini Shaker 250mL Erlenmeyer Flask Clamp 97003-578 1. Unit should be in standby mode. 500mL Erlenmeyer Flask Clamp 97003-580 2. Remove non-skid rubber mat. - Page 15 Universal Platform 11.7 x 8.7” 12620-964 installation of universal Harness - Mini Shaker (29.7 x 22.1cm) 1. Unit should be in standby mode. 2. Remove non-skid rubber mat. installation of universal Platform - Mini Shaker 3. Insert one band through the side of one “U” in the U-shaped cut-outs on the center 1.

- Page 16 anufactured by HEnry troEMnEr LLC 201 Wolf Drive • PO Box 87 • Thorofare, NJ 08086-0087 Phone: 856-686-1600 • Fax: 856-686-1601 • E-mail: troemner@troemner.com www.troemner.com 715054-00 (REV 6 - 8/14)

Need help?

Do you have a question about the Mini Shaker and is the answer not in the manual?

Questions and answers