Table of Contents

Advertisement

Quick Links

WIDOS

W. Dommer Söhne GmbH

Working Instructions

Heating Element Butt Welding Machine

Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Jürgen Dommer

Einsteinstr. 5

D-71254 Ditzingen-Heimerdingen

info@widos.de

Translation

WIDOS 4002 S CNC 3.0

Keep for further use!

Phone

+49 / 71 52 99 39 - 0

Fax

+49 / 71 52 99 39 - 40

Website: www.widos.de

Kunststoffschweißtechnik

Advertisement

Table of Contents

Summary of Contents for widos 4002 S CNC 3.0

- Page 1 +49 / 71 52 99 39 - 40 info@widos.de Website: www.widos.de Kunststoffschweißtechnik Working Instructions Translation Heating Element Butt Welding Machine WIDOS 4002 S CNC 3.0 Keep for further use! Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Jürgen Dommer...

- Page 2 Phone: ++49 / 3 71 / 8 15 73 - 0 Phone: +41 (0) 79 432 5737 Fax: ++49 / 3 71 / 8 15 73 - 20 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 2 of 92...

- Page 3 1/14/2015 WIDOS W. Dommer Söhne GmbH Einsteinstraße 5 D-71254 Ditzingen-Heimerdingen All rights reserved. Reprinting only allowed with permission of the corporation. Any changes are subject to technical innovations. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 3 of 92...

-

Page 4: Table Of Contents

4.2. Elements on the right side .....................17 4.2.1. Main switch.........................17 4.2.2. Service unit.........................17 4.3. Elements at the heating element ...................18 4.4. Emergency-stop switch ......................18 5. STARTING AND OPERATING ................19 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 4 of 92... - Page 5 7.6. Fuses into electric switch cupboard ..................44 7.7. Disposal ...........................44 8. ELECTRO AND PNEUMATIC DIAGRAMS............45 9. SPARE PARTS LIST ..................74 9.1. Basic machine .........................74 9.2. Clamping tool ..........................79 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 5 of 92...

- Page 6 9.4. Heating element........................84 9.5. Three zone heating element (alternative) ................86 9.6. Heating element holder......................88 9.7. Plane girder for planing only at one side................90 10. DECLARATION OF CONFORMITY ..............92 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 6 of 92...

-

Page 7: Description Of Product

1.1. Usage and purpose-oriented use The WIDOS 4002 S CNC 3.0 is a workshop machine and especially designed for the heating element butt welding of plastic pipes and fittings from Ø = 90 up to 315 mm (Standard-: 90 / 110 / 125 / 140 / 160 / 180 / 200 / 225 / 250 / 280 / 315 mm). -

Page 8: Marking Of Product

1,93 kW Voltage: 400 V ( 10 %) Amperage: 4,8 A Frequency: 50 Hz Engine revolution: IP 55 Type of protection: 4000 (U/min) Driving torque: max. 5,8 Nm 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 8 of 92... -

Page 9: Heating Element

1 each Allan key bent, size 3; 6; 7; 8 Order numbers and singular components on request at the WIDOS company. Following optional accessories are available on request: - Program WICON for reading out the data (possibility of displaying included in SD-card) 14.01.2015... -

Page 10: Safety Rules

T h e a c c i d e n t p r e v e n t i o n m e a s u r e s a r e v a l i d ( U V V ) . 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 10 of 92... -

Page 11: Obligations Of The Owner

Only skilled and trained persons are allowed to work at the machine. A person who is being trained may only work at the machine under supervision of an experienced person. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 11 of 92... -

Page 12: Maintenance And Inspection, Repair

2.8. Dangers while handling the machine The machine WIDOS 4002 S CNC 3.0 is constructed according to the latest technical standard and the acknowledged technical safety rules. However, dangers for the operator or other persons standing nearby may occur. Also material damages are possible. -

Page 13: Special Dangers

Lay the cables in such a manner that the danger is minimized. Risk of injury by noise Noise exceeding 80 dB (A) may occur; during planing it is obligatory to wear ear protection! 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 13 of 92... -

Page 14: Warranty And Liability

Unsatisfactory inspection of machine parts which are subject to wearing. Unsatisfactory performed repairs. In case of catastrophes through action of an external body or actions of God. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 14 of 92... -

Page 15: Description Of Process

(cooling time). The welded joint can be unclamped, the welding process is finished. Heating element heats the pipes up to welding temperature. welded pipe with internal and external bead 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 15 of 92... -

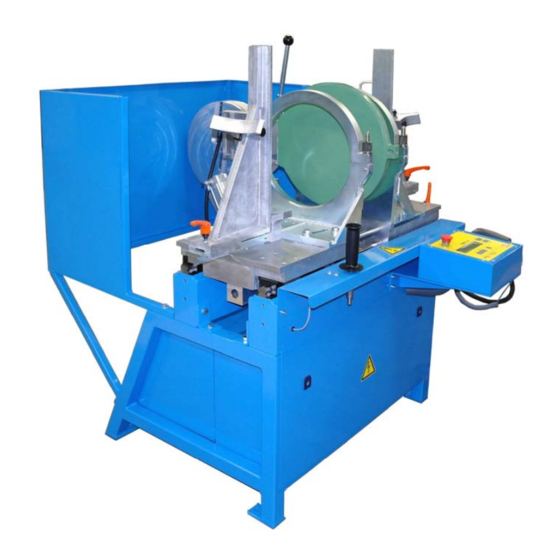

Page 16: Operating And Indicating Elements

Heating element grip, here placed on safety switch Control panel with emergency switch Barcode scanner on Holder for scanner Switch cabinet with fuses etc. Heating element Planer Protective covering 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 16 of 92... -

Page 17: Elements On The Right Side

The input pressure must be at least 1 bar higher than the output pressure. Press the pressure setting button downwards (towards the housing) to secure it against unintentional turning. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 17 of 92... -

Page 18: Elements At The Heating Element

If the Emergency-stop switch is pressed when the heating element is moved in, there is the danger of being burnt. The heating element cools down very slowly 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 18 of 92... -

Page 19: Starting And Operating

Puller claw (basic machine) Take care that the puller bracket of the heating element is positioned between both puller claws when swiveling into the machine. Puller bracket (heating element) 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 19 of 92... -

Page 20: Description Of The Display

Enter Chang the parameters on / off Start Start the welding function Confirm the new set parameters Planer Start planing Abort welding One step back when entering parameters 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 20 of 92... -

Page 21: Accessories For Reading The Data In And Out

The card can be read out with a WICON program. The card may not be bent, opened, overheated and become wet! Please only use SD cards purchased from WIDOS. We will not be liable for any cards from other manufactures! 14.01.2015... -

Page 22: Read-Out Wicon With Usb Card Reader (Optional)

Display: The type of the machine is displayed please identify line: Either: Identify with barcode scanner and general legitimacy card Identify with barcode scanner an gas legitimacy card 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 22 of 92... -

Page 23: Programming And Welding With Gas Legitimacy Card

Identify again with barcode scanner and gas legitimacy card. please read in Display: pipe data card line: Read in with the pipe data card with barcode scanner for changing the parameters. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 23 of 92... -

Page 24: Programming And Welding With General Legitimacy Card

PE80 225 20.5 206° line: The last welding parameters are displayed Select material with <+> or <->. Confirm material with <Start>. mat diam wall temp Display: PE80 225 20.5 206° line: 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 24 of 92... - Page 25 Display of the heating element temperature calculated PE80 225 20.5 206° line: according to the prescriptions of the DVS Press button <Start>. WIDOS 4002 S CNC Display: Basic menu 22.11.2000 10:10 line: 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 25 of 92...

-

Page 26: Welding Process

(when a new project is created, the oldest one is overwritten) Confirm the project name with button <Start>. Abort with button <C> if need be basic menu 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 26 of 92... - Page 27 Pressure systems is calibrated after a few seconds, the display changes opening machine Display: Slide opens line: after a few seconds, the display changes insert planer Display: start planer line: 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 27 of 92...

- Page 28 If the misalignment is too high, re-adjust the pipe ends in the basic clamping devices and repeat the planing process (from: ). Keep pressed button <+> to check the pressure build-up (e.g. whether pipes slip through). 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 28 of 92...

- Page 29 Display: heat.elem.t. 000°C line: The heating element temperature is displayed after the bead height being reached, the display changes 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 29 of 92...

- Page 30 Display: Parameter error: line: Confirm error message with button <Enter>. Unclamp the welded pipe and remove it out of machine, welding completed, Press button <Start>. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 30 of 92...

-

Page 31: Error Messages

Current date and time Press button <Enter>. Print SD card Display: line: Press several time button <Start> until cursor is until “Diag“ Diag Clk WICON Param Display: line: 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 31 of 92... - Page 32 Change the bead height with <+> and <->. Confirm the bead height with <Start>. bead wp-bead up Display: line: Change the bead-up pressure with<+> - and <->. Confirm the bead-up pressure with <Start>. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 32 of 92...

- Page 33 Confirm the cooling time with <Start>. t-cool. wp-cool. Display: line: Change the cooling force with <+> and <->. Confirm the cooling force with <Start>. Diag Clk WICON Param Display: line: Press button <Start>. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 33 of 92...

-

Page 34: Setting Time And Date

Display: 22.11.2000 2. line: Setting the date Change the first digit with <+> and <->. Press <Enter> to a position to the right. Confirm the date with <Start>. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 34 of 92... -

Page 35: Copying Internal Data Onto Sd-Card And Deleting Them (Ram)

Confirm the error message by pressing <Enter>. RAM memory Display: delete 2. line: Either: By pressing <+> the internal memory (RAM) is deleted. By pressing <-> the internal memory (RAM) is not deleted. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 35 of 92... -

Page 36: Administration Of The Welding Data

Markings have been fixed to the table for angles 11.25° and 15°, other angles must be adjusted by goniometer. Afterwards retighten screws 1 and 2. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 36 of 92... -

Page 37: Drillings At The Table

Pivot for clamping tool displaced Pivot for clamping tool Fixing hole Fixing hole for clamping Moving direction tool displaced Inner edge left table Angle marking Angle marking for clamping tool displaced 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 37 of 92... -

Page 38: Welding Of T - Piece 90

T – pieces with 90° (cross-pieces optional) up to OD = 250 mm can be welded. The optionally available clamping device for angles is screwed on together with the adapter plate and standard clamping tools. Heating element Planer T – piece tools 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 38 of 92... -

Page 39: Error Messages

In the depressurized phase Prevent the clamping tools well in place ! the pipes open the clamping from opening tools 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 39 of 92... -

Page 40: Possible Deficiencies And Their Elimination

After the planer program - No 2 mm material were - Make sure that min. 2 mm the planer is needed again planed material are planed (circular and again chip !) 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 40 of 92... -

Page 41: Diagnosis Program

The required change over time which was calculated by the programmed 0015 welding parameters is displayed The required pressure build-up time which was calculated by the 0016 programmed welding parameters is displayed 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 41 of 92... - Page 42 0011 Pressure (4-20 mA) A self-test of the machine and the control unit is performed, as well as a 0044 weld log printout on a connected printer 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 42 of 92...

-

Page 43: Maintenance / Repair / Transport

For machines with especially high usage percentage the testing cycle should be shortened. The works should be performed at the WIDOS GmbH company or by an authorized partner. The linear guides must be cleaned every week, e.g. with a brush. -

Page 44: Clamping Elements

At the end of their life time, the machine and the wear parts have to be disposed of properly and non-polluting, and in accordance with the national laws of waste disposal. 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 44 of 92... -

Page 45: Electro And Pneumatic Diagrams

Telefon +49 (0) 71 52 / 99 39 - 0 W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40 info @ widos.de Website: www.widos.de Kunststoffschweißtechnik 8. Electro and pneumatic diagrams 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 45 of 92... - Page 46 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 46 of 92...

- Page 47 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 47 of 92...

- Page 48 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 48 of 92...

- Page 49 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 49 of 92...

- Page 50 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 50 of 92...

- Page 51 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 51 of 92...

- Page 52 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 52 of 92...

- Page 53 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 53 of 92...

- Page 54 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 54 of 92...

- Page 55 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 55 of 92...

- Page 56 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 56 of 92...

- Page 57 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 57 of 92...

- Page 58 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 58 of 92...

- Page 59 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 59 of 92...

- Page 60 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 60 of 92...

- Page 61 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 61 of 92...

- Page 62 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 62 of 92...

- Page 63 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 63 of 92...

- Page 64 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 64 of 92...

- Page 65 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 65 of 92...

- Page 66 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 66 of 92...

- Page 67 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 67 of 92...

- Page 68 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 68 of 92...

- Page 69 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 69 of 92...

- Page 70 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 70 of 92...

- Page 71 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 71 of 92...

- Page 72 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 72 of 92...

- Page 73 Electro and pneumatic diagrams Chapter 8 Kunststoffschweißtechnik 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 73 of 92...

-

Page 74: Spare Parts List

26 / 27 28 - 30 48 - 50 32 - 37 51 - 53 38 / 39 54 - 56 57 / 58 41 - 44 60 - 62 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 74 of 92... - Page 75 (right button side of slide) 79 / 80 75 - 78 (right button side of slide lateral view) 85 - 87 83 / 84 89 - 91 92 - 93 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 75 of 92...

- Page 76 Spare parts list Chapter 9 Kunststoffschweißtechnik 94 - 96 97 - 101 104 - 105 106 - 107 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 76 of 92...

- Page 77 Spare parts list Chapter 9 Kunststoffschweißtechnik (Basic machine rear view) 111 - 112 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 77 of 92...

- Page 78 Linear guide L20700 Fitting cap L20501 Pan-head screw M 5x16 DIN 912 0912E016 Parallel pin M 5x18 DIN 6325 6325E018 Chips skirtboard for ball screw 172123 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 78 / 1 of 92...

- Page 79 Hlder for servo motor 172125 Cylinder pin 10 M6 x 20 DIN 7 0007J020 Hexagon head screw M 10x25 DIN 933 0933J025 Washer M10 DIN 125 0125J 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 78 / 2 of 92...

- Page 80 Safety fance 172530 Oval-head screw M 8 x16 DIN 7380 7380H016 Washer M 8 DIN 9021 9021H Pan-head screw M 8 x 65 DIN 912 0912H065 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 78 / 3 of 92...

-

Page 81: Clamping Tool

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.2. Clamping tool 4 - 5 8 - 9 17 - 18 19 - 20 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 79 of 92... - Page 82 Thrust washer 023707 Rivet for joint S0426 Knurled screw S0318 Support for bow 020721 Knurled screw S0222 Allan key SW 27 ZRS27 * When ordering state dimension ! 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 80 of 92...

-

Page 83: Planer

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.3. Planer 1 - 3 19 - 21 4 - 7 8 - 16 25 - 30 31 - 32 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 81 of 92... - Page 84 Spare parts list Chapter 9 Kunststoffschweißtechnik 35 - 39 42 - 44 47 - 48 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 82 of 92...

- Page 85 024404 Cylinder-head screw M10x25 DIN 912 0912J025 Retaining plate whith hole 024402 Retaining plate whith thread 024401 Pan-head screw M10x55 DIN 912 0912J055 Washer M10 DIN 125 0125J 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 83 of 92...

-

Page 86: Heating Element

Spare parts list Chapter 9 Kunststoffschweißtechnik 9.4. Heating element 2 - 5 11 - 12 13 - 14 19 - 25 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 84 of 92... - Page 87 Flat-head screw M 4x10 DIN 7991 7991D010 French head screw M 4x10 DIN 7985 7985D010 Housing with cap for control H2114 Cover plate H2116 Oval-head screw M 3x5 DIN 7985 7985C005 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 85 of 92...

-

Page 88: Three Zone Heating Element (Alternative)

Three zone heating element (alternative) (Expansion requires reconstruction of the machine) 13 - 15 2 - 4 16 - 17 6 - 9 23 - 24 25 - 26 27 - 28 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 86 of 92... - Page 89 Cover plate H2116 Oval-head screw M 3x5 DIN 7985 7985C005 Housing with cap for control H2114 Antikink union joint PG 16/13 EVH1613 Antikink union joint PG11/9 EVH1109 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 87 of 92...

- Page 90 Spare parts list Chapter 9 Kunststoffschweißtechnik 9.6. Heating element holder 2 - 3 5 -6 16 - 17 7 - 8 18 - 19 20 - 22 25 - 26 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 88 of 92...

- Page 91 Pan-head screw M10x25 DIN 912 0912J025 Washer M10 DIN 9021 9021J Hexagon-head screw M8x35 DIN 933 0933H035 Surveying for cylinder 172503 Pan-head screw M8x25 DIN 912 0912H025 Washer M8 DIN 125 0125H 14.01.2015 Working instruction WIDOS 4002 S CNC 3.0 Page 89 of 92...

- Page 92 Spare parts list Chapter 9 Kunststoffschweißtechnik 9.7. Planer girder for planing only at one side 3 / 4 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 90 of 92...

-

Page 93: Plane Girder For Planing Only At One Side

Spare parts list Chapter 9 Kunststoffschweißtechnik WIDOS 4002 S CNC Planer girder for planing only at one side Pos. Name Piece Order no. Centering bolt 023418 Bearing L51103 Plane girder for planing only at one side 023427 Protective cap (25x25x3) -

Page 94: Declaration Of Conformity

Electric equipment of industrial machines The technical documentation is completely available. The working instructions in the language of the user are available. Ditzingen-Heimerdingen, the 1/14/2015 Martin Dommer (Technical director) 14.01.2015 Working Instructions WIDOS 4002 S CNC 3.0 Page 92 of 92...

Need help?

Do you have a question about the 4002 S CNC 3.0 and is the answer not in the manual?

Questions and answers