Summary of Contents for Bomag BPH 80/65

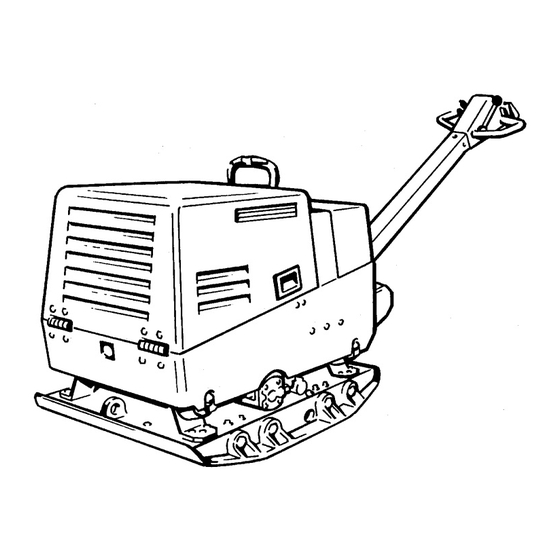

- Page 1 Operating instructions Maintenance instructions BPH 80/65 S/N 101 700 00 ..Vibratory plate compactor Catalogue number 09/2005 008 147 41...

- Page 3 BOMAG. prolongthe lifetime of the machine, We wish you much success with the BOMAG ma- reducerepair costs and downtime. chine. BOMAG will not assume liability for the functioning...

- Page 4 Fill in the above listed data when receiving the ma- chine. Upon receipt of the machine our organization will instruct you about correct operation and mainte- nance. Please observe strictly all safety regulations and notes on potential dangers! Fig. 2 Fig. 3 BPH 80/65 B O M A G...

-

Page 5: Table Of Contents

T r o u b l e s h o o t i n g 5 . 1 G e n e r a l n o t e s 5 . 2 E n g i n e f a u l t s BPH 80/65 B O M A G... - Page 6 Table of Contents BPH 80/65 B O M A G...

-

Page 7: Technical Data

1 Technical Data BPH 80/65 B O M A G... - Page 8 T e c h n i c a l D a t a Fig. 4 BPH 80/65 Dimensions (L) Overall length 2330 (L1) Length of base plate 1080 (W) Overall width (W1) Width with extension plates (W2) Width with extension...

-

Page 9: S A F E T Y R E G U L A T I O N

T e c h n i c a l D a t a BPH 80/65 Drive Engine manufacturer Hatz Type 1D 90 W Cooling Working cycles Number of cylinders Rated power ISO 9249 kW (PS) 11,5 (15,6) Rated speed 3000... - Page 10 Vector total of the weighted effective acceleration in three orthogonal directions: Weighted total vibration value = 7.0 m/sec on crushed rock determined acc. to ISO 5349 and EN 500 Caution Observe the daily vibration load (Industrial safety acc. to 2002/44/EC). BPH 80/65 B O M A G...

- Page 11 2 Safety regulations BPH 80/65 B O M A G...

- Page 12 General Who is allowed to work with the ma- chine? This BOMAG machine is built in accordance The machine must only be operated by trained with the latest technical standard and the valid and authorized persons who are at least 18 years technical rules and regulations.

-

Page 13: O P E R A T I O

Vor jeder Arbeit an Hydraulikleitungen diese For starting remove your feet from the danger drucklos machen. Unter Druck austretendes Hy- zone of the base plate. drauliköl kann die Haut durchdringen und schwere BPH 80/65 B O M A G... - Page 14 S a f e t y r e g u l a t i o n s Verletzungen verursachen. Bei Verletzungen du- Only genuine BOMAG hydraulic hoses ensure rch Hydrauliköl sofort einen Arzt aufsuchen, da that the correct type of hose (pressure range) is sonst schwere Infektionen entstehen können.

- Page 15 If the machine is defective, attach a warning tag on the steering handle. Test Depending on the type of applicational and the op- erating conditions vibratory equipment has to be examined by a specialist whenever required, but at least once every year. BPH 80/65 B O M A G...

- Page 16 S a f e t y r e g u l a t i o n s BPH 80/65 B O M A G...

- Page 17 3 Operation BPH 80/65 B O M A G...

-

Page 18: General Notes

Check the dry air filter service indicator. Check the condition of the whole machine and the screw connections for tight fit. Danger Loss of hearing! Always wear your personal noise protection means (ear defenders) before starting opera- tion. BPH 80/65 B O M A G... -

Page 19: Folding The Steering Rod Down

No. 4 = Travel lever (toggle switch) No. 5 = Back-up protection Fig. 5 Pull the locking lever (Fig. 5) up and fold the steering rod down, so that it can swing freely. BPH 80/65 B O M A G... -

Page 20: Starting The Engine

Then turn the ignition key further to position (Fig. 7) . "II", the engine starts. As soon as the engine has started turn the ig- nition key back to position "I". The warning buzzer stops. BPH 80/65 B O M A G... -

Page 21: Starting With Jump Leads

Too long operation of the starter motor will dis- Fig. 11 charge the battery. Open the front covering hood (Fig. 11) . Fig. 12 Connect the plus poles on auxiliary battery and starter battery with the jump wire (Fig. 12) BPH 80/65 B O M A G... -

Page 22: Work/Operation

Guide the vibratory plate only by the steering rod. Use your personal noise insulation means (ear defenders). Fig. 13 Pull the locking lever (Fig. 13) up and fold the steering rod down. BPH 80/65 B O M A G... - Page 23 Set the throttle lever (Fig. 15) to position "MAX.". Note Vibration must be switched on. Caution Operate the vibratory plate only with full en- gine speed. Note For short breaks always return the throttle lever to idle speed position. BPH 80/65 B O M A G...

- Page 24 Fig. 18 Danger Danger of accident! As a measure to avoid injuries when driving re- verse the vibratory plate should only be guided by the hand from the side. BPH 80/65 B O M A G...

-

Page 25: Back- Up Protection

20) the travel lever (toggle switch) is reversed from reverse travel to forward travel. Fig. 21 Press the push button vibration "ON/OFF" (Fig. 21) . Vibration is switched off and the vibratory plate comes immediately to a halt. BPH 80/65 B O M A G... - Page 26 To shut the engine down turn the ignition key to position "0" (Fig. 25) and pull it out. The warning buzzer stops. Fig. 23 Press the push button vibration "ON/OFF" (Fig. 23) . Vibration is switched off. BPH 80/65 B O M A G...

-

Page 27: O A D I N G

Adjust the steering rod (Fig. 26) upright and lock it in the last locking position. Lash the vibratory plate to the transport vehi- cle so that it properly secured against sliding about and tipping off! BPH 80/65 B O M A G... - Page 28 O p e r a t i o n BPH 80/65 B O M A G...

-

Page 29: M A I N T E N A N C

4 Maintenance BPH 80/65 B O M A G... -

Page 30: General Notes On Mainte- Nance

"thin air" (at high altitudes) and with full power, you no means be compared with the faults which may should consult the after sales service of BOMAG occur when not observing these instructions. or the service department of the engine manufac- turer. -

Page 31: Fuels And Lubricants

(e.g. use of SAE 15W/40 down to -15°C) may ef- fect the cold starting ability of the engine, but will not cause any engine damage. Temperature related lubrication oil changes can be avoided by using multi-purpose oils. The follow- BPH 80/65 B O M A G... - Page 32 When changing to a higher alloyed oil quality after a longer period of operation, it is recommended to perform the first oil change of the higher quality oil already after 25 operating hours. BPH 80/65 B O M A G...

-

Page 33: Table Of Fuels And Lubri- Cants

10 l (-12°C) (+10.4°F)* Vibrator shaft same as engine oil 0,8 l housing Hydraulic oil same as Panolin SHF Synth. 32 28,0 l *For lower temperatures refer to the mixing table in chapter 4.2 BPH 80/65 B O M A G... -

Page 34: Running-In Instructions

Check the oil level in the vibrator shaft hous- ing. Check the hydraulic oil level. Retighten the fastening screws for air filter, ex- haust silencer, fuel tank and other attach- ments. Tighten the screw connections on the ma- chine. BPH 80/65 B O M A G... -

Page 35: Maintenance Chart

Change the fuel filter 4.20 Change the oil in the vibrator housing 4.21 Change the hydraulic oil filter 4.22 Check the rubber buffers As required 4.23 Retighten the bolted connections Check the machine visually BPH 80/65 B O M A G... -

Page 36: Checking The Fuel Level

Check the seal on the dipstick, if necessary Close the tank tightly. use a new one. For quality of fuel refer to the table of fuels and Push the dipstick in until it bottoms. lubricants. BPH 80/65 B O M A G... -

Page 37: Checking The Hydraulic Oil Level

Fill in hydraulic oil to the middle of the inspec- tion glass. Screw the filler cap back on. For quality and quantity of oil refer to the table of fuels and lu- bricants. BPH 80/65 B O M A G... - Page 38 Since water is specifically heavier than diesel fuel, water will run out first, followed by fuel. This can be noticed by a clear separating line. Tighten the hexagon screw again as soon as only fuel runs out. BPH 80/65 B O M A G...

- Page 39 (vaseline). Check the fastening of the battery. Check the condition of the vibration insulation mats, replace if necessary. Close the front hood again tightly after having serviced the battery. Option BPH 80/65 B O M A G...

- Page 40 Remove the air filter cover (Fig. 39) . Fig. 41 Blow the filter cartridge (Fig. 41) out with dry compressed air (max. 5 bar) from inside to out- side. Check the filter cartridge for damage, replace if necessary. BPH 80/65 B O M A G...

- Page 41 M a i n t e n a n c e e v e r y m o n t h Fig. 42 Insert the filter cartridge (Fig. 42) into the housing. Assemble the filter cover, ensure correct fit of cover and seal ring. BPH 80/65 B O M A G...

- Page 42 Insert the oil dipstick and check the oil level. Unscrew the oil filler neck cap. After a short test run check drain plug and oil filter for leaks. Close the rear hood. BPH 80/65 B O M A G...

- Page 43 Push the engine oil filter into the housing and tighten the plug. After filling in engine oil perform a short test run and check for leaks, if necessary retighten the fastening screw. BPH 80/65 B O M A G...

- Page 44 Check the cylinder head cover for leaks after a short test run. Fig. 49 Open the rear hood and clean the intake open- ing for the cooling air area (Fig. 49) . BPH 80/65 B O M A G...

- Page 45 Find the cause of oily dirt and have leaks sealed by the after sales service of BOMAG. Do not hold the water jet directly into the air fil- ter, the exhaust and the electric system (if present).

- Page 46 No dirt or foreign particles must enter the clean air side. Do not blow the filter housing out with com- pressed air. Clean the inside of the filter housing only with a clean cloth. Clean the cover thoroughly. BPH 80/65 B O M A G...

- Page 47 M a i n t e n a n c e e v e r y 6 m o n t h s Fig. 56 Insert the filter cartridge (Fig. 56) into the housing. Assemble the filter cover, ensure correct fit of cover and seal ring. BPH 80/65 B O M A G...

- Page 48 Check fuel filter and lines for leaks after a short test run. Note The fuel system is automatically bled. Fig. 58 Place a suitable container under the filter to catch running out fuel (Fig. 58) . Close the fuel supply line. BPH 80/65 B O M A G...

- Page 49 (2). a new bleeding screw with seal ring. Drain off and catch old oil. Note Leave the machine in this position until all oil has run out of the drain bore. BPH 80/65 B O M A G...

- Page 50 Draw the hydraulic oil out at operating temper- ature. Stand the machine on level ground. Change the hydraulic oil filter with every oil change. Fig. 65 Unscrew the fitting and take the cover off (Fig. 65) . BPH 80/65 B O M A G...

- Page 51 M a i n t e n a n c e e v e r y y e a r 4.22 Checking the rubber buffers Fig. 66 Check all rubber buffers (Fig. 66) for cracks and broken out bits and replace if damaged. Check the rubber buffers for tight fit. BPH 80/65 B O M A G...

- Page 52 4.23 Retightening the bolted connections Check all bolted connections for tight fit, retighten if necessary. Note Do not re-tighten the cylinder head fastening screws! Check the machine for damage and leaks, have repaired if necessary. BPH 80/65 B O M A G...

-

Page 53: T R O U B L E S H O O T I N

5 Trouble shooting BPH 80/65 B O M A G... -

Page 54: General Notes

T r o u b l e s h o o t i n g 5.1 General notes The following work must only be carried out by qualified and trained personnel or by the BOMAG sales service. Please observe strictly the safety regulations in chapter 2 of these operating and mainte- nance instructions. -

Page 55: Engine Faults

The throttle lever does not stay in the cho- Block the throttle control. power (engine sen position. speed drops) No exhaust Air in the injection system Check the function of the bleeding valve fumes Fuel filter dirty Change the fuel filter BPH 80/65 B O M A G... - Page 56 Check the oil pressure, activate the oil system shuts the engine down because of pressure monitoring system too low oil pressure Lack of oil Have the engine repaired, stop work im- mediately (risk of total engine damage!) BPH 80/65 B O M A G...

Need help?

Do you have a question about the BPH 80/65 and is the answer not in the manual?

Questions and answers