Eaton 1 Series Parts And Service

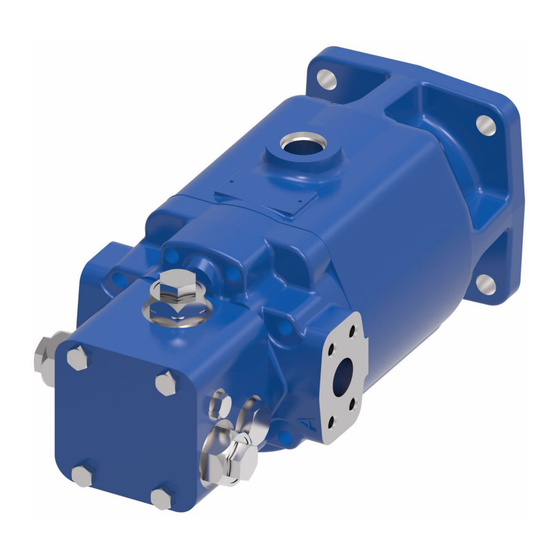

Hydraulics, heavy duty hydrostatic fixed displacement motors

Hide thumbs

Also See for 1 Series:

- Repair information (32 pages) ,

- Repair information (21 pages) ,

- Repair information (28 pages)

Summary of Contents for Eaton 1 Series

- Page 1 Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Model 3331/3333 Model 5431/5433 Model 3931/3933 Model 6431/6433 Parts and Service Model 4631/4631...

-

Page 2: Table Of Contents

Hydraulic Fluid Recommendations ....................30-31 EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 3: Introduction

Introduction This manual will provide you with service information and procedures for disassembly and reassembly of Eaton ® Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors – Models 33, 39, 46, 54, and 64. Procedures outlined in this manual will allow you to better service your motors and obtain the best results possible. -

Page 4: Parts Drawing

End Cover with Integral Shuttle and Low Pressure Relief Valve End Cover with Valve Block 24 5 990709-000 Lip Seal Motors P/N XX33-XXX (Current version) 990231-000 Face Seal Motors P/N XX31-XXX EATON Series 1 Hydrostatic Fixed Motors Repair E-MOPI-TS002-E September 2004... - Page 5 Lifting Strap (models 33/39/46) 96559-000 Lifting Strap (models 54/64) 103223-000 Sealing Washer 104511-300 Cap Screw, Socket Hd 3/8-16 95912-300 Cap Screw, Socket Hd 5/16-18 *Cannot be purchased separately. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 6: Drive Shaft

21 Tooth, 16/32 Pitch Spline W/ (M10 x 1.5 threaded hole) 113811-000 113810-000 103808-000 103222-200 14 Tooth, 122/24 Pitch Spline (3/8-24) UNF x [.75] DP 114816-000 114815-000 103808-000 103222-200 19 Tooth, 16/32 Pitch Spline EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... - Page 7 23 Tooth, 16/32, Pitch Spline, 3/8-24 111052-000 111051-000 103227-000 103222-188 [1.500] Diameter Taper W/ [.375] X [1.00] Square Key 111780-000 111779-000 103227-000 103222-188 19 Tooth, 16/32, Pitch Spline, Speed Sensor EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

- Page 8 [1.500] Diameter Straight W/ [.3750] X [2.5] Square key 111591-000 111590-000 103808-000 103222-200 21 Tooth, 16/32, Pitch Spline, Speed Sensor 113438-000 113437-000 103808-000 103222-200 14 Tooth 12/24, Pitch Spline EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 9: End Cover

Table 3.3 Low Pressure Relief Valve Spring (Integral Shuttle Motor Design) PRESSURE SPRING P/N SETTING RANGE bar[lbf/in 104658-000 11,0 [160]- 16,5[240] 110272-000 19,3[280] - 20,7[300] EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 10: Valve Block

= 396,4 [5500] XXXXX-600 = 413,7 [6000] XXXXX-650 = 448,1 [6500]* XXXXX-675 = 465,4 [6750]* *Do not set this pressure level without Eaton Engineering approval EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 11: Valve Block Kits

End cover Sealing Plate 101129-000 Back-up Ring 095863-150 Hex head Bolts 8765-118 O-ring 008765-118 O-Ring 8775-018 Seal Ring 101129-000 Backup Ring 8775-021 Seal Ring 008775-021 Sealing Ring EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 12: Rotating Group

Swashplate Subassembly 103872-000 Swashplate Subassembly 103852-000 Bearing Plate 103814-000 Bearing Plate 98202-000 Dowel Pin (5/16 x 5/8 long) 98202-000 Dowel Pin (5/16 x 5/8 long) EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 13: Motor Housing

Table 6.1 Motor Housing Subassembly ITEM QTY. DESCRIPTION MODEL PART N0. Dowel Pin 95904-100 Socket Pipe Plug (1/8-27) 95653-012 Case Drain Plug/O-ring 25090-012 Bearing Cup 33-39-46 103232-000 54-64 103807-000 EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 14: Kits

Hall Effect Speed Sensor 114264-002 Quadrature speed Sensor (2-pulse per target Assembly P/N 109823-000 tooth signal and 1 directional signal) (Ref. Installation Instructions 4-416) E-MOPI-TI-002-E Installation Instructions EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 15: Disassembly Shaft Seal

(refer to Special Tools) drive shaft. d. O-ring may remain in rotating seal recess. If not found in recess, remove O-ring from output drive shaft. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 16: Dis-Assembly/Assembly Valve Block

Then remove the valve block. 3. Remove O-rings and back-up rings from Motor with Valve Block mounting face of valve block. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... - Page 17 Torque plugs to 68 lb-ft [92Nm]. Shuttle Valve Spring 12. Install the two high pressure relief valves. Torque to 25 lb-ft [34 Nm]. High Pressure Relief Valves EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 18: Dis-Assembly End Cover

22. Remove and retain rear Housing S/A bearing shims from end cover. Shims are used to adjust shaft bearing end play of motor output shaft. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 19: Dis-Assembly Rotating Group

28. Push inward on shaft assembly to dislodge the swashplate from its pocket in housing. 29. Carefully remove output shaft/cylinder barrel assembly from housing. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 20: Assembly Rotating Group

36. Disassemble cylinder barrel subassembly. Place it on a clean protective surface for inspection and cleaning. Units Having Face Seal (xx31-xxx Part Number Configuration) EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... - Page 21 (i.e., piston shoe sub- assemblies, thrust plate, – B (Spacer Height) (Shoe Flange + Retainer Plate) (Fixed Clearance .008 Max) retaining strap and/or shoe retainer plate). EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

- Page 22 Headless 9. Aligning pin in housing with Cap Serews notch in swashplate, carefully (refer to slide housing over output drive Special Tools) shaft/swashplate/cylinder barrel subassembly. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 23: Assembly End Cover

.007 inches [,05 to ,17 mm] shaft end play. Magnetic Base If end play is incorrect, adjust Indicator by adding or removing shims under bearing cup located in end cover. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 24: Assembly Shaft Seal

MUST be serviced with retaining ring (beveled side the same type of seal of ring out). as was originally installed. The seals are not interchangeable. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... - Page 25 39 lb-ft [53 Nm]. Models 54/64 should be torqued to 63 lb-ft [85 Nm]. Torque each screw a second time to compensate for gasket compression set. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

- Page 26 7. Using the tool and mallet, drive the seal, spacer(as required if using, and retaining ring in until the retaining ring snaps into place in the groove. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 27: Assembly Valve Block/Integral Valves

Install the plug over the spring, making sure the shims are not dis- lodged. Screw the plug in and torque to 68 - 82 lb-ft [50 - 60 Nm]. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... -

Page 28: Special Tools

25 [34] 25 [34] Shuttle Cap 68 [92] 68 [92] Socket Pipe Plug 16 [22] 16 [22] Valve Block Mounting Bolts 28 [38] 28 [38] EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004... - Page 29 2.435 .003 54/64 990469-003 1.25 .010 1.603 .138 .003 20º 0’ 0°-15’ 2.226 .003 2.321 .003 Material: Stentor 45 - 55 R c Heat Treat EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

-

Page 30: Hydraulic Fluid Recommendations

Cleanliness Cleanliness of the fluid is extremely important. Eaton recommends that the fluid used in its hydrostatic components be maintained at ISO Cleanliness Code 18/13 per SAE J1165. The code allows a maximum of 2500 particles per milliliter greater than 5µm and a maximum of 80 particles per milliliter greater than 15µm. When components with different cleanliness requirements are used in the same system, the cleanest standard should be applied. - Page 31 5µm and a maximum of 80 particles per overheating or water contamination milliliter greater than 15µm. problem exists. Take fluid level readings when the fluid is cold. EATON Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004...

- Page 32 Telephone: 952 937-9800 Australia Tel: (49) 7221 682-0 Fax: 952 974-7722 Tel: (61) 3 9319 8222 Fax: (49) 7221 682-788 www.hydraulics.eaton.com Fax: (61) 3 9318 5714 © 2004 Eaton Corporation All Rights Reserved Printed in USA Form No. E-MOPI-TS002-E September 2004...

Need help?

Do you have a question about the 1 Series and is the answer not in the manual?

Questions and answers