Summary of Contents for Metso neles ND9000H

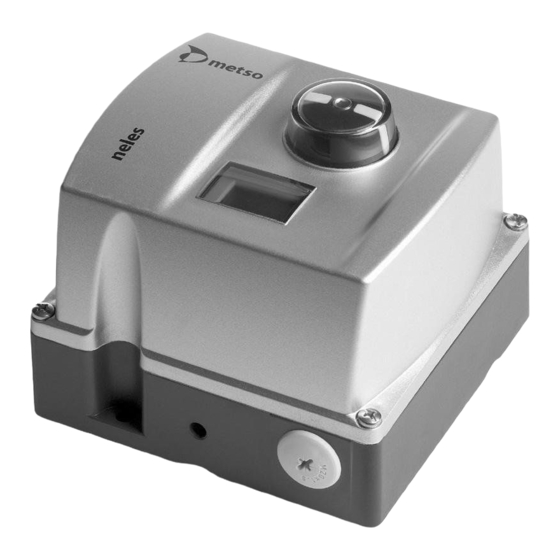

- Page 1 INTELLIGENT VALVE CONTROLLER ND9000H ND9000F ND9000P Rev. 2.3 Installation, Maintenance and Operating Instructions...

-

Page 2: Table Of Contents

12.1 Exploded view ND9100 ....... 38 Mounting on EC and EJ actuators ..9 12.2 Exploded view ND9100_/K0_, ND9100_/I__ Mounting on Metso actuators with and ND9100_/B06 ....... 39 VDI/VDE mounting face ....... 10 12.3 Exploded view ND9200, ND9300 ..40 Mounting on linear actuator of 12.4 Exploded view ND9200_/K0_, ND9200_/I__,... -

Page 3: Nd9000 Product Family Summary

1-point calibration feature ❑ Real time monitoring of valve control parameters 1.1.5 Open solution Metso is committed to delivering products that freely inter- face with software and hardware from a variety of manufac- turers; and the ND9000 is no exception. This open architecture allows the ND9000 to be integrated with other field devices to give an unprecedented level of controllability. -

Page 4: Nd9000 Intelligent Valve Controller With Different Communication Protocols

If you are uncertain about the use of the controller or its suitability for your intended use, please contact Metso’s Automation business for more information. Technical description ND9000H The ND9000H is a 4–20 mA loop-powered microcon-... -

Page 5: Technical Specifications

7 ND90 70 en YY= year of manufacturing ND9300 WW = week of manufacturing Material: Full stainless steel enclosure NNNN = consecutive number Protection class: IP66, NEMA 4X Example: PH11011234 = controller, year 2011, week 1, Pneumatic ports: 1/4 NPT consecutive number 1234. - Page 6 7 ND90 70 en Ui ≤ 32 V Ex nL IIC: IEC 60079-0 :2007-10, IEC 60079-15: 2005-03, Ii ≤ 380 mA IEC 60079-27: 2005-04, IEC 61241-0 :2004, Pi ≤ 5.32 W IEC 61241-1: 2004 Ci ≤ 5 nF Ex nA IIC T4/T5/T6 Gc Li ≤...

-

Page 7: Recycling And Disposal

7 ND90 70 en IECEx IEC 60079-0: 2004, IEC 60079-1: 2003 ND9200H, ND9300H osition transmitter Ex d IIC T4...T6 IEC 61241-0 : 2004 and IEC 61241-1: 2004 Output signal: 4–20 mA (galvanic isolation; Ex tD A21 IP66 T100°C 600 V DC) Certificate IECEx KEM 10.0055X Resolution: 16 bit / 0.244 µA... -

Page 8: Safety Precautions

7 ND90 70 en Safety precautions Ex WARNING (ND9200, ND9300): The locking screw (part 107) of the cover is essen- NOTE (ND9000): tial to explosion protection. Avoid earthing a welding machine in close proximity to The cover has to be locked in place for Ex d protec- an ND9000 valve controller. -

Page 9: Mounting

(single acting, spring to open) actuators, leave the metal plug (54) in the C1 connection at the The controller is equipped with the Metso flush mount- bottom of the controller and remove the metal ing face (not ND9300), the old Neles mounting face plug from the C2 connection at the bottom. -

Page 10: Mounting On Metso Actuators With Vdi/Vde Mounting Face

(53) with sealant to the C1 connection. ❑ Set the direction arrow of the actuator in the Fig. 5 Mounting on Metso actuator with direction of the valve closure member and attach VDI/VDE mounting face the ear (2) to the indicator cover in the position Mounting on linear actuator of shown in Section 12.6-12.7. -

Page 11: Mounting On Linear Actuator With Iec 60534 Mounting Face

7 ND90 70 en ❑ Install the O-ring (31) to the actuator. Place the make sure there are proper supports in the pipe- conical plug into the frame on the stem and line to hold the weight of the valve assembly. ❑... -

Page 12: Piping

7 ND90 70 en VDI/VDE 3845 mounting nelesCV Globe mounting IEC 60534 mounting EC/EJ flush mounting ND9100 pointer marks on housing ND9200 pointer marks on housing ND9300 pointer marks on SHAFT ENDS housing Fig. 6 Shaft coupling alternatives Piping NOTE: An excess of sealant may result in faulty operation of CAUTION: the controller. - Page 13 7 ND90 70 en Table 2 Piping Actuator Actuator piping Spool valve Stroke vol. / in 0.09 / 5 0.2 / 12 0.5 / 31 1.2 / 73 3.0 / 183 7.7 / 470 20.5 / 1250 Stroke vol. Spool valve / in 0.18 / 11 0.4 / 24...

- Page 14 7 ND90 70 en DOUBLE-ACTING ACTUATOR Increasing input signal to open valve (shown) Default setting: DIR = OPE ROT = cC (close valve to clockwise) ATYP = 2-A PFA = CLO A0, CUTL and VTYP according to valve type 2. Increasing input signal to close valve (not recommended) Default setting: DIR = CLO ROT = cC (close valve to clockwise)

- Page 15 7 ND90 70 en DOUBLE-ACTING ACTUATOR Self closing Default setting: ROT = cC (close valve to clockwise) ATYP = 2-A PFA = CLO A0, CUTL and VTYP according to valve type DOUBLE-ACTING ACTUATOR, REVERSED PIPING Self opening Default setting: ROT = cC (close valve to clockwise) ATYP = 2-A PFA = OPE A0, CUTL and VTYP according to valve type...

-

Page 16: Electrical Connections

7 ND90 70 en Electrical connections ND9000F, ND9000P The ND9200F is powered by FOUNDATION Fieldbus ND9000H (IEC 61158-2). The ND9000 is powered by a standard 4–20 mA cur- The ND9200P is powered by Profibus PA (IEC 61158-2). rent loop that also functions as a carrier to the HART communication. - Page 17 7 ND90 70 en HAZARDOUS LOCATION NONHAZARDOUS LOCATION Class I, Division 1 and 2, Groups A, B, C, D Class I, Zone 0, AEX ia, Group IIB/IIC T4/ T5/T6 T4: Ta = -40…80 °C T5: Ta = -40...65 °C T6: Ta = -40...50 °C Position Transmitter Exi barrier 53 µH...

- Page 18 Class I, Zone 0, AEX ia, Group IIB/IIC T4/ T5/T6 to earth ground T4 : Ta = -40…80 °C T5: Ta = -40...65 °C T6: Ta = -40...50 °C METSO Automation OY: FMRC approved associated ND9100PU1/U2 or apparatus with applicable zone and ND9100FU1/U2...

-

Page 19: Local User Interface (Lui)

7 ND90 70 en LOCAL USER INTERFACE (LUI) The local user interface may be used to monitor the device behaviour as well as configuring and commis- sioning the controller during installation and normal operation. The local user interface consists of 2 row LCD and 4 button keypad interface. -

Page 20: Guided Start-Up

7 ND90 70 en Guided start-up Guided startup offers a fast view of the most critical parameters of the ND9000 controller, actuator and valve configuration. After verifying the parameters the valve travel calibration is recommended. The guided start-up is entered by pressing the = and ? keys simultaneously. - Page 21 7 ND90 70 en — brief push — brief push Fig. 20 Configuration, ND9000H Fig. 21 Configuration, ND9000F 5.4.2 MAN During this mode the valve position may be controlled manually by using the keypad and pressing the + or - key.

-

Page 22: Configuration Parameters

7 ND90 70 en 5.5.1 Performance level, PERF If you want to change the tuning of the valve position control, the PERF selection is available. The default fac- tory value is C. ❑ Once PERF is displayed press the ? key to enter the edit state and PERF starts to blink. - Page 23 The α setting is made for Metso segment and ball valves. ❑ To conclude press the ? key when the desired This setting takes into account the "dead angle" α...

-

Page 24: Valve Travel Calibration

7 ND90 70 en Table 5 Dead angle in percentage The cut-off overrides the limit as follows: ❑ If the low cut-off > low limit, the low limit is not Valve Valve series size active. T25, ❑ QMBV QMBV QT25 SOFT If the low cut-off <... - Page 25 7 ND90 70 en Fig. 27 Calibration selection 5.6.1 AUTO calibration function 5.6.3 1-Point calibration During the calibration process the display will show blink- 1-point calibration is useful in cases in which the valve ing CAL and numbers run from 1 to 100 to show calibration controller needs to be changed but it is not possible to progress.

-

Page 26: Special Displays

7 ND90 70 en play. No changes to linearization are made and WARNING: corresponding message is shown to user. Supply pressure can be connected to the valve If linearization fails, a message about the reason will be controller only after 1-point calibration is success- shown on the LUI display and also in event log that can fully completed. -

Page 27: Write Protection

7 ND90 70 en view. The message is scrolled on the top row of the dis- Write protection, ND9000F, ND9000P play twice. You may stop the scrolling by pressing the The ND9000F/ND9000P is delivered from the factory ? key. By pressing the = key, the message will disap- with HW write protection OFF as the default setting. -

Page 28: Maintenance

7 ND90 70 en MAINTENANCE 6.1.2 Installation ND9100 Ex d WARNING (ND9200, ND9300): Service of the cylindrical flameproof joints is not ❑ Place a new O-ring (140) into the groove on the allowed. spool valve and press the prestage into place. This includes the diaphragm cover (part 171), flame Make sure the nozzle is guided into the O-ring arrester plunger (part 200), their mating surfaces in... -

Page 29: Flame Arrestor Assembly

7 ND90 70 en the body with your fingers to avoid dropping the 174 194 spool from the body. ❑ Spool valve removal is only possible in the spring-forced failsafe position of the spool. In the case of a stuck spool it might be necessary to remove the secondary diaphragm cover (167), the spool spring (166) with its disc (164) and the secondary diaphragm (162) with its plate. -

Page 30: Error Messages

7 ND90 70 en ❑ Remove the M3 screws (217, 4 pcs.). Hold the ERROR MESSAGES sides of the circuit board and lift it directly Failsafe errors upwards and outwards. Handle the board care- fully, touching only the sides. Display message Description 6.5.2 Installation POSITION SENSOR FAILURE... -

Page 31: Warnings

7 ND90 70 en Warnings EVENT DATABASE ERROR Failed to store events. The new events will be lost. POSITION CALIBRATION Travel calibration failed. Check Display message Description FAILED the configuration parameters and controller mounting. Check TOTAL OPERATION TIME Operating time exceeded limit. that the controller shaft is WARNING correctly aligned. -

Page 32: Notifications

7 ND90 70 en Notifications TROUBLE SHOOTING Mechanical/electrical defects Display message Description 1. A change in the valve position setpoint will not affect CALIBRATION SUCCESSFULL Position calibration successfully the position of the actuator performed. ❑ LINEARIZATION SUCCESSFUL 3P/9P linearisation successfully Supply pressure too low performed. -

Page 33: Nd9000 With Limit Switches

7 ND90 70 en ND9000 WITH LIMIT SWITCHES 2 microswitches 2 cams Introduction 9.1.1 General description ND9000 can be equipped with limit switches. Limit terminals switches are used for electrical position indication of the valves and other devices. The switching points may 111213141516 be chosen freely. - Page 34 7 ND90 70 en 9.1.2 Markings The limit switch is provided with an identification plate, 2 micro switches 2 cams see Fig. 44 and 45. Identification plate markings include: ND9100 terminals ❑ Type designation ❑ Electrical values ❑ Enclosure class ground ❑...

-

Page 35: Electrical Connections

7 ND90 70 en Materials: Installation on a valve controller Body: Aluminium alloy, epoxy-coated The limit switch may be installed on an existing valve Internal parts: Stainless steel and polymer controller. Sealing: Nitrile and neoprene rubber ND9100 9.1.3.2 ND9000_/I__ ❑ If the valve controller is already mounted on an actuator/valve assembly, operate the actuator Proximity switch type:... -

Page 36: Installation On A Valve Controller

7 ND90 70 en Adjustment ND9200, ND9300 ❑ Remove the cover (100) and the pointer (109). The pointer (109) need not be removed for adjustment. ❑ Loosen the screws (314) in the cam disks (313) When the limit switch is ordered together with the valve and remove the cam disks and spacers (346) and the actuator, the valve controller switches are fac- from the shaft. -

Page 37: Tools

7 ND90 70 en TOOLS Following tools are needed for the product installation and service: ❑ Flat screwdriver 0.4 x 2.5 mm 6.5 x 150 mm ❑ Torx screwdriver ❑ Phillips screwdriver PH1 x 60 mm ❑ Allen key 2 mm 4 mm 5 mm Other tools are depended on actuator where ND... -

Page 38: Drawings And Parts Lists

7 ND90 70 en DRAWINGS AND PARTS LISTS 12.1 Exploded view ND9100 Item Description Spare part modules Housing Exhaust cover Screw Shaft O-ring Washer Wave spring Bushing Grounding screw Electronics cover Screw Prestage cover Screw Screw Screw Screw Cover ............H035118, includes item 107 Screw Pointer... -

Page 39: Exploded View Nd9100_/K0_, Nd9100_/I

7 ND90 70 en 12.2 Exploded view ND9100_/K0_, ND9100_/I__ and ND9100_/B06 I_ _ Item Description Grounding screw Cover Screw Pointer Screw Local user interface (LUI) Housing Gasket Screw Screw Bracket Screw Bed of Local User Interface (LUI) Screw Screw Shaft Screw Cam disc Screw... -

Page 40: 12.3 Exploded View Nd9200, Nd9300

7 ND90 70 en 12.3 Exploded view ND9200, ND9300 ND9300, ND9200_E2 ND9300 162** 169**... - Page 41 7 ND90 70 en Item Description Spare part modules Housing O-ring Washer Wave spring Bushing Grounding screw Inner cover Screw Screw Conduit entry adapter Spool valve cover Gasket Cover ............ND92_E1 = H087634, ND92_E2 = H087617, ND9300 = H087628 O-ring Screw Pointer Stop screw...

-

Page 42: Exploded View Nd9200_/K0_, Nd9200_/I

7 ND90 70 en 12.4 Exploded view ND9200_/K0_, ND9200_/I__, ND9200_/B06 ND9300_/K0_, ND9300_/I__, ND9300_/B06_ ND9300 I_ _ ND9300 ND9200... - Page 43 7 ND90 70 en Item Description Cover O-ring Screw Pointer Stop screw Spring (ND9200) Local user interface (LUI) Housing O-ring Screw Bracket Screw Bracket Screw Screw Extension shaft Screw 2 or 4 Cam disc 2 or 4 Screw Terminal block Base plate Screw Screw...

-

Page 44: 12.5 Mounting Parts For Ec05-14/Ej05-14 Actuators, Rising Signal Opens Valve

7 ND90 70 en 12.5 Mounting parts for EC05-14/EJ05-14 actuators, rising signal opens valve ND9100 Item Description Screw Coupling Screw O-ring Coupler socket Screw E_05 - 14 O-ring Plug Plug (EJ only) ND9100 ND9200 Item Description Coupling Screw O-ring Coupler socket Screw Plug Plug (EJ only) -

Page 45: 12.6 Mounting Parts For B1C/B1J 6-20 Actuators

7 ND90 70 en 12.6 Mounting parts for B1C/B1J 6-20 actuators ND9100 ND9100 ND9100 VDI/VDE 3845 Neles attachment face attachment face Item Description Item Description Mounting bracket Mounting bracket Draught piece Washer Washer Screw Screw Screw Screw Screw Hexagon nut Couplings jacket Screw Coupler socket... -

Page 46: 12.7 Mounting Parts For B1C/B1J 25-50, B1C 502 And B1J322 Actuators

7 ND90 70 en 12.7 Mounting parts for B1C/B1J 25-50, B1C 502 and B1J322 actuators ND9100 Item Description Mounting bracket Draught piece Washer Screw Washer Screw Coupler socket Screw Plug (BJ actuators only) Plug ND9100 ND9200, ND9300 Note: Old series B actuators new hole drilled ø5.5 through Arrow... -

Page 47: Mounting Parts For Quadra-Powr ® Actuators

7 ND90 70 en ® 12.8 Mounting parts for Quadra-Powr actuators ND9100 Item Description Mounting bracket Screw Screw Screw Screw Adapter plug (QP II 1/S- 6/S only) ND9100 Adapter plate (QP II 2B/K thr. 6_/K) Couplings jacket Coupler socket Screw Plug Plug Item... -

Page 48: 12.9 Mounting Parts For Linear Actuators Of Nelescv Globe

7 ND90 70 en 12.9 Mounting parts for linear actuators of nelesCV Globe ND9100 Set conical plug to the scale according to the stroke Item Description Washer Screw Conical plug Screw O-ring O-ring Mounting plate Feedback lever Screw Plug Plug ND9200 Set conical plug to the scale according to the stroke Item... -

Page 49: Iec 60534

7 ND90 70 en 12.10 Mounting parts for linear actuators, IEC 60534 ND9100 Feedback lever in horizontal position at mid travel of stroke. Stroke 10 - 120 mm Plane in the shaft in this position with feedback lever Scale on this side Allowed travel range 45–90°... - Page 50 7 ND90 70 en ND9200, ND9300 Feedback lever in horizontal position at mid travel of stroke. Stroke 10 - 80 mm Stroke 60 - 120) mm Plane in the shaft in this position 45° with feedback lever 45° Scale on this side 45°...

-

Page 51: 12.11 Connection Diagrams

7 ND90 70 en 12.11 Connection diagrams See Section 9.1.3 for additional limit switch data. ND9000/K_ blue OPEN black blue CLOSED black Connection diagram shows limitswitch when actuator is in intermediate position. Switch A (upper) is acti- vated at the open limit of the travel and switch K (lower) at the closed limit. Electrical characteristics: OMRON D2VW-5 (K05): 5A - 30 V DC, 0.4 A - 125 V DC... - Page 52 7 ND90 70 en black ND9000/I56 OPEN black black CLOSED black Factory adjustment: Active faces of proximity switches are free when the actuator is in the intermediate position. Active face A (upper switch) becomes covered at the open limit of the travel and face K (lower switch) at the closed limit. The function may be inverted on site by re-adjusting the cam discs.

-

Page 53: 12.12 Control Drawings

7 ND90 70 en 12.12 Control drawings ND9100H, ND9300H HAZARDOUS LOCATION NONHAZARDOUS LOCATION Class I, Division 1 and 2, Groups A, B, C, D Class I, Zone 0, AEX ia, Group IIB/IIC T4/ T5/T6 T4: Ta = -40…80 °C T5: Ta = -40...65 °C T6: Ta = -40...50 °C Position Transmitter Exi barrier... - Page 54 Class I, Zone 0, AEX ia, Group IIB/IIC T4/ T5/T6 to earth ground T4 : Ta = -40…80 °C T5: Ta = -40...65 °C T6: Ta = -40...50 °C METSO Automation OY: FMRC approved associated ND9100PU1/U2 or apparatus with applicable zone and ND9100FU1/U2...

- Page 55 7 ND90 70 en Installation Notes for FISCO Concepts in FM: 1. The Intrinsic Safety FISCO concept allows the interconnection of FM Approved Intrinsically safe devices with FISCO parameters not specifically examined in combination as a system when: ≤ ≤ ≤...

-

Page 56: Dimensions

7 ND90 70 en DIMENSIONS ND9100 G1/4 0.75 15.5 0.61 M20 x 1.5 M6 x 12 0.16 29.5 1.16 F05-ø50(VDI/VDE3845) 35.4 1.39 G1/8 ø6/10 F05-ø50(VDI/VDE3845) 35.4 ND9100/I, ND9100/K and ND9100/B G1/4 1.39 M6/10 0.55 0.74 G1/8 ø6 ø0.23 M20 x 1.5 0.78 G1/4 0.23... - Page 57 7 ND90 70 en ND9200 35.4 1.39 M20x1.5 (1/2 NPT) 1/4 NPT 0.55 1.54 1.30 1.30 M6 x 12 0.16 0.98 ND9200 1/4 NPT 0.55 2.05 6.37 35.4 1.39 ø6 ø0.23 101.2 3.98 0.23 0.51...

- Page 58 7 ND90 70 en ND9200/I, ND9200/K, ND9200/B 0.55 M20x1.5 (1/2 NPT) M6 x 12 0.16 0.98 6.85 1/4 NPT 0.55 2.05 6.37 4.05 35.4 1.39 ø6 ø0.23 101.2 3.98 ND9300 ø6.5 35.4 1.39 2.20 44.5 M20x1.5 (1/2 NPT) 1/4 NPT 3.11 1.54 1.30...

- Page 59 7 ND90 70 en ND9300 6.42 ø56 2.20 1/4 NPT 0.55 2.05 35.4 1.39 ø6 ø0.23 ø6.5 4.05 ND9300/I, ND9300/K, ND9300/B Linear actuator The feedback lever according to actuator ND930_E1: M20x1.5 ND930_E5: M20x1,5/1/2 NPT (CONDUIT ENTRY NIPPLE) VDI/VDE 3845 F05-ø50 (35.4) M8x15 (3 pcs.) 1/4 NPT...

-

Page 60: Ec Declaration Of Conformity

7 ND90 70 en EC DECLARATION OF CONFORMITY EC DECLARATION OF CONFORMITY Manufacturer: Metso Automation Oy 01301 Vantaa Finland Product: Intelligent Valve Controller Neles ND 9000-series Approvals: Type Approval EC Type examination Certificate ND 9…PA (Profibus PA) (EMC 2004/108/EC) EN61000-6-2(2001) NEMKO 101425 & NEMKO 1052749 (EMC 2004/108/EC) EN61000-6-2(2001) (Same HW as ND9...PA) -

Page 61: Id Plates

7 ND90 70 en ID PLATES FM / CSA : Ex nA ATEX / IECEx : 1 G Ex ia , 1 D Ex tD ATEX / IECEx : 2 G Ex ia , 2 D Ex tD ATEX / IECEx : 3 G Ex nA , 3D Ex tD ATEX / IECEx : 3 G Ex nL , 3 D Ex tD ATEX / IECEx : 2 G Ex d , 2 D Ex tD FM / CSA : Ex d... -

Page 62: Type Coding

T5: < +75 °C / +167 °F; T6: < +60 °C / +140 °F . attachment face according to standard VDI/VDE 3845, No Zener Barrier needed. EC/EJ actuators and Metso standard. Not applicable to 3. sign "20". Relevant shaft adapter included in mounting kits. When valve Ex tD certification is not available with 7. - Page 63 7 ND90 70 en APPROVALS OF STANDARD ENCLOSURE VALVE CONTROLLER OPTIONS OF VALVE CONTROLLER INMETRO certifications: ND9_H_T only: Internal 2-wire (passive) position transmitter. BR-Ex nA II / nL IIC T4/T5/T6 IP66 Analog position feedback signal, output 4–20 mA, supply voltage 12–30 V DC, external load resistance 0–780 Ω . Temperature range: T4: -40°...

- Page 64 7 ND90 70 en Metso Automation Inc. Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151 North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172 South America, Av.

Need help?

Do you have a question about the neles ND9000H and is the answer not in the manual?

Questions and answers