Table of Contents

Advertisement

Instructions — Parts List

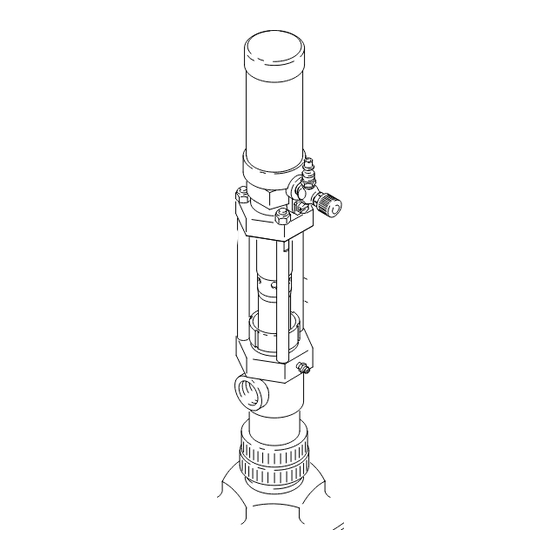

1:1 RATIO, 210 LITER (55 GAL.) SIZE

Foam-Cat

For use in drums of polyurethane chemicals.

180 psi (1.2 MPa, 12.4 bar) Maximum Air Working Pressure

180 psi (1.2 MPa, 12.4 bar) Maximum Material Working Pressure

* Model No. 226946, Series B

Includes airtight bung adapter

Feed Pump Kit 217381

Includes two Model 226946 Feed Pumps, air dryer,

and air and fluid hoses.

Read warnings and instructions. See

page 2 for Table of Contents.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

© Graco Inc., 1982. Graco Inc. is registered to I.S. EN ISO 9001

®

Feed Pump

05217B

II 1/2 G T6

ITSO3ATEX11227

2575

307552K

EN

Advertisement

Table of Contents

Summary of Contents for Graco Foam-Cat Series

- Page 1 Read warnings and instructions. See page 2 for Table of Contents. 05217B GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 © Graco Inc., 1982. Graco Inc. is registered to I.S. EN ISO 9001 II 1/2 G T6 ITSO3ATEX11227 2575...

-

Page 2: Table Of Contents

Technical Data ......15 Graco Standard Warranty ..... . . 16... - Page 3 WARNING TOXIC FLUID HAZARD Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed. • Know the specific hazards of the fluid you are using. • Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

-

Page 4: Installation

Installation NOTE: The terms ISO and RES used in the text refer to the polyurethane foam chemicals, Isocyanate and Resin. NOTE: Reference numbers and letters in parentheses in the text refer to the figure illustrations and the Parts Drawing. WARNING A bleed–type master air valve (E) is required in your system, to help reduce the risk of serious injury, including splashing fluid in the eyes or on the skin, and... - Page 5 Feed Pump Kit Installation The following instructions assume you are using this kit Grounding with a Graco Foam–Cat Sprayer. 1. Install the feed pumps as described in Steps 1–4, on page 4. WARNING 2. Mount the Air Dryer (105) in any suitable location.

- Page 6 If the coupler and fitting ever 9. Connect the ISO fluid hose between the 3/4 npt(f) needs to be replaced use only original Graco parts. fluid outlet of the ISO feed pump and the 3/4 npt(f) inlet of the corresponding displacement pump.

-

Page 7: Operation

Starting and Operating the Pump This pump is designed to be used with a Graco Foam-Cat Sprayer. If you have purchased such a sprayer, complete warning and operating instructions are contained in the manual (307541 or 307542) which accompanied the sprayer. -

Page 8: Maintenance

Maintenance Bung Adapter If the ISO material shows signs of crystallization, and whenever the pump is removed from the drum, check the o- ring (39) and gasket (41) for wear or damage, replacing as needed. Refer to the Parts Drawing. ISO Pump Packing Protection and Lubrication CAUTION... -

Page 9: Troubleshooting

Troubleshooting Check all possible remedies before disassembling the WARNING pump. Follow the Pressure Relief Procedure on page 7 before servicing the pump. PROBLEM CAUSE SOLUTION Pump fails to operate Material crystallized Clean pump, use IPL more liberally Dirty or worn air motor parts Clean air motor, repair Inadequate air supply or restricted Clear line;... -

Page 10: Service

Service Disconnecting the Air Motor Intake Valve Flush the pump, disconnect the air supply and relieve all Unscrew the intake valve housing (35). Disassemble, clean and inspect all parts. Replace worn or damaged pressures in the system. Remove the pump from its parts. - Page 11 Service Torque to 31 N•m (23 ft–lb) Torque to 33 N•m (24 ft–lb) Lips face down 05221 FIG. 7 307552...

-

Page 12: Parts Drawing

Parts Drawing 03768C 03768 05221 307552... -

Page 13: Parts List

Parts List Model 226946, Series B Feed Pump Kit 217381 Includes Items 1–42 Includes Items 101–105 Ref. Part Ref. Description Qty. Part No. Description Qty. DRIVESCREW, #4 x 3/16”, type U 100508 226946 1:1 RATIO FAST-FLO FEED PUMP 104541 LOCKNUT, M8 w/nylon insert See parts at left. - Page 14 Notes ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ 307552...

-

Page 15: Technical Data

Technical Data Recommended Air Operating Range ....40–180 psi (0.3–1.2 MPa, 3–12 bar) Air Consumption ....Approx. 0.05 m /min at 4 liters/min and 5.5 bar input (1.8 cfm at 1 gpm and 80 psi) . -

Page 16: Graco Standard Warranty

Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Foam-Cat Series and is the answer not in the manual?

Questions and answers