Summary of Contents for fadini Dardo 424

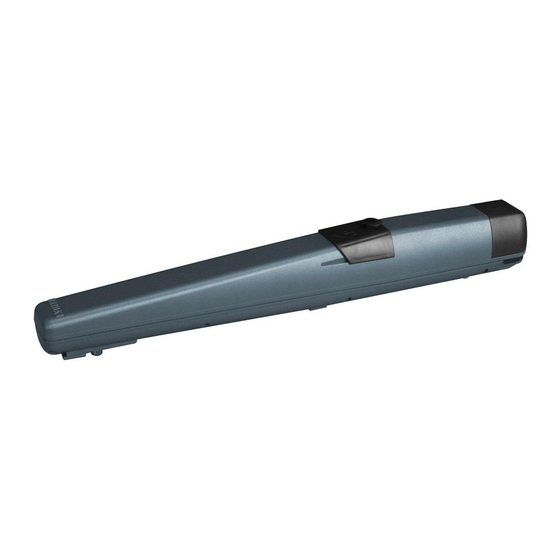

- Page 1 GB Instructions manual 15 - 28 pages DARDO 424 - 24 Vdc EN 13241 EN 12453 EN 12445 the gate opener...

-

Page 2: Installation

CE DECLARATION OF CONFORMITY of the manufacturer: Meccanica Fadini snc (Via Mantova, 177/A - 37053 Cerea - VR - Italy) declares under own responsibility that: Dardo 424 complies with the 2006/42/CE Machinery Directive, and also that it is sold to be installed in an “automatic system”, along with original accessories and components as indicated by the manufacturing company. -

Page 3: Product Applications

In case of an electric power failure, Dardo 424 can be “released” by a custom-made, coded key and the gates moved by hand. Terminals are factory fitted to each operator and provide connections for the power supply and the encoder to the electronic controller Elpro 42 , to be installed stand alone, in a sheltered place. - Page 4 The all installation is to be grounded. LEGEND 1 - Dardo 424 motor operator: 4G x 1,5 mm² cable 2 - Photocell transmitter (2 x 0,5 mm²) 3 - Ground stop in open gate position (not supplied with the equipment) 4 - Photocell receiver (4 x 0,5 mm²)

- Page 5 DARDO 424 DARDO 424 electromechanical operator for swinging gates INSTALLATION DISTANCES FOR OPENING INWARDS 55 mm Installation distances considering the incorporated stop plates ≥ 60 opening 0 - 90° D + 90 max 90 opening 90° - 100° D + 90 max 80 opening 100°-115°...

- Page 6 DARDO 424 DARDO 424 electromechanical operator for swinging gates FIXING BRACKETS PREPARATION AND FASTENING IMPORTANT: before fastening the mount brackets, consider that they are 55 mm vertically offset: the front fixing is 55 mm lower than the rear fixing to the gate post (Pic. 7).

- Page 7 DARDO 424 DARDO 424 electromechanical operator for swinging gates FIXING TO GATE POST Remove the rear cap protecting the electrical connections, located at the back of the operator. Make the opertor rear fork-like bracket to fit the gate post fixing plate on to the central hole (lateral holes are provided to adjust the rear fixing in case A and B distances might be wrong).

- Page 8 DARDO 424 DARDO 424 electromechanical operator for swinging gates RELEASE FOR MANUAL OPERATIONS In the release mode, the operator does not perform any operation on the gate, in spite of voltage continuing to be supplied. In this situation the gate can be opened and closed manually even if the operator is still mounted on to it.

- Page 9 DARDO 424 DARDO 424 electromechanical operator for swinging gates FITTING THE POWER SUPPLY CABLE Terminal block for electrical connections Once the electrical connections are finished, tighten the gland locknut Let the cable dangle free avoiding sharp bending Pic. 14 GATE OPENING INWARDS IMPORTANT: the terminals of M1 (A1, B1, C1) and M2 (A2, B2, C2) motors in the controller correspond to: - M1 = Dardo on 1st gate leaf to open and in pedestrian mode if selected.

- Page 10 DARDO 424 DARDO 424 electromechanical operator for swinging gates GATE OPENING OUTWARDS OPENING OUTWARDS Dardo M2 Dardo M1 Dardo terminals Dardo terminals Dardo M2 power supply ELPRO 42 A2 B2 C2 Dardo M1 power supply A1 B1 C1 Pic. 16...

-

Page 11: Ordinary Maintenance

DARDO 424 DARDO 424 electromechanical operator for swinging gates ORDINARY MAINTENANCE It is recommended that the operators and all the moving parts be inspected periodically (every 2-3 months or whenever necessary) and the inner rolled screw shaft lubricated with some grease from underneath the operator. -

Page 12: Maintenance Record

NOTE WELL: this document must record any ordinary and extraordinary services including installation, maintenance, repairs and replacements to be made only by using Fadini original spare parts. This document, for the data included in it, must be made available to authorized inspectors/officers, and a copy of it must be handed over the end user/s. - Page 13 DARDO 424 DARDO 424 electromechanical operator for swinging gates...

-

Page 14: Technical Data

DARDO 424 DARDO 424 electromechanical operator for swinging gates TECHNICAL DATA Dardo 424 Motor power supply 24 Vdc Rated absorption 1,5 A Max. absorption 3,5 A Max. power 80 W Rated thrust power 130 N Max. thrust power 1000 N Opening time 16 s ÷...

Need help?

Do you have a question about the Dardo 424 and is the answer not in the manual?

Questions and answers