Advertisement

Table of Contents

Advertisement

Table of Contents

Summary of Contents for Eswood ES32

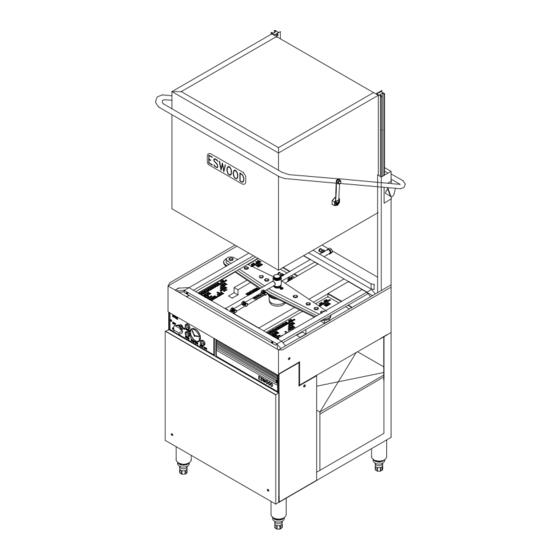

- Page 1 EQUIPMENT MANUAL ES32 COMPACT PASS THROUGH DISHWASHER JUNE 2011...

-

Page 2: Table Of Contents

ABLE OF CONTENTS Important: Prior to Installation General Description Technical Specifications Installation Initial Start-up Procedure Washing Operation Shutdown and Maintenance Trouble Shooting 11-12 Wiring Diagram Drawings 14 & 15 Spare Parts & Service ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 3: Important: Prior To Installation

(Note: Travel time not covered by warranty) In no event will ESWOOD AUSTRALIA be liable for loss of facilities or other property and such things as, but not limited to, additional labour costs, loss of revenue or anticipated profits, and other damages of any kind whether direct, indirect, incidental or consequential. -

Page 4: General Description

Closing the hood automatically begins the pre-selected cycle, and a safety switch ensures that the machine does not operate unless the hood is properly closed. The ES32 features a full wrap around handle with super smooth, wear resistant polymer guides and pivot bushes, and an adjustable counter-balance spring. - Page 5 Quality, Reliability and Performance: Eswood has a reputation for product reliability that is second to none. The finest of stainless steel and durable synthetic materials are used, and all Eswood products are fully guaranteed and backed by a national support network.

-

Page 6: Technical Specifications

Litres per cycle Electrical and Water Connections: Electrical Input 3-ph: 415V, 9.4 kW (14,3 Amp/ph) Water Input 3-ph: 65 C minimum @ 100-400kPa Hot Water Inlet ” B.S.P. fitting Drain Outlet 2” B.S.P. gravity fed ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 7: Installation

To fill tank simply open isolating valve. Tank will fill with water till level is reached. Connect the benching so that there is a fall back towards the machine to allow water to drain back into the machine. ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 8: Initial Start-Up Procedure

When finished, check for leaks. Turn the rotary switch “OFF”, open the door and remove the strainer pans and overflow tube to drain the machine. Replace the lower front panel. ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 9: Washing Operation

Note that the hood should not be opened until the wash and rinse cycle is complete, otherwise the cycle will reset and continue longer than necessary. ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 10: Shutdown And Maintenance

Check for leaks and ensure that the lower and upper arms rotate freely. Leave the hood open to allow the machine to air. ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 11: Trouble Shooting

(a) Check that detergent feeder to machine is operating correctly, if fitted. If operational, adjust the injector to increase dosage. (b) If hand-feeding with detergent, increase dosage. (c) Check for foreign matter in wash arm jets. Clean if necessary. ESWOOD OPERATING MANUAL ES-32 June 2011... - Page 12 (e) Check operation of the ball float valve. Insufficient rinse/ (a) Ensure that temperature of Temperature incoming water supply is at least 65 (b) Check that rinse booster element and thermostat are functioning correctly. Rinse temperature 80°-88°C. ESWOOD OPERATING MANUAL ES-32 June 2011...

-

Page 13: Wiring Diagram

IRING IAGRAM ESWOOD OPERATING MANUAL ES-32 June 2011... -

Page 14: Drawings 14

RAWINGS ESWOOD OPERATING MANUAL ES-32 June 2011... - Page 15 RAWINGS ESWOOD OPERATING MANUAL ES-32 June 2011...

-

Page 16: Spare Parts & Service

(Applicable to landline only charges apply for calls made from a Mobile Phone) 1800 013 123 This number will automatically access your nearest State office, or the technician on duty if after hours. After hours charges apply. ESWOOD OPERATING MANUAL ES-32 June 2011...

Need help?

Do you have a question about the ES32 and is the answer not in the manual?

Questions and answers