Summary of Contents for probst VPH-150

- Page 1 Operating Instructions Translation of original operating instructions VACUUM-POWER-HANDY VPH-150 5271.0008...

-

Page 2: Table Of Contents

Maintenance and care ............................18 Maintenance ..............................18 7.1.1 Mechanical ..............................18 Suction plate ..............................19 Fault finding ..............................19 Repairs ................................20 Safety procedures ............................20 Hints to the type plate ........................... 21 Hints to the renting/leasing of PROBST devices ..................21 5271.0008... - Page 3 EC-Declaration of Conformity 3 / 24 Vacuum pump ..............................22 General ................................22 Safety Advice ..............................22 Description ..............................22 8.3.1 Charge battery ............................23 Maintenance ..............................23 Technical Data ............................... 24 5271.0008...

-

Page 4: Ec-Declaration Of Conformity

DIN EN 60204-1 (IEC 60204-1) Safety of machinery, electrical equipment of industrial machines. Part 1: General requirements. Authorized person for EC-documentation: Name: J. Holderied Address: Probst GmbH; Gottlieb-Daimler-Straße 6; 71729 Erdmannhausen, Germany Signature, information to the subscriber: Erdmannhausen, 11.07.2018................(M. Probst, Managing director) -

Page 5: Safety

Safety 5 / 24 Safety Safety symbols Danger to life! Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will result. Hazardous situation! Identifies a potentially hazardous situation. If you do not avoid the situation, injury or damage to property can result. -

Page 6: Safety Marking

Meaning Order-No. Size Maximum working load limit of the suction plate (VPH-100) 2904.0575 80 x 40 mm Maximum working load limit of the suction plate (VPH-150) 2904.0207 80 x 35 mm 200 x 50 Label with device title 2904.0129 5271.0008... -

Page 7: Personal Safety Requirements

Safety 7 / 24 Personal safety requirements Each operator must have read and understood the operating instructions (and all safety instructions). Only qualified, authorized personal is allowed to operate the device and all devices which are connected (lifting device/carrier). The manual guiding is only allowed for devices with handles. Protective equipment ... -

Page 8: Function Control

Safety 8 / 24 While using the vacuum lifting device is the stay of persons in the working area forbidden. Except it is indispensable. Caused of the way of using the vacuum lifting device , e.g. if the device must be leaded by hand. -

Page 9: General

General 9 / 24 General Authorized use The device “VACUUM-POWER-HANDY VPH” is only for lifting, transporting and installing natural stone and concrete slabs, large slabs, drain joint stones, steps, as well as tiles in close proximity to the ground. The goods to be lifted must have no porous surfaces. - Page 10 Standard suction plates are not suitable for the transport of glass plates! Only suction plates of the manufacturer PROBST shall be used!!! Some suction plates which can be mounted to the device will reduce its carrying capacity. The maximum load is indicated on each suction plate.

-

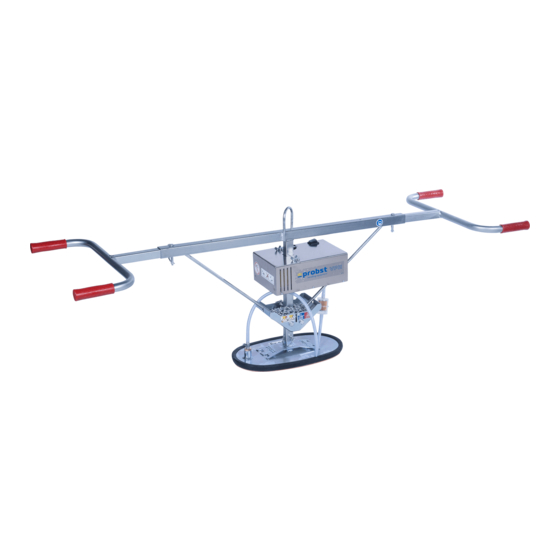

Page 11: Survey And Construction

9. Wheel Set VPH-RS, allow to use the device by one person (optionally) 10. Stop for Wheel Set VPH-RS-AS, for large-size tiles (optionally) Technical data Type Carying capacity/WLL [kg] valve at 500 mbar under-pressure Dead weight [kg] VPH-150 19,5 5271.0008... -

Page 12: Installation

Installation 12 / 24 Installation Mechanical connection Use only original accessories, in case of doubt consult the manufacturer. Take care that the carrying capacity / working load limit (WLL) of the lifting device/carrier is not exceeded, through the load of the device, the attaching devices (turning device, fork sleeves etc.) and the additional load of the gripping goods! Mechanical gripping devices always have to be gimballed, so they can swing freely in any position. -

Page 13: Assembly Of Stop For Wheel Set Vph-Rs-As

Installation 13 / 24 Assembly of Stop for Wheel Set VPH-RS-AS 5271.0008... -

Page 14: Adjustments

Adjustments 14 / 24 Adjustments Adjustment of VPH and the assembly 5271.0008... -

Page 15: Operation

Operation 15 / 24 Operation Operating Elements Main switch –on / off. This is to turn the pump on and off. Caution! The suction guide line is automatically bled when the VPH is switched off. For a description of the other elements, please refer to the Appendix: Operating Instructions for the Battery Diaphragm Pump! To suction and release the load: Main Switch ON... -

Page 16: Lifting, Transport And Installation (Hoist Operation)

Operation 16 / 24 Lifting, Transport and Installation (hoist operation) When using the device in hoist operation the safety chain has to be used in any case! Position the device directly above the load. Avoid pulling it diagonally, make sure the load is evenly distributed. Place the device onto the load. -

Page 17: Lifting, Transport And Installation (Manual Operation)

Operation 17 / 24 Caution! Once the machine is switched off, the suction lead is automatically bled and so the vacuum disappears. Always keep feet well away from the danger area! Lifting, Transport and Installation (manual operation) Position the device directly above the load. Avoid pulling it diagonally, make sure the load is evenly distributed. Place the device onto the load. -

Page 18: Damages Of Suction Plate

Maintenance and care 18 / 24 Damages of suction plate Avoidance of damages: To avoid damages of the rubber seal on the suction plate (chinks, abrasion) take notice, that: during the operation (lifting, transporting and lowering) with the device, the suction plate does not brush or pump against other products or materials. -

Page 19: Suction Plate

Maintenance and care 19 / 24 Suction plate Clean the sealing lips with compressed air and/or water jet once per week to remove any objects and dirt such as sand, stone particles, dust etc. Clean slot in the sealing lip with a cloth and / or blow out with compressed air. -

Page 20: Repairs

Maintenance and care 20 / 24 Load cannot be sucked. Leakage at vacuum plate by deposited Remove rubber seal from suction plate. dirt between rubber seal and suction Clean suction plate and slot in rubber seal. Prescribed negative pressure plate. Draw up and fasten rubber seal on suction plate cannot be achieved no more. -

Page 21: Hints To The Type Plate

Example: Hints to the renting/leasing of PROBST devices With every renting/leasing of PROBST devices the original operating instructions must be included unconditionally (in deviation of the users country's language, the respective translations of the original operating instructions must be delivered additionally)! -

Page 22: Vacuum Pump

The condensation could damage your pump. Let it come to room temperature without switching it on. Description The pump consist of the following parts: Robust aluminium casing with a mounting to fix it onto the Probst stand. Two 12 Volt diaphragm pumps. ... -

Page 23: Charge Battery

Vacuum pump 23 / 24 Voltage- Battery is overcharged Yellow LED above 14.5 Volt Voltage- Normal Green LED 11.5 – 14.5 Volt Battery needs charging Red LED under 11.5 Volt Voltage On the underpart of the pump you will find a socket. You can charge up the battery in this socket without having it dismantled. -

Page 24: Technical Data

Vacuum pump 24 / 24 Technical Data Pump / Solenoid Valve Type of Pump 7012 V (2) Line Voltage 12 Volt DC Power Inut 1.4 A Conveying Caacity 18 NL/min. Final Vacuum Minimum 70 % 2/2 Way Solenoid Valve 12V 6.5 Watt Solenoid Part / Device Diaphragm NBR Perbunan... - Page 25 Tragfähigkeit / Working Load Limit WLL: kg / Eigengewicht / Dead Weight: 19,7 kg / 43,5 1427 / 1565 / 1710 Product Name: VACUUM-POWER-HANDY VPH-150 © all rights reserved conform to ISO 16016 Datum Name Benennung Vakuum-Power-Handy VPH 150 Erst. 26.4.2018 M.Wunder...

- Page 26 20540040 24100076 21600016 31600005 42710098 siehe separate Liste see separate list 42710001 20540040 21050020 © all rights reserved conform to ISO 16016 42700050 Datum Name Benennung siehe separate Liste Vakuum-Power-Handy VPH 150 Erst. 26.4.2018 M.Wunder see separate list Gepr. 26.4.2018 M.Wunder 2-Mann-Bedienung Artikelnummer/Zeichnungsnummer...

- Page 27 25290008 42700070 42730012 © all rights reserved conform to ISO 16016 Datum Name Benennung Saugplatte SPSHP 150-44/25 VPH Erst. 15.7.2015 M.Wunder Gepr. 15.7.2015 M.Wunder mit HP-Dichtung Artikelnummer/Zeichnungsnummer Blatt E42700050 Zust. Urspr. Ers. f. Ers. d.

- Page 28 21000261 20000248 20000248 20100014 33503991 33503990 20100016 20100016 33503991 20000126 Bei Änderungen Rücksprache TB ! Gewicht: 3,2 kg Schutzvermerk nach DIN 34 beachten! Nachdruck nur mit unserer Genehmigung! Benennung Datum Name Kettenspeicher für VPH / MJ II Erst. 4.6.2012 Michael.Wunder Gepr.

- Page 29 167,5 567,53 886,5 717,5 718,5 1436 Tragfähigkeit / Working Load Limit WLL: kg / Eigengewicht / Dead Weight: kg / Product Name: Wheel Set VPH-RS © all rights reserved conform to ISO 16016 Datum Name Benennung VPH-Mobil, Radsatz für VPH, Erst.

- Page 30 21070146 33506086 20400002 20000011 20100015 20400002 33506085 42710156 20540024 20400002 20000010 20100015 © all rights reserved conform to ISO 16016 20400002 Datum Name Benennung Anschlag für Radsatz VPH Erst. 16.5.2018 M.Wunder VPH-RS-AS Gepr. 17.5.2018 M.Wunder Artikelnummer/Zeichnungsnummer Blatt E42710154 Zust. Urspr. Ers.

- Page 31 Für Kunde und Service, A-Zng für Montage siehe A52710008 29040665 29040056 29040129 Auf beiden Seiten / on both sides 29040744 29040209 29040221 VPH-150 | 52710008: 29040207 29040690 Auf beiden Seiten / VPH-100 | 52710009: On both sides 29040575 P 22.06.2018_V0 1 / 1...

- Page 32 After each completed performance of a maintenance interval the included form must be fill out, stamped, signed and send back to us immediately 1) via e-mail to service@probst-handling.de / via fax or post Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _...

Need help?

Do you have a question about the VPH-150 and is the answer not in the manual?

Questions and answers