Advertisement

Quick Links

APPLICATION NOTE

AT02259: QTouch Schematic and Layout Checklist

Atmel QTouch

Introduction

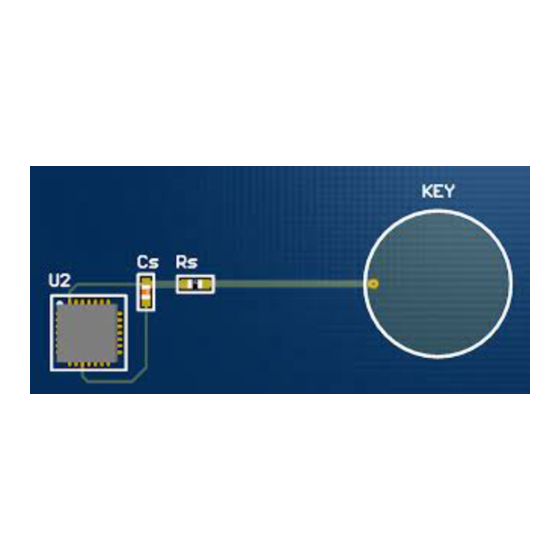

Designing a capacitive touch interface is an involved process that requires myriad

factors to be considered. These interfaces frequently need to co-exist with other

complex systems, which may affect its performance.

®

Since there are several considerations to be made while designing Atmel

®

QTouch

solutions it is important to know these for overall improvement of the

design. The purpose of this document is to provide a checklist that can be used to

review the schematic and PCB layout of these designs. This includes separate

checklists for designs using Atmel QTouch, QTouchADC and QMatrix. This

document only highlights the most important aspects and should not be

considered as a substitute for

QTAN0079 Buttons, Sliders and Wheels – Sensor

Design

Guide.

Features

•

Checklist for reviewing Atmel QTouch schematics and PCB layouts

Atmel-42094C-QTouch-Schematic-and-Layout-Checklist-ApplicationNote_072014

Advertisement

Need help?

Do you have a question about the QTouch and is the answer not in the manual?

Questions and answers