Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Calculated Industries Hot Rod Calc 8703

- Page 1 ™ — 1...

- Page 2 Calculated Industries gratefully acknowledges Patrick Hale (Drag Racing Pro) and Marko Glush (independent engine builder and bracket racer) for their generous time and expertise during the development of this calculator.

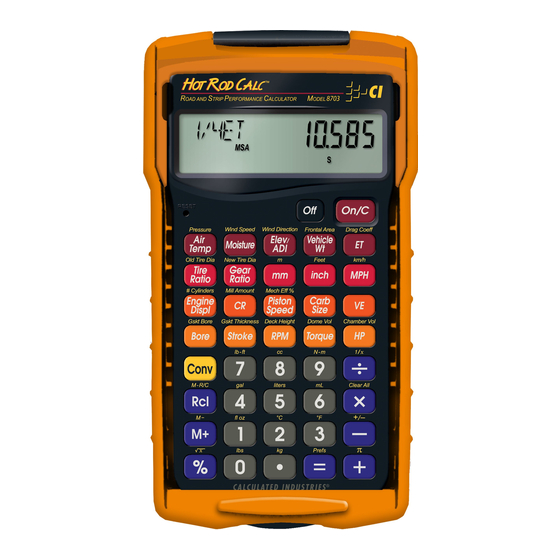

- Page 3 ™ The Hot Rod Calc™ Road and Strip Performance Calculator is specifically designed for today’s hot rod owner/builders, drag and bracket racers, engine builders, and car and truck enthusiasts. Whether you’re into hot rods, street performance, off-road, or drag racing, the Hot Rod Calc can help with its built-in solutions for carburetor size, volumetric efficiency, tire ratios, gear ratios, engine displacement, compression ratio, HP, torque, and RPM.

-

Page 4: Table Of Contents

TABLE OF CONTENTS GETTING STARTED ..............4 KEY DEFINITIONS .................4 Basic Function Keys ..............4 Dimensional Function Keys ............5 Miscellaneous Function Keys ............6 ET Prediction Keys ...............6 Performance Keys ................8 PREFERENCE SETTINGS ............11 ENTERING DIMENSIONS ............12 Distance/Length Dimensions ............12 Square and Cubic Dimensions ...........12 ENTERING CONVERSIONS ............13 Distance/Length Conversions.............13 Speed Conversions ..............13... - Page 5 ET Prediction and HPc ...............27 ET Prediction and Wind Conditions ..........30 Estimating Vehicle Weight ............32 Estimating Rear Wheel Horsepower .........33 Calculating Effects of Changing Tire Sizes ........35 Speed, RPM, Gear Ratios, and Tire Relationships ....37 Calculating Carburetor Size ............40 Calculating Carburetor Size with a Known Volumetric Efficiency ..............42 Calculating Volumetric Efficiency ..........42 Estimating Flywheel Horsepower at a Known RPM ....43...

-

Page 6: Getting Started

GETTING STARTED You may want to practice getting a feel for your calculator keys by reading through the key definitions and learning how to enter data, how to store values, etc., before proceeding to the examples. KEY DEFINITIONS Basic Function Keys ... -

Page 7: Dimensional Function Keys

Dimensional Function Keys Millimeters – Identifies entry as millimeters, with repeated presses toggling between linear, area and volume units. Converts dimensional value to units of millimeters, with repeated presses toggling between millimeters and meters. Meters – Identifies entry as meters, with repeated presses toggling between linear, area and volume units. -

Page 8: Miscellaneous Function Keys

Identifies/Converts to liters (liters). Identifies/Converts to milliliters (mL). Identifies/Converts to pound-force foot (lb-ft). Identifies/Converts to cubic centimeters (cc). Identifies/Converts to Newton-meters (N-m). Identifies/Converts to kilograms (kg). Miscellaneous Function Keys Calculates the square root of the number in the display. ... - Page 9 calculates current local water vapor pressure, saturation water vapor pressure, and dew point temperature. Default value is 0% RH. Wind Speed – Enters current local wind speed; calculates corrected ET and speed. Elevation / Air Density Index – Enters current local elevation;...

-

Page 10: Performance Keys

Drag Coefficient – Enters the vehicle’s drag coefficient when correcting for wind. See Appendix A for typical body styles and associated drag coefficient values. Default value is 35%. Performance Keys Tire Ratio – Calculates tire ratio, effective drive ratio, equivalent drive ratio, drive ratio, actual speed, and indicated (gauge) speed. - Page 11 Piston Speed – Enter or calculate an engine’s Piston Speed. Calculate Piston Speed given values for RPM and Stroke length. Mechanical Efficiency – Enters the engine’s mechanical efficiency, a numeric value representing a percentage of the power available inside the engine’s cylinders that makes its way to the flywheel (e.g.

- Page 12 Deck Height – Enter and store cylinder Deck Height. Used in calculating Compression Ratio. Torque – Enter or calculate flywheel engine torque in lb-ft. Calculates Torque given RPM and Horsepower. Dome Volume – Enter and store Piston Dome Volume. Used in calculating Compression Ratio.

-

Page 13: Preference Settings

PREFERENCE SETTINGS Press , then to access the Preferences menu. Continue pressing to toggle through different Preferences. Press keys to toggle between options of the different Preferences. Press to exit Preferences. Your calculator will keep Preference settings until a Full Reset alters your settings to the default values. -

Page 14: Entering Dimensions

ENTERING DIMENSIONS Distance/Length Dimensions Examples of how linear dimensions are entered (press after each entry): DIMENSIONS KEYSTROKE 4.5 inches 95 millimeters 1320 feet 201 meters Square and Cubic Dimensions Examples of how square and cubic dimensions are entered... -

Page 15: Entering Conversions

ENTERING CONVERSIONS Distance/Length Conversions Enter and convert 1,320 feet to meters. KEYSTROKES DISPLAY 1320 F 402.336 M * Repeated presses of will toggle between meters and millimeters. Enter and convert 4.5 inches to millimeters. KEYSTROKES DISPLAY ... -

Page 16: Engine Displacement Conversions

Engine Displacement Conversions Enter and convert 450 cubic inches (CID) to liters. KEYSTROKES DISPLAY 450 CU IN LITER 7.3741788 Enter and convert 5.0 liters to CID. KEYSTROKES DISPLAY LITER 5 ... -

Page 17: Weight Conversions

Weight Conversions Enter and convert 2700 pounds to kilograms. KEYSTROKES DISPLAY LBS 2700 KG 1224.6994 Volume Conversions Enter and convert 5.5 gallons to liters. KEYSTROKES DISPLAY GAL 5.5 ... -

Page 18: Using The Hot Rod Calc

USING THE HOT ROD CALC Note: The Hot Rod Calc’s built-in horsepower correction calculations are based on formulas designed for naturally aspirated gasoline burning engines. The Hot Rod Calc helps you get the most out of your bracket racing efforts by assisting you at the dragstrip in two very critical ways: •... -

Page 19: Horsepower Correction Factor

slower it will go. More specifically, engine performance is impacted by the ambient air’s density. MSA includes three parameters: absolute pressure (29.92 in Hg), temperature (60° F), and relative humidity (0% RH, or “dry air”). HPc* The Horsepower Correction Factor is calculated and implemented within HP, ET, and MPH estimations on the Hot Rod Calc. - Page 20 current, local measured weather conditions entered into the calculator. Once you have established an air/fuel ratio for the current track and weather conditions, calculate and record the current ADI. As a rule, ADI will be less than 100% for elevations above sea level as well as for temperatures above 60°...

-

Page 21: Absolute Pressure

Pressure There are two types of commonly referenced pressure, Absolute Pressure and Corrected Pressure. Absolute Pressure is the actual, ambient local pressure. There are several tools available to help you measure Absolute Pressure, such as altimeters, absolute barometers, and motorsports weather stations. You do not need to know your track’s elevation when utilizing Absolute Pressure on your calculator. -

Page 22: Calculating Adi And Density Altitude Using Absolute Pressure

Calculating ADI and Density Altitude Using Absolute Pressure For this example, you are at the Los Angeles County Fairplex Auto Club Raceway in Pomona, Calif. The track’s elevation is about 1,025 feet above sea-level. The current local measured weather conditions are 63.2° F, absolute pressure of 28.83 in Hg, and 58% relative humidity at 9 a.m. -

Page 23: Calculating Adi And Density Altitude Using Elevation

conditions are an unseasonably chilly 33° F, absolute pressure of 28.77 in Hg, and a relative humidity of 64% at 8:30 a.m. Calculate the Air Density Index (ADI) and Density Altitude for this example. KEYSTROKES DISPLAY 1. Enter current local measured weather conditions: ... -

Page 24: Calculating And Using A Fuel Correction Index

Calculate the Air Density Index (ADI) and Density Altitude for this example. First, clear the memory on your calculator, including temporary and semi-permanent entries. KEYSTROKES DISPLAY ALL CLEArEd 1. Enter track elevation: ELEV S 3963. F 2. - Page 25 For this example, the current local measured weather conditions are 80° F, absolute pressure of 29.15 in Hg, and 53.5% relative humidity. Your race car ran best, under these baseline conditions, with #78 jets. Calculate the Air Density Index (ADI). First, clear the memory on your calculator, including temporary and semi-permanent entries.

- Page 26 KEYSTROKES DISPLAY 3. Enter current weather conditions: TEMP S 60. °F (Absolute Pressure) P-ABS S 24.72 INHG RH% S 39 % (Moisture/Relative Humidity) 4. Calculate ADI: ELEV S 0. ADI 81.94 % ...

-

Page 27: Calculating Water Vapor Content

To translate a fuel correction index to a new jet number, recall your baseline was recorded with #78 jets, which according to the Appendix B – Holley Jet Chart and Jet Orifice Area Conversion Chart, have a flow of 645 cubic-centimeters per minute. Recall your fuel correction index is about 89%. -

Page 28: Basic Et Prediction

2. Calculate water vapor content by subsequent presses of : P-WV 0.115 INHG (Water Vapor Pressure) P-SAT 0.819 INHG (Saturation Water Vapor Pressure) 21.071 °F (Dew Point) Dew Point is a helpful temperature to know as it tells you approximately at what temperature you can expect to see moisture on the track surface. -

Page 29: Et Prediction And Hpc

1. Enter vehicle weight (including driver): LBS S 3840 2. Enter vehicle’s estimated rear wheel HP: HP S MSA 411. 3. Calculate ET and MPH prediction: 1/4ET 12.269 S 1/4 111.101 MPH 1/8ET 7.864 S ... - Page 30 (HPc) and output for current weather conditions as well as MSA conditions. For this example, the track’s elevation is 3,963 feet above sea- level. Recall that our race car weighs in at about 3,840 pounds, including the driver, and produces about 411 HP in ideal or MSA conditions.

- Page 31 Notice within the ET output sequence, the ET predictions are displayed in 1/4 and 1/8 prediction sets based on current track conditions as well as a HPc of 1.202. Each set displays the horsepower corrected predictions (HPc) followed by the MSA adjusted predictions.

-

Page 32: Et Prediction And Wind Conditions

HPc 1.211 Notice that by changing the ME% from 85% to 80% (reducing the engine’s mechanical efficiency), the corrected HP was reduced whereas the HPc was increased. ET Prediction and Wind Conditions Now let’s say you ran your 3,840-pound 1970 Ford Mustang Notchback at Top Gun Raceway in Fallon, Nev., where there are often raging winds. - Page 33 Enter the estimated Frontal Area value: AREA S 19.006944 S F (Frontal Area) Next, see Appendix A — Body Style and Drag Coefficients, for typical body styles and associated drag coefficient values. The default Drag Coefficient value in the calculator is .35. Using Appendix A for a “Notchback or Sedan”...

-

Page 34: Estimating Vehicle Weight

1. Next, enter vehicle weight, and your actual ET and MPH, the Wind Speed, and if available, Wind Direction, to calculate how the wind effected your speed and time: KEYSTROKES DISPLAY LBS S 3840. ET S 13.85 S ... -

Page 35: Estimating Rear Wheel Horsepower

Your buddy has a 1978 Ford Mustang II with an estimated horsepower of 575 HP and made an ET run of 9.540 seconds. Calculate the estimated Vehicle Weight. KEYSTROKES DISPLAY 1. Enter the estimated HP: HP MSA S 575. 2. - Page 36 KEYSTROKES DISPLAY 1. Enter the estimated Vehicle Weight: LBS S 4280. 2. Enter the 1/4 ET: ET S 13.656 S 3. Solve for the vehicle’s estimated rear wheel HP: ...

-

Page 37: Calculating Effects Of Changing Tire Sizes

Calculating Effects of Changing Tire Sizes Your daily commuter has four-wheel drive, and you want some extra ground clearance for those occasional off-highway excursions on the way home from work. However, before you make the switch to a taller tire, you want to know what the effects will be to your final-drive ratio and even more importantly, to your speedometer as you don’t want to draw any unnecessary attention while you are cruising down the highway. - Page 38 outputs, starting with the current final-drive ratio input. The effect to the final-drive (D-EFF) of going from a tire diameter of 28.9 to 33 inches is an estimated ratio of 2.697, which will create a fairly noticeable loss in your four-wheeler’s pickup from a stop or while rolling down the highway.

-

Page 39: Speed, Rpm, Gear Ratios, And Tire Relationships

Speed, RPM, Gear Ratios, and Tire Relationships Speed, RPM, gear ratios, and tire sizes are interrelated, and with any three values, the fourth value can be solved on your calculator. Getting these four areas set up properly on your road or drag strip vehicle can have very positive performance effects. - Page 40 Repeated presses of will toggle through the inputs and outputs, starting with the gear ratio input. From the above calculation, it is estimated that the mighty 5.0 LX will be going about 70 MPH at 5,500 RPM in 2nd gear. In this example, calculate your RPM at 65 MPH in 5th gear: KEYSTROKES DISPLAY...

- Page 41 gear is direct drive and therefore would be the same as the final- drive ratio you are solving for. KEYSTROKES DISPLAY 7. Enter your RPM, cruising speed of 65 MPH: RPM S 3000. SPEED S 65. M PH ...

-

Page 42: Calculating Carburetor Size

RPM S 3000. SPEED S 65. M PH GEAR S 3.08 RATIO 10. Calculate the New Tire Size: TIREn 22.431 SIZE IN (New tire diameter) Repeated presses of will toggle through the inputs and outputs, starting with the final-drive ratio input. From the above calculation, it is estimated that in order to reach 3,000 RPM in 4th gear, at 65 MPH, the LX could utilize 22.4 inch diameter tires to achieve roughly the same performance as the... - Page 43 Lastly, while carburetors come in many sizes, they are not available in just any size. It is quite possible you won’t find one that is of the exact size you calculated on your Hot Rod Calc. Carburetor sizes are designated by airflow capacity in cubic-feet per minute (CFM).

-

Page 44: Calculating Carburetor Size With A Known Volumetric Efficiency

Calculating Carburetor Size With a Known Volumetric Efficiency Building off of the previous example, you want to calculate your user- defined carburetor size based on a known VE value. Suppose through your experience and knowledge of your 1968 Pontiac GTO’s engine specs and modifications, you know you can reach a VE of 95%. -

Page 45: Estimating Flywheel Horsepower At A Known Rpm

you with this if they have an air-flow meter), as well as your engine displacement. In this example, your 1968 Pontiac GTO has a Ram Air II 400 CID engine and you want to calculate the engine’s VE at 7000 RPM which is the RPM at your maximum speed. -

Page 46: Estimating Flywheel Torque At A Known Rpm

RPM S 3800. 2. Calculate the HP at 3800 RPM: HP MSA 321.966 At 3800 RPM, when your 400 CID engine is producing 445 pounds-feet of torque, it is also producing about 322 HP at the flywheel. Estimating Flywheel Torque at a Known RPM If you know horsepower output at a specific RPM, you can calculate torque at that same RPM. - Page 47 There are several compression ratio effects to consider when determining the appropriate ratio for your application: • The greater the compression ratio, the greater the amount of air/ fuel mix will be compressed. • The greater amount of air/fuel mix that is compressed, the greater the combustion power will be.

- Page 48 Your Hot Rod Calc needs several inputs to calculate a Compression Ratio, but you will need track them down and in some cases, measure manually: • Bore and Stroke – You should be able to find this in your engine repair manual.

- Page 49 KEYSTROKES DISPLAY 1. Enter the values from the example: BORE S 4. IN STROK S 3.48 IN G-BOR S 4.1 IN (Gasket Bore) G-THK S 0.038 IN (Gasket Thickness) DECK S 0.015 IN (Deck Height) DOME S 4.5 VOL CC ...

-

Page 50: Calculating Mill Amount

compression ratio, whereas raising the overall chamber volume will decrease the compression ratio. Piston Dome, Deck Height, and Head Gasket Thickness are several ways to effect your compression ratio. In the next section, you can read about one of the more popular ways to increase compression ratio, which is a process known as milling. -

Page 51: Calculating Piston Speed

starting with the entered Stroke. To raise your compression from 8.5:1 to 10.5:1, your engine building shop would need to remove 0.098 inches of material from the surface of your heads, thus reducing the overall chamber volume and increasing compression. Notice the answer to your mill amount question is given in inches, 0.098 inches, but it’s a simple press of a key to convert to ... - Page 52 1. Enter your Stroke and the RPM for which you want to determine piston speed: STROK S 3.48 IN RPM S 4000. 2. Calculate the Piston Speed at 4000 RPM: FPM 2320. M/MIN 707.136 Repeated presses of [Piston Speed] will toggle through the inputs and outputs, starting with the entered Stroke.

-

Page 53: Calculating Engine Displacement

6. Enter the Piston Speed for which you want to determine an RPM limit, along with stroke of 3.48: FPM S 3500. STROK S 3.48 IN 7. Calculate the RPM limit: RPM 6034.483 Calculating Engine Displacement You could simply check the factory specs on the engine displacement of your vehicle, but that number is usually a rounded up or down number. - Page 54 Repeated presses of will toggle through the inputs and outputs, starting with the entered Bore. While the exact displacement of the 1968 Ram Air II engine is about 399.95 CID, it’s a tough number to market by the factory. To make it simple on the guys in the suits, the displacement was rounded up to a nice even 400 CID.

-

Page 55: Calculating Bore And Stroke

Repeated presses of will toggle through the inputs and outputs, starting with the entered Bore. Calculating Bore and Stroke Building from one of the previous examples, you want to push your cubic inch displacement to a maximum of 405 CID to be competitive at your local club races as well as meet class engine requirements. - Page 56 4. Calculate the new Stroke length: STROK 3.797 IN Notice you can also meet your goals by keeping the stock bore, and going to a longer stroke of 3.797. In terms of cost, it will be more cost effective to go over bore to reach your goals in this particular example.

-

Page 57: Body Style And Drag Coefficients

APPENDIX A – BODY STYLE AND DRAG COEFFICIENTS* BODY STYLE DRAG COEFFICIENT Open Convertible 0.5 – 0.7 Station Wagon and Van Body 0.5 – 0.6 Notchback or Sedan 0.4 – 0.55 Fastback 0.3 – 0.4 Fairings all around, streamlined shape 0.2 –... -

Page 58: Holley Jet Chart And Jet Orifice Area Conversion Chart

APPENDIX B – HOLLEY JET CHART AND JET ORIFICE AREA AND CONVERSION CHART Main Jet Number, Drill Size, and Flow JET NO. DRILL SIZE FLOW .040 .041 .042 .043 .044 .045 .046 .047 .048 .049 .049 .050 .052 .052 .053 .054 .055 .056... - Page 59 .062 .064 .065 .066 .068 .069 .070 .073 .076 .079 .079 .081 .082 .084 .086 .089 .091 .093 .093 .093 .094 .099 .100 .101 .103 .104 .104 .104 1014 .105 1080 ™ — 57...

- Page 60 .105 1150 .105 1200 .108 1260 .118 1320 .118 1375 .125 1440 .125 1500 .125 1570 .128 1640 58 — H ™...

- Page 61 Jet Orifice Area Conversion Size Size Size Size Size Size Size Size Size Size Size Size Dia. Area Dia. Area Dia. Area Dia. Area Dia. Area Dia. Area (") (sq. ") (") (sq. ") (") (sq. ") (") (sq. ") (") (sq.

-

Page 62: Default Settings

APPENDIX C – Default Settings After a Clear All ( ) your calculator will return to the following settings: STORED VALUES DEFAULT VALUE 60.0 °F Air Temperature 29.92 in Hg Absolute Pressure 0% RH Moisture 0 FEET Elevation 100% –... -

Page 63: Care Instructions

APPENDIX D – Care Instructions Please follow the guidelines listed in this section for proper care and operation of your calculator. Not following the instructions listed below may result in damage not covered by your warranty. Refer to the Repair and Return section on page 44 for more details. -

Page 64: Accuracy/Errors, Auto Shut-Off, Batteries, Reset

APPENDIX E – Accuracy/Errors, Auto Shut-Off, Batteries, Reset ACCURACY/ERRORS Accuracy/Display Capacity — Your calculator has an eight- digit display made up of eight digits. Errors — When an incorrect entry is made, or the answer is beyond the range of the calculator, it will display the word ... - Page 65 Should your calculator display become very dim or erratic, replace the batteries. Note: Please use caution when disposing of your old battery, as it contains hazardous chemicals. Replacement batteries are available at most discount or electronics stores. You may also call Calculated Industries at 1-775-885-4900. ™ — 63...

-

Page 66: Warranty, Repair And Return Information

WARRANTY Warranty Repair Service – U.S.A. Calculated Industries (“CI”) warrants this product against defects in materials and workmanship for a period of one (1) year from the date of original consumer purchase in the U.S. If a defect exists... - Page 67 Non-warranty repair covers service beyond the warranty period, or service requested due to damage resulting from misuse or abuse. Contact Calculated Industries at the number listed above to obtain current product repair information and charges. Repairs are guaranteed for 90 days.

- Page 68 66 — H ™...

- Page 69 Software copyrighted and licensed to Calculated Industries by Specialty Calculator Technologies, LLC, 2009. User’s Guide copyrighted by Calculated Industries, Inc., 2009. Hot Rod Calc™ is trademarked and Calculated Industries® is a registered trademark of Calculated Industries, Inc. ALL RIGHTS RESERVED Designed in the U.S.A.

- Page 70 Software copyrighted and licensed to Calculated Industries by Specialty Calculator Technologies, LLC, 2009. User’s Guide copyrighted by Calculated Industries, Inc., 2009. Hot Rod Calc™ is trademarked and Calculated Industries® is a registered trademark of Calculated Industries, Inc. ALL RIGHTS RESERVED Designed in the U.S.A.

Need help?

Do you have a question about the Hot Rod Calc 8703 and is the answer not in the manual?

Questions and answers