Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Tadiran Telecom Swift Inverter 9U

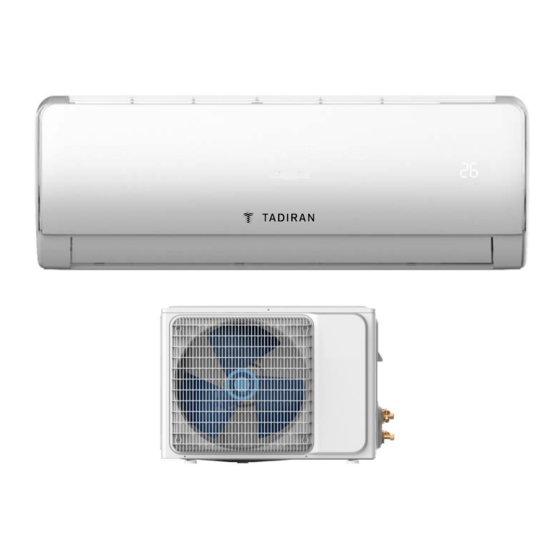

- Page 1 Split-Type Air Conditioner Swift Inverter...

-

Page 2: Table Of Contents

CONTENTS Part I : Technical Information ................1 1. Summary ......................1 1-1 Appearance .........................1 1-2 Model List ..........................3 2. Outline Dimension Diagram ................3 3. Specification sheet ....................5 4. Function and Control ..................10 4-1 H-Style ..........................10 4-2 L-Style .......................... - Page 3 Part I : Technical Information 1. Summary 1-1 Appearance Indoor Unit...

- Page 4 Outdoor Unit Note: The outdoor grille can be replaced.

-

Page 5: Model List

1-2 Model List MODEL MODEL Swift Inverter 9U Swift Inverter 12U Swift Inverter 18U Swift Inverter 24U Swift Inverter 36U 2. Outline Dimension Diagram The following data is for reference only and the actual size may vary. Indoor Unit... - Page 6 Note: 1. The main body size of the front shape after normal installation: width × height × depth (mm). An example of the dimension measurement is shown in the figure. a) Width direction: Width 1: Not include the size of the stop valve. Width 2: Include the size of the stop valve.

-

Page 7: Specification Sheet

3. Specification sheet Swift Inverter 9U Product Model Cooling 2650 Rated Capacity Heating 2650 Dehumidifying Kg/h Cooling Rated Power Consumption Heating Cooling Rated Running Current Heating Electric heating power Max. Input Power 1540 Max. Input Current EER Cooling SEER23 Nameplate... - Page 8 Swift Inverter 12U Product Model Cooling 3500 Rated Capacity Heating 3600 Dehumidifying Kg/h Cooling Rated Power Consumption Heating 1025 Cooling Rated Running Current Heating Electric heating power Max. Input Power 1650 Max. Input Current Nameplate EER Cooling SEER22 Parameter COP Heating SCOP10 Power supply source V/Ph/Hz...

- Page 9 Swift Inverter 18U Product Model Cooling 5300 Rated Capacity Heating 5300 Dehumidifying Kg/h Cooling 1395 Rated Power Consumption Heating 1370 Cooling Rated Running Current Heating Electric heating power Max. Input Power 1900 Max. Input Current EER Cooling SEER21 Nameplate Parameter COP Heating SCOP10 Power supply source...

- Page 10 Swift Inverter 24U Product Model Cooling 7000 Rated Capacity Heating 7050 Dehumidifying Kg/h Cooling 1800 Rated Power Consumption Heating 1950 Cooling 9.77 Rated Running Current Heating 10.55 Electric heating power Max. Input Power 3200 Max. Input Current EER Cooling SEER20 Nameplate Parameter COP Heating...

- Page 11 Swift Inverter 36U Product Model Cooling 10500 Rated Capacity Heating 10550 Dehumidifying Kg/h Cooling 3990 Rated Power Consumption Heating 3640 Cooling Rated Running Current Heating Electric heating power Max. Input Power 4750 Max. Input Current EER Cooling SEER 16.5 Nameplate Parameter COP Heating SCOP 8.2...

-

Page 12: Function And Control

4. Function and Control 4-1 A-Style 1) Remote Controller Introduction Introduction for Buttons on Remote Controller Note: All the figures above are the displays after being initially electrified or re-electrified after power off. In actual operations, the remote controller screen displays related items only. - Page 13 * Press this button once, a "ON(OFF)" will flash. Press “▲”or “ ▼” to set the number of hours in which the unit will be turned ON/OFF, with an interval of 0.5 hour if less than 10 hours, or 1 hour if longer than 10 hours and a range of 0.5-24 hours. * Press it again to confirm the setting the "ON (OFF)"...

- Page 14 * Press this button to enter SLEEP mode, which the unit will exit after 10 hours of continuous operation and restore to the previous status. Note: The SLEEP function cannot be activated in FAN mode. 12. SWING * Press this button to activate up/down swing and press it again to fix the swing position.

- Page 15 1. Press the "MODE" button, select the Cooling or Heating operation mode. 2. By pressing the "▲"or "▼"button, you can set the temperature the display changes as you touch the button. 3. By pressing the "SPEED" button, you can select the fan speed from LOW, MID, HIGH, AUTO.

- Page 16 buttons do not work correspondingly. Battery use and replacement 1. Slide to open the cover according to the direction indicated by the arrowhead. 2. Insert two brand new batteries (7#) and position the batteries to the right electric poles (+ & -). 3.

- Page 17 Note : remote controller outside buttons only valid when surface cover is closed. ①“ON/OFF”button * Press this button,the unit will be started or stopped, which can clear the timer or sleeping function of last time. ②“SPEED”button * Press this button, speed will change as below: ③“...

- Page 18 NOTE: This manual introduces function for all of the remote control, maybe you press one button without any reaction, well, the air-conditioner you bought hasn't this function. 1.“ON/OFF”button * Press this button, the unit will be started or stopped, which can clear the timer or sleeping function of last time.

- Page 19 5. “SILENCE” button * Set silence on or off(the characters of silence will appear or disappear)by pressing this key. * Once energized, the unit will be defaulted to be silence off. 6. “TIMER”button * On the status of the unit on, press this button to set timer off. On the status of the unit off, press this button to set timer on.

- Page 20 * The clean function will be stop working after about 30 minutes running working without any operation. 12.“ELE.H” button(only for hot pump type) * In heating mode, press this button, the mode of operation is shifted into supplementary electric heating. 13.“Anti-FUNGUS”...

- Page 21 ★Fix batteries 1. Slide open the cover according the direction indicated by arrowhead. 2.Put into two brand new batteries (7#), position the batteries to right electric poles (+ &-). 3.Put back the cover. ★Automatic operation mode 1. Press the ON/OFF button, the air-conditioner starts to operate. 2.

-

Page 22: Cooling Only

• No obstacles between the remote controller and receiver. • Do not drop or throw the remote controller. • Do not put the remote controller under the forceful sun rays or heating facilities and other heating sources. • Use two 7# batteries, do not use the electric batteries. •... -

Page 23: Refrigerant System Diagram

5. Refrigerant System Diagram 5-1 Cooling Only Cooling Mode Indoor Unit Outdoor Unit Cooling Cycle Steam-gas of low pressure Indoor heat exchanger Compressor (Evaporation) (Compression) Liquid of low Gas of high pressure & pressure temperature (also a little gas) Super cooled liquid of high pressure Capillary... -

Page 24: Cooling & Heating

5-2 Cooling & Heating Cooling Mode Indoor Unit Outdoor Unit Cooling Cycle Steam-gas of low pressure Indoor heat exchanger Compressor (Evaporation) (Compression) 4-way valve (Heat pump only) Liquid of low pressure Gas of high pressure (also a little gas) &... -

Page 25: Heating Cycle

Heating Mode Indoor Unit Outdoor Unit Heating Cycle Gas of high pressure & temperature Indoor heat exchanger Compressor (Evaporation) (Compression) 4-way valve (Heat pump only) Super cooled liquid of low pressure Steam-gas of low pressure Super cooled liquid of high pressure Capillary Outdoor heat exchanger... -

Page 26: Electrical Part

6. Electrical Part The diagrams listed below for reference only, please refer to the actual product. 6-1 Wiring Diagram Indoor Unit... -

Page 27: Outdoor Unit

Outdoor Unit CN88 Compressor Some models have no content inside dashed frame 0545 1132600700 Outdoor Unit Electric Chart... -

Page 28: Part Ii : Installation And Maintenance

Part II : Installation and Maintenance 7. Main Tools for Installation and Maintenance... -

Page 29: Installation

8. Installation 8-1 Notes for Installation Important Notices Before installation, please contact with local authorized maintenance center, if unit is not installed by the authorized maintenance center, the malfunction may not solved, due to discommodious contact. The air conditioner must be installed by professionals according to the national wiring rules and this manual. -

Page 30: Installation Of Indoor Unit

The minimum clearance between the air conditioner and the combustibles is 1.5 The power cable enables communication between the indoor and outdoor units. You must first choose the right cable size before preparing it for connection. Grounding Requirements ... - Page 31 Mounting plate 1. The wall for installation of the indoor unit shall be hard and firm, so as to prevent vibration. 2. Use the "+" type screw to fasten the peg board, horizontally mount the peg board on the wall, and ensure the lateral horizontal and longitudinal vertical. 3.

- Page 32 Drain pipe connection 1. Remove the mountings and pull the indoor unit pipe out of the housing. 2. Connect the connecting pipe to the indoor unit: Aim at the pipe center, tighten the Taper nut with fingers, and then tighten the T nut with a torque wrench, and the direction is shown in diagram on the right.

-

Page 33: Installation Of Outdoor Unit

●Ground wire: Remove the grounding screw out of the electric bracket, cover the grounding wire end onto the grounding screw and screw it into the grounding hole. ● Fix the cable reliably with fasteners (Pressing board). ● Put the E-parts cover back in its original place and fasten it with screws. Wiring Diagram NOTE: ※... -

Page 34: Wiring Connection

Install the connection pipe Connect the Outdoor Unit with Connecting Pipe: Aim the counter-bore of the connecting pipe at the stop valve, and tighten the Taper nut with fingers. Then tighten the Taper nut with a torque wrench. ★When prolonging the piping, extra amount of refrigerant must be added so that the operation and performance of the air conditioner will not be compromised. -

Page 35: Wiring Diagram

Wiring diagram Wiring Diagram NOTE: ※ This manual is usually includes the wiring mode for the different kind of A/C. We cannot exclude the possibility that some special type of wiring diagrams are not included. ※ The diagram are for reference only. If the entity is difference with this wiring diagram, please refer to the detailed wiring diagram adhered on the unit which you purchased. -

Page 36: Check After Installation And Test Operation

★Vacuum Pumping Method (R410A refrigerant evacuation must use the vacuum pumping method) Before working on the air conditioner, remove the cover of the stop valve(gas and liquid valves)and be sure to retighten it afterward.(to prevent the potential air leakage) 1. To prevent air leakage and spilling tighten all connecting nut of all flare tubes. 2. - Page 37 ② If the water drain is smooth. ③ If the wiring and piping are correctly installed. ④ Check that no foreign matter or tools are left inside the unit. ★ Leak test of the refrigerant Depending on the installation method, the following methods may be used to check for suspect leak, on areas such as the four connections of the outdoor unit and the cores of the cut-off valves and t-valves: ①...

-

Page 38: Maintenance

9. Maintenance 9-1 Troubleshooting Guide Many error codes many appears on this air conditionor, and this troubleshooting guide is prepared for the maintenance personnel to detect the error position and the parts to be replaced during the troubleshooting process. In this Guide, the Troubleshooting Method is guided by the Error Name, and the Reference Code under the General Index is the error code of the internal unit of the mainstream model supplied by the Company. - Page 39 Example: Cause: explain the principle of the specific error. Explanation Inspection path: The basic order of troubleshooting. Related key of error position Tools required Tools that should be carried for such troubleshooting, and for inspection replacing parts that may be necessary for such error. Frequent Any possibly broken part related to the error may be the parts that problematic...

- Page 40 (1)E1- internal temperature sensor error Cause: The detection of short circuit or open circuit of internal temperature sensor during the inspection of main control panel in the Explanation of internal machine, indicated by “internal temperature sensor error”. error Inspection path: Sensor→Sensor wire→Connectors→Main internal control panel Tools required Multimeter, 15KΩ...

- Page 41 (2)E2 -external coil sensor error Cause: The detection of short circuit or open circuit of external coil sensor during the inspection of main external control panel, indicated Explanation of by “external coil sensor error”. error Inspection path: Sensor→Sensor wire→Connectors→Main external control panel Tools required Multimeter, 20KΩ...

- Page 42 (3)E3 -internal coil sensor error Cause: The detection of short circuit or open circuit of internal coil sensor during the inspection of main internal control panel, indicated Explanation of by “internal coil sensor error”. error Inspection path: Sensor→Sensor wire→Connectors→Main internal control panel Tools required Multimeter,, 5KΩ...

- Page 43 (4)E4 -Internal fan error of wall mounted air conditioner(PG motor) Cause: PG motor is equipped with speed feedback signal line. When the feedback signal of speed is not received by the main internal control panel, it has no way to recognize the rotating speed of motor, which will be indicated as “Internal fan error”.

- Page 44 (5) E4- Internal fan error of wall mounted air conditioner (DC motor) Cause: The internal fan of some highly energy efficient models is DC motor using a green plug through which the main internal control panel can drive the motor and sense the current rotational speed feedback. When the main internal control panel cannot receive the rotational speed feedback signal of the motor, it will indicate “DC motor error”.

- Page 45 (6) E4- Sliding door error of floor standing Cause: For the model with upper and lower sliding doors, the position of trap door is sensed via the upper and lower photoelectric switches. When the sliding door closes, it will move upward until the upper photoelectric switch senses the sliding door;...

- Page 46 (7) E5(5E) -Internal and external communication error Cause: The frequency converter needs internal and external communication.When the communication cannot be reached, the internal and external units will indicate “internal and external communication error”. Only “main internal control panel, connecting cable and main external control panel” are related to communication; but sometimes the communication error will be indicated when the external unit has no power and the internal unit cannot connect with the external unit due to other errors, then such situation shall be...

- Page 47 When the external unit not power on: If the internal terminal board does not transmit 220V power, replace the main internal control panel; if the external terminal board has 220V power, first check if (fuse, reactor and bridge rectifier) are normal. There is still something wrong, replace the whole set of external control unit;...

- Page 48 (8) F0- External DC fan error (3-core terminal motor) Cause: Our frequency changing external unit uses the 3-lead-wire DC motor, or “externally driven DC motor” for short, after 2012. It has no speed feedback circuit but 3 drive lead wires and its driving principle is Explanation of similar to that of the compressor.

- Page 49 Tools required Multimeter, pressure gauge, megameter, module panel in normal condition for inspection Supply voltage, compressor wire, reactor, system pressure, module Frequent problematic part panel, main external control panel, compressor 1. Is the order of compressor wires not correct, which makes the compressor rotate reversely? Try exchanging the compressor wires on U-V phase to see if the problem can be solved? 2.

- Page 50 (10) F2- PFC protection error Cause: PFC board is a component of the inverter air conditioner for power factor correction and voltage boosting. When the PFC board cannot perform power calibration as normal because of overcurrent and Explanation of overvoltage, it will indicate “PFC protection error” and its function error may also be integrated with the module panel or main control panel.

- Page 51 (11) F3- Compressor out-of-step error Cause: The module panel will constantly test the current of lead wires of the compressor and calculate the position of the rotator of the compressor when driving the compressor to work. When the compressor deviates far from the normal operating status , it will indicate “compressor out-of-step error”...

- Page 52 For the “compressor out-of-step error” and “module protection error”, the former is calculated by the main chip of the module panel and the latter is detected by the power module itself. They are abnormal operating phenomenon of the compressor essentially. If there is Special attention uncertainty about either error, analyze both together with similar method.

- Page 53 (13) F5 -Compressor top head sensor error Cause: The compressor top head sensor is a compressor top head temperature protection switch most of the time. It keeps closed (short circuit) when the compressor temperature is normal and switches off Explanation of (open circuit) when the temperature is too high.

- Page 54 (14)F6- external temperature sensor error Cause: The detection of short circuit or open circuit of external termperature sensor during the inspection of main external control Explanation of panel, indicated by "external termperature sensor error". error Inspection path: Sensor→Sensor wire→Connectors→Main external control panel Tools required Multimeter, 15KΩ...

- Page 55 (15)F7-OVP or UVP error Cause: All the inverter air conditioners are equipped with voltage inspection circuits, but differnt models of machines have differnt locations for the voltage inspection (on the modue panel or main external control panel). When the supply voltage is lower than 135V or Explanation of higher than 275V, the inspectio circuit would detect over or under voltage protection signal and send it to the main external control panel...

- Page 56 (16)F8-main external control panel and module panel communication error (exclusive of external machine of single panel) Cause: Only the models with the module panels separated with the main external control panels may have this error. When the machine is running normally, the module panel and the main external control panel would coordinate with each other on the communication to work Explanation of and when the communication is off, the main external control panel...

- Page 57 Inspection procedure and 1. Replace the main external control panel directly. key points (18)FA- recirculated sensor error (only models of electronic expansion valves are involved) Cause: The recirculated sensors are only used on machine models of electronic expanssion valves and the back temperature value is considered as the basis for adjustment of the electronic expanssion valve and determination if the four-way valve changes the position normally during heating.

- Page 58 (19)Function protection prompt of frequency conversion external machine Cause: In the regular running of the air conditioner, for some nonfaulted status, it may need the compressor to shut down or limit or lower the frequency so as to protect the normal operating of the entire cooling system (eg.

- Page 59 6. Over or under pressure protection: this protection is a pilot protection for the "over or under pressure error". When the power pressure is too high or too low but not so high or so low to reach limit for shutting down (within 165V-265V), it would limit and lower the frequency first to reduce the air conditioner's needs for the power to keep teh air conditioner running.

-

Page 60: Common Parameters

9-2 Common Parameters 1. Display error code of indoor unit: Frequency conversion air conditioners only involve E1, E2, E3 and E4 Error Error Name Probable Trouble Location Code Internal room temperature Internal room temperature sensor, main sensor error internal control panel External coil sensor error, main external External coil sensor error control panel... - Page 61 2. Display error code of outdoor unit's indicator lights: Display by the 3 LED indicator lights on the control panel of the outdoor unit: ○ for off; ● for on; ★ for flashing. Error Name Probable Trouble Location Normal (outdoor Normal, all three lights off for standby ○...

-

Page 62: Troubleshooting For Normal Malfunction

Internal coil Internal coil sensor, main internal control ● ★ ○ sensor error panel. Mechanical jam of fan, internal fan, main ○ ★ ● Indoor fan error internal control panel. Refer to tooling ○ ○ ★ display for other Entire set of external controller. errors System pressure, compressor cap sensor Compressor cap... - Page 63 please also notice that even different models may have the connecting cord of the same specification. Please check if the marks at the connecting terminal and the marks on the cord can match, otherwise, the air-conditioner will not work normally. ③...

-

Page 64: Fault Diagnosis By Symptom

Fault Diagnosis by Symptom ①No Power Display (1) Items a) Check if the input voltage is correct? b) Check if the AC power supply connecting is correct? c) Check if the output voltage of the manostat L7805 (IC2) is correct? (2) Trouble shooting procedure... - Page 65 ②The Indoor Fan Motor Does Not Work (1) Items a) Check if the indoor fan motor is connected correctly to the connector (CN8)? b) Check if the AC input voltage is correct? c) Check if the IC of indoor fan motor is connected correctly to the connector (CN2)? d) Check if the capacity of indoor fan motor is connected correctly to the connector (CN8)?

- Page 66 ③The Outdoor Unit Does Not Work (1) Items a) Check if the input voltage is correct? b) Check if the wire connection of the outdoor connecting terminal is correct? (2) Trouble shooting procedure...

- Page 67 ④The Step Motor Does Not Work (1) Items a) Check if the input voltage is correct? b) Check if the step motor controlling the up-down movement firmly connected to Cn2? (2) Trouble shooting procedure...

- Page 68 ⑤Heating Mode Can Work, But No Hot Air Blow (1) Check if the set temperature is lower than the indoor temperature? (2) Check if the indoor PCB is connected to the terminal correctly?

- Page 69 ⑥ Remote Control Can Not Work Trouble shooting procedure...

-

Page 70: Removal Procedure

10. Removal Procedure Stop operation of the air conditioner and remove the power cord before repairing the unit. 10-1 Indoor Unit 9000BTU Parts Procedure Diagram 1) Turn off the power, hold the middle panel with the middle finger Front Panel 2) open the panel upwards, remove the panel fixing shaft,... - Page 71 Loosen the screws of the Medium medium frame wiring cover frame wiring with screwdriver,remove the cover electric box cover. Use thumb to open the middle Decorative frame remove panel decorative plate. Left and right Remove left and right terminal terminal board board Press screw cover firmly on the...

- Page 72 1) Take all the connector of PCB upper side out.(Including Power cord) Electrical 2) Detach the outdoor unit Parts connection wire from (Main PCB) terminal block. 3) If pulling the main PCB up, it will be taken out. Remove axial sleeve of louver air vent, link, bend the air vent outwards louver link...

- Page 73 Remove the screw of the motor Motor press press plate and then remove the plate press plate. 1) Loosen fixing screws and detach the motor holder. 2) Loosen fixing screw of fan Fan Motor motor. (with a M6 wrench) & 3) Detach the fan motor from Cross Fan the fan.

- Page 74 12000BTU Parts Procedure Diagram 3) Turn off the power, hold the middle panel with the middle finger Front Panel 4) open the panel upwards, remove the panel fixing shaft, remove panel. Remove axial sleeve of air louver, bend louver air louver outwards and then remove the louver.

- Page 75 Left and right Remove left and right terminal terminal board board Press screw cover firmly on the middle frame , the mark Screw cover becomes unlocked, then remove the two screw caps . Loosen the clasps of the medium medium frame, remove the frame medium frame.

- Page 76 Mounting Remove the Mounting plate. plate 1) Loosen fixing earth screws of right side. 2) Detach the connection pipe. 3) Detach the holder pipe at the Heat rear side. Exchanger 4) Loosen fixing screws of right and left side. 5) Detach the heat exchanger from the indoor unit.

- Page 77 18000BTU Parts Procedure Diagram 5) Turn off the power, hold the middle panel with the middle finger Front Panel 6) open the panel upwards, remove the panel fixing shaft, remove panel. Remove axial sleeve of air louver, bend louver air louver outwards and then remove the louver.

- Page 78 Loosen the screws of the Medium medium frame wiring cover frame wiring with screwdriver,remove the cover electric box cover. Use thumb to open the middle Decorative frame remove panel decorative plate. Left and right Remove left and right terminal terminal board board Press screw cover firmly on the...

- Page 79 1) Take all the connector of PCB upper side out.(Including Power cord) Electrical 2) Detach the outdoor unit Parts connection wire from (Main PCB) terminal block. 3) If pulling the main PCB up, it will be taken out. Remove axial sleeve of louver air vent, link, bend the air vent outwards louver link...

- Page 80 1) Loosen fixing earth screws of right side. 2) Detach the connection pipe. 3) Detach the holder pipe at the Heat rear side. Exchanger 4) Loosen fixing screws of right and left side. 5) Detach the heat exchanger from the indoor unit. Remove the screw of the motor Motor press press plate and then remove the...

- Page 81 24000BTU Parts Procedure Diagram 7) Turn off the power, hold the middle panel with the middle finger, Front Panel 8) open the panel upwards, remove the panel fixing shaft, remove panel. Remove axial sleeve of air louver, bend louver air louver outwards and then remove the louver.

- Page 82 Loosen the screws of the Medium medium frame wiring cover frame wiring with screwdriver,remove the cover electric box cover. Loosen the clasps of the medium medium frame , remove the frame medium frame. 1) Take all the connector of PCB upper side out.(Including Power cord) Electrical 2) Detach the outdoor unit...

- Page 83 Remove the screw of the motor Motor press press plate and then remove the plate press plate. 1) Loosen fixing screws and detach the motor holder. 2) Loosen fixing screw of fan Fan Motor motor. (with a M6 wrench) & 3) Detach the fan motor from Cross Fan the fan.

-

Page 84: Outdoor Unit

10-2 Outdoor Unit Part Procedure Diagram Turn off the power , remove connection screws among top cover plate, front panel top cover and right side panel, then remove the top cover. Main Remove the main controller cover (no controller screw) cover Remove connection screws between the panel grille... - Page 85 Remove connection screws connecting the front panel with the chassis and the Front panel motor support , and remove the front pannal. Remove connection screws Connecting E-part cover the right side panel, then remove the E-part cover. Remove connection screws connecting Right side the right side panel with the valve support panel...

- Page 86 Remove the nut fixing the blade and then Axial flow blade remove the axial flow blade. Remove the tapping screws fixing the Outer motor motor, pull out the lead-out wire and remove the motor. Loosen the wire and disconnect the Electric box terminal.

- Page 87 Remove the tapping screws fixing the Motor motor support . Lift motor support to support remove it. Remove 2 connection screws Connecting reactor the partition board, remove the reactor. Loosen the screws of the partition board, Partition then lift and pull the partition board to board remove .

- Page 88 Remove connection screws connecting left side the left side support plate with the valve support plate support, then remove the left side support plate. After the unit is discharged, Unscrew the Pipeline fastening nut of the 4-way Valve Assy assembly coil and remove the pipeline assembly.

- Page 89 Loosen 1 footing screws of valve plate, Valve plate remove the valve plate. Loosen 3 footing screws of compressor, Compressor Remove and remove the compressor. Loosen 2 fixing screws Connecting condenser chassis, and remove the condenser. Last remaining chassis.

-

Page 90: Exploded Views And Parts List

11. Exploded Views and Parts List The models listed below for reference only, please refer to the actual product. 11-1 Indoor Unit 1) Swift Inverter 9U Exploded View... - Page 91 Part List Part Name Quantity Part Name Quantity Panel Evaporator assembly Display board 13.1 Evaporator left side carriage Air louver(Horizontal) 13.2 Evaporator part A Filter 13.3 Evaporator part B Medium frame decorative strip Motor cover Left side panel IDU fan motor Medium frame Mounting plate assembly Right side panel...

- Page 92 2) Swift Inverter 12U Exploded View...

- Page 93 Part List Part Name Quantity Part Name Quantity Panel Evaporator assembly Display board 14.1 Evaporator left side carriage Air louver(Horizontal) 14.2 Evaporator assembly Filter 14.2 Evaporator assembly Medium frame wiring cover Cross flow fan Middle frame wiring cover fire Motor cover board Screw cover...

- Page 94 3) Swift Inverter 18U Exploded View...

- Page 95 Part List Part Name Quantity Part Name Quantity Panel 13.4 Left-right swing blade Display board 13.5 Manual louver link Air louver(Horizontal) Mounting plate assembly Filter Pipe clamp Screw cover Air louver step motor Medium frame wiring cover Step motor shaft sleeve Medium frame decorative strip Main controller Medium frame unit...

- Page 96 4) Swift Inverter 24U Exploded View...

- Page 97 Part List Part Name Quantity Part Name Quantity Panel 13.2 Stopple Display board 13.3 Air louver Air louver(Horizontal) 13.4 Left-right swing blade Filter 13.5 Manual louver link Screw cover Mounting plate assembly Medium frame wiring cover Pipe clamp Medium frame decorative strip Air louver step motor Medium frame unit Step motor shaft sleeve...

- Page 98 11-2 Outdoor Unit 1) Swift Inverter 9U Exploded View...

- Page 99 Part List Part Name Quantity Part Name Quantity Right side panel Top cover E-parts cover Isolation cardboard Valve plate 4-way valve tubing assembly Stop valve 17.1 4-way valve Stop valve 17.2 Suction pipe assembly Chassis assembly 17.3 Discharge pipe assembly Chassis Partition board Base footing...

- Page 100 2) Swift Inverter 12U Exploded View...

- Page 101 Part List Part Name Quantity Part Name Quantity Right side panel 15.2 Capillary assembly E-parts cover Isolation cardboard Valve plate Partition board Stop valve Reactor Stop valve Main controller Compressor assembly 19.2 Control box Chassis assembly 19.3 Outer board Chassis 19.4 Control box cover...

- Page 102 3) Swift Inverter 18U, Swift Inverter 24U Exploded View...

- Page 103 Part List Part Name Quantity Part Name Quantity Right side panel 17.1 Condenser unit E-parts cover 17.2 Capillary assembly Valve plate Isolation cardboard Stop valve Partition board Stop valve Reactor Base pan assembly Main controller Chassis 21.1 Radiator Base footing 21.2 Pallet Compressor footing bolt...

-

Page 104: Appendix

Appendix Common Sensor R-T Analysis Table Temperature sensor R-T analysis table (15K ) Sensor standard resistance:15KΩ±3% B:B(25/50)=3950K± 2%Reference temperature:25(℃) MCU_A/D exchange ± 3LSB(at10bit) Series (sampling) resistor:10(KΩ)± 1% (except disk sensor) Single chip (A/D reference voltage) supply voltage:5V Temp Resistance(KΩ) MCU Input voltage(V) A/D Exchange value (℃)... - Page 105 33.05 34.64 36.29 1.072 1.120 1.170 31.50 32.99 34.52 1.114 1.163 1.214 30.03 31.42 32.84 1.158 1.207 1.258 10.0 28.64 29.94 31.26 1.203 1.252 1.304 11.0 27.32 28.53 29.77 1.248 1.298 1.350 12.0 26.07 27.20 28.35 1.294 1.344 1.396 13.0 24.89 25.94 27.01...

- Page 106 52.0 4.732 4.987 5.251 3.267 3.336 3.405 53.0 4.553 4.802 5.060 3.309 3.378 3.446 54.0 4.382 4.625 4.877 3.350 3.419 3.487 55.0 4.219 4.457 4.703 3.390 3.459 3.527 56.0 4.061 4.293 4.534 3.429 3.498 3.566 57.0 3.911 4.137 4.373 3.468 3.537 3.604 58.0...

- Page 107 97.0 1.013 1.100 1.194 4.462 4.505 4.544 98.0 0.9826 1.068 1.160 4.476 4.518 4.557 99.0 0.9535 1.037 1.127 4.489 4.530 4.569 100.0 0.9252 1.007 1.095 4.502 4.543 4.580 101.0 0.8981 0.9778 1.064 4.515 4.555 4.592 102.0 0.8717 0.9497 1.034 4.527 4.566 4.603 103.0...

- Page 108 Temperature sensor R-T analysis table (20K) Sensor standard resistance:20KΩ±3% B:B(25/50)=3950K± 2% reference temperature:25(℃) MCU_A/D exchange ± 3LSB(at10bit) Series(sampling)resistor:10(KΩ)± 1% Single chip (A/D reference voltage) supply voltage:5V Temp Resistance(KΩ) MCU Input voltage(V) A/D Exchange value (℃) 318.3 347.0 377.6 0.128 0.140 0.154 299.6 326.2...

- Page 109 41.90 43.92 45.99 0.886 0.927 0.971 39.95 41.85 43.78 0.922 0.964 1.009 38.11 39.88 41.68 0.960 1.002 1.047 36.37 38.02 39.69 0.998 1.041 1.087 34.71 36.25 37.81 1.038 1.081 1.127 33.14 34.57 36.03 1.078 1.122 1.168 31.65 32.98 34.34 1.119 1.163 1.210 30.23...

- Page 110 5.623 5.942 6.270 3.061 3.136 3.212 5.415 5.726 6.046 3.104 3.179 3.255 5.216 5.519 5.831 3.147 3.222 3.297 5.025 5.321 5.625 3.188 3.263 3.339 4.842 5.131 5.428 3.229 3.304 3.380 4.667 4.948 5.238 3.270 3.345 3.420 4.499 4.773 5.055 3.310 3.385 3.459 4.338...

- Page 111 1.172 1.270 1.371 4.392 4.437 4.480 1.137 1.233 1.332 4.407 4.451 4.494 1.104 1.198 1.295 4.422 4.465 4.507 1.070 1.164 1.258 4.436 4.479 4.521...

- Page 112 Temperature sensor R-T analysis table (50K) Sensor standard resistance:50KΩ±2% B:B(25/50)=3950K± 2% reference temperature:25(℃) MCU_A/D exchange ± 2LSB(at8bit) Series(sampling)resistor:5.1(KΩ)± 1% Single chip (A/D reference voltage) supply voltage:5V Temp Resistance(KΩ) MCU Input voltage(V) A/D Exchange value (℃) 465.7 486.2 507.3 0.049 0.052 0.055 439.7 458.7...

- Page 113 66.83 68.41 69.99 0.336 0.347 0.358 63.88 65.36 66.85 0.351 0.362 0.373 61.08 62.47 63.86 0.366 0.377 0.389 58.42 59.72 61.02 0.382 0.393 0.405 55.88 57.1 58.32 0.398 0.410 0.422 53.47 54.61 55.76 0.415 0.427 0.439 51.18 52.25 53.32 0.433 0.445 0.457 0.450...

- Page 114 9.927 10.29 10.66 1.607 1.657 1.708 9.577 9.931 10.29 1.646 1.696 1.749 9.24 9.585 9.94 1.684 1.736 1.790 8.916 9.253 9.599 1.723 1.777 1.831 8.605 8.934 9.271 1.763 1.817 1.872 8.307 8.627 8.955 1.803 1.858 1.914 8.02 8.331 8.652 1.843 1.899 1.955 7.744...

- Page 115 2.143 2.255 2.373 3.401 3.467 3.531 2.08 2.19 2.305 3.433 3.498 3.562 2.02 2.127 2.239 3.464 3.528 3.592 1.961 2.066 2.176 3.494 3.558 3.621 1.905 2.007 2.114 3.524 3.588 3.650 1.85 1.95 2.055 3.554 3.617 3.679 1.797 1.895 1.997 3.583 3.645 3.707 1.746...

Need help?

Do you have a question about the Swift Inverter 9U and is the answer not in the manual?

Questions and answers