Inficon LDS3000 Original Operating Instructions

Mass spectrometer module

Hide thumbs

Also See for LDS3000:

- Original operating instructions (77 pages) ,

- Translation of the original operating instructions (170 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Inficon LDS3000

- Page 1 Translation of the original operating instructions LDS3000, LDS3000 AQ Mass spectrometer module 560-300, 560-600 From software version: jiqa54en1-07-(1803) MS-Modul 2.71...

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

3 Shipment, Transport, Storage ........................ 14 4 Description.............................. 15 4.1 Function .............................. 15 4.2 Device setup ............................ 16 4.2.1 Entire device (LDS3000)...................... 16 4.2.2 Entire device (LDS3000 AQ)....................... 16 4.2.3 Connection block ........................ 20 4.2.4 MSB box ............................. 20 4.2.5 Nameplate........................... 23 4.3 Technical data ............................ 24 4.4 Factory settings ............................ 25... - Page 4 7.17 Setting capillary surveillance ........................ 63 7.18 Set the rotation speed of the turbo molecular pump................ 64 7.19 Cathode Selection .......................... 65 7.20 Settings for the XL sniffer adapter ...................... 65 7.21 Resetting the settings .......................... 68 8 Operation LDS3000 AQ (Accumulation)...................... 69 8.1 Switching the device on .......................... 69 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

- Page 5 8.17 Set the rotation speed of the turbo molecular pump................ 84 8.18 Cathode Selection .......................... 85 8.19 Resetting the settings .......................... 85 9 Using the expansion module (LDS3000, LDS3000 AQ)................. 87 9.1 Selecting the type of expansion module .................... 87 9.2 Settings for I/O module IO1000 ...................... 87 9.2.1 General interface settings ......................

- Page 6 11.3.4.1 Updating the software of the control unit................ 123 11.3.4.2 Checking and updating the software version of the MSB box.......... 123 11.3.4.3 Updating the software of the I/O module................ 124 12 Maintenance .............................. 126 12.1 Maintenance at INFICON ........................ 126 12.2 General maintenance information...................... 126 12.3 Maintenance plan .......................... 127 12.4 Maintenance work.......................... 128 12.4.1 Change operating fluid reservoir of turbo molecular pump ............

-

Page 7: About These Instructions

Product names may occur in the document, which are added for identification pur- poses only and belong to the respective owner of the rights. This operating manual describes the installation and operation of the LDS3000 mass spectrometer module. It is available in two variants: •... -

Page 8: Definition Of Terms

The pressure in the test object is less than the ambient pressure. In the operation mode "sniffing" the tracer gas flows out from the test object and is ex- tracted with a sniffer probe. The pressure in the test object is greater than the ambient pressure. 8 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 9 Operation mode "Sniffing": Ambient air is continuously fed into the leak detector via the sniffer line. The amount of helium or hydrogen occurring naturally in air creates a constant background signal. LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 9 / 138...

- Page 10 It produces a slowly decreasing measurement signal. If you want to hide this background signal or the display of existing leaks, then use the function ZERO. 10 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

-

Page 11: Safety

The LDS3000 AQ is intended for the measurement of test gases when enriched in an external measuring chamber, but can also be rebuilt for all other purposes. -

Page 12: Duties Of The Operator

The device is operated with electrical voltages of up to 24 V. Inside the device there power are voltages that are considerably higher. There is a danger to life from the contact of conductive parts inside the device. 12 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 13 • Take appropriate precautions. Danger due to implod- An external measuring chamber connected to an LDS3000 AQ is pumped off at ap- ing measuring chamber proximately 60 sccm. Within normal measurement times (2 - 30 seconds) no danger- ous negative pressure is generated.

-

Page 14: Shipment, Transport, Storage

(LDS3000 AQ version only) Operating instructions USB flash drive with instructions, 3D drawings and videos 1.) Includes either 560-300 LDS3000 or 560-600 LDS3000 AQ (accumulation). 2.) See "Select components and connect [} 36]". ► Please check the delivery for completeness after receiving the device. -

Page 15: Description

Device Interfaces The mass spectrometer module is part of the leak detection system LDS3000 and LDS3000 AQ. Es can be operated in a test system together with a bus module or I/O module and a data cable without additional INFICON accessories. -

Page 16: Device Setup

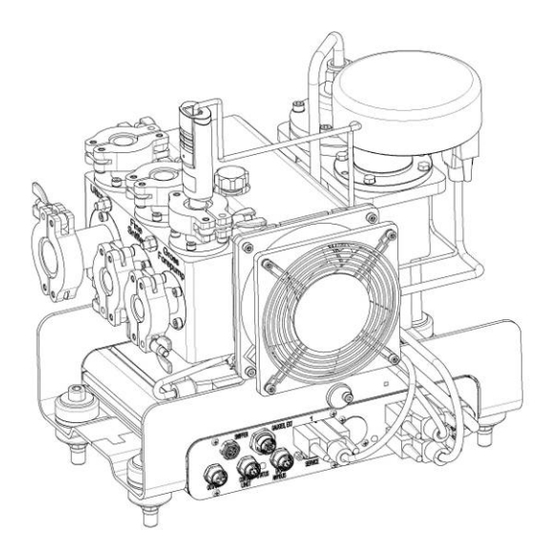

4 | Description INFICON 4.2 Device setup 4.2.1 Entire device (LDS3000) Fig. 1: Mass spectrometer module LDS3000 Connection block. Connections for test system, backing pump, pressure sen- sor PSG500, internal calibration leak and sniffer line, see also "Connection block [} 20]". Pressure sensor PSG500 for measuring the pressure of the backing pump... - Page 17 8 Dry backing pump with separate power supply) 3 Inlet module 9 Hose ID 10 4 Corrugated tube 10 Straight connector 8 to 10 mm 5 Blank flange 11 Adapter to DN16 6 Mass spectrometer module LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 17 / 138...

- Page 18 If you want to use your own backing pump, make sure it is a dry backing pump with a gas flow greater than 60 sccm and a base pressure of less than 5 mbar. It should have its own power supply. 18 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

- Page 19 • BM1000 (The bus module is a device interface between e.g. the MSB box of the mass spectrometer module LDS3000 and an external controller.) • Dry backing pump from INFICON (catalog number 560-630) Connection for hose ID 10 mm...

-

Page 20: Connection Block

Connection for gas ballast and three valves Connection plug arrangement Valve 2 (gas ballast), 24 V, max.1 A Valve 3 (not used, reserve) Valve 4 (not used, reserve) Valve 6 (not used, reserve) SNIFFER Electrical connection for the sniffer line 20 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 21 INFICON Description | 4 GAUGES, EXT Connection for optional external service gauges (0 - 10 V / 0 - 20 mA) for INFICON service Connection plug arrangement +24-V-Output, max. 200 mA Input for P3 service gauge, 0 - 10 V Reference to input for P3 service gauge...

- Page 22 Green Green, flashes Software is being updated SERVICE RS232 connection for INFICON Service I/O / ANYBUS CONTROL UNIT Connection for I/O or bus module or control unit The connections "I/O Anybus" and "Control Unit" have the same functions. You have the choice of connecting: –...

-

Page 23: Nameplate

Instrument cannot be scrapped with the normal domestic waste. Information given on the nameplate are: • Manufacturer's address • Device name • Year of production • Catalog number • Serial number • Operating temperature • Disposal instructions • Detectable gases LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 23 / 138... -

Page 24: Technical Data

< 1 s Ambient conditions 560-300, 560-600 Permissible ambient temperature (during 10 °C ... 45 °C operation) Max. altitude above sea level 2000 m Permissible magnetic field max. 7 mT Max. relative humidity above 40 °C 24 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) -

Page 25: Factory Settings

Gas percentage in H (M3, He) 100 % 5 % H (-, 100 % He) Gas ballast I/O module protocol ASCII Calibration request Calibration factor VAC/SNIF Mx (for vacuum, sniffing and all masses) Cathode selection Auto Cat1 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 25 / 138... - Page 26 4 | Description INFICON Parameter Factory setting Compatibility mode LDS3000 Config. Analog output 1 Leak rate mantissa Config. Analog output 2 Leak rate exponent Config. Analog output scale 0.5 V / decade Configuration of digital outputs Pin 1: Trigger 1, inverted...

- Page 27 Trigger level 1 (2, 3, 4) 1 x 10 mbar l/s 5 x 10 (1 x 10 ) mbar l/s Preamplifier test at CAL Maintenance warning ZERO with start ZERO mode Suppress everything 1) in AQ mode LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 27 / 138...

-

Page 28: Mounting Lds3000

5 | Mounting LDS3000 INFICON 5 Mounting LDS3000 5.1 Adjust the position of the connections to the installation dimensions Select location Select the most helium-free environment possible for the measurement setup. For reli- able measurements with the device, the helium content in the air must be less than 10 ppm. -

Page 29: Installing The Mass Spectrometer Module On The Test System

INFICON Mounting LDS3000 | 5 5.2 Installing the mass spectrometer module on the test system The mass spectrometer module can be mounted in any position. Fig. 9: Components of a fastener Hexagon socket head screw Nut M8 (self-locking) M8 x 50 Washer Base frame... -

Page 30: Select Connection Ultra, Fine, Or Gross

The following information applies to the use of helium as a tracer gas. To reach the MDLR, the following conditions must be met: • The LDS3000 must be in operation for at least 20 minutes. • Ambient conditions must be steady (temperature, no vibrations/shocks, clean envi-... -

Page 31: Establish Component Connection

INFICON Mounting LDS3000 | 5 • The specimen must be operated with switched-off ZERO until to the background is stable. The ZERO function may be switched on only after that. Connection Turbo molecular pump rotation speed 1000 Hz 1500 Hz... -

Page 32: Establish Electrical Connections

5 | Mounting LDS3000 INFICON For sniffer mode, connect the sniffer line to one of the FINE-/SNIFFER connec- tions. If available, connect internal calibration leak 560-323 to the second free flange (FINE or ULTRA) of the vacuum connection. When using a sniffer valve: For the device to operate correctly upon opening of the sniffer valve, no additional line can be connected between the connection block and the sniffer valve or between the sniffer valve and the sniffer line. -

Page 33: Mounting Lds3000 Aq (Accumulation)

INFICON Mounting LDS3000 AQ (Accumulation) | 6 6 Mounting LDS3000 AQ (Accumulation) 6.1 Adjust the position of the connections to the installation dimensions Select location Select the most helium-free environment possible for the measurement setup. For reli- able measurements with the device, the helium content in the air must be less than 10 ppm. -

Page 34: Installing The Mass Spectrometer Module On The Test System

6 | Mounting LDS3000 AQ (Accumulation) INFICON 6.2 Installing the mass spectrometer module on the test system The mass spectrometer module can be mounted in any position. Fig. 11: Components of a fastener Hexagon socket head screw Nut M8 (self-locking) M8 x 50... - Page 35 INFICON Mounting LDS3000 AQ (Accumulation) | 6 In delivery condition, the bearings are attached to the base frame with the hexagon socket screws and transport nuts. Use the supplied self-locking nuts for the installation of the mass spectrometer module – not the transport nuts.

-

Page 36: Select Components And Connect

ü You have a dry backing pump with its own power supply. All dry vacuum pumps can be used with a gas flow of more than 60 sccm at a basic pressure of under 5 mbar. This manual describes how to use the dry INFICON backing pump (catalog number 560-630). - Page 37 Fit an adapter to DN16 with throttle on the connection GROSS / FOREPUMP of the mass spectrometer module. Insert the 8 mm pin of the straight connector supplied with the INFICON backing pump (catalog number 560-630) into the adapter. Fig. 13: Straight connector, 8 to 10 mm Connect the 10 mm connector of the straight connector via a ID 10 mm hose to the dry backing pump.

-

Page 38: Establish Electrical Connections

6 | Mounting LDS3000 AQ (Accumulation) INFICON The backing pump exhaust air opening should be as far as possible from the test chamber. See also 2 Entire device (LDS3000 AQ) [} 16] 6.4 Establish electrical connections All electrical connections run from and to the MSB box. -

Page 39: Operation Lds3000

(operation in "high flow" mode). LDS3000 AQ devices can also be used if they are not operated in AQ mode. Additional information on the control unit, the modules and the XL sniffer adapter is in- cluded in the documents: •... -

Page 40: Default Settings

7 | Operation LDS3000 INFICON ð If an XL Sniffer Adapter and the CU1000 are connected, your will be asked after run-up, whether the "XL Sniffer Adapter" operation mode should be set. This does not apply to devices in AQ mode. - Page 41 INFICON Operation LDS3000 | 7 LD protocol Command 450 ASCII protocol *HOUR:TIME LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 41 / 138...

-

Page 42: Selecting A Unit For The Leak Rate

7 | Operation LDS3000 INFICON 7.3 Selecting a unit for the leak rate Leak rate unit display Selecting the leak rate unit in the display for vacuum or sniff mbar l/s (factory setting) Pa m3/s atm cc/s Torr l/s ppm (not VAC, not AQ) -

Page 43: Select Device For Pressure

The language is displayed according to the factory setting. To change the language, see “Default settings [} 40]“. If you want to use the LDS3000 later in normal operation mode, make sure to save your parameters on a USB flash drive, see "Loading and saving parameters [} 59]". - Page 44 7 | Operation LDS3000 INFICON LDS2010 LDS3000 Trigger outputs without joint reference with joint reference other outputs with joint reference with joint reference Trigger 1 (sniffer LED, relay exit, Control of sniffer LED, PWM audio Control of sniffer LED, audio out-...

-

Page 45: Select Operation Mode

• XL Sniffer Adapter (sniffing mode with a high flow rate, XL Sniffer Adapter re- quired). The device automatically switches over to the "XL Sniffer Adapter" if you connect an XL Sniffer Adapter. The LDS3000 AQ is preset to "AQ". ► If necessary, you can reset "AQ" under "Compatibility Mode". Select operation mode LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) -

Page 46: Select Gas Type (Mass)

7 | Operation LDS3000 INFICON VAC (vacuum) SNIF (sniffing) Operation mode XL Sniffer Adapter Control unit Operation mode vacuum operation or sniffing mode: Main menu > Features > VAC / SNIF Operation mode XL Sniffer Adapter: Settings > Set up > Accessories > XL Sniffer Adapter... -

Page 47: Calibrating The Device

INFICON Operation LDS3000 | 7 7.8 Calibrating the device 7.8.1 Time and general preferences NOTICE Incorrect calibration because of operating temperature that is too low Calibrating the device in the cold state can deliver incorrect measurement results. ► For optimum accuracy the device should have been turned on at least 20 minutes previously. - Page 48 7 | Operation LDS3000 INFICON Control unit Functions > CAL > Settings > CAL request. > Calibration re- quest Settings > Set-up> CAL request. > Calibration request LD protocol Command 419 ASCII protocol *CONFig:CALREQ (ON,OFF) Calibration warning The warning message Wrn650 "Calibration within the first 20 minutes is not recom- Wrn650 mended"...

-

Page 49: Internal Calibration Configuration And Start

INFICON Operation LDS3000 | 7 - Consideration of the characteristics of the testing equip- ment (pressure, partial flow ratio) - Amplifier test - Autotune (mass adjustment) - Determine the calibration factor after the signal of the cali- bration leak has settled... -

Page 50: External Calibration Configuration And Start

7 | Operation LDS3000 INFICON ASCII protocol Command *STATus:VALVE:TestLeak (ON, OFF) ► Start calibration Operating unit: Features > CAL > Intern LD protocol: 4, Parameter 0 ASCII protocol: *CAL:INT IO1000: CAL internal, see "Settings for I/O module IO1000 [} 87]" ð... - Page 51 INFICON Operation LDS3000 | 7 Functions > CAL > Settings > Ext. calibration leak (for current mass in selected unit) LD protocol Command 392 ASCII protocol Command *CONFig:CALleak:EXTSniff (for current mass in device selected unit) ► LD and ASCII protocol: The status must be queried via: Command 260 or *STA- Tus:CAL Open external calibration leak or hold sniffer line to calibration leak.

-

Page 52: Start External Dynamic Calibration

7 | Operation LDS3000 INFICON Fig. 15: External calibration with IO1000 using the example of sniffer line SL3000XL, description of PLC inputs and outputs: "Assigning inputs and outputs [} 87]" 7.8.4 Start external dynamic calibration To taken into account the special time and pressure conditions of a test bench a dy- namic calibration can be performed. - Page 53 INFICON Operation LDS3000 | 7 Start measurement. Wait until the leak rate signal is optimally suited to the normal measurement se- quence of the plant. Start calibration: Control unit: Features > CAL > Dynamic LD protocol: 4, Parameter 2 ASCII protocol: *CAL:DYN IO1000 see the figure below.

-

Page 54: External Calibration With Sniffer Line Sl3000Xl

7 | Operation LDS3000 INFICON Fig. 16: Fig. 7 External dynamic calibration with IO1000 using the example of sniffer line SL3000XL, description of PLC inputs and outputs:"Assigning inputs and outputs [} 87]" 7.8.5 External calibration with sniffer line SL3000XL The procedure complies with that of external or external dynamic calibration in sniffer mode. -

Page 55: Check The Calibration

INFICON Operation LDS3000 | 7 7.8.6 Check the calibration To check whether a re-calibration is necessary, check the already existing. 7.8.6.1 Calibration using the internal calibration leak test The test is only possible with the setting "Mass 4". ► Start test: Control unit: Features >... -

Page 56: Entering The Calibration Factor

7 | Operation LDS3000 INFICON 7.8.7 Entering the calibration factor The calibration is usually determined by the appropriate calibration routine. Therefore, it is usually not necessary to adjust the calibration factor manually. An incorrectly set calibration inevitably leads to wrong leak rate indicator! 7.8.7.1 Calibration factor sniffing... -

Page 57: Setting Machine And Sniff Factor

INFICON Operation LDS3000 | 7 7.8.8 Setting machine and sniff factor The internal calibration will only calibrate the measurement system of a mass spec- trometer module that is uncoupled from the test system. If the measurement system is operated in parallel to an additional pump system after an internal calibration though (following the partial flow principle), the measurement system will indicate a leak rate that is too low based on the partial flow ratio. -

Page 58: Setting Machine And Sniff Factor Using Machine Calibration

7 | Operation LDS3000 INFICON Control unit Settings > Set up > Operation modes > Sniffing > Sniff factor Mass 2 (3, 4) > Sniff factor H2 (M3, He) LD protocol Command 523 ASCII protocol Command *FACtor:FACSniff 7.8.8.2 Setting machine and sniff factor using machine calibration ü... -

Page 59: Loading And Saving Parameters

INFICON Operation LDS3000 | 7 STOP = Measuring --> Standby Control unit Functions > Start/Stop LD protocol Commands 1, 2 ASCII protocol Command *STArt, *STOp During the measurement During standby ZERO is possible. ZERO is not possible. The trigger outputs switch depending on The output at the trigger outputs is: Leak the leak rate and the trigger threshold. -

Page 60: Copying Measurement Data, Deleting Measurement Data

7 | Operation LDS3000 INFICON 7.11 Copying measurement data, deleting measurement data The measurement data can be saved to a USB flash drive with CU1000. • "Functions > Data > Recorder > Copy > Copy files" The measurement data can be deleted on the CU1000. -

Page 61: Measurement Result Display With Signal Filters

INFICON Operation LDS3000 | 7 1 – 2 decades 2 – 3 decades 2 decades 3 – 4 decades 19/20 of the helium background are suppressed Control unit Settings > ZERO/Filter > ZERO > ZERO > mode LD protocol Command 410... -

Page 62: Control Of The Gas Ballast Valve Of The Backing Pump

7 | Operation LDS3000 INFICON I-Filter slope sup- Same as I-Filter, but with additional slope suppression. The press. edge suppression corrects the measurement changes during the warm-up phase. Control unit Settings > ZERO/Filter > Filter > Filter mode LD protocol... -

Page 63: Selecting Display Limits

INFICON Operation LDS3000 | 7 7.15 Selecting display limits Display range Lowering and raising the display limits: If very small leak rates are not of interest for your application, raising the lower limit of the display can facilitate the assessment of the leak rate indicator. -

Page 64: Set The Rotation Speed Of The Turbo Molecular Pump

7 | Operation LDS3000 INFICON Control unit Settings > Set up > Operation modes > Sniff > Capillary > Blocked > Pressure capillary blocked LD protocol Command 452 ASCII protocol Command *CONFig:PRESSLow Pressure value capil- You set a maximum pressure value in order to detect if the 25/300-sccm capillaries lary broken are blocked. -

Page 65: Cathode Selection

INFICON Operation LDS3000 | 7 1500 Control unit Settings > Set up > MS module > TMP > Settings > TMP rota- tional speed LD protocol ASCII protocol *CONFig:SPEEDTMP 7.19 Cathode Selection Selecting a cathode The mass spectrometer includes two cathodes. In the factory setting the device uses cathode 1. - Page 66 7 | Operation LDS3000 INFICON • Switched-on Search Function and operation in Low Flow: Alarm, when Trigger 1 is exceeded. • Switched-on Search Function and operation in High Flow: Alarm, when Trigger 2 is exceeded. Control unit Setting > Trigger > Search...

- Page 67 INFICON Operation LDS3000 | 7 ASCII protocol Command *CONFig:BEEP Display of the hydro- The sniffing with forming gas involves the use of hydrogen. The hydrogen percent- gen percentage age is taken into consideration with this specification. This will increase the displayed leak rate by the corresponding factor.

-

Page 68: Resetting The Settings

7 | Operation LDS3000 INFICON Select flow Select low flow or high flow. Comment: The selection can also be made with the right sniffer key or assigned to one of the favorite keys of the control unit. Small (low flow) -

Page 69: Operation Lds3000 Aq (Accumulation)

INFICON Operation LDS3000 AQ (Accumulation) | 8 8 Operation LDS3000 AQ (Accumulation) 8.1 Switching the device on Switch on the backing pump. Establish the power supply to the mass spectrometer module. ð System starts up automatically. ð If an XL Sniffer Adapter and the CU1000 are connected, your will be asked after run-up, whether the "XL Sniffer Adapter"... -

Page 70: Selecting A Unit For The Leak Rate

8 | Operation LDS3000 AQ (Accumulation) INFICON Control unit Settings > Date/Time > Date LD protocol Command 450 ASCII protocol *HOUR:DATE Setting the time Format: hh: mm Control unit Settings > Date/Time > Time LD protocol Command 450 ASCII protocol *HOUR:TIME 8.3 Selecting a unit for the leak rate... -

Page 71: Select Device For Pressure

The language is displayed according to the factory setting. To change the language, see “Default settings [} 69]“. If you want to use the LDS3000 later in normal operation mode, make sure to save your parameters on a USB flash drive, see "Loading and saving parameters [} 83]". - Page 72 8 | Operation LDS3000 AQ (Accumulation) INFICON Control unit Settings > Set up > Compatibility > Compatibility mode LD protocol Command 2594 (dec) ASCII protocol Command *CONFig:COMP The following table shows the functional differences between and common features of LDS2010 and LDS3000:...

-

Page 73: Making Basic Settings Via The Wizard

INFICON Operation LDS3000 AQ (Accumulation) | 8 LDS2010 LDS3000 Opening the sniffer valve in SNIF after start in SNIF after start Rotation speed of turbo molecular only 2 rotation speeds adjustable Adjustable via serial interface from pump 750 Hz to 1500 Hz, via operator unit 1000 Hz and 1500 Hz... -

Page 74: Determine Peak

8 | Operation LDS3000 AQ (Accumulation) INFICON Main menu > Functions > Assistant Alternatively press the word “Wizard” at the bottom of the display. Make your entries in the windows that are called one after the other. 1. Chamber volume (net volume) The unit of volume can be selected under Main Menu >... -

Page 75: Store Leak Rate Of Calibration Leaks

INFICON Operation LDS3000 AQ (Accumulation) | 8 Confirm with “OK”. ð The "CAL peak" window opens. Remove the calibration leak from the chamber. Wait until the background signal is stable. To confirm the stable background value and start the adjustment, confirm with "OK". -

Page 76: Calibrating The Device

8 | Operation LDS3000 AQ (Accumulation) INFICON 8.9 Calibrating the device 8.9.1 Time and general preferences NOTICE Incorrect calibration because of operating temperature that is too low Calibrating the device in the cold state can deliver incorrect measurement results. ► For optimum accuracy the device should have been turned on at least 60 minutes previously. -

Page 77: Entering The Calibration Factor

INFICON Operation LDS3000 AQ (Accumulation) | 8 ASCII protocol *CONFig:CALREQ (ON,OFF) Calibration warning The warning message Wrn650 "Calibration within the first 20 minutes is not recom- Wrn650 mended" can be allowed or suppressed. OFF (suppressed) ON (allowed) Control unit Functions > CAL > Settings > CAL request. > Calibration warning W650 Settings >... -

Page 78: Calibrating

8 | Operation LDS3000 AQ (Accumulation) INFICON 8.9.4 Calibrating Please also note the general instructions for calibration, see “Calibrating the device [} 47]“. Requirements for all procedures • You have an external calibration leak. • The information on the calibration leak is entered, see also “Store leak rate of cali- bration leaks [} 75]“. - Page 79 INFICON Operation LDS3000 AQ (Accumulation) | 8 Remove the calibration leak from the measuring chamber and close the measur- ing chamber. For a stable leak rate signal, wait at least the duration of the set AQ measure- ment time. Start the background measurement.

-

Page 80: Perform Zero

“Assigning inputs and outputs [} 87]“ 8.10 Perform ZERO After the run-up of the LDS3000 AQ and the choice of forming gas as gas type, the existing hydrogen in the vacuum system initially ensures that a rising curve is visible on the display. -

Page 81: Setting Machine And Sniff Factor

INFICON Operation LDS3000 AQ (Accumulation) | 8 ü Mass is hydrogen (forming gas). If no hydrogen (forming gas) is entered, you can set it under "Main menu > Settings > Mass" or via "Wizard" at the bottom of the measurement window display. -

Page 82: Carrying Out A Measurement

8.12 Carrying out a measurement WARNING Danger due to imploding measuring chamber An external measuring chamber connected to an LDS3000 AQ is pumped off at ap- proximately 60 sccm. Within normal measurement times (2 - 30 seconds) no danger- ous negative pressure is generated. -

Page 83: Loading And Saving Parameters

INFICON Operation LDS3000 AQ (Accumulation) | 8 ü AQ ZERO has been determined, see “Perform ZERO [} 80]“. If you are measuring with forming gas, make sure that the device has been run- ning for at least half an hour. This time is needed to perform stable measure- ments. -

Page 84: Adjust "Zero Time Factor Aq

8 | Operation LDS3000 AQ (Accumulation) INFICON 8.15 Adjust ”Zero time factor AQ” In order to avoid apparently negative leak rates when measuring with forming gas, the leakage rate display is adjusted to 0 after a certain time (zero time factor AQ x mea- suring time). -

Page 85: Cathode Selection

INFICON Operation LDS3000 AQ (Accumulation) | 8 For devices with AQ mode: Do not change the set 1000 Hz. Rotation speed of turbo molecular pump in Hertz 1000 1500 Control unit Settings > Set up > MS module > TMP > Settings > TMP rota-... - Page 86 8 | Operation LDS3000 AQ (Accumulation) INFICON Control unit Functions > Data > Parameters > Reset > Control unit settings Functions > Data > Parameters > Reset > MSB settings Functions > Data > Parameters > Reset > Parameter access level...

-

Page 87: Using The Expansion Module (Lds3000, Lds3000 Aq)

INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 9 Using the expansion module (LDS3000, LDS3000 AQ) 9.1 Selecting the type of expansion module Selecting the expan- Selecting the type of module connected to the I/O connection sion module... - Page 88 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Possible functions: see the following table Control unit Settings > Set up > Interfaces > I/O module > Analog outp. > Con- fig. Analog outputs 1/2 LD protocol Commands 222, 223, 224...

- Page 89 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 The upper limit (= 10 V) is set via the parameter "Upper limit exponent". The lower value is always 0 (leak rate), which corresponds to 0 V output voltage. The exponent of the upper limit can be set in entire decades, such as 1 x 10...

- Page 90 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Fig. 18: Analog output voltage leak rate log. 1 V / decade Fig. 19: Analog output voltage leak rate log. 5 V / decade Output voltages in case The following voltages will be applied at the analog outputs in the event of an error:...

- Page 91 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Configuration The following table can be used for the transmission of settings from LDS2010 to (LDS2010-compatible) LDS3000. LDS2010 Analog Function LDS2010 Function Scaling of the Upper limit (10 setting. output...

- Page 92 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON LDS2010 Analog Function LDS2010 Function Scaling of the Upper limit (10 setting. output LDS3000 leak rate V = ...) Menu channel item 22 Leak rate log. in Pa·m³/s Leak rate 1 V/dec.

- Page 93 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 LDS2010 Analog Function LDS2010 Function Scaling of the Upper limit (10 setting. output LDS3000 leak rate V = ...) Menu channel item 22 Leak rate log. in mbar l/s Leak rate 2 V/dec.

- Page 94 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON LDS2010 Analog Function LDS2010 Function Scaling of the Upper limit (10 setting. output LDS3000 leak rate V = ...) Menu channel item 22 Leak rate log. in mbar l/s Leak rate 1 V/dec.

-

Page 95: Assigning The Digital Inputs Of The I/O Module

INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 – LD command 220 can be used to read out the voltage value on the analog input. 9.2.2.1 Assigning the digital inputs of the I/O module The digital inputs PLC-IN 1 ... The available functions can be assigned in any way necessary to the 10 I/O module. - Page 96 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Function Flank/state: Description SNIF/VAC inactive→ ac- Enable sniffer mode. tive: Enable vacuum mode. active→ inac- tive: Start inactive→ ac- Switch to Meas. (ZERO is possible, all trigger outputs switch depending tive: on the leak rate.)

- Page 97 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Function Flank/state: Description ZERO update inactive→ ac- A new zero word is formed. tive: inactive→ ac- The internal calibration leak is opened. tive: The internal calibration leak is closed. active→ inac-...

-

Page 98: Assigning The Digital Outputs Of The I/O Module

9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Function Flank/state: Description Internal CAL inactive→ ac- Check calibration with internal calibration leak check tive: External CAL inactive→ ac- Check calibration with external calibration leak check tive: Start / Stop im- inactive→... - Page 99 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Function State: Description Ready closed: Emission switched on, calibration process inactive, no error open: Emission switched off or calibration process active or error Warning closed: Warning open: no warning Error...

-

Page 100: Settings For Bus Module Bm1000

9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Function State: Description Calibration closed: calibration leak is active leak open open: calibration leak is inactive CAL stable closed: Calibration completed with calibration leak (see "Time and general prefer- ences [} 47]") -

Page 101: Warning And Error Messages (Lds3000, Lds3000 Aq)

INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 10 Warning and error messages (LDS3000, LDS3000 AQ) The instrument is equipped with extensive self-diagnostic functions. Error messages Errors are events that the device cannot correct itself and that force interruption of its operation. - Page 102 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message LDS3000 Error number Limit values Cause (Wrn) Binary or S1000Pr ASCII Error (Err) otokoll protocol compatibil- ity mode LDS1000/ LDS2010 Wrn123 Unsupported configuration The selected configuration is not...

- Page 103 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message LDS3000 Error number Limit values Cause (Wrn) Binary or S1000Pr ASCII Error (Err) otokoll protocol compatibil- ity mode LDS1000/ LDS2010 Wrn222 Internal voltage 24V_IO Short circuit 24V at IO output...

- Page 104 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message LDS3000 Error number Limit values Cause (Wrn) Binary or S1000Pr ASCII Error (Err) otokoll protocol compatibil- ity mode LDS1000/ LDS2010 Wrn304 Anode-cathode voltage too Short circuit anode-cathode, IF...

- Page 105 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message LDS3000 Error number Limit values Cause (Wrn) Binary or S1000Pr ASCII Error (Err) otokoll protocol compatibil- ity mode LDS1000/ LDS2010 Wrn350 Suppressor not connected Supressor cable is not plugged in...

- Page 106 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message LDS3000 Error number Limit values Cause (Wrn) Binary or S1000Pr ASCII Error (Err) otokoll protocol compatibil- ity mode LDS1000/ LDS2010 Err404 TMP current consumption too high Err405 No TMP run-up time 5 min.

- Page 107 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Wrn522 Pressure rise, emission < 90% of Emission was stable previously, collapsed the target pressure p1 too high, message af- value ter 5s > 110% of the target value Wrn540...

- Page 108 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Wrn610 Machine factor too low 1.00E-04 Machine factor adjustment inaccu- rate Wrn611 Machine factor too high 1.00E+04 Machine factor adjustment inaccu- rate, partial flow factor too high Wrn612 Machine factor lower than <...

-

Page 109: Illustration Of Error Codes With The Help Of The Status Leds

INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Err711 Max. MSB temperature ex- 65°C Temperature too high ceeded 8xx not used 9xx maintenance messages (e.g. TMP) Wrn901 Maintenance bearing/lubri- 3 years TMP maintenance necessary cant Wrn910 Maintenance diaphragm... -

Page 110: Operating Cu1000 (Optional)

Leak rate with peak hold function 10 Graphic representation of the leak 11 Time axis 12 Foreline pressure rate and the peak hold function 13 Button "Favorite 2" 14 Button "Favorite 1" 15 Menu 16 Value axis 17 Value axis 110 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 111 Active warnings are stored in the unit. The active warnings can be displayed via the menu "Info > History > Warnings". 7 - Tracer gas Set tracer gas and tracer gas concentration percentage. Display Meaning Helium ( Hydrogen LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 111 / 138...

- Page 112 You can assign preferred parameters to this button (see Page 19 ). In Fig. 4 the button "Favorite 1" is assigned the function "ZERO" for example. 15 - Icon for the menu All functions and parameters of the control unit can be accessed using the "Menu" key . 112 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

-

Page 113: Elements Of The Error And Warning Display

Settings and functions of the control unit are explained in the following. You will find the settings and functions of the mass spectrometer module LDS3000 you can set us- ing the control unit in the operating instructions of the mass spectrometer module. - Page 114 11 | Operating CU1000 (optional) INFICON • the user is not authorized to modify the values, • the older version of the software run by mass spectrometer module LDS3000 does not support this parameter. Scaling of the Q(t)axis Linear or logarithmic Lin.

- Page 115 Start/Stop (At AQ additionally: AQ Wizard) View settings Control unit Settings > Favorites > Favorite 1 (2, 3) Display of messages Warnings and error messages can be displayed on the touch screen. on the touch screen LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 115 / 138...

- Page 116 Control unit Settings > Set up > Control unit > Audio > Audio alarm mode Behavior with warnings or error messages: If the touch screen shows a warning or an error, then a two-pitch signal sounds simultaneously. 116 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

-

Page 117: Operator Types And Authorizations

A key-operated switch can be used in addition to a PIN if an I/O module is connected. The key-operated switch is connected to the I/O module via three digital inputs (see operating instructions of the LDS3000). The following table shows the authorizations of individual operator types. -

Page 118: Logging Out The Operator

11 | Operating CU1000 (optional) INFICON The menu "Service" is accessible only to INFICON service staff. Load parameters The saved/backed-up parameters of control unit CU1000 and of the mass spectrom- eter module can be loaded from a USB stick. Control unit Function >... -

Page 119: Recording Data

Functions > Data > Recorder > Settings > Storage location Copy data The data stored in the control unit can be saved to a USB stick. The memory in the control unit is limited to the recording of a 24-hour measurement. LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 119 / 138... -

Page 120: Calling Up Information

• Data exchange: Information on the data exchange between mass spectrometer module and the control unit Mass spectrometer • MSB (1): Information on the software version module • MSB (2): Information on operating parameters • TMP controller (1): Information on the turbo molecular pump 120 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 121 • I/O module (1): Information on the software version, inputs and outputs • I/O module (2): Visualized information to the digital inputs Fig. 21: I/O module (2): Visualized information to the digital inputs Input signal condition Configured function (INV = Func- tion is inverted) LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 121 / 138...

- Page 122 Configured function (INV = Func- Output signal condition tion is inverted) Status of the function (active or in- active) • Bus module (1): Information on the bus module • Bus module (2): Information on the bus module, continued 122 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

-

Page 123: Updating The Software

Operating CU1000 (optional) | 11 11.3.4 Updating the software Software updates from INFICON are installed with the aid of a USB flash drive. The update function of the device can be found under "Functions > Data > Update". An update is possible, •... -

Page 124: Updating The Software Of The I/O Module

ð The following tips are shown after selecting the "Start" button on the touch- screen: • Connect and switch on the IO1000. • Activate boot mode (switch DIP S2.3 on and off once). • When the STATUS LED flashes green, press OK. 124 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 125 INFICON Operating CU1000 (optional) | 11 Fig. 23: DIP switch on the I/O module LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 125 / 138...

-

Page 126: Maintenance

Servicing the mass spectrometer module merely requires that you change the operat- ing fluid reservoir of the turbo molecular pump and check the fan on the turbo molecu- lar pump. We recommend that you sign a service agreement with INFICON or one of INFICON's authorized service partners. 12.1 Maintenance at INFICON... -

Page 127: Maintenance Plan

Calibrate internal calibration leak Internal calibra- Perform internal calibration tion External calibra- Perform external calibration tion Leak test MS Perform helium leak test on module MS module X: after operating hours or time period X1: after operating hours LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 127 / 138... -

Page 128: Maintenance Work

Disconnect 24 V power supply pack from MSB box. Allow the turbo molecular pump to cool down if necessary. Remove turbo molecular pump. Open the ventilation screw slowly. ð Turbo molecular pump is flooded until it reaches atmospheric pressure. 128 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) - Page 129 INFICON Maintenance | 12 Fig. 24: Turbo molecular pump SplitFlow 80 Cover Oil wick cartridge O ring Ventilating screw LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 129 / 138...

- Page 130 Check the expiration date of the new operating fluid reservoir. Do not fill in any more operating fluid. Use a face pin wrench to unscrew the cover. Remove old o-ring. Use two screwdrivers to lift out the oil wick cartridge. 130 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

- Page 131 INFICON Maintenance | 12 Fig. 25: Changing the oil wick cartridge O ring Porex rods Oil wick cartridge LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 131 / 138...

- Page 132 Install the turbo molecular pump. Put the mass spectrometer module into operation. Confirm maintenance work ü Control unit installed ü Access = Integrator ► Confirm maintenance work on control unit: "Access ctrl > Integrator > Maintenance > Maintenance work“ 132 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

-

Page 133: Decommissioning The Measuring Instrument

Wait until the turbo molecular pump has stopped running. 13.2 Disposing of the mass spectrometer module The operator can dispose of the device or it can be sent to INFICON. The device consists of materials that can be recycled. This option should be exercised to prevent waste and also to protect the environment. -

Page 134: Appendix

14 | Appendix INFICON 14 Appendix 14.1 CE Declaration of Conformity 134 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) -

Page 135: Declaration Of Incorporation

INFICON Appendix | 14 14.2 Declaration of Incorporation LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 135 / 138... -

Page 136: Declaration Of Contamination

14 | Appendix INFICON 14.3 Declaration of Contamination 136 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Need help?

Do you have a question about the LDS3000 and is the answer not in the manual?

Questions and answers