Summary of Contents for Inficon CU1000

- Page 1 Translation of the Original Operating Instructions CU1000 Operating Unit Catalog No. 560-320 jina54en1-09-(2404) From software version 3.16 (LDS3000) / 3.14 (CU1000)

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

5 Installation .............................. 11 5.1 Connecting the control unit ........................ 11 5.2 Installing the control unit ........................ 11 6 Operation CU1000 ............................ 13 6.1 Touchscreen elements........................... 14 6.1.1 Measurement display elements .................... 14 6.2 Elements of the error and warning display..................... 17 6.3 Settings and functions.......................... - Page 4 Updating the software of the I/O module ................ 32 7 Decommissioning the measuring instrument ................... 34 7.1 Disposing of the device .......................... 34 7.2 Returning the device for maintenance, repair or disposal.............. 34 8 Gas library.............................. 36 9 CE Declaration of Conformity ........................ 44 CU1000-Operating-Instructions-jina54en1-09-(2404)

-

Page 5: About These Instructions

Imminent hazard resulting in death or serious injuries WARNING Hazardous situation resulting in potential death or serious injuries CAUTION Hazardous situation resulting in minor injuries NOTICE Hazardous situation resulting in damage to property or the environment CU1000-Operating-Instructions-jina54en1-09-(2404) 5 / 46... -

Page 6: Safety

• Always observe the complete operating instructions for all work. • If you have any questions about operation or maintenance that are not answered in this operating instructions, contact INFICON service. 2.3 Owner requirements Safety conscious Operate and install the device only in technically perfect working order and as... -

Page 7: Dangers

INFICON Safety | 2 ► Define responsibilities, authorizations and supervision of personnel. 2.4 Dangers • Only use the device away from areas with a risk of explosions. CU1000-Operating-Instructions-jina54en1-09-(2404) 7 / 46... -

Page 8: Shipment, Transport, Storage

Transport in unsuitable packaging material can damage the device. ► Transport the device only in the original packaging. ► Keep the original packaging. Storage ► Always store the device in compliance with the technical data, see "Technical Data". 8 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404) -

Page 9: Description

Display is set to power saving mode Fig. 2: Rear view Rating plate with control unit Calibration button for calibrating the touch screen (LCD-CAL), can be operated with touch PIN Connection for headphones Connection for the cable to the leak detector (LD) CU1000-Operating-Instructions-jina54en1-09-(2404) 9 / 46... -

Page 10: Function

Max. relative humidity above 40 °C Max. relative humidity from 31 °C to 40 °C 80% to 50% (linear abfallend) Max. relative humidity to 40 °C Permissible ambient temperature (during 10°C - 45°C operation) Storage temperature -20°C - 60°C Pollution degree 10 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404) -

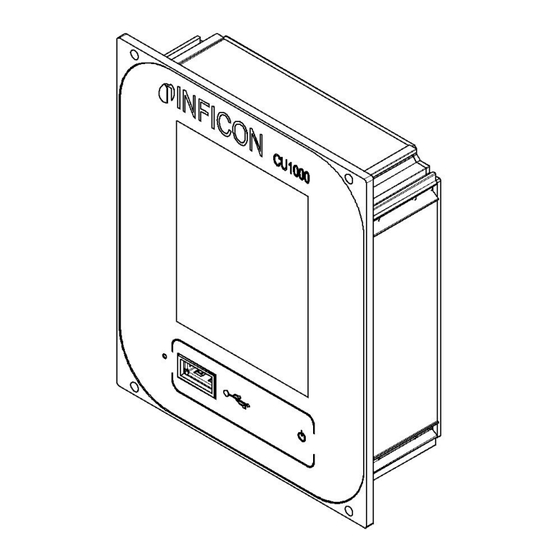

Page 11: Installation

Hearing damage from loud volume setting Loud volume setting can damage hearing. ► Do no set volume of headphones too loud. 5.2 Installing the control unit Fig. 3: Dimensions of the control unit in mm (inches in brackets) CU1000-Operating-Instructions-jina54en1-09-(2404) 11 / 46... - Page 12 5 | Installation INFICON ü Recess for control unit is incorporated in the test system. Push the control unit into the recess and screw it tight. Pull protection film from touch screen. 12 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404)

-

Page 13: Operation Cu1000

INFICON Operation CU1000 | 6 6 Operation CU1000 NOTICE Damage to touch screen from incorrect operation. The touch screen can be damaged with a hard or pointed item. ► Operate touch screen with fingers only. CU1000-Operating-Instructions-jina54en1-09-(2404) 13 / 46... -

Page 14: Touchscreen Elements

6 | Operation CU1000 INFICON 6.1 Touchscreen elements 6.1.1 Measurement display elements Fig. 4: Measurement display Keyboard lock Communication status Data recording Operator ZERO Message Tracer gas Operation mode Leak rate with peak hold function 10 Graphic representation of the leak... - Page 15 INFICON Operation CU1000 | 6 1 - Keyboard lock The control unit is locked or unlocked by pressing and holding the icon for the keyboard lock. 2 - Icon for the communication status • Icon connected: The device communicates with the mass spectrometer module.

- Page 16 6 | Operation CU1000 INFICON 8 - Operation mode Configured operation mode Display Operation mode Vacuum SNIF Sniffing LOW FLOW XL sniffer adapter in LOW FLOW HIGH FLOW XL sniffer adapter in HIGH FLOW Standby XL sniffer adapter in HIGH FLOW on...

-

Page 17: Elements Of The Error And Warning Display

INFICON Operation CU1000 | 6 16 - Value axis Value axis of the leak rate Q(t). 17 - Device of measurement Device of measurement of the value axis. 18 - Display equivalence leak rate Correction factor for the test gas used. - Page 18 6 | Operation CU1000 INFICON • the user is not authorized to change the values, see also “Operator types and authorizations [} 21]“. • an older version of the software run by mass spectrometer module LDS3000 does not support this parameter.

- Page 19 INFICON Operation CU1000 | 6 Diagram Bar graph Control unit Display > Measurement view > Measurement view mode Numeric representation of the measurements Control unit Display > Measurement view > Show value Display brightness Display brightness 20 ... 100 % Control unit Display >...

- Page 20 6 | Operation CU1000 INFICON Control unit Settings > Set up > Control unit > Messages > Show warnings Show calibration note Suppress or allow the calibration note with the following content: • Leak rate of the applied calibration leak •...

-

Page 21: Operator Types And Authorizations

The following table shows the authorizations of individual operator types. Function Viewer Operator Supervisor Integrator Changing parameters Changing the display of error information Calling up factory settings Entering maintenance history The menu "Service" is accessible only to INFICON service staff. CU1000-Operating-Instructions-jina54en1-09-(2404) 21 / 46... -

Page 22: Logging Out The Operator

Control unit Function > Data > Parameters > Load Save parameters The parameters of control unit CU1000 and of the mass spectrometer module can be saved to a USB flash drive. Control unit Function > Data > Parameters > Save Display error The type of error information can be set differently for each operator type. -

Page 23: Recording Data

INFICON Operation CU1000 | 6 Control unit The control unit settings can be reset to factory settings. Control unit Functions > Data > Parameters > Reset > Control unit settings 6.3.4 Recording data The data is saved as a TXT file. Each TXT file contains the following information: •... -

Page 24: Calling Up Information

6 | Operation CU1000 INFICON Control unit Functions > Data > Recorder > Delete > Delete files 6.3.5 Calling up information Different information and states of the system can be called up with the info menu. Measurement values • Preamplifier •... - Page 25 INFICON Operation CU1000 | 6 Fig. 5: I/O module (2): Visualized information to the digital inputs Input signal condition Configured function (INV = Function is inverted) Status of the function (active or inactive) CU1000-Operating-Instructions-jina54en1-09-(2404) 25 / 46...

-

Page 26: Display Equivalence Leak Rate For Other Gas

6 | Operation CU1000 INFICON • I/O module (3): Visualized information to the digital outputs Fig. 6: Visualized information to the digital outputs Configured function (INV = Output signal condition Function is inverted) Status of the function (active or inactive) • Bus module (1): Information on the bus module •... -

Page 27: Gas Equivalent Selection

INFICON Operation CU1000 | 6 Fig. 7: Measurement screen with displayed equivalence leak rate and configured favorites key 1 Display of gas name and equivalence factor 2 Favorites button for fast configuration of "gas equivalent selection" after set up, see "Touch screen settings [} 17]", ”Assigning favorite buttons”. -

Page 28: Configure Gas List

"Equivalence gas name" and confirm your choice. Then enter the molar mass and viscosity factor of the equivalence gas. For all gases that are not available in the gas library, please feel free to contact INFICON. Make your customer-specific entries in the following windows, which are brought up by the assistant, first "Absolute pressure equivalence gas". -

Page 29: Calculate Equivalence Factor

INFICON Operation CU1000 | 6 ð This is the gas proportion of the tracer gas in percent, e.g. for forming gas (95/5) it would be 5%. Window "Absolute pressure measuring gas". ð Corresponds to the absolute pressure of the tracer gas in the test object in bar. -

Page 30: Set Equivalence Factor And Molar Mass

6 | Operation CU1000 INFICON 6.3.6.4 Set equivalence factor and molar mass ü The equivalence factor is known. See also "Calculate equivalence factor [} 29]". ü The test gas used is specified (hydrogen or helium, mass 2, 3 or 4). ü The molar mass of the equivalence gas you want to display is known. -

Page 31: Updating The Software

Fig. 8: Top left: Display of Molar Mass (102) and Equivalence Factor (127) 6.3.7 Updating the software Software updates from INFICON are installed with the aid of a USB flash drive. The update function of the device can be found under "Functions > Data > Update". -

Page 32: Updating The Software Of The Control Unit

6.3.7.2 Checking and updating the software version of the MSB box The current software is available from the Inficon support. The functions of the XL Sniffer adapter set are taken into consideration in system software version 2.11 or higher. - Page 33 INFICON Operation CU1000 | 6 Connect the USB flash drive to the USB port on the device. Select: "Functions > Data > Update > I/O module" ð The display shows information on the current and the new software as well as on the current boot loader.

-

Page 34: Decommissioning The Measuring Instrument

ð You will then receive a return number and the shipping address. Use the original packaging when returning. Before sending the device, attach a copy of the completed contamination declaration. See below. 34 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404) - Page 35 INFICON Decommissioning the measuring instrument | 7 CU1000-Operating-Instructions-jina54en1-09-(2404) 35 / 46...

-

Page 36: Gas Library

0.545 1.217 R115 154.5 0.627 R116 0.709 1.583 R123 152.9 0.54 1.205 R124 136.5 0.581 1.297 R125 0.653 1.458 R134a 0.591 1.319 R141b 0.464 1.036 R142b 100.5 0.494 1.103 R143a 0.561 1.252 R152a 66.1 0.515 1.15 36 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404) - Page 37 2% R290 R402B Mixture of 94.7 0.642 1.433 60% R22 38% R125 2% R290 R403A Mixture of 0.642 1.433 75% R22 20% R218 5% R290 R403B Mixture of 103.3 0.647 1.444 56% R22 39% R218 5% R290 CU1000-Operating-Instructions-jina54en1-09-(2404) 37 / 46...

- Page 38 52% R134a R407E Mixture of 83.8 0.622 1.388 25% R32 15% R125 60% R134a R407F Mixture of 82.1 0.67 1.496 40% R134a 30% R125 30% R32 R408A Mixture of 0.602 1.344 7% R125 46% R143a 47% R22 38 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404)

- Page 39 Mixture of 92.2 0.602 1.344 70% R22 5% R218 25% R142b R413A Mixture of 0.581 1.297 9% R218 88% R134a 3% R600 R414A Mixture of 96.9 0.586 1.308 51% R22 28.5% R124 4% R600a 16.5% R142 CU1000-Operating-Instructions-jina54en1-09-(2404) 39 / 46...

- Page 40 6% R600a 3.1% R170 R442A Mixture of 81.8 0.629 1.404 31% R32 31% R125 30% R134a 5% R227ea 3% R152a R448A Mixture of 99.3 0.625 1.395 26% R32 26% R125 21% R134a 20% R1234yf 7% R1234ze 40 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404)

- Page 41 0.709 1.583 40% R23 60% R13 R504 Mixture of 79.3 0.678 1.513 48% R32 52% R115 R505 Mixture of 103.5 0.612 1.366 78% R12 22% R31 R506 Mixture of 93.7 0.561 1.252 55% R31 45% R114 CU1000-Operating-Instructions-jina54en1-09-(2404) 41 / 46...

- Page 42 1.393 R1234ze 0.619 1.382 R1243zf 1.339 Argon 1.127 2.516 R744 0.744 1.661 Hydrogen 0.448 R718 0.459 1.025 Helium 2.232 HT135 Galden HT135 2.232 Krypton 1.275 2.846 Nitrogen 0.892 1.991 Neon 20.2 1.586 3.54 R717 0.505 1.127 42 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404)

- Page 43 Gas library | 8 Gas designation Other designations Molecular mass Helium viscosity Hydrogen/mass 3 (max. 8 digits) (amu) factor viscosity factor Oxygen 1.03 2.299 146.1 0.765 1.708 Xenon 131.3 1.153 2.574 ZT130 Galden ZT130 2.232 Table 1: Gas library V3.24 CU1000-Operating-Instructions-jina54en1-09-(2404) 43 / 46...

-

Page 44: Ce Declaration Of Conformity

9 | CE Declaration of Conformity INFICON 9 CE Declaration of Conformity 44 / 46 CU1000-Operating-Instructions-jina54en1-09-(2404)

Need help?

Do you have a question about the CU1000 and is the answer not in the manual?

Questions and answers