Inficon LDS3000 Translation Of The Original Operating Instructions

Mass spectrometer module

Hide thumbs

Also See for LDS3000:

- Original operating instructions (138 pages) ,

- Original operating instructions (77 pages)

Summary of Contents for Inficon LDS3000

- Page 1 Translation of the original operating instructions LDS3000, LDS3000 AQ Mass spectrometer module Catalog No. 560-300, 560-600 From software version MS-Modul 3.14 jiqa54en1-13-(2211)

- Page 2 INFICON GmbH Bonner Straße 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

5.4 Establish component connection ...................... 34 5.5 Establish electrical connections ...................... 35 6 Mounting LDS3000 AQ (Accumulation) ..................... 36 6.1 Adjust the position of the connections to the installation dimensions ............ 36 6.2 Installing the mass spectrometer module on the test system .............. 37 6.3 Select components and connect ...................... - Page 4 Table of contents INFICON 6.4 Establish electrical connections ...................... 44 7 Operation LDS3000 ............................ 45 7.1 Switching the device on ......................... 45 7.2 Default settings ............................ 46 7.3 Selecting a unit for the leak rate...................... 47 7.4 Select device for pressure........................ 48 7.5 Select Compatibility Mode........................

- Page 5 8.19 Set the rotation speed of the turbo molecular pump ................ 95 8.20 Cathode Selection.......................... 95 8.21 Reset settings ............................ 96 9 Using the expansion module (LDS3000, LDS3000 AQ) ................ 97 9.1 Selecting the type of expansion module .................... 97 9.2 Settings for I/O module IO1000...................... 97...

- Page 6 Assigning the digital outputs of the I/O module ............... 108 9.3 Settings for bus module BM1000 ...................... 110 10 Warning and error messages (LDS3000, LDS3000 AQ)................ 111 10.1 Illustration of error codes with the help of the status LEDs .............. 120 10.2 Display warnings as errors........................

- Page 7 12.3.4 Exchange Porex rods........................ 155 12.3.5 Inserting a new oil reservoir ...................... 156 12.3.6 Confirm maintenance work ....................... 159 12.4 LDS3000 AQ - maintenance relevant components................ 160 12.5 Maintenance plan.......................... 160 13 Decommissioning ............................ 163 13.1 Shutting down the leak detector...................... 163 13.2 Disposing of the mass spectrometer module ..................

-

Page 8: About This Manual

Product names may occur in the document, which are added for identification purposes only and belong to the respective owner of the rights. This operating manual describes the installation and operation of the LDS3000 mass spectrometer module. It is available in two variants: •... -

Page 9: Target Groups

The pressure in the test object is greater than the ambient pressure. FINE FINE denotes the connection to the turbo molecular pump for inlet pressures up to 0.4 mbar. This is also used for the "Sniffing" operation mode. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 9 / 170... - Page 10 Operation mode "Sniffing": Ambient air is continuously fed into the leak detector via the sniffer line. The amount of helium or hydrogen occurring naturally in air creates a constant background signal. Foreline pressure Pressure of the backing pressure between the turbo molecular pump and the backing pump. 10 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

- Page 11 It produces a slowly decreasing measurement signal. If you want to hide this background signal or the display of existing leaks, then use the ZERO function. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 11 / 170...

-

Page 12: Safety

The LDS3000 AQ is intended for the measurement of test gases when enriched in an external measuring chamber, but can also be rebuilt for all other purposes. -

Page 13: Duties Of The Operator

Hazards due to Liquids and chemical substances can damage the instrument. liquids and chemicals • Comply with application limits, see "Technical Data". LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 13 / 170... - Page 14 • Take appropriate precautions. Danger due to An external measuring chamber connected to an LDS3000 AQ is pumped off at imploding measuring approximately 60 sccm. Within normal measurement times (2 - 30 seconds) no chamber dangerous negative pressure is generated.

- Page 15 INFICON Safety | 2 • Do not continue pumping a measuring chamber after the measuring time has expired. • Consider suitable protective measures! LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 15 / 170...

-

Page 16: Scope Of Delivery, Transport, Storage

(LDS3000 AQ version only) Short instruction USB flash drive with instructions, 3D drawings and videos 1.) Includes either 560-300 LDS3000 or 560-600 LDS3000 AQ (accumulation). 2.) See "Select components and connect [} 39]". ► Please check the delivery for completeness after receiving the device. -

Page 17: Description

Device Interfaces The mass spectrometer module is part of the leak detection system LDS3000 and LDS3000 AQ. Es can be operated in a test system together with a bus module or I/O module and a data cable without additional INFICON accessories. -

Page 18: Design Of Device

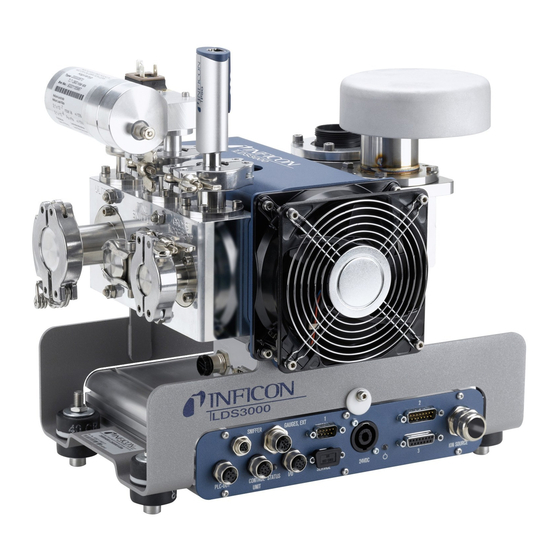

4 | Description INFICON 4.2 Design of device 4.2.1 Entire device (LDS3000) Fig. 1: Mass spectrometer module LDS3000 Connection block. Connections for test system, backing pump, pressure sensor PSG500, internal calibration leak and sniffer line, see also "Connection block [} 23]". Pressure sensor PSG500 for measuring the pressure of the backing pump... -

Page 19: Entire Device (Lds3000 Aq)

INFICON Description | 4 4.2.2 Entire device (LDS3000 AQ) In the accumulation version, the mass spectrometer module is integrated into a special measurement setup by hardware and software. Fig. 2: LDS3000 AQ (schematic view) 1 Fan system 2 Test chamber at atmospheric pressure... - Page 20 Fig. 3: Mass spectrometer module (execution accumulation) 1 Pressure sensor PSG500 for measuring the inlet pressure 2 GROSS throttle flange with connecting hose to backing pump 3 Hose to the measuring chamber 4 Inlet module 5 ULTRA connections blind flanged 20 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

- Page 21 • BM1000 (The bus module is a device interface between e.g. the MSB box of the mass spectrometer module LDS3000 and an external controller.) • Corrugated hose, available on the homepage of INFICON under "Vacuum components". • ISO-KF connections (eg screw-in flange), available on the homepage of INFICON under "Vacuum components". LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 21 / 170...

- Page 22 • ISO-K centering rings and seals, available on the homepage of INFICON under "Vacuum components". • DIN rail power supply 24V, 10A from INFICON (catalog number 560-324) for the dry backing pump of INFICON. • Dry backing pump from INFICON (catalog number 560-630).

-

Page 23: Connection Block

Fig. 7: MSB box connections SNIFFER Electrical connection for the sniffer line GAUGES, EXT Connection for optional external service gauges (0 - 10 V / 0 - 20 mA) for INFICON service Connection plug arrangement +24-V-Output, max. 200 mA Input for P3 service gauge, 0 - 10V... - Page 24 Valve 6 (not used, reserve) CONTROL UNIT, I/O / ANYBUS Connection for I/O module or bus module or control unit. Cable length of the INFICON data cable < 30 m. In order to avoid the display of incorrect measured values, the specified maximum cable length must be observed.

- Page 25 Green, flashes fast Supply voltage > 26.4 V Green, flashes Software is being updated Green Green, flashes Software is being updated 3 (See also Figure MSB box) Connection for preamplifier ION SOURCE Connection for ion source LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 25 / 170...

-

Page 26: Markings On The Device

24 V +/-5% Protection class EN 60529 IP30 UL 50E Type 1 Physical data 560-300, 560-600 Response time in Sniffer mode Gross: < 5 s, Fine/Ultra: < 1 s Maximum inlet pressure 0,2 mbar - 18 mbar 26 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 27: Factory Settings

Max. relative humidity to 40 °C Storage temperature -20 °C ... 60 °C Pollution degree 4.4 Factory settings Parameter Factory setting AO upper limit exp. 1 x 10 Operation mode Vacuum AQ Mode 1 AQ chamber volume LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 27 / 170... - Page 28 Calibration request Calibration factor VAC/SNIF Mx (for vacuum, sniffing and all masses) Cathode selection Auto Cat1 Compatibility mode LDS3000 Config. Analog output 1 Leak rate mantissa Config. Analog output 2 Leak rate exponent Config. Analog output scaling 0.5 V / decade...

- Page 29 Trigger level 1 (2, 3, 4) 1 x 10 mbar l/s 5 x 10 (1 x 10 ) mbar l/s Preamplifier test at CAL Display warning as error (1 - 8) No Entry Maintenance warning ZERO with start LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 29 / 170...

- Page 30 4 | Description INFICON Parameter Factory setting ZERO mode Suppress everything 1) in AQ mode 30 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

-

Page 31: Mounting Lds3000

INFICON Mounting LDS3000 | 5 5 Mounting LDS3000 5.1 Adjust the position of the connections to the installation dimensions Select location Select the most helium-free environment possible for the measurement setup. For reliable measurements with the device, the helium content in the air must be less than 10 ppm. -

Page 32: Installing The Mass Spectrometer Module On The Test System

5 | Mounting LDS3000 INFICON 5.2 Installing the mass spectrometer module on the test system The mass spectrometer module can be mounted in any position. Fig. 9: Components of a fastener Hexagon socket head screw Nut M8 (self-locking) M8 x 50 Washer Base frame... -

Page 33: Select Connection Ultra, Fine, Or Gross

The following information applies to the use of helium as a tracer gas. To reach the MDLR, the following conditions must be met: • The LDS3000 must be in operation for at least 20 minutes. • Ambient conditions must be steady (temperature, no vibrations/shocks, clean environment) •... -

Page 34: Establish Component Connection

5 | Mounting LDS3000 INFICON Connection Turbo molecular pump rotation speed 1000 Hz 1500 Hz ULTRA MDLR: 5 x 10 mbar l/s 1 x 10 mbar l/s 0.2 mbar 0.2 mbar short-term (< 3 s): 0.2 mbar 0.4 mbar 5l/s... -

Page 35: Establish Electrical Connections

24 V +/-5%, current carrying capacity: min. 10 A. ► Provide a short-circuit protection of 15 A for the supply of the LDS3000. ► Use a power cable with a large enough cross section. -

Page 36: Mounting Lds3000 Aq (Accumulation)

6 | Mounting LDS3000 AQ (Accumulation) INFICON 6 Mounting LDS3000 AQ (Accumulation) 6.1 Adjust the position of the connections to the installation dimensions Select location Select the most helium-free environment possible for the measurement setup. For reliable measurements with the device, the helium content in the air must be less than 10 ppm. -

Page 37: Installing The Mass Spectrometer Module On The Test System

INFICON Mounting LDS3000 AQ (Accumulation) | 6 6.2 Installing the mass spectrometer module on the test system The mass spectrometer module can be mounted in any position. Fig. 11: Components of a fastener Hexagon socket head screw Nut M8 (self-locking) M8 x 50... - Page 38 6 | Mounting LDS3000 AQ (Accumulation) INFICON In delivery condition, the bearings are attached to the base frame with the hexagon socket screws and transport nuts. Use the supplied self-locking nuts for the installation of the mass spectrometer module – not the transport nuts.

-

Page 39: Select Components And Connect

Dry backing pump with separate power supply. Not included in delivery. You can order the "Diaphragm pump LDS AQ" from INFICON under the order number 560-630, furthermore the "DIN Rail Power supply 24 V, 10 A" under the order number 560-324. - Page 40 ü You have a dry backing pump with its own power supply. All dry vacuum pumps can be used with a gas flow of more than 60 sccm at a basic pressure of under 5 mbar. This manual describes how to use the dry INFICON backing pump (catalog number 560-630).

- Page 41 INFICON Mounting LDS3000 AQ (Accumulation) | 6 ð If not, insert the positive and negative cables with ferrules 8 mm AWG 18 with red insulation into the corresponding terminals and then connect the cables to a DC power source, 24 V +/- 10 %, 5 A.

-

Page 42: Variant 2

Dry backing pump with separate power supply. Not included in delivery. You can order the "Diaphragm pump LDS AQ" from INFICON under the order number 560-630, furthermore the "DIN Rail Power supply 24 V, 10 A" under the order number 560-324. - Page 43 Make sure that the throttle insert points in the direction of the LDS FINE port. Insert an ISO-KF centering ring without filter between the throttling flange and the measuring FINE port. For details see also “LDS3000 AQ - maintenance relevant components [} 160]“.

-

Page 44: Establish Electrical Connections

24 V +/-5%, current carrying capacity: min. 10 A. ► Provide a short-circuit protection of 15 A for the supply of the LDS3000 AQ. ► Use a power cable with a large enough cross section. -

Page 45: Operation Lds3000

(operation in "high flow" mode). LDS3000 AQ devices can also be used if they are not operated in AQ mode. Additional information on the control unit, the modules and the XL sniffer adapter is included in the documents: •... -

Page 46: Default Settings

7 | Operation LDS3000 INFICON ð If an XL Sniffer Adapter and the CU1000 are connected, your will be asked after run-up, whether the "XL Sniffer Adapter" operation mode should be set. This does not apply to devices in AQ mode. -

Page 47: Selecting A Unit For The Leak Rate

INFICON Operation LDS3000 | 7 7.3 Selecting a unit for the leak rate Leak rate unit Selecting the leak rate unit in the display for vacuum or sniff display mbar l/s (factory setting) Pa m atm cc/s Torr l/s ppm (not VAC, not AQ) -

Page 48: Select Device For Pressure

The language is displayed according to the factory setting. To change the language, see “Default settings [} 46]“. If you want to use the LDS3000 later in normal operation mode, make sure to save your parameters on a USB flash drive, see "Loading and saving parameters [} 64]". - Page 49 INFICON Operation LDS3000 | 7 LDS2010 LDS3000 Trigger outputs without joint reference with joint reference other outputs with joint reference with joint reference Trigger 1 (sniffer LED, relay exit, Control of sniffer LED, PWM audio Control of sniffer LED, audio...

-

Page 50: Select Operation Mode

7 | Operation LDS3000 INFICON LDS2010 LDS3000 Default value for int. calibration 1E-15 mbar l/s 9.9E2 mbar l/s leak Default value ext. calibration leak 1E-7 mbar l/s 9.9E2 mbar l/s VAC/SNIF mode Setting range for int. calibration 10E-7 1E-9 ... 9.9E-1 mbar l/s... -

Page 51: Select Gas Type (Mass)

Command 401 ASCII protocol Command *CONFig:MODE On the LDS3000 AQ, the text "AQ" or the value "3" or "4" is displayed for the operation mode. ► With the LDS3000 AQ, you change the operation mode by changing the "Compatibility mode", see "Select Compatibility Mode [} 80]". -

Page 52: Calibrate Device

7 | Operation LDS3000 INFICON 7.8 Calibrate device 7.8.1 Time and general preferences NOTICE Incorrect calibration because of operating temperature that is too low Calibrating the device in the cold state can deliver incorrect measurement results. ► For optimum accuracy the device should have been turned on at least 20 minutes previously. - Page 53 INFICON Operation LDS3000 | 7 Control unit Functions > CAL > Settings > CAL request. > Calibration request Settings > Setup > Notifications > CAL request. > Calibration request LD protocol Command 419 ASCII protocol *CONFig:CALREQ (ON,OFF) Calibration warning The warning message Wrn650 "Calibration within the first 20 minutes is not Wrn650 recommended"...

-

Page 54: Internal Calibration Configuration And Start

7 | Operation LDS3000 INFICON equipment (pressure, partial flow ratio) - Amplifier test - Autotune (mass adjustment) - Determine the calibration factor after the signal of the calibration leak has settled - Determination of the background external-dynamic - with external calibration leak in test equipment... -

Page 55: External Calibration Configuration And Start

INFICON Operation LDS3000 | 7 ► Start calibration Operating unit: Functions > CAL > Intern LD protocol: 4, Parameter 0 ASCII protocol: *CAL:INT IO1000: CAL internal, see "Settings for I/O module IO1000 [} 97]" ð Calibration is performed automatically. 7.8.3 External Calibration Configuration and Start Requirement for the calibration with the external calibration leak is the one-time entry of the leak rate of the calibration leak and an open calibration leak. - Page 56 7 | Operation LDS3000 INFICON LD protocol Command 392 ASCII protocol Command *CONFig:CALleak:EXTSniff (for current mass in device selected unit) ► LD and ASCII protocol: The status must be queried via: Command 260 or *STATus:CAL Open external calibration leak or hold sniffer line to calibration leak.

-

Page 57: Start External Dynamic Calibration

INFICON Operation LDS3000 | 7 Fig. 14: External calibration with IO1000 using the example of sniffer line SL3000XL, description of PLC inputs and outputs: "Assigning inputs and outputs [} 97]" 7.8.4 Start external dynamic calibration To taken into account the special time and pressure conditions of a test bench a dynamic calibration can be performed. - Page 58 7 | Operation LDS3000 INFICON Start measurement. Wait until the leak rate signal is optimally suited to the normal measurement sequence of the plant. Start calibration: Control unit: Functions > CAL > Dynamic LD protocol: 4, Parameter 2 ASCII protocol: *CAL:DYN IO1000 see the figure below.

-

Page 59: External Calibration With Sniffer Line Sl3000Xl

INFICON Operation LDS3000 | 7 Fig. 15: Fig. 7 External dynamic calibration with IO1000 using the example of sniffer line SL3000XL, description of PLC inputs and outputs:"Assigning inputs and outputs [} 97]" 7.8.5 External calibration with sniffer line SL3000XL The procedure complies with that of external or external dynamic calibration in sniffer mode. -

Page 60: Check The Calibration

7 | Operation LDS3000 INFICON 7.8.6 Check the calibration To check whether a re-calibration is necessary, check the already existing. 7.8.6.1 Calibration using the internal calibration leak test The test is only possible with the setting "Mass 4". ► Start test: Control unit: Functions >... -

Page 61: Entering The Calibration Factor

INFICON Operation LDS3000 | 7 7.8.7 Entering the calibration factor The calibration is usually determined by the appropriate calibration routine. Therefore, it is usually not necessary to adjust the calibration factor manually. An incorrectly set calibration inevitably leads to wrong leak rate indicator! 7.8.7.1 Calibration factor sniffing... -

Page 62: Setting Machine And Sniff Factor

7 | Operation LDS3000 INFICON 7.8.8 Setting machine and sniff factor The internal calibration will only calibrate the measurement system of a mass spectrometer module that is uncoupled from the test system. If the measurement system is operated in parallel to an additional pump system after an internal calibration though (following the partial flow principle), the measurement system will indicate a leak rate that is too low based on the partial flow ratio. -

Page 63: Setting Machine And Sniff Factor Using Machine Calibration

INFICON Operation LDS3000 | 7 Control unit Settings > Set up > Operation modes > Sniffing > Sniff factor Mass 2 (3, 4) > Sniff factor H2 (M3, He) LD protocol Command 523 ASCII protocol Command *FACtor:FACSniff 7.8.8.2 Setting machine and sniff factor using machine calibration ü... -

Page 64: Loading And Saving Parameters

7 | Operation LDS3000 INFICON Control unit Functions > Start/Stop LD protocol Commands 1, 2 ASCII protocol Command *STArt, *STOp During the measurement During standby ZERO is possible. ZERO is not possible. The trigger outputs switch depending on The output at the trigger outputs is: Leak the leak rate and the trigger threshold. -

Page 65: Suppressing Gas Backgrounds With "Zero" Functions

INFICON Operation LDS3000 | 7 The measurement data can be deleted on the CU1000. • “Functions > Data > Recorder > Delete > Delete files” 7.12 Suppressing gas backgrounds with "ZERO" functions ZERO can be used to suppress undesired helium backgrounds. If "ZERO" is enabled, the currently measured leak rate value will be interpreted as a helium background and subtracted from all subsequently measured values. -

Page 66: Suppressing Decreasing Gas Backgrounds With I·zero 3.0 Beta

7.13 Suppressing decreasing gas backgrounds with I·ZERO 3.0 Beta I·ZERO 3.0 Beta is only available for LDS3000 in vacuum operation mode with helium as test gas, not for LDS3000 AQ. I·ZERO 3.0 Beta is in an early stage of development. - Page 67 ð If the status message for I·ZERO 3.0 Beta does not go to "STABLE” and you cannot activate ZERO, then in this case use the standard ZERO function of the LDS3000, see also “Suppressing gas backgrounds with "ZERO" functions [} 65]“.

-

Page 68: Measurement Result Display With Signal Filters

• The final background of the vacuum chamber is indicated as a leak. • If the background is almost stable, the ZERO suppression is only a factor of 3. In this case, use the standard ZERO function of the LDS3000. See also "Suppressing gas backgrounds with "ZERO" functions [} 65]". -

Page 69: Control Of The Gas Ballast Valve Of The Backing Pump

INFICON Operation LDS3000 | 7 I•CAL The leak rates are averaged at time intervals that are optimized for the range of the leak rates. The algorithm used offers excellent sensitivity and response time. Use of this setting is strongly recommended. -

Page 70: Selecting Display Limits

7 | Operation LDS3000 INFICON Controlling the gas Controlling the gas ballast valve using digital outputs. ballast valve Continuously on Control unit Functions > Valves > Gas Ballast LD protocol Command 228 ASCII protocol – 7.16 Selecting display limits Display range... -

Page 71: Setting Capillary Surveillance

INFICON Operation LDS3000 | 7 LD protocol Command 385 ASCII protocol Command *CONFig:TRIGger1 (2, 3, 4) 7.18 Setting capillary surveillance Pressure value You set a minimum pressure value in order to detect if the 25/300-sccm capillaries capillary clogged are blocked. If the value is fallen short of, the system issues warning 540. Error message 541 is output with strong lower deviation. -

Page 72: Cathode Selection

7 | Operation LDS3000 INFICON For devices in AQ mode, see “Set the rotation speed of the turbo molecular pump [} 95]“. Rotation speed of turbo molecular pump in Hertz 1000 1500 Control unit Settings > Setup > MS module > TMP > Settings > TMP rotational... - Page 73 INFICON Operation LDS3000 | 7 Control unit Settings > Set up > Operation modes > Sniff > Sniffer > Keys > Sniffer flow key LD protocol Command 415 ASCII protocol Command *CONFig:HFButton Search Function When the search function is activated, the alarm is automatically connected to Trigger 2 as soon as it is switched to High Flow.

- Page 74 7 | Operation LDS3000 INFICON Sniffer beep: Alarm Response by the beep on the sniffer if the trigger value is exceeded. configuration No response Trigger Acoustic signal / vibration alarm Control unit Settings > Set up > Operation modes > Sniff > Sniffer > Beep >...

-

Page 75: Display Equivalence Leak Rate

INFICON Operation LDS3000 | 7 Pressure value XL You set a maximum pressure value in order to detect a disruption in the XL capillary capillary broken (high (high flow, 3000 sccm). If the value is exceeded, the system issues warning 552. -

Page 76: Set Equivalence Factor And Molar Mass

7 | Operation LDS3000 INFICON Dynamic viscosity of the equivalent gas Absolute pressure of the test gas in the test object in bar Absolute pressure of the equivalent gas in the test object in bar Example An air conditioning system is to be checked for leaks. -

Page 77: Reset Settings

INFICON Operation LDS3000 | 7 7.23 Reset settings Mass spectrometer The settings of the mass spectrometer module can be reset to factory settings. module Load factory settings Reset the settings for compatibility mode LDS1000 Reset the settings for compatibility mode LDS2010... -

Page 78: Operation Lds3000 Aq (Accumulation)

8 | Operation LDS3000 AQ (Accumulation) INFICON 8 Operation LDS3000 AQ (Accumulation) 8.1 Switching the device on Switch on the backing pump. Establish the power supply to the mass spectrometer module. ð System starts up automatically. ð If an XL Sniffer Adapter and the CU1000 are connected, your will be asked after run-up, whether the "XL Sniffer Adapter"... -

Page 79: Selecting A Unit For The Leak Rate

INFICON Operation LDS3000 AQ (Accumulation) | 8 LD protocol Command 450 ASCII protocol *HOUR:TIME 8.3 Selecting a unit for the leak rate Leak rate unit Selecting the leak rate unit in the display for vacuum or sniff display mbar l/s (factory setting) -

Page 80: Select Device For Pressure

To change the language, see “Default settings [} 78]“. If you want to switch the LDS3000 to another mode now and switch back to the previously set mode at a later time, save your parameters on a USB stick beforehand, see "Loading and saving parameters [} 93]". - Page 81 INFICON Operation LDS3000 AQ (Accumulation) | 8 • LDS1000: Compatibility mode to retrofit an existing LDS1000 leak detection system with an LDS3000. • LDS2010: Compatibility mode to retrofit an existing LDS2010 leak detection system with an LDS3000. • LDS3000 • XL Sniffer Adapter Control unit Settings >...

- Page 82 8 | Operation LDS3000 AQ (Accumulation) INFICON LDS2010 LDS3000 LDS1000 compatibility mode 9.2 other functions Default values and error messages (default values are output via interface, the touchscreen shows the original message - -> reason: new hardware can cause errors that...

-

Page 83: Making Basic Settings Via The Wizard

INFICON Operation LDS3000 AQ (Accumulation) | 8 8.6 Making basic settings via the wizard We recommend using the AQ Wizard for important settings and calibration. The following information refers to a CU1000 that has been adapted for use with the LDS3000 AQ. -

Page 84: Determine Peak

8 | Operation LDS3000 AQ (Accumulation) INFICON terminated after the set measuring time has elapsed. The result of the cycle measurement can be read until the manual restart of another measuring cycle. To set the compatibility mode, see “Select Compatibility Mode [} 80]“. -

Page 85: Calibrate Device

INFICON Operation LDS3000 AQ (Accumulation) | 8 Minimum size for leak rate of the calibration leak In order to perform a stable calibration, we recommend a minimum size for the leak rate of the used calibration leak. If the measurement time proposed by the AQ Wizard is maintained, the leak rate... - Page 86 8 | Operation LDS3000 AQ (Accumulation) INFICON Control unit Settings > Set-up > MS-module > Preamplifier > Test > Preamplifier test with CAL LD protocol Command 370 ASCII protocol Command *CONFig:AMPTest (ON,OFF) Enabling calibration If Calibration request is enabled, the device will prompt the operator to perform a...

-

Page 87: Entering The Calibration Factor

INFICON Operation LDS3000 AQ (Accumulation) | 8 8.9.2 Entering the calibration factor The calibration is usually determined by the appropriate calibration routine. Therefore, it is usually not necessary to adjust the calibration factor manually. An incorrectly set calibration inevitably leads to wrong leak rate indicator! 8.9.3 Calibration factor vacuum... - Page 88 8 | Operation LDS3000 AQ (Accumulation) INFICON LD or ASCII protocol, IO1000 Place the open calibration leak in the measuring chamber and close the measuring chamber. Only applies to the “AQ Mode 1“: For a stable leak rate signal, wait at least the duration of the set AQ measurement time.

-

Page 89: Start And Stop Measurement (Aq Mode 2)

INFICON Operation LDS3000 AQ (Accumulation) | 8 Fig. 17: External calibration with IO1000 on a device for AQ mode. Description of the PLC inputs and outputs see “Assigning inputs and outputs [} 97]“. 8.10 Start and stop measurement (AQ Mode 2) Applies only to “AQ Mode 2“. See also "Select Compatibility Mode [} 80]". -

Page 90: Perform Zero

2 Carrying out a measurement [} 92] 8.11 Perform ZERO After the run-up of the LDS3000 AQ and the choice of forming gas as gas type, the existing hydrogen in the vacuum system initially ensures that a rising curve is visible on the display (AQ Mode 1). -

Page 91: Setting Machine And Sniff Factor Manually

INFICON Operation LDS3000 AQ (Accumulation) | 8 consideration along wit the ratio of effective pumping speed of the measurement system in a comparison to the pumping speed of the measurement system on the test system. 8.12.1 Setting machine and sniff factor manually ü... -

Page 92: Carrying Out A Measurement

8.13 Carrying out a measurement WARNING Danger due to imploding measuring chamber An external measuring chamber connected to an LDS3000 AQ is pumped off at approximately 60 sccm. Within normal measurement times (2 - 30 seconds) no dangerous negative pressure is generated. -

Page 93: Loading And Saving Parameters

INFICON Operation LDS3000 AQ (Accumulation) | 8 ð The leak rate is calculated and displayed. Due to the endlessly running measurement, the result of a measuring cycle must be time-adjusted manually. ð If the test object leaks, the display shows an increasing leak rate. -

Page 94: Selecting Display Limits

8 | Operation LDS3000 AQ (Accumulation) INFICON In order to avoid apparently negative leak rates when measuring with forming gas, the leakage rate display is adjusted to 0 after a certain time (zero time factor AQ x measuring time). Zero time factor AQ can be set under: Main menu >... -

Page 95: Set The Rotation Speed Of The Turbo Molecular Pump

For measurements with hydrogen / forming gas, it may be useful to set the turbo the turbo molecular molecular pump of the LDS3000 AQ to 1250 Hz. pump This is always the case if fluctuating environmental conditions such as humidity have a greater influence on the signal quality than the lower signal strength (greater calibration factor) for hydrogen / forming gas at 1250 Hz operation. -

Page 96: Reset Settings

8 | Operation LDS3000 AQ (Accumulation) INFICON Control unit Settings > Set up > MS module > Ion source > Cathode selection LD protocol ASCII protocol *CONFig:CAThode *STATus:CAThode 8.21 Reset settings Mass spectrometer The settings of the mass spectrometer module can be reset to factory settings. -

Page 97: Using The Expansion Module (Lds3000, Lds3000 Aq)

INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 9 Using the expansion module (LDS3000, LDS3000 AQ) 9.1 Selecting the type of expansion module Selecting the Selecting the type of module connected to the I/O connection expansion module I/O module... - Page 98 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Control unit Settings > Set up > Interfaces > I/O module > Analog outp. > Config. Analog outputs 1/2 LD protocol Commands 222, 223, 224 ASCII protocol Command *CONFig:RECorder:LINK1 Command *CONFig:RECorder:LINK2...

- Page 99 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 The upper limit (= 10 V) is set via the parameter "Upper limit exponent". The lower value is always 0 (leak rate), which corresponds to 0 V output voltage. The exponent of the upper limit can be set in entire decades, such as 1 x 10...

- Page 100 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Leak rate log. x ... 10 V; logarithmic; in the selected unit The upper limit (= 10 V) and the scale (V / decades) are set via the parameters "Upper limit exponent" and "Scale for leak rate".

- Page 101 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Fig. 18: Analog output voltage leak rate log. 1 V / decade Fig. 19: Analog output voltage leak rate log. 5 V / decade LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 101 / 170...

- Page 102 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Output voltages in The following voltages will be applied at the analog outputs in the event of an error: case of error Compatibility mode Voltage LDS1000 LDS2010 LDS3000 10.237V Configuration...

- Page 103 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 LDS2010 Analog Function LDS2010 Function Scaling of Upper limit setting. output LDS3000 the leak rate (10 V = ...) Menu item channel Leak rate log. in Pa·m³/s Leak rate 1V/dec.

- Page 104 9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON LDS2010 Analog Function LDS2010 Function Scaling of Upper limit setting. output LDS3000 the leak rate (10 V = ...) Menu item channel Leak rate log. in mbar l/s Leak rate...

- Page 105 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 LDS2010 Analog Function LDS2010 Function Scaling of Upper limit setting. output LDS3000 the leak rate (10 V = ...) Menu item channel Leak rate lin. In mbar l/s Linear leak...

-

Page 106: Assigning The Digital Inputs Of The I/O Module

9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON LDS2010 Analog Function LDS2010 Function Scaling of Upper limit setting. output LDS3000 the leak rate (10 V = ...) Menu item channel Leak rate log. in mbar l/s Leak rate 1V/dec. - Page 107 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Button 3 - Integrator Example for a suitable key switch: Hopt+Schuler, No. 444-05 Functions, assignment of digital inputs: Function Flank/ Description state: No function – No function CAL dynam. inactive→ active: Start external dynamic calibration.

-

Page 108: Assigning The Digital Outputs Of The I/O Module

9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Function Flank/ Description state: inactive→ active: When set to Standby, the device will start an internal calibration. When set to Meas, the device will start an external calibration. ZERO update inactive→... - Page 109 INFICON Using the expansion module (LDS3000, LDS3000 AQ) | 9 Function State: Description Trigger 1 closed: Value exceeded leak rate threshold Trigger 1 open: Value fell below leak rate threshold Trigger 1 Trigger 2 closed: Value exceeded leak rate threshold Trigger 2...

-

Page 110: Settings For Bus Module Bm1000

9 | Using the expansion module (LDS3000, LDS3000 AQ) INFICON Function State: Description Standby closed: Standby (ZERO is not possible, all trigger outputs will return “Leak rate threshold value exceeded”.) Measuring (ZERO is possible, all trigger outputs switch depending on the leak open: rate.) -

Page 111: Warning And Error Messages (Lds3000, Lds3000 Aq)

INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 10 Warning and error messages (LDS3000, LDS3000 AQ) The device is equipped with extensive self-diagnostic functions. Error messages Errors are events that the device cannot correct itself and that force interruption of its operation. - Page 112 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn123 Unsupported configuration The selected configuration is not...

- Page 113 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn221 Internal voltage 24V_RC Short circuit 24V at the control unit...

- Page 114 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn303 Suppressor voltage too 363V MSB defective...

- Page 115 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn342 Cathodes not connected Both cathodes defective during...

- Page 116 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Err403 TMP rotation speed too < 95% of...

- Page 117 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn522 Pressure rise, emission < 90% of...

- Page 118 10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn603 KalFaktor higher than last > 200% of...

- Page 119 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Warning Error message Error number Limit Cause (Wrn) LDS3000 values LDS1000 Binary or Protocol ASCII Error protocol (Err) compatibil ity mode LDS1000/ LDS2010 Wrn650 Calibration is not A calibration during the first 20...

-

Page 120: Illustration Of Error Codes With The Help Of The Status Leds

10 | Warning and error messages (LDS3000, LDS3000 AQ) INFICON 10.1 Illustration of error codes with the help of the status LEDs Any errors or warnings occurring in the MSB box will be indicated both as an error code by the control unit and as a blink code by the Status LED. - Page 121 INFICON Warning and error messages (LDS3000, LDS3000 AQ) | 10 Confirm with “OK.” ð Alternatively, exit the window without saving by pressing the "X" button. Undoing the upgrading of warnings to errors "Settings > Setup > Notifications > Warning -> Error"...

-

Page 122: Operating Cu1000 (Optional)

10 Graphic representation of the leak 11 Time axis 12 Foreline pressure rate and the peak hold function 13 Button "Favorite 2" 14 Button "Favorite 1" 15 Menu 16 Value axis 17 Measurement unit 18 Display equivalence leak rate 122 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) - Page 123 The active warnings can be displayed via the menu "Info > History > Active warnings". 7 - Tracer gas Set tracer gas and tracer gas concentration percentage. Display Meaning Helium ( Hydrogen E.g. H-D, He or H LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 123 / 170...

- Page 124 All functions and parameters of the control unit can be accessed using the "Menu" key . A full display of the menu of the menu is included as a file on the USB flash drive supplied with the LDS3000. 124 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

-

Page 125: Elements Of The Error And Warning Display

Settings and functions of the control unit are explained in the following. You will find the settings and functions of the mass spectrometer module LDS3000 you can set using the control unit in the operating instructions of the mass spectrometer module. - Page 126 INFICON • the user is not authorized to change the values, see also “Operator types and authorizations [} 129]“. • an older version of the software run by mass spectrometer module LDS3000 does not support this parameter. Scaling of the Linear or logarithmic Q(t)axis Lin.

- Page 127 ZERO (at AQ instead of ZERO: ZERO - - - (= without function) Control unit Settings > Favorites > Favorite 1 (2, 3) Displaying warnings The display of warnings on the touchscreen can be allowed or suppressed. on the touchscreen LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 127 / 170...

- Page 128 Behavior with warnings or error messages: If the touch screen shows a warning or an error, then a two-pitch signal sounds simultaneously. Automatic switch off The touch screen can be switched off automatically after a specific time without any of the touch screen operation to save energy. 128 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

-

Page 129: Operator Types And Authorizations

The following table shows the authorizations of individual operator types. Function Viewer Operator Supervisor Integrator Changing parameters Changing the display of error information Calling up factory settings Entering maintenance history The menu "Service" is accessible only to INFICON service staff. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 129 / 170... -

Page 130: Logging Out The Operator

Functions > Data > Parameters > Reset > MSB settings Access controls The authorization for changing parameters can be reset to factory setting. Control unit Functions > Data > Parameters > Reset > Param. Access control 130 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 131: Recording Data

Copy data from the internal memory of the control unit to a connected USB stick. Control unit Functions > Data > Recorder > Copy > Copy files Delete data Delete data in the internal memory of the control unit LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 131 / 170... -

Page 132: Calling Up Information

• Preamplifier: Information on the preamplifier • Preamplifier test: Information on the preamplifier test. Interfaces • I/O module (1): Information on the software version, inputs and outputs • I/O module (2): Visualized information to the digital inputs 132 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) - Page 133 INFICON Operating CU1000 (optional) | 11 Fig. 21: I/O module (2): Visualized information to the digital inputs Input signal condition Configured function (INV = Function is inverted) Status of the function (active or inactive) LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 133 / 170...

-

Page 134: Display Equivalence Leak Rate For Other Gas

The explanations on the equivalence rate only refer to sniffing operation. If you measure with the test gases helium or hydrogen, but want to display another gas with its leak rate, use a correction factor for the test gas used. 134 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 135: Gas Equivalent Selection

ð If the desired gas equivalent is already stored (numbers 1 to 4), select the desired gas equivalent number and confirm with "OK". The gas name and the equivalence factor of this gas equivalent are then displayed at the top left in the measuring window. You can perform measurement. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 135 / 170... -

Page 136: Configure Gas List

"Equivalence gas name" and confirm your choice. Then enter the molar mass and viscosity factor of the equivalence gas. For all gases that are not available in the gas library, please feel free to contact INFICON. Make your customer-specific entries in the following windows, which are brought up by the assistant, first "Absolute pressure equivalence gas". -

Page 137: Calculate Equivalence Factor

The dynamic viscosity of helium is 19.62 µPa*s. The dynamic viscosity of R134a is 11.49 µPa*s. In order to obtain an R134a equivalent leak rate display during the helium leak detection, the following equivalence factor must be entered: LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 137 / 170... -

Page 138: Set Equivalence Factor And Molar Mass

Set your molar mass. In the example for 102: ð If the equivalence factor is not equal to 1 or the molar mass is not set to factory settings, the equivalence factor is displayed both on the calibration result and on the measurement screen. 138 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 139: Gas Library

(max. 8 digits) (amu) factor viscosity factor CFCl 137.4 0.515 1.15 120.9 0.591 1.319 R12B1 ClBr 165.4 0.523 1.167 Halon 1211 104.5 0.857 1.913 R13B1 0.852 1.902 Halon 1301 0.857 1.913 CHFCl 102.9 0.535 1.194 86.5 0.632 1.411 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 139 / 170... - Page 140 0.561 1.252 R400 Mixture of 141.6 0.571 1.275 50% R12 50% R114 R401A Mixture of 94.4 0.607 1.355 53% R22 13% R152a 34% R124 R401B Mixture of 92.8 0.612 1.366 61% R22 11% R152a 28% R124 140 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

- Page 141 R406A Mixture of 89.9 0.566 1.263 55% R22 4% R600a 41% R142b R407A Mixture of 90.1 0.637 1.422 20% R32 40% R125 40% R134a R407B Mixture of 102.9 0.647 1.444 10% R32 70% R125 20% R134a LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 141 / 170...

- Page 142 25% R124 10% R142b R410A Mixture of 72.6 0.673 1.502 50% R32 50% R125 R410B Mixture of 75.6 0.673 1.502 45% R32 55% R125 R411A Mixture of 82.4 0.617 1.377 1.5% R1270 87.5% R22 11% R152a 142 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

- Page 143 R416A Mixture of 111.9 0.576 1.286 59% R134a 39.5% R124 1.5% R600 R417A Mixture of 106.7 0.61 1.362 50% R134a 46% R125 4% R600a R422D Mixture of 112.2 0.622 1.388 65.1% R125 31.5% R134a 3.4% R600a LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 143 / 170...

- Page 144 24.7% R125 24.3% R32 R450A Mixture of 0.592 1.321 58% R1234ze 42% R134a R452A Mixture of 103.5 0.612 1.366 59% R125 30% R1234yf 11% R32 R452B Mixture of 72.9 0.639 1.426 67% R32 26% R1234yf 7% R125 144 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

- Page 145 0.729 1.627 39% R23 61% R116 R508B Mixture of 95.4 0.729 1.627 46% R23 54% R116 R513A Mixture of 108.7 0.582 1.299 44% R134a 56% R1234yf R600 58.1 0.377 0.842 Butane R600a 58.1 0.377 0.842 Iso-Butane LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 145 / 170...

-

Page 146: Updating The Software

Table 1: Gas library V3.24 11.3.8 Updating the software Software updates from INFICON are installed with the aid of a USB flash drive. The update function of the device can be found under "Functions > Data > Update". An update is possible, •... -

Page 147: Updating The Software Of The Control Unit

11.3.8.2 Checking and updating the software version of the MSB box The current software is available from the Inficon support. The functions of the XL Sniffer adapter set are taken into consideration in system software version 2.11 or higher. -

Page 148: Updating The Software Of The I/O Module

ð The following tips are shown after selecting the "Start" button on the touchscreen: • Connect and switch on the IO1000. • Activate boot mode (switch DIP S2.3 on and off once). • When the STATUS LED flashes green, press OK. 148 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) - Page 149 INFICON Operating CU1000 (optional) | 11 Fig. 25: DIP switch on the I/O module LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 149 / 170...

-

Page 150: Maintenance

Servicing the mass spectrometer module merely requires that you change the oil reservoir of the turbo molecular pump and check the fan on the turbo molecular pump. We recommend that you sign a service agreement with INFICON or one of INFICON's authorized service partners. - Page 151 The mass spectrometer module is a precision measurement device. Even little pollution can already damage the device. ► Make sure that the working environment is clean and you use clean tools whenever performing any maintenance work. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 151 / 170...

-

Page 152: Change Oil Reservoir Of Turbo Molecular Pump

Disconnect 24 V power supply pack from MSB box. Allow the turbo molecular pump to cool down if necessary. Remove turbo molecular pump. Open the ventilation screw slowly. ð Turbo molecular pump is flooded until it reaches atmospheric pressure. 152 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 153: Removing Old Oil Wick Cartridge

ü Face spanner, P/N: 551-200 ü Two screwdrivers ü Mass spectrometer and turbo molecular pump flooded. Unscrew the cover (1) using a face spanner. Use two screwdrivers to lift out the oil reservoir (2). Do not loosen any screws! LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 153 / 170... - Page 154 Unscrew the 3 screws (M4) of the cover with the Allen key. Screw a threaded screw (M5) a few turns into the empty central threaded opening of the aluminum cover. Use the screw to lift the cover. 154 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

-

Page 155: Exchange Porex Rods

Pull out old Porex rods (1) (8 pieces) with tweezers. Remove any contaminants found on the turbo molecular pump and the cover using a clean, lint-free cloth. Insert new Porex rods (1) (8 pieces) with tweezers. LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 155 / 170... -

Page 156: Inserting A New Oil Reservoir

12.3.5 Inserting a new oil reservoir NOTICE Material damage if o-ring is mounted improperly An improperly mounted o-ring can cause leaks. The device will experience malfunctions and become damaged. ► Carefully insert the O-ring of the cover. 156 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) - Page 157 As soon as this is achieved, the cover will slightly sink back into the pump. This position allows the threads to mesh better. Tighten the cover with a torque of 13 Nm +/-10%. Hand-tighten the ventilation screw (4). LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 157 / 170...

- Page 158 ð The new oil wick cartridge will be positioned correctly when you screw in the cover. Insert a new o-ring for the cover. Replace the cover using a threaded screw (M5). Screw in the 3 screws (M4) of the cover with the Allen key and a torque of 3 158 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

-

Page 159: Confirm Maintenance Work

Install the turbo molecular pump. Put the mass spectrometer module into operation. 12.3.6 Confirm maintenance work ü Control unit installed ü Access = Integrator ► Confirm maintenance work on control unit: "Authorization > Integrator > Maintenance > Maintenance Work“ LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 159 / 170... -

Page 160: Lds3000 Aq - Maintenance Relevant Components

12 | Maintenance INFICON 12.4 LDS3000 AQ - maintenance relevant components Fig. 29: Throttle for AQ Designation Quantity Order number 1 ISO-KF centering ring without filter. 211-059 Only to be used for connection according to variant 2 (with filter unit 0.45 µm Pall, pos. N° 5). - Page 161 Replace preventively - ISO KF filter ring - 0.45 µm Pall *) Applies only to LDS3000 AQ: Unsuitable environmental influences or operating conditions as well as contamination and the type of application process can reduce the recommended maintenance LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 161 / 170...

- Page 162 INFICON interval of the AQ filter used to less than 8000 hours or 1 year. Depending on the type of setup, different AQ filters are in use, see "LDS3000 AQ - maintenance relevant components [} 160]". Reduced flow/pressure caused by clogged filters may result in warning or error messages.

-

Page 163: Decommissioning

Wait until the turbo molecular pump has stopped running. 13.2 Disposing of the mass spectrometer module The owner can dispose of the device or it can be sent to INFICON. The device consists of materials that can be recycled. This option should be exercised to prevent waste and also to protect the environment. -

Page 164: Appendix

14 | Appendix INFICON 14 Appendix 14.1 CE Declaration of Conformity 164 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 165: Declaration Of Incorporation

INFICON Appendix | 14 14.2 Declaration of Incorporation LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 165 / 170... -

Page 166: Declaration Of Contamination

14 | Appendix INFICON 14.3 Declaration of Contamination 166 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) -

Page 167: Rohs

INFICON Appendix | 14 14.4 RoHS LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211) 167 / 170... -

Page 168: Index

Background suppression 10 Compatibility mode AQ 80, 83, 93 Declaration of Contamination 163 Definition of terms 9 Equivalence factor 75, 134 Equivalence leak rate 75, 134 I·ZERO 3.0 Beta 66 I•ZERO 3.0 Beta 110 Return shipment 163 168 / 170 LDS3000(AQ)-MSM-Operating-instructions-jiqa54en1-13-(2211)

Need help?

Do you have a question about the LDS3000 and is the answer not in the manual?

Questions and answers