Summary of Contents for Pfeiffer Vacuum Prisma QMS 200

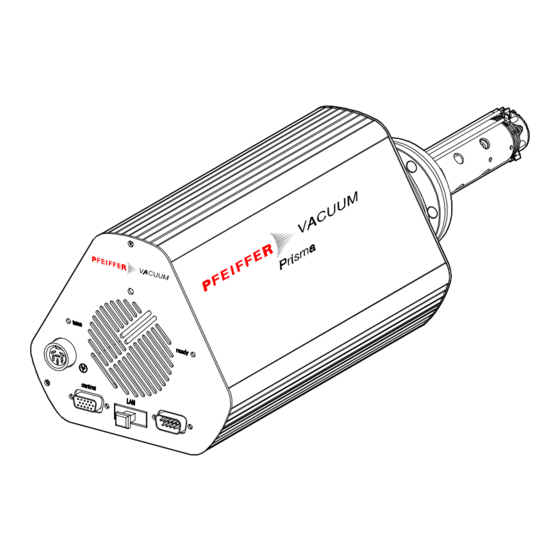

- Page 1 Operating manual incl. Declaration of conformity QMS 200 Quadrupole mass spectrometer Prisma Installation Operation Maintenance PRODUCT SERVICE geprüfte Sicherheit Technical data BG 805 201 BE (9911)

-

Page 2: Product Identification

Typical applications are measurement, monitoring and process control functions in vacuum systems. Training Training Pfeiffer Vacuum offers application, operating and maintenance courses for the best use of this product. Please contact your local Pfeiffer Vacuum representative. BG 805 201 BE (9911) QMS200.om... -

Page 3: Table Of Contents

Table of contents Product identification Validity Intended use Training 1 Safety 1.1 Symbols used 1.2 Personnel qualifications 1.3 General safety instructions 1.4 Liability and warranty 2 Technical data 2.5 System overview 2.6 Standards complied with 2.7 Ambient conditions 2.8 QMS 200 F 2.9 QMS 200 M 2.10 QME 200 2.11 SP 200... -

Page 4: Safety

1 Safety 1.1 Symbols used DANGER Information on preventing any kind of physical injury. WARNING Information on preventing extensive equipment and environmental damage. Note Information on correct handling or use. Disregard can lead to malfunctions or minor equipment damage. DANGER Caution: mains voltage Products that are not professionally connected to ground can be extremely hazardous in the event of a fault. -

Page 5: Personnel Qualifications

1.2 Personnel qualifications Skilled personnel All work described in this document may only be carried out by persons who have suitable technical training and the necessary experience or who have been instructed by the end-user of the product. 1.3 General safety •... -

Page 6: Technical Data

In all communications with Pfeiffer please specify the information given on the nameplate. For convenient reference transfer this information of all assemblies into the nameplate replicas in this manual. QME 200 Pfeiffer Vacuum, D-35614 Asslar Typ: QME 200 No: BG D28 F-No:... - Page 7 SP 200 Power cable Software Balzers Quadstar™ Balzers Limited FL-9496 Balzers QUADSTAR 422 Version: 6.xx BN 882 236 -T Copyright (C) Accessories → BG 805 201 BE (9911) QMS200.om...

-

Page 8: Standards Complied With

2.6 Standards complied Safety QME/QMA EN 61010-1:1993 with IEC1010-1:1990 +A1:1992 Protection class I SP 200 DIN EN 60950 IEC 950, UL 1950 CSA 22.2 Nr.234 Immunity EN 50082-2 Emission EN 50081-1 2.7 Ambient conditions Operation Only in inside rooms Altitude max. 2000 m NN Protection IP 30... -

Page 9: Qms 200 M

2.9 QMS 200 M QMS 200 M1 QMS 200 M2 QMS 200 M3 Mass range 1 ... 100 1 ... 200 1 ... 300 Detector type Channeltron / Faraday Detection limit mbar <10 <10 <2×10 <10 <5×10 <2×10 Unit resolution (valley, <10 full mass range) at 10 % peak height... -

Page 10: Sp 200

2.11 SP 200 Voltage 90 ... 260 V~ Frequency 47 ... 63 Hz Power requirements 1.5 A @ 115 V / 60 W 0.8 A @ 230 V / 60 W Output voltage 24 V=, stabilized Insulation 10 MOhm min., output to ground Overvoltage category II (according to EN 61010) Weight... - Page 11 VACUUM Assignment JIS F07 (TOSLINK) tune ready Transmit Receive RS-232-C control RS-232-C Assignment Assignment D-Sub. 9-pin male Received Data (RXD) optional signal Request To Send (RTS) Transmitted Data (TXD) optional signal Clear To Send (CTS) optional signal Data Terminal Ready (DTR) Signal Ground (SGND) Case...

-

Page 12: Installation

3 Installation 3.1 Unpacking Note Store the transport fastening devices and re-install them before transporting the product again. 3.2 Montage DANGER Voltages up to 330 VDC appear on the QMA 200 during operation. Other parts in the vacuum chamber (e.g. gauges) may possibly be exposed to this voltage under unfavorable conditions. -

Page 13: Required Space

3.2.1 Required space Note Note the required installation depth. Do not kink the cables. Note The QMA 200 F may only be installed in flanges or rubes with an internal diameter ≥37 mm, otherwise short circuits to the wall can occur. The diameter of the extension tube for the QMA 200 M must be at least 40.5 mm. -

Page 14: Required Tools

54.6 27 Prisma with 90° connection Channeltron + Faraday DN 40 CF-F KA 139 127.5 SP 200 3.2.2 Required tools 4 mm hexagon socket screw key 10 mm open-end wrench (2 pieces) Screwdriver (blade width 3…4 mm) BG 805 201 BE (9911) QMS200.om... -

Page 15: Qma Installation

3.2.3 QMA installation DANGER The analyzer flange must be properly grounded. • By connecting with all 6 screws to the properly grounded. vacuum system. • If the mounting flange is not grounded, the QMA 200 flange (grounding screw M4) must be connected to the protective ground by means of a separate ground conductor. -

Page 16: Qme Installation

3.2.4 QME installation DANGER The QME may be mounted only to a correctly installed QMA as the only ground connection is via the QMA flange. The 24 V feeder line from the SP 200 must never be connected if QMA is not screw fastened to the QME. - Page 17 This connection allows vacuum measurements with a TPR 250 or PKR 250 3.3.1.1 - connection compact gauge head, and protection of the filament FIL and Channeltron SEM against inadequate vacuum conditions. • Total pressure Pirani Compact Gauge measurement and protective VACUUM functions 5×10...

- Page 18 If SEM+FIL control is not used, the input can be used as a digital input for a Digital input floating contact between the signal lines EXT_PROT and COM. In this case the configuration parameter SEM+FIL must be set to INTERN. Logic assignment: Contact open: →...

-

Page 19: Connecting The Sp 200 Power Supply To Prisma

Digital input If “External measurement cycles/Start” is not used, the EXT_RUN connection is available as a digital input for interrogating a contact state. For this application the cycle/TRIG parameter must be set to INTERN: Logic assignment Contact open: → DI 1 = true Contact closed: →... -

Page 20: Connecting The Pc

3.3.3 Connecting the PC Open the enclosed Balzers Quadstar software package. Remove the enclosed cables. Establish the connections. RS-232-C Interface: Use the supplied 9-conductor null modem cable. VACUUM (If required use the extension cable and/or the DB9 male / DB25 female Adapter). -

Page 21: Operation

4 Operation 4.1 Commissioning DANGER Caution: damaged product Putting a damaged product into operation can be extremely hazard- ous. In case of visible damages, make sure the product is not put into operation. WARNING Make sure that the limits and ambient conditions specified in the technical data (→... -

Page 22: Configuration

Check the line voltage + available power connection 24 V= Ready for operation ready Not ready Contact Pfeiffer Vacuum Service Center ready Start Balzers Quadstar™ → Balzers Quadstar 4.2 Configuration The system must be configured when it is put into service for the first time. -

Page 23: Maintenance

5 Maintenance 5.1 QMA 5.1.1 Filament change Skilled personnel Filaments are supplied as preassembled units. They should only be changed by qualified personnel. Detach all electrical connections to the QME. Separate the QME from the analyzer by performing the same steps described in Chapter 3.2.5 but in reverse order. -

Page 24: Qme

Support bracket Replacement cathode Replacement filament assembly Open the packing tube of the replacement filament assembly. Carefully lift off the support bracket while gripping the filament assembly at the base of the protective packing. WARNING Do not touch the filament, not even with gloved hands. Mount the replacement filament on the ion source. -

Page 25: Replacing The Filter Mat

DANGER Disconnect the 24V power supply of the QME from the AC power source before any moist cleaning. Make sure the connectors do not get moist. No liquid must seep into the unit. Do not operate the unit until it is completely dry. 5.2.2 Replacing the filter mat Replace the filter mat if it is decomposed or if it can no longer be cleaned as described above. -

Page 26: Tune" Of Rf Generator

5.2.3 “TUNE” of RF generator The RF circuit has to be tuned: When the unit is put into service for the first time, when the analyzer is changed (especially from Faraday to Channeltron), or when a corresponding error message is displayed on the screen. Correct tuning assures optimum measurement accuracy across the entire mass range. -

Page 27: Replacing The Qme

Repeatedly measure the spectrum of the peak groups that are of interest because in this optimization not only the intensity but also the resolution and the peak shape are important. Standard parameters are: SPEED: 1s/u MODE: SCAN-N RESOL: RANGE: or AUTO IonRef: 150 V / Cathode: 90 V Adjust the Extraction and Focus voltages to max. -

Page 28: Accessories And Spare Parts

6 Accessories and spare parts Item Designation A/E/Z Ordering number. Hexagon-socket-screw key M5 (SW4) N 5701 009 BC Hexagon-socket-head screw M3 × 8 B 3079 191 X Lock washer B 3547 137 X Filter mat B 5099 154 FE D-Sub connector 15 pin BG 442 639 -T Connector... -

Page 29: Disposal

7 Disposal DANGER Caution: contaminated parts Contaminated parts can be detrimental to health. Before beginning to work, find out whether any parts are contami- nated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts. WARNING Caution: substances detrimental to the environment Electronic components must be disposed of in accordance with special regulations. -

Page 30: Appendix

• For fiber-optic conductors with length < 750 m → factory configuration. • For fiber-optic conductors with length > 750 m → reconfiguration required Pfeiffer- Vacuum ... please contact your nearest Pfeiffer Vacuum service center. Connection via HUB OHA 200 OHA 200 [2] → OHA 200... -

Page 31: B: Literature

[3] Operating manual Network controller board OPA 200 SH - ARC BAL (9603) SoHard, Gesellschaft für Soft- und Hardware-Entwicklung mbH, D-90766 Fürth/Germany [4] Communication protocol BG 805 203 BE Pfeiffer Vacuum GmbH, D-35614 Asslar BG 805 201 BE (9911) QMS200.om... -

Page 32: Declaration Of Contamination

Declaration of contamination The repair and/or service of vacuum equipment and components will only be carried out if a correctly completed declaration has been submitted. Non-completion will result in delay. This declaration can only be completed and signed by authorized and qualified staff. Reason for return Description of product Type... -

Page 33: Declaration Of Conformity

Declaration of conformity QMS 200 Product Quadrupole mass spectrometer Prisma EU Declaration of Conformity as We herewith declare that the above product complies with the provisions of the defined by the listed Guidelines listed Guidelines. Guidelines, harmonised standards, national standards in languages and specifica- tions which have been applied: 73/23/EWG (7/93) 89/336/EWG (7/93) - Page 34 BG 805 201 BE (9911) QMS200.om...

- Page 35 BG 805 201 BE (9911) QMS200.om...

- Page 36 Pfeiffer Vacuum GmbH Emmeliusstrasse 33 D–35614 Asslar Deutschland Tel +49 (0) 6441 802-0 Fax +49 (0) 6441 802-202 info@pfeiffer-vacuum.de Original: German BG 805 201 BD (9911) www.pfeiffer-vacuum.de...

Need help?

Do you have a question about the Prisma QMS 200 and is the answer not in the manual?

Questions and answers