Summary of Contents for IWAKI APN-30GD3-W

- Page 1 IWAKI Gas-Liquid Transfer Pump APN-30/-60 GD3-W Instruction Manual Read this manual before use of product...

-

Page 2: Table Of Contents

Important Instruction Thank you for selecting an IWAKI APN-30/-60 GD3-W gas- liquid transfer pump (BLDC motor). This instruction manual For the Safe and deals with "Safety Instructions", "Outline", "Installation", Correct Handling of the Pump "Operation" and "Maintenance" sections. "Safety Instruction" section deals with important details about Please read through this instruction manual to ensure the opti- handling of the product. -

Page 3: Safety Instructions

Safety Instructions WARNING CAUTION Turn off power Restriction on operators Risk of electrical shock. Dismantling/assem- The pump should be handled by a quali- bling the pump unit without turning off power fied person with a full understanding. may cause an electrical shock. Before Prohibited Ventilation engaging in any maintenance or inspec-... - Page 4 Safety Instructions CAUTION CAUTION Damaged pumps Damaged power cable Do not use any damaged pump. Using a Do not use any damaged power cable for damaged pump may lead to an electric leak the prevention of a fire or electrical shock. or shock.

-

Page 5: Outline

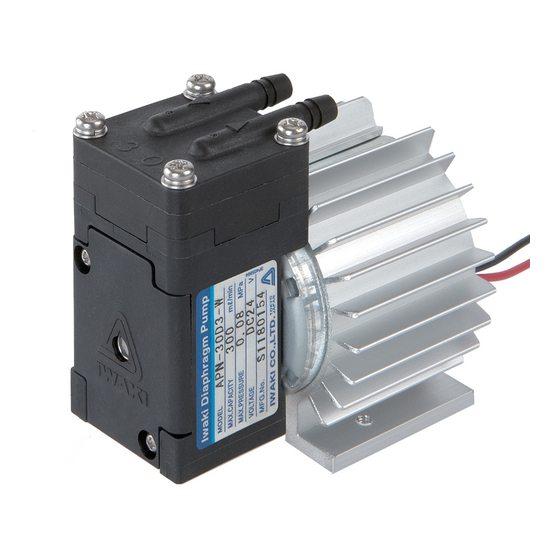

Outline Before use, check the specification, limitation and hazardous 2. Operating principle nature of the pump. The APN-30/-60 GD3-W is a gas-liquid transfer pump with 1. Unpacking & Inspection a small size diaphragm. The rotary motion of the motor is converted via a con- On unpacking the product, check the following points. -

Page 6: Specifications

Outline 4. Specifications ■ Pump Lowest Maximum Motor Connection bore Maximum Liquid discharge starting Mass Type flow rate vacuum flow rate Amperage Voltage pressure temperature Hose (MPa) (ml/min) (kPa) (ml/min) (°C) APN-30 1000 0.08 47.99 24DC ø5.5 APN-60 NOTE 1. Discharge pressure should not exceed the limit shown above. 2. -

Page 7: Outer Dimension

Outline ■ Wet end material 5. Outer dimension Material FKM type Parts Pump head GFRPP (69) Diaphragm (51) Valve Valve seat GFRPP Gasket (10) (240) 2×M3 - 5 - - 5 -... -

Page 8: Performance Curve

Outline 7. Overview & Label 6. Performance curve (gas transfer) Pressure (MPa) 0.08 Pump head 0.06 Inlet Outlet 0.04 0.02 Pump body (Driven unit) 101.32 1000 1200 installation location Air Flow (ml/min) should be free from liq- 74.66 uid spillage. 47.99 Name plate 21.33... -

Page 9: Part Names & Structure

Outline 8. Part names & Structure Code Name Q‘ty Code Name Q‘ty Pump head Bracket Valve Motor Valve seat Screw Diaphragm Gasket Connecting rod unit 1 set - 7 -... -

Page 10: Installation

Installation 1. Before Installation ■ Instruction for use Do not install the pump in a Read through this instruction manual before use. Carry place where the pump can out installation work with a full understanding. get wet. CAUTION For gas transfer, do not use No fire the pump in a dusty place. - Page 11 Installation Do not tube two or more Observe the rated voltage pumps in series. It may pre- specified on the name plate. vent the motor from starting Applying any voltage than and lead to a burn out. the rated one may result in failure.

-

Page 12: Installation/Tubing/Electrical Wiring

Installation 2. Installation/ Tubing/ Electrical wiring 2. Pump fixation Secure the pump by fixing the base. WARNING CAUTION Do not install the pump on a Stop working upon sensing danger or abnormality. wobbly pedestal. 3. Tube preparation 2.1 Installation Cut the tube ends and have 1. - Page 13 Installation 3. For liquid transfer, a suction line bore should be ø4mm or 2.3 Electrical wiring less. Otherwise, the motor is locked by overfeeding. Electrical wiring must be done by a qualified person who has A discharge line bore should also be ø4mm or less. a full knowledge of safety.

-

Page 14: Operation

Operation 1. Before operation Always use a suction valve to adjust an air/liquid flow. Suction line Dropping or subjecting the pump to strong impact, fail- ure may result. Handle the pump with care. If the compressed air or The pump can not start with liquid (higher pressure Pressure full discharge/suction pres-... -

Page 15: Pump Operation

Operation ■ Operation 2. Pump operation Operate the pump according to the following steps. ■ Start-up Procedure Contents 1. Before pump operation, check Check installation, tubing and wiring are properly done and wiring system that each tube and the outlet & Check tubing, wir- is fused. - Page 16 Operation ■ Stop and storage Before a long period of stop (1 week or more)... Release pressure and remove liquid from the pump and then stop air/gas supply. Some liquids may harden or crystallize when they are left for a long time. In this case clean wet ends before resuming operation.

-

Page 17: Maintenance

Maintenance 1. Trouble shooting 2. Maintenance & Inspection Turn off power on sensing danger and check the follow- ■ Daily inspection ing. In case trouble can not be solved, contact us or your Pay attention to the following items during operation. Stop nearest distributor. - Page 18 Maintenance Handling of the pump, maintenance and inspection should be carried out within this instruction manual. Do not handle the pump beyond the descriptions in this manual. We are not responsible for personal injury or property dam- age due to nonobservance of this warning. Contact us or your nearest distributor as necessary.

- Page 19 - 17 -...

- Page 20 IWAKI Norge AS TEL : (47)66 81 16 60 FAX : 66 81 16 61 China IWAKI Pumps (Guandong) Co., Ltd. TEL : (86)750 3866228 FAX : 750 3866278 Singapore IWAKI Singapore Pte. Ltd. TEL : (65)6316 2028 FAX : 6316 3221 China GFTZ IWAKI Engineering &...

Need help?

Do you have a question about the APN-30GD3-W and is the answer not in the manual?

Questions and answers