Armstrong Design Envelope 4312 Installation And Operating Instructions Manual

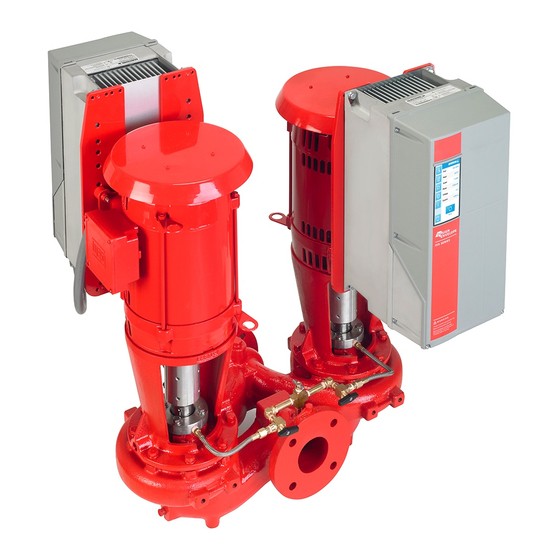

Vertical in-line twin pumping unit with ivs drive

Hide thumbs

Also See for Design Envelope 4312:

- Quick installation manual (4 pages) ,

- Installation and operating instructions manual (40 pages) ,

- Quick installation manual (4 pages)

Summary of Contents for Armstrong Design Envelope 4312

- Page 1 Design Envelope 4312 & 4392 Vertical In-line Twin Pumping Unit with ivs drive Installation and operating instructions File No: 105.80iec Date: janaury 21, 2019 Supersedes: 105.80iec Date: august 08, 2018...

-

Page 3: Table Of Contents

contents 4.3.7 alarms & warnings 1.0 introduction 4.3.8 trend-graph precautions 4.3.9 brightness adjustment 1.1.1 uncrating 4.3.10 touch screen calibration 1.1.2 handling design envelope 4312 and 4392 units 4.3.11 data logging 1. 2 mechanical installation 4 . 4 web interface 1.2.1 location 4.4.1 connecting via ethernet 1.2.2... -

Page 4: Introduction

Rustproofing or packing the casing with moisture absorb- ing material and covering the flanges is acceptable. When Design Envelope 4312 and 4392 twin pumps are handled in returning to service be sure to remove the drying agent from a similar manner to the normal twin pumping units. Extra the pump. -

Page 5: Pump Piping - General

Discharge valve only must be used to reduce the All Design Envelope 4312 pumps contain a tapped hole in the pump flow, not the suction valve. motor bracket above the discharge flange for draining the Care must be taken in the suction line layout and well. - Page 6 & Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s fig. 1. 2 pipe mounted supported at ceiling fig. 1.5 floor saddle support Pipe hanger (typ.)

-

Page 7: Electrical Setup

Design Envelope 4312 and 4392 vertical in-line install a tio n & twin pumping unit with ivs drive oper ating instr uctio n s fig. 1.8 tapped collection well on design do not envelope 4312 from sides Design Envelope 4312 seal leaks or condensate drain hole. -

Page 8: Start / Stop Of Pump

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 2 .3 . 2 supply fusing Since the leakage current is >3.5ma (approx... -

Page 9: Relay Connections

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s fig. 2 . 2 Mains and grounding connections for a5 units fig. -

Page 10: Electrical Installation And Control Connections

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 2 .3 .5 electrical installation and control connections fig. 2 .7... -

Page 11: Control Terminals

Digital Input Start Digital Input Pump Operating Mode Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive Common o pera t ing instr uct io n s... - Page 12 & Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s webserver configur ation Select Pump in the left side-menu...

-

Page 13: Design Envelope Pump

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s 2. 4 design envelope pump 2 . 4 . 2 can bus wiring controller wiring Connections, Low, High, and Ground as per fig. -

Page 14: Networking Controls

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 3 .0 networking controls For connection to the building automation system (ba s), the pump needs to be properly configured to the network. -

Page 15: Modbus Ip & Rtu

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s 3 .1 modbus ip & rtu function code change... - Page 16 & Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s function code change start modbus # of data read...

- Page 17 Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s function code change start modbus # of data read...

-

Page 18: Bacnet Ip & Ms/ Tp

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 3 . 2 BACnet ip & ms/ tp object id object name... -

Page 19: Operation

Does not cover any damages to the equipment resulting from the suction piping. energize the motor momentarily and failure to observe the above precautions. Refer to Armstrong check that the rotation corresponds with the directional ar- General Terms and Warranty sheet. Contact your local row on the pump casing (clockwise when viewed from non- Armstrong representative for full information. -

Page 20: Auto Flow Balancing

Check rotation arrow prior to operating the unit. The rotation of all Armstrong 4 20 0H & 4 28 0 Vertical In-Line units is clockwise when viewed from behind the motor (nde). important:... -

Page 21: Touch Screen

Design Envelope 4312 and 4392 vertical in-line install a tio n & twin pumping unit with ivs drive oper ating instr uctio n s 4 .3 touch screen 4 .3 . 2 logout 4 .3 .1 login Default Password 1234 1234 4 .3 .3 about... -

Page 22: General Settings

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 4 .3 . 4 gener al settings save save... -

Page 23: Manual/Auto Mode

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s 4 .3 .5 manual /auto mode... -

Page 24: Pump Control

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 4 .3 .6 pump control Activate Energy Performance Bundle... - Page 25 Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s Single...

- Page 26 & Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s Pressure Sensor Control Pump is now setup for Pressure...

-

Page 27: Alarms & Warnings

Design Envelope 4312 and 4392 vertical in-line install a tio n & twin pumping unit with ivs drive oper ating instr uctio n s Pump is now setup for 2 Sensor Control Pump is now setup for Bypass Valve Control 4 .3 .7 alarms &... -

Page 28: Trend-Graph

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 4 .3 .8 trend-gr aph There are 3 parameters that can be trended on the touch screen interface: •... -

Page 29: Touch Screen Calibration

Design Envelope 4312 and 4392 vertical in-line install a tio n & twin pumping unit with ivs drive oper ating instr uctio n s 4 .3 .10 touch screen calibr ation If you are having issues with the touch screen, including: •... -

Page 30: Data Logging

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 4 .3 .11 data logging Data logs can be used for energy performance analyses or to troubleshoot system issues. The data logs can be used with a building automation system (ba s) or for each standalone pump. -

Page 31: Web Interface

Design Envelope 4312 and 4392 vertical in-line insta l l a t io n & twin pumping unit with ivs drive op er atin g instr u ct io n s 4 . 4 web interface To access the control modes: Press settings ... -

Page 32: Design Envelope Flow Readout Tolerance

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 5 .0 control modes 4 .5 design envelope flow readout toler ance 5 .1 constant flow... -

Page 33: Quadratic Curve Control With

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s 5 . 4 quadr atic curve control 5 .6 quadr atic curve control with... -

Page 34: Embedded Parallel Sensorless

Ensure that only the first and last terminating resistor switch- Parallel Sensorless Pump Control (pspc) pre-programmed in es are set to Enabled (towards the en label for the canbus the controls at Armstrong factories. For all other models (ex- port). cept twin pumps), pspc can be enabled aftermarket; please contact your local Armstrong factory for details. -

Page 35: 100% Capacity Split Units

5 .11 alternation indicator and that filter cartridges are replaced as recom- mended. (See Armstrong files 43 . 85 and 43 . 86 for seal Design Envelope Tango, dualARM, and Twin units are pre- environmental instructions). set to alternate lead-pump operation of each pump head to achieve equal run hours. -

Page 36: Mechanical Seal

If mechanical seal environmental accessories are installed, ensure water is flowing through the sight flow indicator and that filter cartridges are replaced as recom- mended. (See Armstrong files 43 . 85 and 43 . 86 for seal environmental instructions). caution... -

Page 37: Mechanical Seal Replacement Instructions For 4392 Close Coupled Vertical In-Line Pump

Design Envelope 4312 and 4392 vertical in-line in sta l l a t io n & twin pumping unit with ivs drive o pera t ing instr uct io n s c Remove the mechanical seal rotating assembly (8) shaft collar; the rotating assembly may be levered and raised-up in that manner. - Page 38 & Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s tions, File No. 6042.25, for removal of the motor shaft spring holder sleeve).

-

Page 39: Warnings And Alarms

One or more of the parameters to control the vsd are not correct. Check the settings on the control card. If the alarm persists after cycling power to the pump, contact an Armstrong Technical Service representative. vsd startup An error occurred during the startup of the motor. -

Page 40: Warning Summary For Interfaces

The voltage into the vsd is out of range. Verify that the correct voltage required to operate the voltage vsd is present by measuring each of the 3 phases. If the warning persists, contact an Armstrong Technical Service representative. Internal vsd An internal voltage generated by vsd is out of range. -

Page 41: Fuse And Wire Recommendation

Design Envelope 4312 and 4392 vertical in-line install a tio n & twin pumping unit with ivs drive oper ating instr uctio n s 8.0 fuse and wire recommendation table 1: ul fuses, 20 0 -240v ul compliance fuses frequency... -

Page 42: Pump Manager

& Design Envelope 4312 and 4392 vertical in-line twin pumping unit with ivs drive o p era t i n g i n stru ction s 9.0 pump manager cloud smart Connect router to cloud...

Need help?

Do you have a question about the Design Envelope 4312 and is the answer not in the manual?

Questions and answers