Summary of Contents for Kalvis Kalvis-100MG

- Page 1 SOLID FUEL WATER HEATING BOILER WITH PELLET BURNER KALVIS - 100 MG ... - 500 MG INSTALLATION AND SERVICE MANUAL ГОСТ 20548-87 ГОСТ 20548-93 LST EN 303-5:2012 Made in Lithuania Изготовлено в Литве Made in Lithuania...

- Page 3 - 3 - Dear Buyer, Thank you for selecting KALVIS product. Please read through this manual carefully, paying especial attention at the safety precautions given on the starting pages. Be sure to preserve this manual to be able to use it in future or pass to the next users.

-

Page 4: Table Of Contents

- 4 - CONTENTS 1. Intended use ..........................5 2. Safety requirements ........................5 3. General remarks .......................... 7 4. Product description........................8 4.1. Technical specifications ......................8 4.2. Design ............................ 8 5. Boiler installaton ......................... 11 5.1. Smoke discharge system ..................... 12 5.2. -

Page 5: Intended Use

- 5 - Intended use Central heating boiler with pellet burner Kalvis-100 MG... Kalvis-500 MG (the boiler) is used to heat various premises where central heating system with forced circulation is installed. Automatic mechanisms for heat exchanger cleaning, sooth and ash removal are installed in the boiler. - Page 6 - 6 - Boiler putting out when stoking. Boiler has to be stopped for service maintenance or stoking brake by stopping burner operation. Emergency extinguishing out. Operating personnel has to stop the boiler immediately in the case of triggered emergency alarm or noticing the following emergency situations as it is provided for in the valid legislation of the country where the boiler is operated: •...

-

Page 7: General Remarks

Low grade pellets reduce boiler efficiency, fuel consumption grows, fuel slags, making boiler maintenance difficult, burner has to be cleaned more often. It is strictly forbidden to pour water into hearth or onto burner. This can damage the boiler irreparably. KALVIS-100MG ... -500MG 2019.03.18... -

Page 8: Product Description

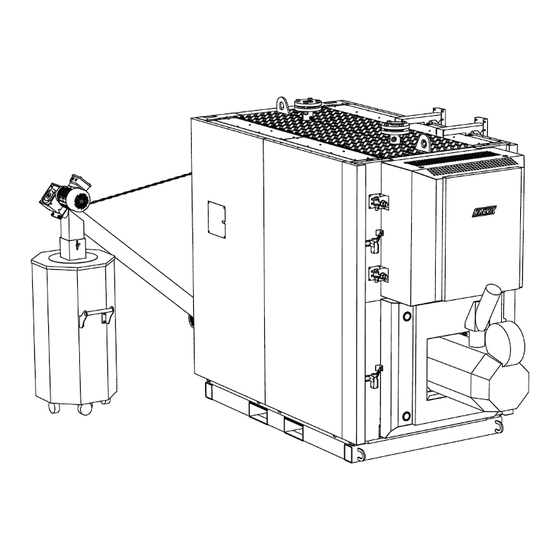

- 8 - Product description 4.1. Technical specifications Table 1 Boiler model Kalvis-100MG Kalvis-130MG Kalvis-150MG Kalvis-200MG Nominal power (Q Minimum power (Q UNI-MAX UNI-MAX UNI-MAX UNI-MAX Burner model 100 kW 150 kW 150 kW 200 kW Control unit PLUM ecoMAX850P1-O... - Page 9 Flue pipe branch pipe is attached to one of the holes, selecting the direction, the remaining two holes are covered with sooth removal lids. In the boilers Kalvis-300MG ...-500MG, burner UNI-MAX 500 kW ... 300 kW is installed on rails (see fig. 3).

- Page 10 - 10 - Fig. 1. Boiler construction Fig. 2. External elements of the boiler. 1. Boiler body. 2. Emergency thermostat temperature sensor mounting location. 3. Outflowing water branch pipe. 4. Installation location of water temperature measuring devices. 5. Pipe heat exchanger with rotary turbulizers. 6. Thermal insulation cover.

-

Page 11: Boiler Installaton

Put the boiler in the intended place on even non-combustible floor capable to withstand safe boiler operation. In the boilers Kalvis-300MG ... -500MG, burner UNI-MAX 300 kW ... 500 kW is mounted on rails in front of hearth door (see fig. 3). -

Page 12: Smoke Discharge System

- 12 - 5.1. Smoke discharge system Requirements: As the boiler has high rates of efficiency, aerodynamic resistance gets larger and smoke temperature gets lower, the chimney draught has to be higher than for the boilers with lower technical rate. Flue pipe and chimney have to meet the following requirements (see fig. -

Page 13: Connecting To Heating System

Before installation or cleaning of the burner, make sure that its power cable is disconnected! Fig. 6. Connection of draught measurement tube. When installing the control panel on the other side of the boiler, turn the blind with T-valve to the opposite side of the boiler. KALVIS-100MG ... -500MG 2019.03.18... -

Page 14: Boiler Commissioning

- 14 - 5.4. Boiler commissioning • After the boiler is connected to the heating and smoke discharge system, the person who did the work has to transfer the completed works to the customer and sign the following documents: − Pipeline and boiler hydraulic test report; −... -

Page 15: Stoking

• Periodically check the state of ash container. Lift the lid of ash removal container connection duct and check how full is the container. Do not overfill the ash container. • Burner cleaning intensity depends on type and quality of the fuel. IT IS FORBIDDEN to discharge untreated condensate into sewage! KALVIS-100MG ... -500MG 2019.03.18... - Page 16 - 16 - Fig. 7. Lubrication of the heat exchanger cleaning mechanism. In order to check the state of heat exchanger cleaning mechanism, take off its protective cover. To do so, pull forward its bottom part (1, see fig. 7), then lift up (2) to disjoin; by unscrewing the screws take away the remaining part of the lid (3).

-

Page 17: Boiler Equipment Servicing Periodicity

* See fig. Burner control unit PLUM ecoMAX850P2-O (or KEY RK-2006LPGP2) for Pellet Boilers Installation, Maintenance, Service and Operation Manual. IT IS FORBIDDEN: To fill the system with cold water when the boiler is hot. To extinguish the boiler by pouring water into the hearth or burner. KALVIS-100MG ... -500MG 2019.03.18... -

Page 18: Transportation And Storing

Recovery actions must comply with the laws and rules of the user country. 10. Acceptance certificate Central heating boiler with pellet burner “Kalvis-...MG” complies with the drawings, LST EN 303-5 standard requirements and is fit for operation. Boiler was tested with 6,0 bar (0,6MPa) pressure. -

Page 19: Scope Of Supply

5. Ash removal conveyor fastening chain - 1 pc. 6. Documents: 6.1. Boiler „Kalvis - 100 MG.. Kalvis - 500 MG“ technical specification - 1 pc. 6.2. Technical specification. Low pressure boiler “KALVIS - ....MG” 6.3. Boiler with burner control panel KVS-K100...500MG user manual - 1 pc. -

Page 20: Sales Note

Sold by: Company: Date of sales: Address: Telephone: In the case of malfunction we recommend the following contacts: Company: Address: Telephone: Manufacturer Kalvis UAB Pramonės 15, LT-78137 Šiauliai, Lithuania Telephone: +370-671-88891 E-mail: prekyba@kalvis.lt Guarantee service registration: Telephone: +370-672-61000 E-mail: garantinis@kalvis.lt...

Need help?

Do you have a question about the Kalvis-100MG and is the answer not in the manual?

Questions and answers