Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for sitrex SM/230

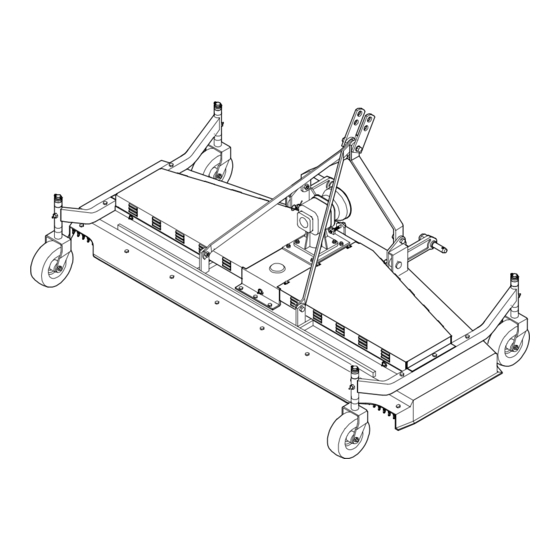

- Page 1 ASSEMBLY, USE AND MAINTENANCE SPARE PARTS LIST FINISHING MOWERS SM/230 01/07...

- Page 2 WARRANTY On delivery, check that the machine has not been damaged during transport and that all the attachments are present. Claims must be made in writing to the agent within 8 days of receipt. The manufacturer warrants new machinery at the time of delivery to the original purchaser to be free from defects in material and workmanship if properly set up and operated in accordance with this Operator’s Manual.

- Page 3 1) GUIDE TO THE SIGNS AND SYMBOLS USED ON THE MACHINE IMPORTANT These signs and symbols give information to the operator on how to make the best use of the machine so as to prolong life, avoid damage, optimise work and, above all, to avoid injury to the operator and anyone within range of the machine.

- Page 4 6) Indicates that there is a risk of cutting one’s hand. Keep your distance. 7) Warns the danger of cutting blade. 8) Generic danger. 9) Indicates that it is dangerous to touch the cardan (P.T.O.) shaft. For all the other information regarding the cardan shaft, see the use and maintenance booklet specifically for the cardan shaft which, together with this manual, makes up the documentation on safety, use and...

- Page 5 INDICATION SIGNS 13) This indicates to check the oil level. 14) This indicates to check the belts tension. 15) This indicates the cap oil level. 16) Indicates a greasing points. 17) Shows the direction of rotation of the power takeoff and the maximum number of revolutions.

- Page 6 GENERAL SUMMARY SAFETY ACCIDENT PREVENTION INSTRUCTIONS Read all the directions carefully before using the machine. When in doubt, seek advice from the manufacturers. The manufacturing company declines all responsibility for non-compliance with the following safety and accident-prevention instructions. Pay attention to the danger signs and symbols in this manual and on the machine. Do not touch moving parts.

- Page 7 Take maximum care when connecting and disconnecting the machine to and from the tractor. The machine and any road transport attachments must bear the appropriate signs and symbols and have suitable protection. Never leave the driving seat when the tractor is running. It is extremely important to appreciate that road holding, steering and braking may be significantly affected with the machine attached.

- Page 8 Only use the Cardan shaft provided by the manufacturer and, in case of replacement, substitute it with one having the same characteristics. Regularly check all protection on the Cardan shaft. This should always be in excellent condition and securely fixed. It is important to ensure that the protection on the Cardan shaft is complete.

- Page 9 1" to 4" - 25 to 100 mm Number of blades Blade RPM 2630 Standard PTO RPM PTO Tractor requirement 30 to 60 HP Weight 685 LBS - 310 KG All data are indicative. Sitrex reserves the right to change them without advance notice.

- Page 10 Voir dessin 8 page 4 See drawing 4 page 3 Voir dessin 4 page 3 See drawing 13 page 5 Voir dessin 13 page 5 Sitrex decal Etiquette commerciale See drawing 7 page 4 Voir dessin 7 page 4 See drawing 16 page 5...

- Page 11 4) DELIVERY AND ASSEMBLY CHECKING THE MACHINE ON DELIVERY All parts are carefully checked before dispatch or delivery. On receiving the machine, ensure that it not been damaged during transport. If damage has occurred, contact the dealer concerned. How the machine is lifted will depend on the model and the type of packing.

- Page 12 Notes : 1) Slightly different packaging from those represented may occasionally be used, depending on the methods of transport or handling. 2) The packing consist mainly of wood which should be disposed of according to the laws in force in the country where the machine is used. The plastic film should also be disposed of according to the laws in force in the country where the machine is used.

- Page 13 The contents of item 8 (bag) are as follows : Shim ø30-40x2 - 1,18"-1,57"x0,08" Q.ty 4 Flat washer ø8,5 Q.ty 2 Shim ø30-40x6 - 1,18"-1,57"x0,24" Q.ty 4 Flat washer ø12,5 Q.ty 4 Shim ø30-40x12 - 1,18"-1,57"x0,47" Q.ty 4 Spring washer ø13 Q.ty 4 Shim ø30-40x25 - 1,18"-1,57"x0,98"...

- Page 14 ASSEMBLY Assembly is highly dangerous and must be carried out in strict accordance with the following instructions. We recommend that assembly be performed by qualified personnel. We also recommend that assembly be carried out in a flat, open area with no people (particularly children) nearby who could be severely injured if they were to touch or move any parts of the machine.

- Page 15 STEP “C” The order of assembly for spacers 2-3- 4-5-6 depends on the cutting height you wish to obtain (see pg.21). A standard assembly is described in this step. Add spacers 2-3 to the wheel assemblies 1 and then insert the entire assembly in the axle seats 7.

- Page 16 STEP “E” SPECIAL MODELS For the assembly of the front version of the mower, the preceding steps apply. Here we describe briefly what is different. Fasten brackets 1 and counter plates 2 to part “A” of the machine body using screws 3, washers 4 and nuts 5. Insert pin 6 into bracket 1 and fasten with split pins 7.

- Page 17 5) ADJUSTMENT,PREPARATION AND USE INTRODUCTION Connection to the tractor is highly dangerous. Take great care and carry out the entire operation in strict compliance with the following instructions. Nobody should go near the area between the tractor and the machine. Check that all warning and danger signs are in place and legible.

- Page 18 2 (see Fig. A-F). Connect the lifting arm 3 to the pins 4 of the machine and fasten with the split pins 5 (see Fig. B-C-D-F-G). Connect the tie-rod (or hydraulic cylinder) 6 to the 3 point hitch and fasten with the pin 7 and the split pin 8. Hitch 11 has two holes 12-13 to fit the variety of connecting tie-rods pins.

- Page 19 TRANSPORT INSTRUCTIONS FOR FINISHING MOWERS Once the machine is attached to the tractor, before proceeding with the transport check to make sure all attachment pins are fully inserted in place and correctly fastened with the fastening pins. For transport, the machine must be raised by the tractor power-lift. If when raised the position reached is not satisfactory, adjust the power-lift adjustment rods 1-2.

- Page 20 USE IN THE FIELD Once the machine is prepared, before beginning work read the chapter on “General Instructions for Use in the Field” (see pg.27) PRELIMINARY CHECK Check that, depending on which is the case, the rotation direction “A” (counterclockwise – standard) or “B” (clockwise) of the PTO of gearbox 1 matches that of the tractor PTO 2.

- Page 21 USE IN THE FIELD – PRELIMINARY ADJUSTING ADJUSTING THE CUTTING HEIGHT To adjust the cutting height in regard to the height of the grass to be mowed, spacers 1-2-3- 4-5 must be suitably placed above and/or below the axle bushings 7 (see Fig. A-B). By suitably combining spacers 1-2-3-4-5, a minimum cutting height of about 20 mm - 3/4”...

- Page 22 USE IN THE FIELD – PRELIMINARY ADJUSTING ADJUSTMENT OF THE UPPER FLOATING HITCH With the mower and tractor standing on a flat, level surface, adjust the upper floating hitch 9 (see Fig. A-E) so that it is in the middle position “G” between the farthest frontward “H” and farthest rearward “I”...

- Page 23 ADJUSTING THE BELT TENSION The tension of the belts 5 is set correctly by the manufacturer, but the tension must be checked periodically according to the time schedule given on pg..29, and reset to the proper tension if necessary. This check is very important, because belts that are too loose or too tight wear out quickly and impair the performance of the mower.

- Page 24 Over ø356 FOR THE SM/120-150-180-230 MOWERS SEE THE K-C-E VALUES IN THE FOLLOWING TABLE. MOWER C mm/inches E mm/inches SM/120 422 - 16,6" 12,5 - 0,49" SM/150-SM/230 522 - 20,6" 15,5 - 0,61" SM/180 622 - 24,5" 18,5 - 0,73"...

- Page 25 INSTRUCTIONS ON HOW TO CHANGE THE BELTS The replacement of the belts 5 must be done using maximum caution, and always with the tractor shut off and the cardan shaft disconnected. First the protective covers 1-2 must be removed by unscrewing the screws at points A-B. Next, loosen the nuts 3 that fasten the slide-reduction unit-pulley assembly 4.

- Page 26 INSTRUCTIONS FOR REPLACING THE BLADES The replacement of the blades 3 must be done using maximum caution, and always with the tractor shut off and the cardan shaft disconnected. Raise the mower body to the maximum height possible with the tractor power-lift so as to allow you to work properly on the underneath part of the mower.

- Page 27 TEMPORARY PARKING 1) Choose a flat, hard open space away from frequented areas if possible. 2) Switch off the engine, leaving the tractor in gear. 3) Apply the parking brake and remove the ignition key. 4) Put the parking stand in the parking position. 5) Turn the angle adjustment crank so that the weight of the machine is on the parking stand, thus avoiding the risk of having the machine tip over backwards.

- Page 28 6) MAINTENANCE DIRECTIONS All cleaning, lubrication and maintenance operation must be carried out with the machine disconnected from the tractor. In an emergency with the machine still connected to the tractor, switch off the engine, apply the parking brake, disengage the power takeoff and remove the ignition key from the instrument panel.

- Page 29 MAINTENANCE POINTS ITEM Q.ty DESCRIPTION OPERATION EVERY NOTES HOURS BLADE HUBS LUBRICATE Grease NLGI 2 WHEEL SUPPORTS LUBRICATE Grease NLGI 2 GEARBOX 50/500 SEE NOTE A PTO SHAFT CLEAN SEE NOTE B ARM LINKAGE PINS CLEAN SEE NOTE C WHEELS (only CHECK INFLATE TO 35...

- Page 30 NOTE A: The first oil change must be done after 50 hours working time and then after 400-500 hours of work. Keep in mind that intense and continuous working conditions will necessitate more frequent oil changes and periodic checks. It is a good practice to check the oil level every 50-60 hours of work.

- Page 32 GENERAL INSTRUCTIONS FOR REPAIR WORK Any repair work must be carried out with the machine at rest and disconnected from the tractor. Do not carry out welding without authorisation and instructions from the manufacturers. Disconnect the machine from the tractor before any welding work in order not to damage the battery.

- Page 33 NOISE AND VIBRATION Noise affecting the tractor driver (from the machine only) is less than 80dB. Vibration from the machine affecting the upper body and limbs of the driver is insignificant and is lower than the values given in Point 3.6.3 of Enclosure 1 of the Machine Directives (89/392/EEC, 91/386/EEC) THE FOLLOWING SHOULD BE NOTED IF THE MACHINE IS SCRAPPED...

- Page 35 TABLE PART NO 910.065 ITEM Q.ty PART NO DESCRIPTION NOTE 110.062 COMPLETE HOOD 110.070 WHEEL AXLE 100.147 WHEEL SUPPORT 100.136 BELT COVER, RH 100.137 BELT COVER, LH 100.135 GEARBOX SUPPORT 100.126 SLIDING 100.273 ** GEARBOX 100.037 TIE ROD 100.038 3rd POINT HITCH 100.062 SPACER 100.041...

- Page 37 TABLE PART NO 910.065 ITEM Q.ty PART NO DESCRIPTION NOTE 600.335 WASHER ø25 600.296 NUT M24x2 600.347 SPLIT PIN ø5x50 600.746 NUT M18x1,5 600.034 GREASE NIPPLE M8 600.124 GREASE NIPPLE M6 600.116 LINCH PIN ø8 600.165 WHEEL 620.647 BELT XPB 2800 600.019 CLIP ø3 600.158...

- Page 38 120/L COMPLETE HOOD COFFRE COMPLET 100.085 150/L COMPLETE HOOD COFFRE COMPLET 100.086 180/L HITCH ATTELAGE 100.079 SM/120-150-180 HITCH ATTELAGE 100.317 SM/230 COUNTERPLATE CONTRE-PLATE 100.080 SM/120-150-180 COUNTERPLATE CONTRE-PLATE 100.330 SM/230 SCREW (M12x70) VIS (M12x70) 600.210 SM/120-150-180 SCREW (M12x80) VIS (M12x80) 600.390...

- Page 39 NOTE WHEEL AXLE ESSIEU ROUE 100.932 SM/150 P WHEEL AXLE ESSIEU ROUE 100.931 SM/180 P WHEEL AXLE ESSIEU ROUE 100.721 SM/230 P WHEEL AXLE ESSIEU ROUE 100.285 SM/150 L WHEEL AXLE ESSIEU ROUE 100.284 SM/180 L SUPPORT SUPPORT 100.297 HITCH ATTELAGE 100.298...

- Page 40 SOLID WHEEL KIT / KIT ROUES SOLIDE...

- Page 41 WHEEL AXLE ESSIEU ROUE 110.069 SM/150 P WHEEL AXLE ESSIEU ROUE 100.699 SM/180 P WHEEL AXLE ESSIEU ROUE 110.070 SM/230 P WHEEL AXLE ESSIEU ROUE 100.207 SM/120 L WHEEL AXLE ESSIEU ROUE 100.208 SM/150 L WHEEL AXLE ESSIEU ROUE 100.209...

- Page 43 TABLE PART NO.910.066 SOLID WHEEL SUPPORT AND ACCESORIES-GROUPE ROUES SOLIDE ET ACCESSORIES (SM/120-150-180=100.578/SM/230=110.030) ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE WHEEL SUPPORT SUPPORT DE ROUE 100.020 120-150-180 WHEEL SUPPORT SUPPORT DE ROUE 100.047 SM/230 P SHIM EPAISSEUR 100.006 SPACER ENTRETOISE 100.008...

- Page 44 TABLE PART NO 910.059 PNEUMATIC WHHEL ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE BEARING 6005 Z PALIER 6005 Z 610.867 PNEU PENEU 610.321 TUBE CHAMBRE AD AIRE 610.315 CIRCLE 610.468 GREASE NIPPLE M6 GRAISSEUR M6 600.124 SPACER ENTRETOISE 100.350 COMPLETE PNEU WHEEL ROUE PNEU COMPLETE 610.434 SOLID WHEEL...

- Page 45 MULCHING KIT TABLE PART NO 910.067 ITEM DESCRIPTION DESCRIPTION Q.ty PART NO RH CONVEYOR CONVOYEUR DROITE 100.739 LH CONVEYOR CONVOYEUR GAUCHE 100.740 BLADE LAME 100.358 NUT M16x1,5 ECROU M16x1,5 610.701 SCREW M10x25 VIS M10x25 600.006 WASHER ø10,5 RONDELLE ø10,5 600.322 NUT M10-DIN980 ECROU M10-DIN980 600.029...

- Page 46 * OPTIONAL TABLE PART NO 910.057 ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE SUPPORT SUPPORT 100.258 SM/120-150-180 SUPPORT SUPPORT 100.263 SM/230 SPACER ENTRETOISE 100.259 SM/120-150-180 SPACER ENTRETOISE 100.504 230/P ROLLER ROULEAU 100.260 SM/120-150-180 ROLLER ROULEAU 100.505 SM/230 SCREW (M12x160) VIS (M12x160) 600.807 SM/120-150-180...

- Page 47 GEARBOX / MULTIPLIER PART NO 100.273 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7 100.272 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.268 PTO SHAFT ARBRE 600.325 LATCH A10x8x30 CLAVETTE A10x8x30 100.269...

- Page 48 GEARBOX / MULTIPLIER PART NO 100.274 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7 100.272 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.268 PTO SHAFT ARBRE 600.325 LATCH A10x8x30 CLAVETTE A10x8x30 100.276...

- Page 49 GEARBOX / MULTIPLIER PART NO 100.275 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7 100.272 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.279 PTO SHAFT WITH PINION Z14 ARBRE AVEC PINION Z 14 600.325 LATCH A10x8x30...

- Page 50 GEARBOX / MULTIPLIER PART NO 100.299 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 100.303 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.302 PTO SHAFT ARBRE 600.325 LATCH A10x8x30 CLAVETTE A10x8x30 100.269 CROWN Z34 COURONNE Z34 200.274...

- Page 51 GEARBOX / MULTIPLIER PART NO 100.300 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 100.303 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.302 PTO SHAFT ARBRE 600.325 LATCH A10x8x30 CLAVETTE A10x8x30 100.276 CROWN Z19 COURONNE Z19 200.274...

- Page 52 GEARBOX / MULTIPLIER PART NO 100.301 ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE 600.054 SCREW (M10x25) VIS (M10x25) 100.303 COVER BOUCHON 600.345 OR GASCKET JOINT 600.342 BEARING 6007 PALIER 6007 100.314 SHAFT WITH PINION Z14 ARBRE AVEC PINION Z14 600.325 LATCH A10x8x30 CLAVETTE A10x8x30 100.278...

- Page 53 CARDAN SHAFT E3 090 E PART NO 610.014 CARDAN SHAFT/ARBRE A CARDAN Part No. 610.014 Item Part No. Q.ty DESCRIPTION DESCRIPTION Pos. Code 610.071 QUICK RELEASE YOKE 1 3/8" Z6 FOURCHE 610.070 CROSS JOURNAL SET CROISILLION COMPLET 610.072 YOKE WITH OUTER TUBE FOURCHE AVEC TUYAU EXT, 610.073 YOKE WITH INNER TUBE...

- Page 54 CARDAN SHAFT B3 090 B PART NO 610.326 CARDAN SHAFT/ARBRE A CARDAN Part No. 610.326 Item Part No. Q.ty DESCRIPTION DESCRIPTION Pos. Code 610.057 COMPLETE PUSH BUTTON POUSSOIR COMPLET 610.071 YOKE FOURCHE 610.070 CROSS JOURNAL ASS. CROISILLION COMPLET 610.205 CIRCLIP BAGUE 610.206 GREASE NIPPLE...

- Page 56 Zona Industriale-Viale Grecia, 8 06018 TRESTINA-(Perugia)-ITALY Tel. +39.075.8540021-Telefax +39.075.8540523 e-mail: sitrex@sitrex.it www.sitrex.com...

Need help?

Do you have a question about the SM/230 and is the answer not in the manual?

Questions and answers

What length belt for sm230

The length of the belt for the Sitrex SM/230 is not provided in the given context.

This answer is automatically generated

what is the part number for replacement blade on a SM-180