Summary of Contents for ADB L-852D

- Page 1 User ManualUser Manual L-852A-D, J & K ITCF, F- Airfield Lighting Range, ICAO LED Taxiway Product Solutions Catalog Centerline Light FAA and ICAO Taxiway Centerline Lights 96A0460, Rev. C, 6/15/16 www.adb-air.com...

-

Page 2: Disclaimer / Standard Warranty

Storage precautions that must be followed. ADB reserves the right to examine goods upon which a claim is made. Said goods must be presented in the same condition as when the defect therein was discovered. ADB Airfield Solutions furthers reserves the right to require the return of such goods to establish any claim. -

Page 3: Liability

Use this equipment only as described in the manual. ADB cannot be held responsible for injuries or damages resulting from non-standard, unintended uses of its equipment. The equipment is designed and intended only for the purpose described in the manual. -

Page 4: Adb Bvba

This manual could contain technical inaccuracies or typographical errors. ADB BVBA reserves the right to revise this manual from time to time in the contents thereof without obligation of ADB BVBA to notify any person of such revision or change. Details and values given in this manual are average values and have been compiled with care. -

Page 5: Table Of Contents

2.3.4.1 Installation on L-868 Base ..................16 2.3.5 Torquing and Installation Guidance for In-pavement Fixtures ............17 2.3.5.1 Installation on a Shallow Base ..................17 2.4 Maintenance ........................18 2.4.1 L852 A-D ITCF Maintenance ....................18 © ADB Airfield Solutions All Rights Reserved... - Page 6 3.2.1 Use of Ceramic Bolts ...................... 38 3.3 L-867 base can installation (non-load bearing) ................39 3.4 Checking Bolt Torque ......................42 Parts ..................................43 4.1 Part Diagrams and Part Numbers ....................44 4.1.1 ITCF Spare Parts ......................50 © ADB Airfield Solutions All Rights Reserved...

-

Page 7: Safety

1.0 Safety This section contains general safety instructions for installing and using ADB Airfield Solutions equipment. Some safety instructions may not apply to the equipment in this manual. Task- and equipment-specific warnings are included in other sections of this manual where appropriate. -

Page 8: To Use This Equipment Safely

Failure to follow these warnings may cause the fasteners to loosen, damage the equipment, potentially to loosen the equipment. This can lead to a highly dangerous situation of FOD, with potential lethal consequences. © ADB Airfield Solutions All Rights Reserved... -

Page 9: Operation

• Verify that the moving equipment is rated to handle the weight. • When removing equipment from a shipping pallet, carefully balance and secure it using a safety strap. Failure to follow these instructions can result in death, serious injury, or equipment damage. © ADB Airfield Solutions All Rights Reserved... -

Page 10: Action In The Event Of A System Or Component Malfunction

ARC FLASH AND ELECTRIC SHOCK HAZARD Allow only qualified personnel to perform maintenance, troubleshooting, and repair tasks. • Only persons who are properly trained and familiar with ADB Airfield Solutions equipment are permitted to service this equipment. • An open airfield current circuit is capable of generating >5000 Vac and may appear OFF to a meter. -

Page 11: Itcf Led Light

2. Carry out the actions completely and in the given sequence. 2.1.2 Record of changes PAGE DESCRIPTION CHECKED APPROVED DATE Released new manual 12/20/13 Updated manual 8/15/15 update manual, parts, torque 6/16/16 © ADB Airfield Solutions All Rights Reserved... -

Page 12: Introduction

2.2.1.4 Packaging In cardboard box: 7 x 13 x 13 in (17.8 x 33 x 33 cm) • Weight with packing: 15.3 lb (6.94 kg) • Weight without packing: 12.3 lb (5.58 kg) © ADB Airfield Solutions All Rights Reserved... -

Page 13: Electrical Supply

The light fixtures are manufactured in accordance with FAA specification AC 150/5345-46 (current edition), Style 3: ≤ 1/4 in. (6.35mm) height above grade. The ICAO straight and curved fixture is designed to be in compliance with ICAO Annex 14. © ADB Airfield Solutions All Rights Reserved... -

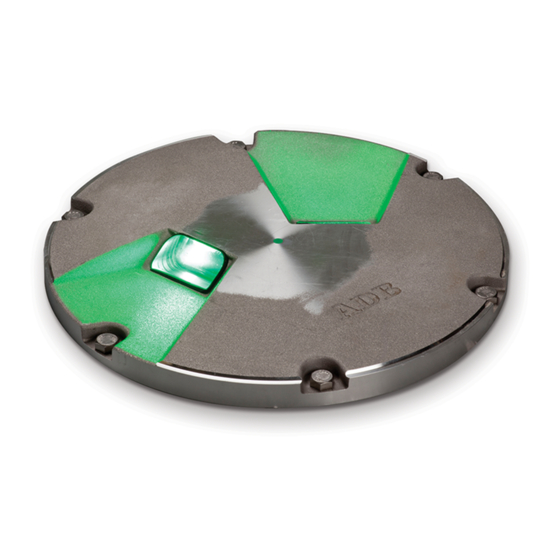

Page 14: Inner Pan Subassembly

R E D = RED 2.2.2.3 Optical Unit L852D & K Figure 3: Optical Unit 48A0443-XXX-XXX for L852D and K 48A0443/ X X X G R N = Green Y L W = Yellow © ADB Airfield Solutions All Rights Reserved... -

Page 15: Installation

6. The fixture hold down bolts must be torqued properly and must not be over torqued. Recommended torque values are given in “Installation on L-868 Base” on page 16. If the torque limit is exceeded (typically due to the use of impact wrenches), the bolt is © ADB Airfield Solutions All Rights Reserved... - Page 16 L-852A-D, J & K ITCF, F-Range, ICAO LED Taxiway Centerline Light 96A0460 Rev. C Installation overstressed and is on its way to failure. After corrosion occurs, removal can cause the head to snap off. The head can then become FOD. © ADB Airfield Solutions All Rights Reserved...

-

Page 17: Electrical Requirements

FAA AC 150/5340-30, Design and Installation Details for Airport Visual Aids, may be downloaded at http://www.faa.gov/airports/resources/advisory_circulars/ ADB Instruction Manuals may be downloaded at: http://www.adb-airfield.com/product_center/products.aspx. Then click on the “In-pavement Lighting” tab and then click on the link for your particular fixture. The manuals are in the “Literature Downloads”... -

Page 18: Installing The Fixture

Provide space for adjustment with spacers, maximum number of spacers shall be 3. 4. Se specific details as shown in FAA AC 150/5340-30 (current edition). © ADB Airfield Solutions All Rights Reserved... -

Page 19: Safety Considerations

Details for Airport Visual Aids, and site plans and specifications for field installation of taxiway in-pavement lights. WARNING Allow only qualified personnel to install ADB Airfield Solutions and auxiliary equipment. Use only approved equipment. Using unapproved equipment in an approved system may void FAA approvals. Observe and follow the safety instructions in this document and all other related documentation. -

Page 20: Snow Plow Ring Assembly

SEE NOTE 1 OF PAGE 5 HBOLT 0.3750-16x1.25x1.25-N 64A0176-20 CEC LOCKWASHER PAIRS S.S 3/8" 2 EA ACC0375 TOP CVR ASSEM., BI-DIR., L-852B 44A6760-X3X0 BOTTOM PAN ASSEMBLY, NO MONITOR, STYLE 6 44A7335-XXXXX 2-PIECE ITCF SNOW PLOW RING 62A2193 © ADB Airfield Solutions All Rights Reserved... - Page 21 NOTE: Per FAA AC 150/5340-30, Chapter 10, and FAA Engineering Brief No 83, it is extremely important that other types of washers, such as split washers, must not be used. Failure to use properly installed anti-vibration lock washers will cause mounting bolts to become loose. © ADB Airfield Solutions All Rights Reserved...

-

Page 22: Installation On L-868 Base

7. Turn on the power to determine whether the LED fixture will illuminate. Operate for a minimum of five minutes. 8. See “Torquing and Installation Guidance for In-pavement Fixtures” on page 17. © ADB Airfield Solutions All Rights Reserved... -

Page 23: Torquing And Installation Guidance For In-Pavement Fixtures

L868B LIGHT BASE 2" PVC CONDUIT W/BELL END L-823 PRIMARY EXTENSION L-823 SECONDARY CONNECTOR L868B JUNCTION HOUSING 3/4" DRAIN HOLE (CENTERED) Earth Ground ISOLATION TRANSFORMER (max 3 per can) 3/4" DRAIN HOLE (CENTERED) (if used) © ADB Airfield Solutions All Rights Reserved... -

Page 24: Maintenance

5. Take the replaced in-pavement fixture unit back to the maintenance shop where it can be serviced fully. NOTE: Never hold the light fixture by the wires. This may damage the insulation, break the waterproof seal, and cause insulation faults and water leakage. © ADB Airfield Solutions All Rights Reserved... -

Page 25: Repair Procedures

Figure 9: Separating Inner Cover from Top Cover W/MON, 1 CDST 7080.90.335 O-RING F-RANGE FIXTURES APPLY SILICONE GREASE 67A0009 TO O-RING ON TOP Screw in center slot COVER ASSEMBLY. © ADB Airfield Solutions All Rights Reserved... -

Page 26: Replacing The Prism

9. See Figure 10. Reinstall hardware with the Phillips pan head screws. Apply a drop of sealant Loctite 270 (or equivalent) to the last threads. Torque to 31 ± 4 inch-pounds (3.5 ± 0.5 N•m). © ADB Airfield Solutions All Rights Reserved... -

Page 27: Replacing A Prism On An L-852 Led Light Assembly

4. Torque to 31 ±4 in-lb (3.5 ±0.5 N•m). 5. Connect the wires to the circuit board as shown in Figure 17. 6. Go to “Installing a New Optical Unit” on page 28 to complete the installation. © ADB Airfield Solutions All Rights Reserved... -

Page 28: Testing An Led Assembly

Figure 13: Diode testing an LED assembly with a Fluke 87 Meter Low meter reading Meter on Diode Test Dim but Glowing LED Correct polarity (forward Bias) red to red, black to black. © ADB Airfield Solutions All Rights Reserved... -

Page 29: Replacing An Led Assembly

3. Position the new LED Assembly, replace screws and tighten. Torque the fixing screws to 31 ± 4 inch-pounds (3.5 ± 0.5 N•m). 4. Connect the LED assembly wires to the power supply for that light. 5. Close the unit. © ADB Airfield Solutions All Rights Reserved... -

Page 30: Replacing The Cord Set

4. Cut the fast-on terminals from the cord set. 5. Pull the cord set out of the inner pan assembly. 6. Bring the new ADB Airfield Solutions cord set through the base pan (one wire per hole). 7. Pull the wires into the pan assembly. -

Page 31: Installing Power Supplies, Heaters, And Thermostats

TWO HEATER ONE THERMOSTAT REFERENCE ONLY WIRING CONFIGURATION BASE AS A GUIDE TO USED WITH ITCF/XXX31X CONFIGURATIONS CONNECTION PATH ONE HEATER ONE THERMOSTAT WIRING CONFIGURATION USED WITH ITCF/A THRU C & J, BI-DIR. 2-CORD © ADB Airfield Solutions All Rights Reserved... - Page 32 L-852A-D, J & K ITCF, F-Range, ICAO LED Taxiway Centerline Light 96A0460 Rev. C Maintenance Figure 18: 1 heater and 1 Thermostat per Side Figure 19: 2 heaters and 1 Thermostat © ADB Airfield Solutions All Rights Reserved...

- Page 33 LIGHT ENGINE W/KEY RESISTOR REBEL LED GREEN-495 SECURE BARRIER 48A0444-GRN-495 LIGHT ENGINE W/KEY RESISTOR REBEL LED GREEN-640 48A0444-GRN-640 LIGHT ENGINE W/KEY RESISTOR REBEL LED AMBER-640 48A0444-YLW-640 TOP COVER ASSY FOR L-852K FOR ASSY WITH ARCTIC KIT SEE SHT 3 © ADB Airfield Solutions All Rights Reserved...

-

Page 34: Installing A New Optical Unit

To close the optical unit: Figure 21: Typical 12" L-852D, BI-Directional., 2 Cordset Assembly Shown BOTTOM PAN ASSEMBLY, SINGLE DRIVER, UNI DIR, NO MON, STYLE 6, 1 CORD 44A7335-11010 BOTTOM PAN ASSEMBLY, DUAL DRIVER, BI- DIR, NO MON, STYLE 6, 2 CORD... -

Page 35: Closing Optical Unit

“Testing for Leaks” on page 30. Make sure the O-ring seal for the pressure release screw is in good condition and reinstall the pressure release screw. Figure 22: Alignment Pin Power Supply Fast-on Connectors Paper Barrier © ADB Airfield Solutions All Rights Reserved... -

Page 36: Testing For Leaks

Lock hose plug sleeve 6. Locate the leak source, depressurize, replace the leaky seal or part, reassemble and repeat the test. 7. If the leak is fixed, depressurize and reinstall the pressure release screw. © ADB Airfield Solutions All Rights Reserved... -

Page 37: Troubleshooting

VOLTAGES ARE MORE LIKELY WHEN A FAULT IS PRESENT. 2.5.1 Troubleshooting Tips This guide covers only the most common problems. For additional help, contact your local ADB Airfield Solutions representative or the ADB service department. Table 3: Troubleshooting Guide Reference “Mechanical... - Page 38 Refer to “Replacing the Cord Set ” on page 24 and fixture • Use care when remounting fixture on the base can to ensure that the wires do not get pinched. © ADB Airfield Solutions All Rights Reserved...

-

Page 39: Installation Guidance For In-Pavement Fixtures

In-pavement fixtures may be installed on one of several types of mounting systems: • Deep base FAA L-868 base cans (Load bearing) • Deep base FAA L-867 base cans (Non-Load bearing) • Shallow base cans © ADB Airfield Solutions All Rights Reserved... -

Page 40: L-868 Base Can Installation (Load Bearing)

Always use a new bolt. Never reuse existing bolts. © ADB Airfield Solutions All Rights Reserved... - Page 41 Always use a new anti-vibration washer. Never reuse an existing anti-vibration washer. Recommended stainless steel anti-vibration washers are: • Heico Part Number HLS-3/8” SS [ADB part number ACC0375] • Nordlock Part Number NL 3/8 SS Insure that the anti-vibration washer is installed properly. An anti-vibration washer consists of two halves.

- Page 42 Do not use the bolts to force the fixture onto the base can. If this happens the threaded hole in the base can be damaged. Torque each bolt to 500 ±10 in-lbs. (56.5 ± 1.1 N·m). Use a manual calibrated torque wrench to tighten the bolt. © ADB Airfield Solutions All Rights Reserved...

- Page 43 6 bolts used with an 8-to-12 inch in-pavement fixture adapter ring. • 4 bolts used on an 8-inch in-pavement fixture. • 2 bolts/2-pins 4 bolts used on an 8-inch fixture. • Snow plow ring used on any fixture. © ADB Airfield Solutions All Rights Reserved...

-

Page 44: Use Of Ceramic Bolts

— Do not torque ceramic bolts to 500 in-lbs. (56.5 N·m). Do not use anti- seize or threadlocking compounds with ceramic bolts. Tighten to the bolt manufacturer’s recommendation. Failure to follow these warnings may result in serious injury or equipment damage. © ADB Airfield Solutions All Rights Reserved... -

Page 45: L-867 Base Can Installation (Non-Load Bearing)

If anti-seize (lubricant) is used on the bolt, the following products are recommended: • Loctite LB 8009™ Heavy Duty Anti-Seize. This is also available in stick form as Loctite LB 8070™ Heavy Duty Anti-Seize Stick © ADB Airfield Solutions All Rights Reserved... - Page 46 Do not use the bolts to force the baseplate or fixture onto the base can. If this happens the threaded hole in the base can be damaged. Torque each in-pavement fixture bolt to 500 ±10 in-lbs. (56.5 ± 1.1 N·m). © ADB Airfield Solutions All Rights Reserved...

- Page 47 6 bolts used on a 12-inch in-pavement fixture. • 6 bolts used on either an 8-to-12 inch in-pavement fixture adapter ring. • All bolts used on an 8-inch fixture mounted in an 8-to-12 inch snow plow ring. © ADB Airfield Solutions All Rights Reserved...

-

Page 48: Checking Bolt Torque

Increase the frequency of bolt torque inspection to insure that no bolts become loose or missing. • Quickly replace/repair the mounting system components, which may include replacing the entire base can. Airport operators must also ensure these maintenance activities are properly documented. © ADB Airfield Solutions All Rights Reserved... -

Page 49: Parts

Notes Notes Color or color options not recognized by the FAA. Not available for L-852J(L) and L-852K(L). Color options not available for L-852B(L), L-852D(L), L-852J(L) Not ETL CertiÀ ed. and L-852K(L). Color or color options not recognized by the FAA. -

Page 50: Part Diagrams And Part Numbers

Part Diagrams and Part Numbers 4.1 Part Diagrams and To order parts, call ADB Airfield Solutions Customer Service or your local representative. Part Numbers This section provides a schematic drawing of each F-Range type, along with a list of part numbers, ordering codes and spare components. - Page 51 Figure 29: Typical 12” L-852D, Bi-Dir., Cordset Assembly Shown L-852A, B & C - LED P.S. 300mA W/O MON 44A6698/7/2 L-852A, B & C - LED P.S. 300mA W/O MON 44A6698/7/2 2 CORDSETS W/O MONITORING 60A3339-3 F-RANGE CORD SET OVERMOLD 44A7387-10 ©...

- Page 52 PCB ASSY, LED PWR SUPPLY 50/60Hz, SINGLE DRIVER, NO MON, FAA / ICAO 44A7228-00101 PCB ASSY, LED PWR SUPPLY 50/60Hz,DUAL DRIVER, NO MON, FAA / ICAO 44A7228-00201 POWER INTERFACE BOARD LEAD LENGTH - 1 44A7273-1 © ADB Airfield Solutions All Rights Reserved...

- Page 53 6-32 PAN HD PHIL W/CAPTURED EXT STAR WASHER TOP CVR ASSEM., BI-DIR., 12" L-852B 44A6760-2220 THRMSTAT, NO-HERM STUD, N.O. C80F-O60F 54A0022-8060 BARRIER IS HELD IN PLACE BY PASSING SCREWS FOR HEATERS THRU BARRIER. THERMOSTAT MAX TORQUE: 6.7 INCH POUNDS. © ADB Airfield Solutions All Rights Reserved...

- Page 54 PRISM F-RNG NARR BM OPT GLASS 44A6760-1120 44A6760-2230 44A6760-2130 44A6760-1230 44A6760-1220 44A6760-1130 NOTE: L-852N is not an ITCF fixture but uses this top cover. 2-piece covers are in blue and are marked with an *. © ADB Airfield Solutions All Rights Reserved...

- Page 55 LOCATION OF SINGLE THERMOSTAT ONE CORD HEATER DISC, 2 LEADS CONFIGURATION 61A0459 ITCF/K10310 SEE NOTE 5 GASKET SLEEVE FRC/FTZ/FTD/FEDD 4071.50.030 PRISM CLAMP O-RING F-RANGE FIXTURES 7080.90.335 4071.50.360 WIDE BEAM LAMP ASSEM., LED 48A0443-YLW-640 © ADB Airfield Solutions All Rights Reserved...

-

Page 56: Itcf Spare Parts

1) for the total amount of equipment in the field. This allows for repairs to be made in the shop. Components that are more likely to need replacement, such as prisms, should be stocked at higher quantities, while PCB assemblies should be stocked in smaller quantities. If you have questions, contact your ADB representative. Table 5: ITCF Parts Part No. - Page 57 ADB Airfield Solutions Email: info@adb-air.com Suite 4 2820 Argentia Rd., Unit #2 110 High Street Mississauga, Ontario L5N 8G4 ADB Airfield Technologies Ltd. China Maidenhead Canada Room 901, 9F, Fang Heng Intl. Plaza Berkshire Tel: +1 (905) 331 6887 Building C, No. 6 Futong East Road,...

- Page 58 ADB Airfield Solutions LLC Leuvensesteenweg 585 977 Gahanna Parkway Columbus, OH 43230 B-1930 Zaventem Belgium Phone: +32 (2) 722.17.11 Tel: +1 (614) 861 1304 info.adb@adb-air.com Fax: +1 (614) 864 2069 www.adb-air.com Web: www.adb-air.com Email: adb-sales.us@adb-air.com © ADB bvba All Rights Reserved www.adb-air.com...

Need help?

Do you have a question about the L-852D and is the answer not in the manual?

Questions and answers