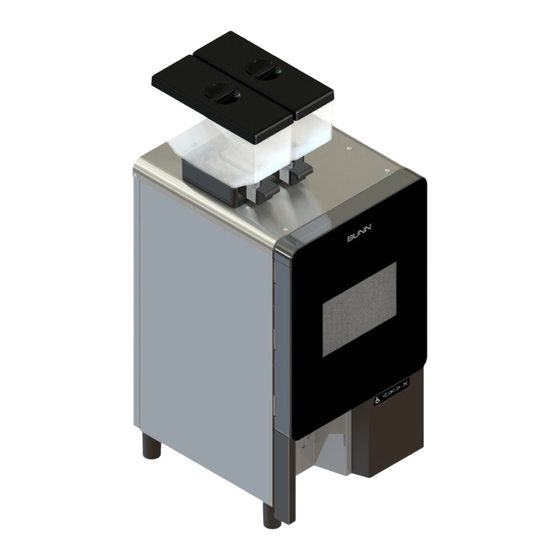

Bunn Sure Immersion 220 Installation & Operating Manual

Hide thumbs

Also See for Sure Immersion 220:

- Programming manual (108 pages) ,

- Installation & operating manual (68 pages) ,

- Daily cleaning instructions (6 pages)

Table of Contents

Advertisement

Sure

Immersion

®

220

INSTALLATION & OPERATING GUIDE

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601

FAX: (217) 529-6644

www.bunn.com

To ensure you have the latest revision of the Operating Manual, Illustrated Parts Catalog, Programming Manual, or Service Manual,

please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog

and manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

53058.0000 D 08/18 © 2016 Bunn-O-Matic Corporation

Advertisement

Table of Contents

Summary of Contents for Bunn Sure Immersion 220

- Page 1 To ensure you have the latest revision of the Operating Manual, Illustrated Parts Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

-

Page 2: Warranty

REPAIR, REPLACEMENT OR REFUND. In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equip- ment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages. -

Page 3: Table Of Contents

Authorized service personnel only. READ THE ENTIRE OPERATING MANUAL BEFORE Disconnect power before servicing. USING THIS PRODUCT 00986.0000M 10/14 ©1994 Bunn-O-Matic Corporation 00986.0000 37881.0000 Warnings • Unplug the machine or turn off the main switch before servicing the interior components of the machine. -

Page 4: North America Requirements

NORTH AMERICAN REQUIREMENTS • This appliance must be installed in locations where it can be overseen by trained personnel. • For proper operation, this appliance must be installed where the temperature is between 41°F to 95°F (5°C to 35°C). • Appliance shall not be tilted more than 10° for safe operation. •... -

Page 5: Site Requirements

25 feet from the 1⁄2" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer to clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. -

Page 6: Electrical Hookup

ELECTRICAL HOOKUP FOR INDOOR USE ONLY Site Requirements 1. Counter able to support at least 200 pounds (90kg). 2. Counter area large enough for machine. 3. Minimum clearance of 2˝ around machine. 4. Machine must be level within 2˚ for proper operation. WARNING - The brewer must be disconnected from the power source until specified in Initial Set-Up. -

Page 7: Initial Setup

INITIAL SET-UP 1. Unpack the drip tray assembly and slide it in between the front legs. Remove taped keys from above drip tray and use them to unlock the front door. (Figure 1). Figure 1 2. Remove the bean hoppers from the packaging, and note the differences;... - Page 8 INITIAL SET-UP - continued 5. Push the hopper locking lever towards the back (Figure 5). This locks the hopper in place and allows beans to flow down- ward to the grinder. 6. Repeat Steps 3 and 4 for Right Hopper. Lock Lever Figure 5 7.

-

Page 9: Filter Paper Installation

FILTER PAPER INSTALLATION Installing Filter Paper 1. Open the door to access the brewing system. 2. On the lower right, turn the paper roll handle to the vertical position (as shown in Figure 8), then pull forward to remove the paper take up roller. - Page 10 FILTER PAPER INSTALLATION - continued 4. With the handle in the vertical position (as shown in Figure 10), slide the roller through the guide, with filter paper engaging the slot in the roller. Figure 10 5. Push the roller in until it engages the roller drive, then turn the handle clockwise to the horizontal position (Figure 11).

- Page 11 FILTER PAPER INSTALLATION - continued 6. Close the door, then press and hold the "BUNN" logo icon (at the top of the screen) for three (3) seconds, to access the "SERVICE ACCESS" screen. 7. In the lower left corner of the "SERVICE ACCESS"...

-

Page 12: Operating Interface

OPERATING INTERFACE NOTE: The machine comes pre-loaded with four (4) recipes; two (2) hot beverage, and two (2) cold beverage. 1. The first screen to appear is a "User" interface screen, also known as the beverage "Carousel". Drink selections viewable are accessed by swip- ing left or right across the screen, or by touch- ing the arrows located on the left and right. - Page 13 OPERATING INTERFACE - continued 4. The next screen shown after "Grinding" is "Immersing" where brew water is added to the ground beans. 5. The next screen after "Immersing", is the "Brewing" screen. The the ground beans and brew water is allowed to sit permitting the fla- vors to bloom.

- Page 14 OPERATING INTERFACE - continued 7. The next screen shown to the user is the "Dis- pensing" screen. The user's selection is now being dispensed. 8. If the "STOP" button has been pressed, the user will be presented with a new screen that indicates that the unit has "Paused"...

-

Page 15: Ada Operating Interface

ADA OPERATING INTERFACE 1. To activate the ADA screen interface, the user must press the accessibility symbol (wheelchair icon). This will cause the screens to be modified with a blue banner at the top and a blue highlight around the item being selected. The left/right arrows will move the blue highlight from one selection to the next. - Page 16 ADA OPERATING INTERFACE 4. Press start. 5. During operation, the following screens will ap- pear in this order: Grinding, Immersing, Brewing, Dispensing. The user can press the "STOP" during this process to cancel this recipe selection. 6. The Stop/Reset is automatically highlighted. The user can cancel and reset by pressing "OK"...

-

Page 17: Optional Cashless Payment System

OPTIONAL CASHLESS PAYMENT SYSTEM 1. Place cup under dispense nozzle. Select cup size. 2. Swipe credit/debit card to start process. 3. Press the “CHECKOUT” button to lock in size 4. Press the “START” button to dispense. selection. 53058.0 071117... -

Page 18: Bar Code Printer

BAR CODE PRINTER SETUP. 1. If the machine is printer capable, and a printer has been connected, the machine must be set up to enable printing. 2. Navigate to the MACHINE SETTINGS screen, and touch the BARCODE PRINTER tab on the left. - Page 19 BAR CODE PRINTER SETUP. b. Use the keypad to enter the barcode ID number for the first barcode you require. c.Hit ENTER, and the ID: fields will be automatically populated with barcodes, starting with the ID number you entered above. d.

- Page 20 BAR CODE PRINTER SETUP. 5. Barcode ID’s can be cleared by touching the Clear Barcode ID’s button in the upper right. 6. Press Yes to clear all barcode ID’s, No to exit the menu. 7. To set the price for a size, press the Price: box for the size to be set.

- Page 21 BAR CODE PRINTER SETUP. 11. The barcode and price settings can be exported by pressing the Export Setting button in the upper right. 12. Insert a USB stick into the USB port on the back side of the front door, then press OK. 13.

- Page 22 BAR CODE PRINTER SETUP. 16. Select any beverage. 17. Verify that the correct price is shown for each size selection. 18. On the service access panel, the last reciept can be printed by pressing the Print Last Receipt button on the lower right. 53058.0071718...

-

Page 23: Filter Paper Removal

The used paper must be removed. 1. To remove the used paper, press and hold the "BUNN" logo icon at the top of the screen for three (3) sec- onds, to access the "SERVICE ACCESS" screen. - Page 24 Removing Spent Filter Paper (Continued) 4. Turn the handle for the paper take-up roller to the vertical position (as shown in Figure 13), then pull the handle away from the machine to remove. Figure 13 5. Remove the used paper roll from the ma- chine (Figure 14), or push it into the grounds bin.

-

Page 25: Service Access - Care And Cleaning

SERVICE ACCESS - Care And Cleaning Care and Cleaning - General Cleaning The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all surfaces on Bunn-O-Matic equipment. Exterior Surfaces: • Do not use any abrasive materials. - Page 26 SERVICE ACCESS - Care And Cleaning - continued Daily - System Rinse Cycle Care and Cleaning - Rinse Selecting the "Rinse" tab from the Care and Cleaning screen will prepare the equipment for rinsing the brew funnel and brew box. Follow the directions shown on the screen.

- Page 27 SERVICE ACCESS - Care And Cleaning - continued Weekly - Care and Cleaning From the "Service Access" screen, press the "Care and Cleaning" button to access the Care and Cleaning screens. Care and Cleaning - Clean Selecting the "Clean" tab from the "Care and Cleaning"...

- Page 28 SERVICE ACCESS - Care And Cleaning - continued Weekly Care and Cleaning - Clean continued Once the "Continue" button has been pressed, the operator will be presented with a new screen indicating that the cleaning process has begun, and to "Please Wait ... Removing Loose Grounds".

- Page 29 SERVICE ACCESS - Care And Cleaning - continued Care and Cleaning - Clean continued Weekly Care and Cleaning - Touch Screen Cleaning With internal cleaning complete, the operator will be prompted with a new screen to "Begin Cleaning Touch Screen", by pressing "Start". Care and Cleaning - Touch Screen Cleaning - continued During the "Touch Screen Cleaning", the system will shown a countdown, indicating time...

-

Page 30: Care And Cleaning - Weekly

Care and Cleaning - Weekly Cleaning Brew Funnel: Removal & Washing The brew funnel can be removed for a more thorough cleaning; this is recommended weekly or more often if required (heavy usage of the machine). 1. Open front door to remove brew funnel. Funnel must be in the upper position to be removed. 2. - Page 31 Care and Cleaning - Weekly Cleaning continued 4. Clean the funnel using any mild, non-abrasive, liquid detergent. Do Not use abrasives to clean as this can damage the surface of the funnel. Rinse and Dry. 5. To reinstall the funnel, tip the top edge of the funnel under the coffee chute, and place the metal pins on the flat springs.

-

Page 32: Service Access - Active Notices

SERVICE ACCESS - ACTIVE NOTICES Active Notices From the "Service Access" screen, press the "Active Notices"" button access Active Notices screens. Active Notices The "Active Notices" screen will display by name & description, any faults that have occurred, and give probable causes, and a solution to clear the fault.

Need help?

Do you have a question about the Sure Immersion 220 and is the answer not in the manual?

Questions and answers

Sure Immersion 220 error message: Bin not detected