Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

2

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone (419) 524.8388

Fax (419) 522.7867

SANDPIPERPUMP.COM

© Copyright 2022 Warren Rupp, Inc.

All rights reserved

3

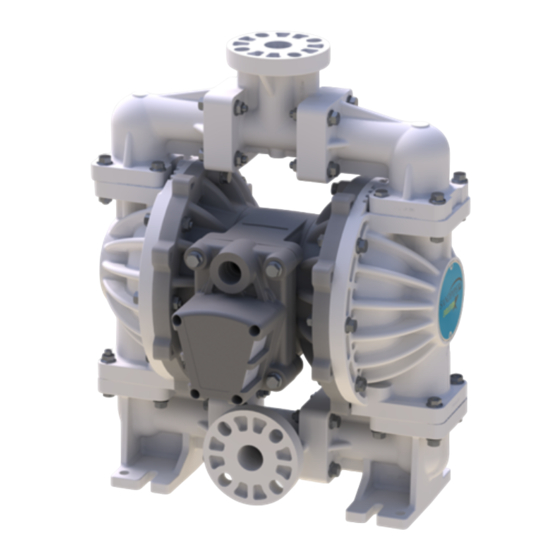

Evolution X

Model SPE10

1" Non-Metallic Pump

Design Level 1

4

s a n d p i p e r p u m p. c o m

TM

5

Advertisement

Table of Contents

Summary of Contents for Sandpiper Evolution X SPE10

- Page 1 SERVICE & OPERATING MANUAL Original Instructions Certified Quality Evolution X Model SPE10 1" Non-Metallic Pump Design Level 1 ISO 9001 Certified ISO 14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone (419) 524.8388 Fax (419) 522.7867 SANDPIPERPUMP.COM...

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. - Page 3 ATEX Compliant Pump Temperature Ratings Table 1. Category 1 & Category 2 ATEX Rated Pumps Ambient Temperature Process Temperature Range Temperature Maximum Surface Range Class Temperature -20°C to +80°C T100°C -20°C to +108°C T135°C -20°C to +60°C -20°C to + 160°C T200°C -20°C to +177°C (225°C) T2...

- Page 4 Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ...5 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......8 •...

-

Page 5: Explanation Of Pump Nomenclature

Type Option Level Brand Line Size Material Position..PUMP BRAND DIAPHRAGM MATERIAL AIR VALVE Nitrile (Buna) SANDPIPER Standard SANDPIPER EPDM AIR VALVE OPTION PRODUCT LINE Hytrel (FDA Compliant) Matched ground sleeve and spool Evoltuion Neoprene EXHAUST OPTION Santoprene PUMP SIZE... - Page 6 Performance SPE10 NON - METALLIC FLUID PORT SIZE MODEL Evolution X Performance Curve • 1" ANSI/DIN Flange Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. AIR INLET PORT 5 (8.5) •...

- Page 7 Air End Kits 476.404.000 Standard; 476.404.379 ATEX Compliant 476.405.000 - Air Seal Kit Item Item Description Description Assembled valve body, includes Air Valve Gasket main & pilot sleeve and spool sets Air Inlet Cap Gasket Bumpers O-Rings, Nitrile Air Valve Gasket O-rings, Main Air Sleeve, Nitrile Air Inlet Cap Gasket 1-FA...

-

Page 8: Dimensional Drawings

Dimensional Drawings SPE10 Non-Metallic Center Ported Options Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm). 13.86 9.09 7.44 12.25 DISCHARGE PORT 5.83 (SEE NOTE 1 AND 2) 15.61 3.63 AIR INLET 3/4 NPT EXHAUST PORT (OPTIONAL) 1" FNPT (SEE NOTE 3) 19.39 15.76... - Page 9 Dimensional Drawings SPE10 Non-Metallic End Ported Option- Polypropylene Wet End Models ONLY Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm). sandpiperpump Model SPE10 Non-Metallic • SPE10nmdl1sm-rev0523...

- Page 10 Pump Operation & Recommended Installation Principle of Pump Operation Air Operated Double Diaphragm (AODD) pumps are powered with compressed air. A directional control valve (1) distributes compressed air to an air chamber while simultaneously exhausting the air from the opposite air chamber directed through the valve, and exhausted to atmosphere through muffler (4) Compressed air exerts uniform pressure (P1) on the inner surface of diaphragm Air Line...

-

Page 11: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). Air valve or intermediate gaskets installed incorrectly. -

Page 12: Material Codes

• Nylatron is a registered tradename of Polymer Corp. impact our products have on the environment. Many components of SANDPIPER® AODD pumps • Gylon is a registered tradename of Garlock, Inc. are made of recyclable materials. We encourage pump users to recycle worn out parts and pumps •... -

Page 13: Center Section Assembly

Center Section Assembly Tools Required • Lineman or standard pilers (air valve repair) • Torque wrench • ½” Socket • Ratchet • 7/32” Hex bit socket • Phillips screwdriver Torque Values • Capscrews (#6)………150 in-lb • Capscrews (#7)………..150 in-lb Center Section Assembly Servicing DETAIL B Step 1. - Page 14 Air / Pilot Valve Assembly Main Air Sleeve and Spool Set 1-AA Step 1. Remove end caps (1-C). Use lineman pilers and rotate end caps 90° counter - clockwise to unlock (disengage locking tabs, see figure below). Then pull the end caps straight out of bore.

-

Page 15: Fluid Section Assembly

Fluid Section Assembly Tools Required • Torque wrench • ½” Socket • Ratchet • ½” box end wrench Torque Values • End ported manifolds (32 & 31) to outer chambers (25)……….100 in-lb • Manifolds (31 & 32) or Elbows (26 & 27) to outer chambers (25)...100 in-lb •... - Page 16 Fluid Section Assembly PORTING NOMENCLATURE ITEM NO. PART NUMBER DESCRIPTION CENTER MATERIAL (See Page 5) 050.028.354 Santoprene 050.028.360 Nitrile Check Ball 050.028.365 Neoprene 050.028.600 PTFE 171.068.115 Capscrew, Flanged Hex Hd, 5/16-18 x 1.75 Stainless Steel Common 171.070.115 Capscrew, Flanged Hex Hd, 5/16-18 x 3 Stainless Steel 196.225.552 Unfilled Polypropylene...

-

Page 17: Diaphragm Assembly

Diaphragm Assembly Tools Required • Torque wrench • ½” Socket • 6 point socket, 1.375” or 35 mm • Ratchet Torque Values • Outer diaphragm plate (18) to inner diaphragm plate (20) ………320 in-lb Step 1. With manifolds and outer chambers removed, remove outer diaphragm plate (18), diaphragm overlay (17), if equipped, diaphragm (16) and inner plate (20) from one side. - Page 18 Dual Port Option Dual Ported Configuration Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm). 3.35 3.13 20.56 DISCHARGE PORT SEE NOTE #1 SLOT 15.76 SUCTION PORT SEE NOTE #1 2.50 4.00 14.37 NOTES SUCTION AND DISCHARGE PORT FLANGES ARE DESIGNED TO FIT BOTH ANSI 125# CONNECTION AND PN10 50mm DIN CONNECTION FOR ALL OTHER DIMENSIONS REFER TO PAGE 8 Dual Porting...

- Page 19 Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. Warren Rupp brands include Warren Rupp ,SANDPIPER ® ® SANDPIPER Signature Series , MARATHON , Porta-Pump , SludgeMaster™ and Tranquilizer ®...

-

Page 20: Ec Declaration Of Conformity

EC Declaration of Conformity Manufacturer: Warren Rupp, Inc. 800 N. Main Street Mansfi eld, Ohio, 44902 USA Certifi es that Air-Operated Double Diaphragm Pump Models: DSB Series, DMF Series, G Series, HDB Series, HDF Series, HP Series, F Series, MS Series, S Series, SL Series, SP Series, SSB Series, T Series, U1F Series, WR Series; High Pressure Pump Models: EH Series, GH Series, SH Series;... -

Page 21: Eu Declaration Of Conformity

ATEX EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc. declares that Air Oper- ated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of Directive 2014/34/EU and applicable harmonized standards. - Page 22 UKEx EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc declares that Air Operated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of United Kingdom Statutory Instruments 2016 No.

Need help?

Do you have a question about the Evolution X SPE10 and is the answer not in the manual?

Questions and answers