Summary of Contents for SUNSTONE CD200DP-A

- Page 1 Sunstone Welders Sunstone Welders Advanced Capacitive Discharge Dual Pulse Welder User Manual : CDDP-A User Manual for Models: CD200DP-A, CD400DP-A, CD600DP-A...

-

Page 2: Table Of Contents

Sunstone Welders User Manual: CDDP-A Table of Contents FORWARD - P.3 Configuration 1 - P.11 CHAPTER 1: WELDER OVERVIEW - P.4 Configuration 2 - P.11 Features - P.4 Configuration 3 - P.12 Applications - P.4 Welder to Hand Held Attachment Setup - P.12 CHAPTER 2: RESISTANCE WELDING - P.5... - Page 3 Thank you for choosing Sunstone Engineering and congratulations on your purchase! You are now the proud owner of a Sunstone Capacitive Discharge (CD) Dual Pulse (DP) Welder. This manual was designed to have you welding safely within minutes of unpacking your new welder.

-

Page 4: Chapter 1: Welder Overview

Extremely fine energy adjustment (0.01ws increments) • Applications Sunstone Capacitive Discharge Welders are used all across the globe for a variety of different welds. Some of the most common uses of our CD Welders include: Battery pack manufacturing and repair •... -

Page 5: Chapter 2: Resistance Welding

This ‘heat-affected zone’ around the weld can suffer from rapid heating and cooling from the weld. But with Sunstone’s proprietary technology, this zone can be localized to just a small spot around the weld. -

Page 6: Weld Formation

Sunstone Welders User Manual: CDDP-A WELD FORMATION Spot welding relies on metal resistivity (resistance) to heat and fuse metal. A large current is passed through the workpiece metal. Energy is dissipated due to metal resistance in the form of heat which melts and fuses the weld materials. -

Page 7: Weld Energy

Pre Setup Information VOLTAGE AND POWER REQUIREMENTS Sunstone Advanced Capacitive Discharge Dual Pulse (CDDP-A) welders are equipped with universal power supplies and can be used with either 110 or 220VAC. No voltage selection is required prior to connecting and powering on the welder. The welder will detect the voltage, and make the appropriate adjustments automatically. -

Page 8: Thermal Protection

Normally Open. THERMAL PROTECTION Sunstone’s capacitive discharge welders are equipped with temperature sensors. If the unit is hot it will warn the user with a pop up. After the unit is cool enough to operate, the welder will go back to normal operation. -

Page 9: Back Panel Connections

Back Panel Connections All DIN connections are displayed as viewed from the back panel. Plug an Ethernet cable into this port if you ETHERNET: desire to control the CDDP-A with a PLC. Used to connect external accessories ACCESSORY: (Coming Soon). FIGURES 9 through 13 show the DIN connectors pin-out, looking at the back panel. -

Page 10: E-Stop

Sunstone Welders User Manual: CDDP-A E-STOP: (MATES TO SD-60LP) Pin 1: GND/Shield Pin 2 & 3: Normally open, ESTOP enabled. Close circuit to disable ESTOP FIGURE 10: E-STOP Connector (SD-60LS) WH CONTROL: (MATES TO SD-40LP) Pin 1: GND/Shield Pin 2: Weld Head Actuation 2. +12VDC(0.5A Max) is sent when weld head needs to actuate. -

Page 11: Negative Weld Terminal

Negative weld terminal. Connect weld cable NEGATIVE (-): using ¼-20 x ¾” bolt and nut. Make sure your total weld cable resistance is greater or equal to 1 milliohm of resistance. Positive weld terminal. Connect weld cable using POSITIVE (+): ¼-20 x ¾”... -

Page 12: Configuration 3

Welder to Hand Held Attachment Setup QUICK START SET UP OF HAND HELD ATTACHMENTS TO CDDP-A WELDERS Sunstone Engineering manufactures a variety of welding hand pieces to accommodate a diverse range of welding applications. Hand piece welding attachments allow ease of use and versatility. -

Page 13: Roll Spot Setup

2a. Single probe, dual probe, and tweezer hand held attachments - Connect the hand held attachment cables to the negative and positive terminals on the back of the welder, then connect the 3 pin actuation foot pedal cable to the back of the welder. 2b. -

Page 14: Chapter 4: Operating Instructions

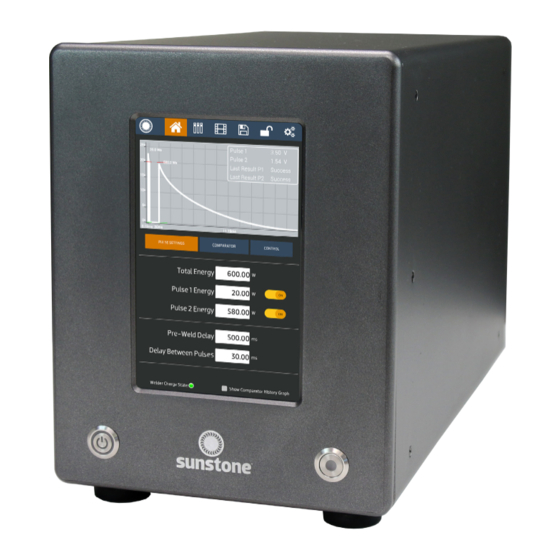

Pulse Control DUAL PULSE WELDING Sunstone dual pulse welders have two pulse width energy controls. Each pulse can be adjusted separately or turned off if desired. Pulse 1 is adjustable between 0.1WS and 30% of Total Stored Energy. Pulse 2 is adjustable between 0.1WS and 100% of Total Stored Energy. In order for Pulse 2 to use all of the Total Stored Energy, Pulse 1 must be disabled. -

Page 15: Timing Diagrams

the total welder energy storage and is also used to set the peak weld current. The pulse energies are then adjusted to provide the appropriate weld energy released during each weld. Timing Diagrams D1: A delay that occurs from the time primary trigger is triggered and the signal to the weld head is sent. - Page 16 Sunstone Welders User Manual: CDDP-A D1: A delay that occurs from the time primary trigger is triggered and the weld ready signal changes to a low value. Typical time for this is between 1 and 50 milliseconds. Pre-Weld: A user defined delay that happens before the signal to the weld head is sent. Can be set between 1 and 10000 milliseconds.

-

Page 17: Automation

D2: A delay set to allow time for the weld head to fully extend. Once the weld has fully descended, the weld discharge will be triggered. This will timeout after 10000 milliseconds. Pulse 1: The duration of this delay is dependent on the energy programmed on welder for pulse 1. Cool: The duration of this delay is dependent on the time programmed on welder for time between pulses. -

Page 18: Maintenance

• User will want to perform this Internal verification at least once a year to ensure that their welder is performing optimally. • Certificate of Calibration • This is a service that Sunstone Engineering can perform. Contact Sunstone Support if desired. Safety Safety Precautions for Mechanical Moving Parts Refer to the user manual included with your weld head or hand piece. -

Page 19: Chapter 5: User Interface

Chapter 5: User Interface Home Screen/Pulse Settings 1. Navigation Bar: Home, Communications, Media, Save/Load, Lock, Settings 2. Waveform display of current energy settings. a. Voltage is displayed on the y-axis, time is displayed on the x-axis b. The green lines indicate the lower limit of the comparator values. -

Page 20: Comparator

Sunstone Welders User Manual: CDDP-A Comparator 1. The Comparator tab within the Home screen. 2. A generated waveform of the previous weld. 3. The user can choose three different types of comparators; voltage, current, and/or power. The green dots will turn red if that type of comparator fails. -

Page 21: 2Nd Comparator

2nd Comparator 1. When this box is checked the histogram will appear instead of the single previous weld result. 2. A histogram of previous weld results. a. It shows the upper and lower limit. b. Shows the median line between upper and lower limit. -

Page 22: Control

Sunstone Welders User Manual: CDDP-A Control 1. Control tab within the main weld screen 2. Weld head is being used 3. Weld head control scheme a. Fully Manual i. Squeeze Time and Hold Time are ignored, because user will bring weld head down manually and also trigger manually. -

Page 23: Basic Plc I/O

Basic PLC I/O 1. PLC tab within communication screen 2. Basic PLC I/O sub tab a. Basic PLC PIN States displays the status of PINS 3-8 on the 8DIN connector i. Inputs are the green squares and Outputs are red squares ii. -

Page 24: Alarms

Sunstone Welders User Manual: CDDP-A Remote Schedule Select 1. Remote Schedule Select sub tab 2. User can enable/disable remote schedule select a. The two input PLC PINS will be automatically assigned to Remote Schedule Select if it is enabled, and they will return to an unassigned stated when it is disabled. -

Page 25: Import/Export

4. Shows the current state of all alarms and warnings. Import/Export 1. Communication Screen 2. Import/Export tab 3. This will export your weld results history to a USB stick. 4. This will clear your weld results history. 5. This will save all your welder settings, including saved settings to a USB stick. -

Page 26: Media Screens

Sunstone Welders User Manual: CDDP-A Media Screen 1. User can view videos of applications, PDF’s, and training videos. 2. Show the different folders where videos are stored. Press any of them to display files within that folder. 3. Button can be pressed to update with latest files. - Page 27 1. Manipulating videos a. Videos can be swiped to the left to delete. b. Files can be rearranged within the folder, or moved to a new folder, by long pressing the file and dragging it to the desired location. 1. This is what the video will look like when viewed. 2.

-

Page 28: Save/Load Screen

Sunstone Welders User Manual: CDDP-A 1. Shows page number of PDF you are currently viewing. User can press the page number to go to a different page number. 2. Allows user to search PDF for keywords. 3. Allows user to scroll through searched keywords. - Page 29 5. Creates a new saved slot with current settings. 6. Load setting that has been selected. 7. Takes the current weld settings and replaces the selected saved weld settings. 8. Deletes the selected weld setting. 1. Save over existing weld pop up a.

-

Page 30: Lock Screen

Sunstone Welders User Manual: CDDP-A Lock screen 1. User has the ability to lock the screen. a. Full lock – Blocks the user from making changes to the welder settings. Users can still cycle through the different screens to view settings and parameters, but no changes can be made. -

Page 31: Settings Screen

User will be prompted for this information. 6. This button will take user to a test suite screen. a. Can only be accessed with a password, contact Sunstone Support if this password is needed. 7. System information is displayed for support... -

Page 32: Settings Screen Pop Ups

Sunstone Welders User Manual: CDDP-A Settings Screen Pop Ups 1. Restore all default settings pop up. a. Click “Yes” to restore defaults and click “No” to not restore defaults and go back to the system settings screen. 1. Clear all memory pop up. - Page 33 1. Sunstone Support may have user go into this screen if diagnostics are needed. a. User can give Sunstone Support the support code. b. Sunstone Support will then give the user a password to get into a diagnostics screen.

-

Page 34: Warnings And Alarm Pop Ups

Sunstone Welders User Manual: CDDP-A Warnings and Alarms (Pop ups) User can define the number of comparator failures in a row in the Alarms page. Once this has been met this pop up will appear. If the electrode is stuck after a weld has occurred, this pop up will appear. - Page 35 If updating the firmware fails this pop up will appear. If the firmware updates this pop up will appear. After you press “Okay” you can go back to normal operation. While the firmware is in the process of updating this pop up will appear. If the welder is having hardware issues this pop up will appear.

- Page 36 Sunstone Welders User Manual: CDDP-A If the welder is in a weld off state and receives a trigger this pop up will appear notifying the user to switch to “Weld On”. Once the number of weld count hits the limit defined by the user in the alarms page this pop up will appear.

- Page 37 If Roll Spot is enabled and user tries to enable comparator this pop up will appear. If a trigger was received from a different source than specified this pop up will appear. If you are trying to export data to a USB drive and the drive is out of memory this pop up will appear.

-

Page 38: Data Tables

Sunstone Welders User Manual: CDDP-A CDDP-A Data Tables WELDER DATA SPECIFICATIONS Cabling between welder and weld head is important in determining peak weld current and adjusting weld pulse timing. Table 1 indicates peak currents that can be expected with 3 to 4 foot sections of these cables. - Page 39 TABLE 3: Sunstone Dual Pulse General Technical Specifications Feature All CDDP-A Welders Single and Dual Pulse Pulse 1 Energy Adjustment (%of set-point energy) 0% - 30% Pulse 2 Energy Adjustment (%of set-point energy) 0% - 100% TABLE 4: Power Specifications...

- Page 40 Sunstone Welders User Manual: CDDP-A SUNSTONE ENGINEERING R&D CORPORATION 1693 American Way Suite #5 Payson, UT 84651 1.877.786.9353 (toll free) +1-801-658-0015 (international) SunstoneWelders.com...

Need help?

Do you have a question about the CD200DP-A and is the answer not in the manual?

Questions and answers