Summary of Contents for SUNSTONE Scout

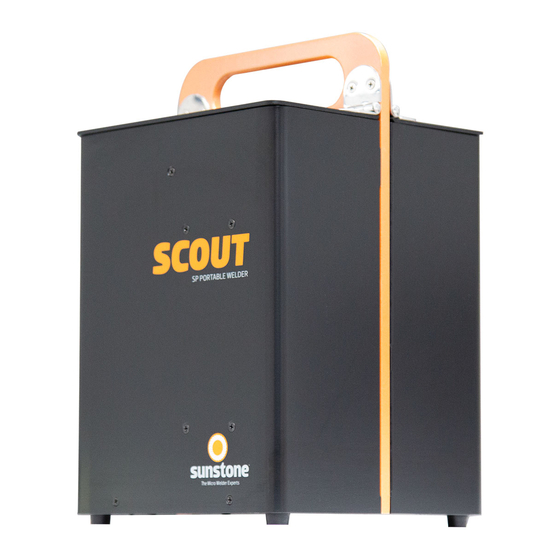

- Page 1 SCOUT SP PORTABLE WELDER Users Guide Version 20200708 • Part #1143 e Micro Welder Experts...

- Page 2 INCIDENTAL, CONSEQUENTIAL, SPECIAL, EXEMPLARY OR PUNITIVE DAMAGES, OF ANY NATURE WHAT- SOEVER, ARISING OUT OF THE USE OF OR INABILITY TO USE ANY SUNSTONE ENGINEERING LLC PROD- UCT, INCLUDING, WITHOUT LIMITATION, PROPERTY DAMAGE, LOSS OF VALUE OF THE SUNSTONE ENGI-...

-

Page 3: Table Of Contents

Table of Contents Chapter 1: Product Overview Chapter 3: Set-up About the Sunstone Scout Attach a Hand piece/Weld Head Common Applications Trigger Cable Features Attaching the Weld Cables Unpacking the Scout Chapter 4: Operation What’s in the Box Controls Overview... -

Page 4: Chapter 1: Product Overview

Chanc- es are you’ll be wearing gloves when using the Scout, so the knobs and switches are built for easy operation. Additionally, as a CD welder, the Scout can perform strong and repeatable welds for high levels of consistency and quality control. -

Page 5: Unpacking The Scout

SP Portable Welder Users Guide SCOUT The Sunstone Scout Single Pulse CD welder provides the following features: • 100 watt seconds (Ws) Available Energy Discharge • Single Pulse Operation • Microprocessor Controlled • Thermal Protection Circuit – Internal Monitoring •... -

Page 6: Chapter 2: Resistance Welding Overview

If that is the case, you may feel the urge to skip Chapter 2. However, even an experienced welder can appreciate the need to occasionally review the science behind the weld. For that reason, Sunstone recom- mends that every operator reads Chapter 2. -

Page 7: How A Spot Weld Is Formed

SP Portable Welder Users Guide SCOUT Figure 4.1. On the micro scale, surface roughness limits surface-to-surface contact. More contact points result in lower contact resistance. How a Spot Weld is Formed Spot welding relies on metal resistivity to heat and fuse metal. A large current is passed through the workpiece metal. -

Page 8: Choosing The Right Electrode Material, Shape, And Diameter

WELD ENERGY The amount of energy discharged has the most influence on weld strength and quality. The Scout can store up to 100 Ws of energy. Operators can adjust the amount of energy stored (weld energy), and fine tune the weld results further by adjusting the amount of stored energy that will be discharged (which is called the weld pulse length) from 0.1% of the stored energy to 100% of the stored energy. -

Page 9: Chapter 3: Set-Up

Sunstone sells a wide variety of hand pieces for any type of application. Visit www.sunstonewelders.com or call or text +1-801-658-0015. TRIGGER CABLE You can configure the Scout to actuate (or release energy and initiate a weld) using any one of the following configurations: •... -

Page 10: Attaching The Weld Cables

ATTACHING THE WELD CABLES Every Sunstone welding attachment comes with weld cables. Refer to each attachment’s users guide for more detailed weld cable set up. Generally speaking, follow these steps to attach the weld cables to the Scout. • Attach one cable to the copper terminal labeled “-“ (located in the storage compartment). See Figure 7.2 below. -

Page 11: Chapter 4: Operation

• Charge. When not in use and you wish to keep the Scout ready for anytime use, flip the toggle to this mode while the unit is connected to a power source. The Scout will recharge only when the Mode Toggle Switch is in the Charge position. - Page 12 Micro Welder Experts Figure 9.1 Scout Control Panel Mode Toggle Swich. Flip Battery. Indicates the Welder Beep. Enables or the switch to Charge when charge strength of the disables an audible beep to charging the battery. Flip the batteries.

-

Page 13: Adjusting The Hand Piece (If Applicable)

Thicker materials and conductive materials require more energy than thin materials and resistive materials. The Scout’s ability to control energy storage and pulse width allows you to manage both the energy released during the welding process and the peak electrical current experienced by the weld material. -

Page 14: Making A Weld (Using A Hand Piece)

The Sunstone Scout is equipped with temperature sensors. If the internal temperature nears the preset maxi- mum (unit is overheating), you’ll hear six successive beeps. You will not be able to weld when the Scout is over- heated. When the unit has cooled, you’ll hear three successive beeps, signifying the unit is ready to weld again. -

Page 15: Chapter 5: Maintenance

• Allow the Scout to charge for six hours to recharge from no charge to full charge. The Scout can be used if the batteries are not fully charged, albeit the number of available welds will be less than those available with a full charge. - Page 16 Do not discard the batteries in a municipal waste facility or bin. The spent batteries can be returned to Sunstone for a discount on replacement batteries or disposed at the nearest recycling/battery collection facility. Contact Sunstone’s customer service team for more information...

-

Page 17: Chapter 6: Troubleshooting

Make sure the Mode Toggle Switch is set to “Weld” Contact the Sunstone customer service team if the Scout will not power on after verifying the two previous troubleshooting measures have been tried but unsuccessful in powering on the unit. - Page 18 e Micro Welder Experts SPECIFICATIONS KEY UNIT SPECIFICATIONS TABLETOP FOOTPRINT (L X W X H) 22.9x22.9x38.1 cm / 9x9x15 inches UNIT WEIGHT 11.4 kg/25 lbs. INPUT VOLTAGE 100-240 VAC FREQUENCY RANGE 50-60 Hz INPUT AC CURRENT 0.7 A OUTPUT 28.6 VDC, 1.04 A, 30 W MAX WELDS PER CHARGE 2,000 at 30 Ws RE-CHARGE TIME...

- Page 19 RECOMMENDED HAND PIECES Single Probe PG1 The PG1 is the smallest single side gun you’ll find in the Sunstone collection of hand pieces. The PG1 includes a built-in switch and can be fitted with a straight or 90-degree tip. The PG1 comes with a 3”...

- Page 20 Precise, Repeatable Control Over Every Aspect of Every Weld! The Sunstone hallmark is precision control find the sweet spot for any welding application. over power delivery details. And the Sunstone The CDDP-A is PLC-enabled and automation CDDP-A line of fine-spot resistance welders is ready for any production floor.

- Page 21 Micro Welder Experts 1693 American Way Ste 5 • Payson UT 84651 USA Tel. +1-801-658-0015 wwww.sunstonewelders.com PART #1143 ©2020 Sunstone Engineering LLC. Safety information subject to change. Sunstone and Orion are trademarks of Sunstone Engineering LLC. 20200708 •...

Need help?

Do you have a question about the Scout and is the answer not in the manual?

Questions and answers