Table of Contents

Advertisement

[Sears !

owners

manual

MODEL NO.

113.298141

SAW ONLY

113.298031

SAW WITH LEGS

TWO TABLE

EXTENSIONS

AND MOTOR

113.298151

SAW WITH LEGS

ONETABLEEXTENSION

AND MOTOR

Serial

Number.

Model and serial

number may be found

at the left-hand

side

of the base.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read

GENERAL

and

ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

IO-INCH

TABLE SA IN

• assembly

• operating

• repair parts

Sold by SEARS,

ROEBUCK

AND

CO.,

Chicago,

IL. 60684

U.S.A.

Part No. 62753

Printed

n U.S.A.

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.298141

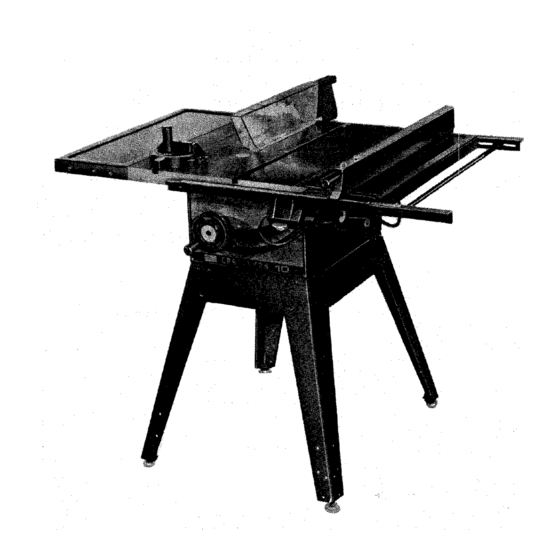

- Page 1 CAUTION: Read GENERAL ADDITIONAL SAFETY INSTRUCTIONS carefully Sold by SEARS, ROEBUCK Part No. 62753 IO-INCH TABLE SA IN • assembly • operating • repair parts CO., Chicago, IL. 60684 U.S.A.

-

Page 2: General Safety Instructions For Power Tools

FULL ONE YEAR WARRANTY If within one year from the date of purchase, this Craftsman Table Saw fails due to a defect in material or workmanship, Sears will repair it, free of charge. WARRANTY SERVICE IS AVAILABLE OR SERVICE CENTER THROUGHOUT This warranty givesyou specific legal rights, and you may also have other rights which vary from state to state. -

Page 3: Safety Instructions

SEE PAGE 23 ADJUSTMENTS... SEE PAGE 29 MAINTENANCE... SEE PAGE STABILITY OF SAW If there is any tendency for the saw to tip over or move durmg certain cutting ooerations extremely large heavy panels or long saw should be bolted down. -

Page 4: Motor Specifications

If power cord is worn or cut, or damaged in any way, have it replaced immediately. VOLTAGE. If your saw is for use on less than 150 volts it has _ l_lug and requlrcs that looks like below. a 15 an"_. or USE ON Catalog No. -

Page 5: Table Of Contents

This plug requires a mating 3-conductor outlet as shown. If the outlet you are planning to use for this saw is of the prong type DO NOT REMOVE GROUNDING PRONG IN ANY MANNER. -

Page 6: Toolsneeded

Loose Parts to make certain all items are accounted for, before discarding any packing material. If any parts are missing, do not attempt table saw, plug in the power cord or turn the switch on until missing parOs are obtained correctly. -

Page 7: Assembly

(approx.dia. of hole5/16 in.) ... Hex Nut, 1/2-13 (approx.dia. of hole1]2 in.) ... FlatWasher(dia. of hole, 11/32 in.) ... Before mounting the saw on legs, a stand or a bench, the Table Insert and Blade Squareness must be checked at this time. INSTALLING... -

Page 8: Checking Blade Squareness To Table

To replace insert. Place insert into insert opening in table and push toward rear of saw to engage spring clip and until keyslot in insert will drop over screw. Tighten screw. Do not tighten screw to the point where it will deflect the insert. -

Page 9: Mounting Saw

4 Lockwashers, 5/16 in. External Type (approx. dia. of hole, 5/16 in.) 8 Flat Washers, (dia. of hole 11/32 in.) 2. Place saw on legs so that holes in bottom of saw line up with holes in top of legs. Install screws, washers, Iockwashers and nuts as shown. -

Page 10: Installing Rip Fence Guide Bars

1 Fence Guide Bar Rod Lay guide bars on sawtable. NOTE: The various holes in the bar allow them to be positioned on this saw and also makes them adaptable to other models. Insert a 1-3/4 in. long screw through... - Page 11 Nold rod with one hand and with a 1/2 in. wrench pliers start screwing on ONE of the nuts only OR TWO... screw on other nut the same way. Using TWO 1/2 in. wrenches or pliers tighten the nuts. 1 I. Slide the bars so that screws are in the MIDDLE slotted...

-

Page 12: Aligning Rip Fence

For very close adjustments, grasp the guide bar with both hands and move the fence with your thumbs. Place fence on saw but DO NOT LOCK IT. Move the REAR END of the fence slightly to the right or left when you release it, the fence should "spring"... -

Page 13: Adjusting Rip Scale Pointer

If the fence does not slide easily along the bars, the pressure of the spring can be REDUCED. 1. Loosen the screws. 2. Move spring slightly toward rear of fence ... screws. The rip fence must be PARALLEL (see page 29) and miter Gauge grooves... until it is along side of groove. -

Page 14: Installing Blade Guard

INSTALLING BLADE GUARD From among the loose parts, find 2 Hex Head Screws, 1/4 - 20 x 5/8 in. long 2 Hex Head Screws, 5/16 - 18 x 5/8 in. long 2 Hex Head Screws, 5/16 - 18 x 1 in. long 2 Hex Nuts, 1/4 - 20 (approx. - Page 15 Raise blade all the way up . .. make sure it is _quare with table. 10. Raise Blade Guard lift up both PAWLS insert one of the SETSCREW in the notches to hold the pawls out of the way, 11. Lay blade of square or other...

-

Page 16: Mounting Th_ Motor

16.Place R IP FENCE on table CAREFULLY move it against blade so that to the blade, and just TOUCHES tips of saw teeth tighten RIP FENCE LOCK KNOB HANDLE. 17. Insert folded paper between FENCE... hold spreader flat against screws using 7/16 in. - Page 17 MOTOR SC REWS. 17. Loosen Pivot Screw slightly. 18. Lower the saw blade all the way down. 19. IMPORTANT; Motor should pivot freely downward as blade is lowered. If it does not, LOOSEN the PIVOT SCREW some more.

-

Page 18: Installing Belt Guard

•.. LONG END of cl p facingAWAY Reinstall ,motor pulley the same way aligned the belt, Place belt SAW'PULLEY through opening in END of guard, Slip belt over motor pulley. BELT GUARD SUPPORT BRACKET threading" SUPPORT BRACKET... -

Page 19: Plugging In Motor

Press guard onto support so that bottom approximately 3/4 in. away from belt. NOTE: remove guard, lift up on cl ps ... pull guard outward. clips should on the BELT GUARD SUPPORT. PLUGGING IN MOTOR From among the loose parts, find two wire ties Route motor... -

Page 20: Getting To Know Your Saw

!n the event this should ever occur, allow the sawblade to come to a complete stop and retighten the arbor nut normally, not excessively, Never leave the saw while the power is "'ON". C. TO turn saw OFF ... -

Page 21: Elevation Handwheel

INSERT. Lower the blade below the table surface. In some Raise blade guard. C. Loosen Screw. D. Lift front of saw. NEVER OPERATE PROPER INSERT IN PLACE. USE THE SAW BLADE INSERT with COMBINATION DADOING OR MOLDING. drill AUXIELIARY FACING "\... -

Page 22: Exacti-Cut

When installing the blade . .. make sure the teeth are pointing toward the front of the saw ... blade and collars are clean, and free from any burrs. The HOLLOW side of the collar must be against the blade. -

Page 23: Basic Saw Operation

11. Do not remove Replace guard become TRAPPED molding RUNNING. HANDS or cause a KICKBACK. Turn the saw OFF. After would increase lift the guard and remove SUPPORT a piece of 3/8 and 3/4 in. plywood. with glue and woodscrews. -

Page 24: Crosscutting

CROSSCUTTING CROSSCUTTING is known as cutting the grain, at 90 °, or square with both the edge and the flat side of the wood, This is done with miter gaugeset at "'O". The graduations on the miter gauge provide accuracy for average woodworking. -

Page 25: Bevel Crosscutting

1. NEVER USE THE RIP FENCE AS A LENGTH BECAUSE CUTOFF PIECE BETWEEN THE FENCE AND THE BLADE CAUSING A KICKBACK, 2. When making repetitive cuts shorter than 6 in., clamp a block of wood 2 in. long to the table to act as a length stop. -

Page 26: Using The Rip Fence

Freouently check the action the ANTIKICKBACK PAWLS passing workpiece spreader while saw is OFF. Pull the workpiece TOWARD you, RIPPING RIPPING is known as cutting a piece grain, or lengthwise. This isdone using the rip fence. - Page 27 When "WIDTH OF RIP" is 2 in. to 6 in, wide USE THE PUSH STICK to feed the work. When WIDTH OF RIP is NARROWER stick CANNOT be used because the guard will interfere. AUXILIARY FENCE_WORK PUSH BLOCK. Attach Auxiliary Fence/Work Support two "'C'"...

-

Page 28: Resawing

BLADE GUARD IMMEDIATELY UPON OF RABBETING OPERATION. also be made using the dado head SAW TABLE _R NUT heat it will be necessary to remove Spreader. CAUTION. PUSH STICKS, BLADE GUARD FINISHED MOLDING. etc. (per... -

Page 29: Adjustments

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH "OFF" REMOVE PLUG FROM POWER SOURCE OUTLET BEFORE MAKING ANY ADJUSTMENTS. MITER GAUGE NOTE: The slots for the stop pin and the graduations are manufactured very close tolerances which accuracy for average woodworking. In some cases where extreme accuracy is required, when making angle cuts, for example, make a trial cut and then recheck it. -

Page 30: Blade Tilt

OUTLET. Raise blade all the way UP... raise blade guard Place the square against blade. Make sure square touching the TIP of one of the saw TEETH. amount to make FRONT TRUNNION TOWARD between in step 4, AWAY from square back of saw. - Page 31 45 ° STOP COLLAR. Place an ACCURATE square sure square is not touching the TIP saw TEETH. If blade is 45 ° to table; Check pointer. If POINTER DOES point to the 45 ° mark scale; Remove Elevation Handwheel.

-

Page 32: Tilt Mechanism

BEFORE MAINTAINING OR LUBRICATING YOUR SAW. Do not allow sawdust to accumulate inside the saw. Frequently blow out any dust that may accumulate inside the saw cabinet and the motor. Frequently clean your cutting tools with Craftsman Gum and Pitch Remover. -

Page 33: Lubrication

9-22208 Sanding Wheel 9-29957 Miter-Gauge Stop Rods ... 9-3217 Miter-Gauge Hold-Down Clamp 9-3218 Taper Jig ... 9-3214 Universal Jig ... Power Tool Know How Handbooks 9-29997 Table Saw 9-2480 CAT. NO. 9-2481 9-3263 9-3257 9-22723 9-29924 9-29928 9-3233 9-3235 9-2918... -

Page 34: Troubleshooting

-- MOTOR 1. Have motor checked by qualified service technician. Repair service is available at your nearest Sears store. 1. Do not use other appliances or motors on same circuit when using the saw. 2. Increase wire sizes, or reduce See "Motor... - Page 35 Motor overheats. Motor overloaded. I mproper cooling. (Air circulation restricted through motor due to sawdust, accumulating inside of saw). 1. Burned switch contacts Starting switch in motor will not (due to extended operate. hold-in periods caused by low line voltage, etc,) 2.

- Page 36 Figure I PARTS LIST FOR CRAFTSMAN 10 INCH TABLE SAW MODEL NO. 113.298141, 113.298031 & 113.298151...

- Page 37 *Screw, Hex, 5/16-18 x 1-3/4 STD 523117 62704 Gauge Assembly, Miter (See Fig. 4) PARTS LIST FOR CRAFTSMAN 10 INCH TABLE SAW MODEL NO. 113.298141, 113.298031 & 113.298151 Always order by Part Number - not by Key Number. FIGURE 1 PARTS LIST Description...

- Page 38 PARTS LIST FOR CRAFTSMAN 10 INCH TABLE SAW MODEL NO. 113.298141, 113.298031 & 113.298151 Figure 2...

- Page 39 Wrench, Hex L 5/32 30628 Screw, Pivot 6423 Washer, Spring STD 551025 *Washer, 17/64 x 47/64 x 1/16 62585 Rod, Spreader Stock Item - May be secured through the Hardware of most Sears Retail Stores or Catalog Order Houses. Department...

- Page 40 PARTS LIST FOR CRAFTSMAN MODEL NO. 113.298141, FIGURE 3 -- 62705 FENCE ASSEMBLY Key { Part 62705 62693 62692 STD 551031 62711 60049 62527 423350 62582 STD 600805 62528 62529 62531 625_3 14 • 62533, STD 551210 STD 611005 62532 * Standard Hardware Item - May Be Purchased Locally.

-

Page 41: Gauge Assembly

PARTS LIST FOR CRAFTSMAN MODEL NO. 113.298141, FIGURE 4 -- 62704 MITER GAUGE ASSEMBLY Part Description 62704 +Gauge Assembly, Miter 62693 Plug, Button 62692 Knob, Miter Gauge (Includes Key No. 1) STD 551031 *Washer, Plain, 21/64 x 1 x 1/16... -

Page 42: Power Outlet

PARTS LJST FOR CRAFTSMAN MODEL NO. 113.298141, FIGURE 6 -- ON/OFF Kevl • Paff- 60381 60375 60380 60256 60374 _i 4 60377 448007 =Does Not Include Kev No. 3 Order Separately If Required. • 10 INCH TABLE SAW 113.298031 & 113.298151... - Page 43 Bag of Loose Parts For Legs (not illust. * Standard Hardware Items • Bag contains all Loose Parts for Extensions. t Stock Item - May be secured through the Hardware Department of most Sears retail stores or catalog order house. 10 INCH TABLE SAW 113.298031 &...

-

Page 44: Repair Parts

PART DESCRIPTION MODEL NUMBER NAME OF ITEM 10-INCH TABLE 113.298141.113.298031 or113.298151 All parts listed may be ordered from any Sears Service Center and most Sears stores. If the parts locally, your order will be electronically Repair Parts Distribution Center for handling.

Need help?

Do you have a question about the 113.298141 and is the answer not in the manual?

Questions and answers