Summary of Contents for Dynamatic EC 2000

- Page 1 EC 2000 Instruction Manual Sturtevant, Wisconsin, USA 53177 Telephone: 262-554-7977 Fax: 262-554-7041 Toll Free: 800-548-2169 www.dynamatic.com sales@dynamatic.com...

-

Page 2: Table Of Contents

Table of Contents Section 1 - THEORY OF OPERATION ......................5 Section 2 - SPECIFICATIONS ......................... 7 2.1 - Features ............................7 2.2 – Power and Load Ratings ........................7 2.3 – Electrical Protection ......................... 7 2.4 – Environmental Ratings ........................8 2.5 –... - Page 3 7.6 – Menu F: Analog Outputs ........................ 31 7.7 – Menu G: Relay Output ........................32 7.8 – Menu H: Units ..........................33 7.9 – Menu J: Potentiomtr Setup ......................34 7.10 – Menu K: Source Select ......................... 34 7.11 – Menu L: Process ........................... 36 7.12 –...

- Page 4 List of Figures Figure 1: Eddy Current Drive & Control Block Diagram ................5 Figure 2: EC 2000 Keypad Display ....................... 6 Figure 3: Standard Panel Dimensions ....................... 12 Figure 4: Keypad Cutout Template ......................13 Figure 5: Keypad Dimensions ........................14 Figure 6: Standard NEMA Rated Enclosure Dimensions ................

-

Page 5: Section 1 - Theory Of Operation

Preset speeds, jog, thread, and external reference inputs are available as standard parameter selections with the EC 2000 control. The EC 2000 uses digital technology to provide a flexible, low noise control for today’s high tech industrial environment. It provides setup and programming via a keypad with a user friendly alphanumeric display;... -

Page 6: Figure 2: Ec 2000 Keypad Display

Figure 2: EC 2000 Keypad Display... -

Page 7: Section 2 - Specifications

Available in panel and NEMA enclosed configurations • Adjustable output voltage from 0 – 90VDC • Up to 8 amps output (see EC 2000 – HP models for higher voltage or current outputs) • Ethernet IP add-on available • Speed (AC tachometer generator or speed pickup) or torque (clutch current) feedback permissible •... -

Page 8: Environmental Ratings

EMI Susceptibility: Complies with IEC 801(1984)-3, class 2. It operates without fault or disturbance under the specified level of radiated EMI (Performance Criteria 1). Enclosures • Available in NEMA Type 1 (Dynamatic Part Number: 015-002000-0300) • Other enclosures available upon request (lead times may vary) Weight •... -

Page 9: Section 3 - Control Operation Modes

SECTION 3 – CONTROL OPERATION MODES Control Modes • Speed (AC Tachometer Generator or Pulse Pickup) • Torque (Current Feedback) • Speed/Torque (switchable) Other Modes of Operation • Local/Remote o Allows the user to switch between keypad use and externally wired devices •... -

Page 10: Section 4 - Inputs/Outputs

SECTION 4 – Inputs/Outputs Analog Inputs • Potentiometer/Reference Voltage o Used for setpoints • Automatic Signal o 0-10V, 0-5V, 4-20mA, 8-40mA o Used for setpoints • Motor Current Feedback (AC) • Speed Feedback Digital Inputs • E-Stop (Normally closed) • Stop (Normally closed) •... -

Page 11: Digital Outputs

Digital Outputs • Run Relay (Normally open) o 2A, 115VAC • Programmable “F” Relay (SPDT) o Speed Mode o Torque Mode o Local Mode o Manual Mode o Auto Mode o Stopped o Stopping o E-Stop o Run o Run 0 o Coasting o Jogging o Fault... -

Page 12: Section 5 - Installation

SECTION 5 – INSTALLATION Figure 3: Standard Panel Dimensions (Not to scale) -

Page 13: Figure 4: Keypad Cutout Template

Figure 4: Keypad Cutout Template (to Scale, Inches) -

Page 14: Figure 5: Keypad Dimensions

Figure 5: Keypad Dimensions (to Scale) -

Page 15: Mounting Hardware

Figure 6: Standard NEMA Rated Enclosure Dimensions (Not to Scale) Mounting Hardware • Standard Panel o ¼” - 20 Bolts, Flat Washers, Lock Washers (Not included) • Standard Enclosure o ¼” - 20 Bolts, Flat Washers, Lock Washers (Not included) •... -

Page 16: Wiring

Wiring • Dynamatic recommends adhering to the National Fire Protection Association’s “NFPA 70: National Electrical Code” codes and standards for proper branch protection, SCCR ratings, and ampacity ratings. o https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes- and-standards/detail?code=70 • Terminal Block Tightening Torque o “TB” : 25 lb-in. -

Page 17: Figure 8: Start/Stop/Jog & E-Stop Wiring

Figure 8: Start/Stop/Jog & E-STOP Wiring Figure 9: Setpoint Reference & Manual/Auto Mode Wiring... -

Page 18: Figure 10: Programmable Analog Outputs Wiring

Figure 10: Programmable Analog Outputs Wiring Figure 11: Current Transformer Wiring for Torque Limiting... -

Page 19: Figure 12: Preset Speeds And Plc Run Wiring

Figure 12: Preset Speeds & PLC Run Wiring Figure 13: Speed Pickup Wiring... -

Page 20: Hardware Setup

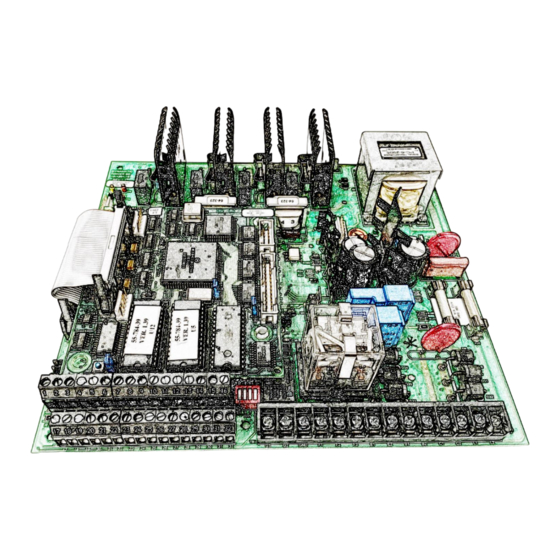

There are several 3 contact male pin headers on the board with a jumper either occupying the center and left pins (position A) or the center and right pins (position B). Below is a list of jumper settings for the EC 2000. All jumpers not listed should be left in the default position. -

Page 21: Table 2: Follower Setpoint Jumper Settings

8 – 40 mA (DC) • To properly utilize motor torque limiting with the EC 2000, the red dip switch “SW1” must be set in conjunction with a current transformer. Below is a table with “SW1” contact configurations with Dynamatic® approved current transformers. -

Page 22: Section 6 - Keypad

SECTION 6 – KEYPAD • The EC 2000 can be either controlled via the keypad or from external pilot device, but initial programming must be done with the keypad. • The keypad is plugged into the “PL2-KEYPAD” male pin header on 15-1200-1. -

Page 23: Section 7 - Programming

SECTION 7 – PROGRAMMING Menu A: Control Setup 1. CONTROL TYPE • Speed (default) o Uses the AC Tachometer Feedback for speed feedback and control. • Torque o Clutch coil voltage is regulated. This is frequently used for take-up or spooler applications where torque is proportional to tension and speed varies with the diameter of the roll. - Page 24 6. TORQ PULSES/REV Sets an alternate pulses per revolution rate (PPR) for applications that use more than one transducer. To enable this rate, enable Menu A. Parameter 18 and close TB2-25. 7. CLUTCH MIN RPM The minimum speed for the clutch. 8.

- Page 25 (Default: 0). 15. SPEED FILTER CLAMP Limits the amount of speed feedback readings done by the EC 2000. This is primarily used for non-standard speed feedback configurations, noise affected configurations, or heavy loads not getting up to speed in a timely manner (Default: 0).

- Page 26 Used to adjust the difference between the actual clutch current (measured with a DC clamp on meter) and the current reading of the EC 2000. If the keypad displayed clutch current is less than measured, increase the percentage, and vice-versa (Default: 100%).

- Page 27 26. CONTRLR BAUD RATE Changes the BAUD rate (how fast data is sent over a serial line) of the control data transfer. • 4800 • 9600 (default) • 19200 • 38400 27. DATA XMIT ENABLE Allows the user to enable or disable data transmission. •...

-

Page 28: Menu B: Clch Performance

Default: 0% 7. ENABLE CURRENT LOOP The EC 2000 has two PID loops (as seen in the previous parameters), speed and current, where the speed PID loop is fed into the current PID loop. This parameter allows the user to disable the current PID loop. -

Page 29: Menu C: Accel/Decel Setup

Allows to user to adjust the brake output (TB1 – B1/B2). Note, the brake will enable when the clutch drops out. For simultaneous clutch and brake output, a “Mutuatrol” modification is required (please consult Dynamatic). 1. Brake Coil Rating Enter the brake current rating found on the nameplate. -

Page 30: Menu E: Follower Setup

If the follower signal is lost or drops below a certain value due to an external failure, the user can program the EC 2000 to run at a specific speed. This parameter allows the user to set the level at which to activate this. -

Page 31: Menu F: Analog Outputs

Menu F: ANALOG OUTPUTS The EC 2000 can output two different analog values based on a variety of statuses or setpoints. Note that for a 4-20mA or 8-40mA output, proper programming and a 500 Ohm resistor should be connected (See Figure 10). -

Page 32: Menu G: Relay Output

Menu G: RELAY OUTPUT 1. F RELAY The F Relay corresponds to TB1- F1/F2/F3 (see Figure 7). Trip ON means the relay is normally deenergized, TRIP OFF means the relay is normally energized. TRIP ON and TRIP OFF have the same options. •... -

Page 33: Menu H: Units

Menu H: UNITS 1. PROCESS UNITS • RPM (default) • PERCENT (used for torque mode) • USER USER can be selected to display speed in something other than RPM. If chosen, Parameters 2-4 are opened for changing. If not, Parameter 1 is the only one that is open. 2. -

Page 34: Menu J: Potentiomtr Setup

Menu J: POTENTIOMTR SETUP The setup menu if an external potentiometer is used for a setpoint reference. 1. POT MINIMUM 2. POT MAXIMUM 3. POT MINIMUM REF 4. POT MAXIMUM REF 7.10 Menu K: SOURCE SELECT The setup menu for run, jog, presets, stop, start, and setpoint reference modes. “TERM” refers to devices attached to TB2, “KEYPAD”... - Page 35 5. PRESET SOURCE Allows the user to change between P1,P2,P3, and P4 on the keypad or through TB2 (see Figure 12). Note: the user changes the programmed presets in “Menu L: PROCESS”. • TERM • KEYPAD 6. PRESET 1 SOURCE Allow the user to change what “P1”...

-

Page 36: Menu L: Process

7.11 Menu L: PROCESS Match minimum and maximum values to previously set values for minimum/maximum speed. 1. MINIMUM PROCESS 2. MAXIMUM PROCESS 3. PRESET 1 The setpoint for “P1”. 4. PRESET 2 5. PRESET 3 6. PRESET 4 7. JOG SETPOINT The setpoint for “JOG”. - Page 37 7. COIL OPEN FLT EN If enabled, the control will fault if there is no detected clutch current when the output voltage is applied. • ENABLE (default) • DISABLE 8. SPD FDBK FLT EN If enabled, the control will fault if there is no detected speed feedback signal (ie AC Tachometer Generator) when the control is trying to run at a set speed.

- Page 38 14. UNDERSP FLT EN If enabled, the control will fault if the speed set by parameter 10: UNDERSPEED TRIP is reached. • ENABLE • DISABLE (default) 15. UNDSPD FLT ACTION • RUN (keeps running if an overspeed occurs) • STOP (stops if an overspeed occurs) 16.

-

Page 39: Menu N: Auto Restart

7.13 Menu N: AUTO RESTART 1. RESTART POWER EN If enabled, the control will start and enter run mode right after power is applied. • ENABLE • DISABLE (default) 2. RESTART FAULT EN If enabled, the control will restart and enter run mode again after a fault. •... -

Page 40: Section 8- Troubleshooting

• Disconnect the clutch coil leads from the EC 2000 (C1 and C2). Try to run the control with a setpoint and measure the DC voltage on the TB1-C1 and C2 (where the clutch coil leads were just connected). -

Page 41: Follower Or Potentiometer Signal Not Changing Setpoint

TB2 connections and placing a jumper between TB2-32 and TB2-29. 8.10 SCREEN IS LIT, BUT NOTHING IS DISPLAYED • Try resetting the EC 2000. If the issues persists, check to see if the keypad cable is inserted correctly or not damaged. 8.11 LOCAL/REMOTE KEY DOES NOT WORK •... -

Page 42: Section 9 - Ethernet Ip And Serial Communications

SECTION 9 – ETHERNET IP AND SERIAL COMMUNICATIONS The latest major change to the EC 2000 is the implementation of serial communications on the EC 2000 control. The capabilities offered are allowing complete control of the EC 2000 thru its serial port along with data acquisition. -

Page 43: Data Acquisition

DATA ACQUISITION Table 6: Ethernet IP/Serial Data Acquisition Item #1 Drive Speed in % 0 to 10000 Item #2 Drive Speed In RPM 0 to Max RPM Item #3 Reference 0 to 10000 Item #4 Set Point 0 to 10000 Item #5 Motor Amps (XFMR) -

Page 44: Section 10 - Index

SECTION 10 – INDEX Item: Page(s) Acceleration/Deceleration 2, 7, 24, 29 Adjustable Braking 7, 10, 20, 22, 29 Analog Inputs 10, 17 Analog Outputs 10, 18, 31 Auto Reference 9, 10, 11, 17, 22, 31, 29, 34, 35, 41, 43 Auto Restart 9, 39 Brake Amps... - Page 45 Select Meter Set Point 9, 10, 11, 22, 30, 31, 32, 34-36, 40-43 Set Point Mode 10, 11, 31, 32 Setup 16-39 Source Select 34-35, 43 Specifications Speed Control 7, 9, 11, 20, 23, 25, 26 Speed Feedback 7, 9, 10, 20, 23, 25, 26, 28, 40, 41 Speed Feedback Scaling 23-26, 40 Speed Range...

- Page 46 International, Inc. claims proprietary rights in the information disclosed hereon. This document is issue in confidence and is not to be reproduced or used to manufacture anything shown hereon without the written permission of Drive Source International, Inc. Drive Source International, Inc. Sturtevant, Wisconsin, USA 53177 Telephone: 262-554-7977 Fax: 262-554-7041 Toll Free: 800-548-2169 www.dynamatic.com sales@dynamatic.com...

Need help?

Do you have a question about the EC 2000 and is the answer not in the manual?

Questions and answers