Table of Contents

Advertisement

Quick Links

2016.03

AIR PLASMA CUTTER

MATCO MA48

PCA48 PFC

OPERATOR'S MANUAL

IMPORTANT: Read this Owner's Manual Completely before attempting to use this

equipment. Save this manual and keep it handy for quick reference. Pay particular

attention to the safety instructions we have provided for your protection. Contact your

distributor if you do not fully understand this manual.

Part # 740.0000

2016-03

Processes

110-240VAC Plasma System

Plasma

.

Advertisement

Table of Contents

Summary of Contents for Matco Tools MA48

- Page 1 2016-03 Processes Plasma 110-240VAC Plasma System AIR PLASMA CUTTER MATCO MA48 PCA48 PFC 2016.03 OPERATOR’S MANUAL IMPORTANT: Read this Owner’s Manual Completely before attempting to use this equipment. Save this manual and keep it handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

-

Page 2: Table Of Contents

CONTENT §1 SAFETY ..........................1 §2 TECHNOLOGY PARAMETERS ................... 3 §2.1 P ........................3 ARAMETERS §3 INSTALLATION ........................4 §3.1 U ........................4 NPACKING 3.2 I ....................4 NPUT POWER CONNECTIONS §3.3 G ......................4 AS CONNECTIONS §4 OPERATION .......................... 5 §4.1 L CUT40 ) ....... -

Page 3: Safety

§1 SAFETY Important Safety Precautions OPERATION AND MAINTENANCE OF PLASMA ARC EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS TO YOUR HEALTH. Plasma arc cutting produces intense electric and magnetic emissions that may interfere with the proper function of cardiac pacemakers, hearing aids, or other electronic health equipment. Persons who work near plasma arc cutting applications should consult their medical health professional and the manufacturer of the health equipment to deter- mine whether a hazard exists. - Page 4 • Wear dry gloves and clothing. Insulate yourself from the work piece and live torch parts. • Repair or replace all worn or damaged parts. • Extra care must be taken when the workplace is moist or damp. • Disconnect power source before performing any service or repairs. •...

-

Page 5: Technology Parameters

§2 Technology Parameters §2.1 Parameters Models PCA48 PFC Parameters Input power 110-220VAC, Single-Phase,50/60Hz 21(220V) Rated input current(A) 31(110V) 4.7(220V) Rated input power(KW) 3.4(110V) 20~40(220V) Adjustment range of current(A) 20~30(110V) Max. no-load voltage (V) 50%(220V) Duty cycle(40℃ @ 10 minutes) 50%(110V) Note: The above parameters are subject to change with the improvement of machines. -

Page 6: Input Power Connections

3.3 Input Power Connections The PCA48 PFC plasma cutting machine features electronic switching power supply allowing it to be connected to any 110-240VAC, 1-Phase LINE power outlet. 208-240VAC LINE CONNECTION: Machine is provided with NEMA 6-50P LINE Service cord to be plugged into any 6-50R outlet with 208-240VAC, single-phase power and 50-amp circuit breaker. -

Page 7: Operation

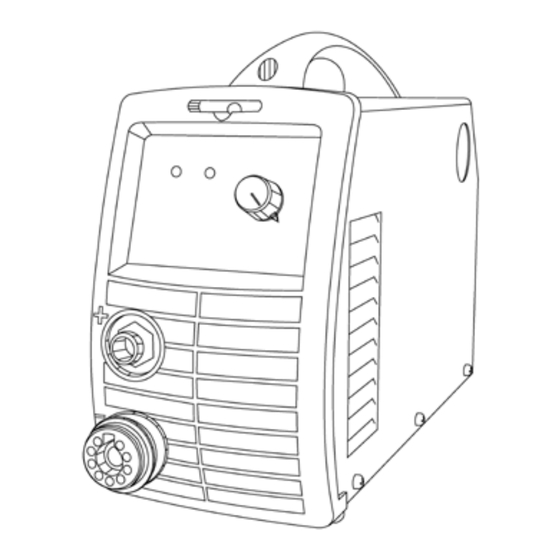

§4 Operation 4.1 Layout of Front and Rear Panel Power pilot LED Illuminates when machine power is switched ON Alarm pilot LED Illuminates when machines exceeds duty-cycle operation (auto reset) Current regulator Allows operator adjustment of output cutting current Earth cable connector Connect earth cable from machine to the work-piece Torch cable connector Connect plasma cutting torch cable to the power source... -

Page 8: Cutting Preparation

4.2 Cutting Preparation 1、Connect the power cable to electrical outlet (the input voltage, refer to the section 3). 2、Connect the air hose to the air supply equipment and set pressure to ~60 psi (4.2 bar). 3、Connect the earth cable to the workpiece not being removed with cut. 4、Make certain operator is wearing proper safety glasses (1.7-6.0 DIN) gloves and protective clothing. -

Page 9: Maintenance

§5 Maintenance 5.1 Cutting Torch Maintenance Plasma cutting torches use ionized air (plasma) as the arc that “melts” the metal and is pushed away by the compressed air. This plasma arc exceeds 50,000°F (28,000°C) when it is pushed through the .030”-.040” (0.8-1.0mm) hole in the berylium copper cutting tip. Considering these extreme temperatures, it is easy to understand the need to replace tips &... -

Page 10: Troubleshooting Principle

5.2 Trouble Shooting Principle WARNING There are extremely dangerous voltage and power levels present inside this unit. Do not attempt to diagnose or repair unless you have had training in power electronics measurement and troubleshooting techniques. A. The cutting torch fails to ignite the arc when torch trigger depressed, DC pilot light on. 1. -

Page 11: Npt48 Plasma Torch Consumables

G. No gas flow with the power lamp ON and fan operating Gas not connected or pressure too low, check gas connections. Adjust gas pressure to proper setting. Faulty components in unit, return for repair or have qualified technician repair. L. -

Page 12: Electrical Principle Drawing

5.4 Electrical principle drawing... - Page 13 5.5 PCA48 Parts Drawing...

Need help?

Do you have a question about the MA48 and is the answer not in the manual?

Questions and answers