Summary of Contents for Hyundai HYC6220

- Page 1 FOR YOUR SAFETY You must read and understand this manual before use. Keep this manual for future reference. Licensed by Hyundai Corporation, Korea...

-

Page 2: Table Of Contents

INDEX CONTENTS PAGE NO.S SAFETY 3 - 8 PART LOCATIONS 9 - 10 ASSEMBLY 11 - 13 QUICK START GUIDE FUEL & OIL STARTING PROCEDURE STOPPING PROCEDURE OPERATING INSTRUCTIONS 21 - 22 MAINTENANCE 23 - 26 TROUBLE SHOOTING STORAGE & TRANSPORTATION RECYCLING AND PRODUCT DISPOSAL 27 - 28 DECLARATION OF CONFORMITY... -

Page 3: Safety

1. SAFETY General Safety Notes. The operator of the machine is responsible for, and has a duty of care in making sure that the machine is operated safely and in accordance with the instructions in this user manual. Keep the manual safe and pass it on if the machine is loaned or sold to another user. - Page 4 1.10 Carbon Monoxide (where applicable). 1.11 Carbon monoxide is a colourless and odourless gas. Inhaling this gas can cause death as well as serious long term health problems such as brain damage. 1.12 The symptoms of carbon monoxide poisoning can include but are not limited to the following;...

- Page 5 1.30 Fueling/De-fueling (where applicable). CAUTION ALL FUELS ARE FLAMABLE 1.31 ALWAYS fuel and defuel in a well ventilated area outside of buildings. 1.32 ALWAYS wear correct, suitable and fit for purpose Personal Protective Equipment (PPE), suggested items are but not limited to safety gloves, overalls. 1.33 When fueling/de-fueling ALWAYS avoid inhaling fumes.

- Page 6 1.50 Batteries (where present). 1.51 Batteries present a risk if they become damaged by the possible leaking of electrolyte. This electrolyte is an acid and can cause serious burn injuries. Care should be taken when working on or near them. NOTE the electrolyte may be in a liquid or gel form.

- Page 7 1.70 Noise (where applicable). 1.71 The operating noise of the machine can damage your hearing. Wear hearing protection such as earplugs or ear defenders to protect your hearing. Long-term and regular users are advised to have hearing checked regularly. Be especially vigilant and cautious when hearing ear protection because your ability to hear alarm warnings will be reduced.

- Page 8 1.93 Make sure you keep this manual handy so you may refer to it whenever questions arise and ensure you pass this manual on if the machine is loaned or sold. 1.94 Correct Personal Protective Equipment (PPE) MUST be worn at all times when operating or repairing this machine.

-

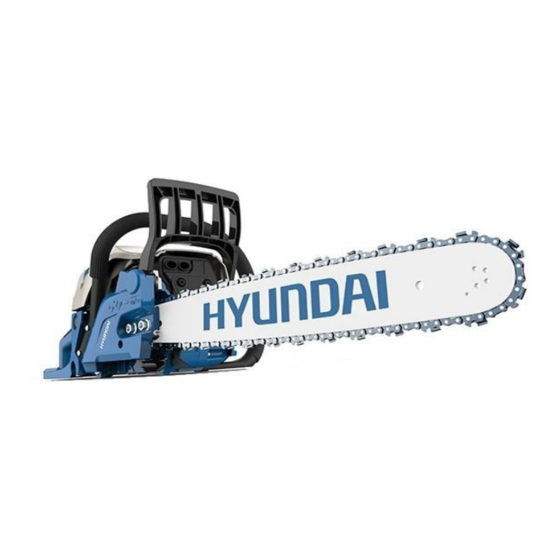

Page 9: Part Locations

2. PART LOCATIONS & SYMBOLS 1. Saw Chain 2. Guide Bar 3. Chain Brake Lever 4. Front Handle 5. Starter Handle 6. Throttle Lock 7. Ignition Switch 8. Fuel Filler Cap 9. Chain Oil Filler 10. Throttle 11. Air Filter Cover 12. - Page 10 Fueling point ‘MIX PETROL’. Located on the fuel tank cap. Chain Oil filling point. Located on chain oil cap. Engine switch operation. Move the switch to the ‘O’ (STOP) position. Located on the rear left of the unit. Choke lever operation. Located on the rear right of the unit.

-

Page 11: Assembly

3. ASSEMBLY CAUTION The saw chain is very sharp and MUST be handled using thick protective gloves. Open the box and check that all parts are present as per the list below. 1. Power Unit 2. Guide Bar 3. Saw Chain 4. - Page 12 assembly continued… Pull the chain guard towards the front handle until you hear an audible click to check the chain brake is disengaged (1). Loosen the nuts and remove the chain sprocket cover (2). Install the bumper spike to the power unit using the 2 screws provided in the tool kit (3).

-

Page 13: Assembly

assembly continued… Fit the chain cover back to the power unit making sure the chain tensioner stud passes through the lower adjustment hole on the guide bar and tighten the nuts finger tight (7). 3.10 While holding the tip of the bar, adjust the chain tension by turning the tensioner screw until the tie straps on the chain just touch the bottom side of the guide bar rail (8 &... -

Page 14: Quick Start Guide

4. QUICK START GUIDE CAUTION This guide is meant to serve as a quick reference for operating your machine. We ALWAYS recommend reading the manual in full before operation. Please consult the manual for the correct oil/fuel mixture and familiarise yourself with all the safety and operation aspects of the chainsaw. -

Page 15: Fuel & Oil

5. FUEL & CHAIN OIL WARNING All fuels are flammable and must be handled and stored correctly. Always ensure there is adequate ventilation when handling fuels. NOTE This machine is equipped with a two stroke engine and must always be run using a mixture of petrol and two stroke oil. -

Page 16: Starting Procedure

6. STARTING PROCEDURE NOTE This machine is shipped without oil, therefore you MUST fill the engine with oil before starting the engine. Failure to do so will result in engine damage which will not be covered by warranty. Fill with a 40:1 ratio of semi-synthetic 2 stroke oil and fresh unleaded petrol. See section 5. - Page 17 Put the engine switch to the ‘I’ ON position. 6.11 6.12 Operate the chain brake by pushing it forward. 6.13 Pull out the choke knob. NOTE Choke only required when starting the machine from cold. Engine Switch 6.14 Press the primer bulb at least 8 times or until the fuel fills the bulb. 6.15 Place the chainsaw on flat ground, free from obstacles and secure by placing your foot thorough the back handle with the chainsaw blade facing away from yourself.

- Page 18 6.17 Press the decompression valve in. NOTE this will need doing every time you try to start the machine from cold and will automatically pop out once the starter handle has been pulled. 6.17 Pull the starter handle swiftly 2 to 4 times or until the engine begins to fire. (NOTE the chainsaw may not start at this stage.

-

Page 19: Stopping Procedure

7. STOPPING PROCEDURE Release the throttle and interlock trigger. Interlock Trigger Throttle Trigger Allow the engine to idle for a few seconds. Move the ignition switch to the ‘O’ OFF position. The engine should now stop. -

Page 20: Operating Instructions

8. OPERATING INSTRUCTIONS The saw chain must be lubricated at all times. Before starting work find a clean area, run the chainsaw at medium power and visually check for oil scatter. The chain oil flow can be altered by inserting a screwdriver in to the hole on the underside of the chain saw and adjusting the oil flow according to your work conditions. - Page 21 carburetor continued… 8.3.1 Stop the engine and allow to cool then screw in both H and L needles until the stop, DO NOT apply excess pressure when doing this. 8.3.2 Then turn them back the initial number of turns shown below; H needle 1 L needle 1 ¼...

- Page 22 saw chain brake continued… 8.4.1 To confirm the inertia chain brake is operating correctly, follow these steps; 8.4.2 Turn OFF the engine. 8.4.3 Holding the chainsaw horizontally, release your hand from the front handle and allow the tip of the chain bar to hit a stump or piece of wood and confirm the brake operation.

-

Page 23: Maintenance

9. MAINTENANCE WARNING Before cleaning, inspecting or repairing your unit, you MUST make sure that the engine has stopped and allowed to cool. You MUST disconnect the spark plug lead to prevent any accidental starting. Maintenance after each use. Air filter. Dust on the air filter must be removed and can be done by gently tapping a corner of the filer on a hard surface. - Page 24 With the guide bar dismounted, remove any saw dust in the bar groove (1) and oiling port. Grease the nose sprocket using the fill port (2) on the tip of the bar. Check for fuel leaks and repair as required. Check for any loose fastenings and tighten as required.

- Page 25 9.17 Sprocket. 9.18 Check for cracks and for excessive wear interfering with the chain drive. 9.19 If wear is obvious, replace with a new one. Never fir a new chain to a worn sprocket, or a worn chain on a new sprocket. 1.

- Page 26 Use the correct size round file (3/16” / 4.76mm) for your chain type (type 21VB). 9.34 9.35 Place your file on the cutter and push straight forward. Keep the file position as illustrated. 9.36 After every cutter has been set, check the depth gauge and file to the proper level as illustrated 1.

-

Page 27: Trouble Shooting

10. TROUBLE SHOOTING PROBLEM PROBABLE CAUSE CORRECTIVE ACTION Water in the fuel or sub- Replace fuel. standard mixture. Remove and dry the spark Engine will not start Engine flooding. plug. Start engine without choke. No or bad spark. Replace spark plug. Water in the fuel or sub- Replace fuel. - Page 28 10.1 You MUST make sure that all unused oil and fuel is disposed of correctly either beforehand or at your local Civic Amenity Site. Under NO circumstances must any fuel or oil be put down any drains. 10.2 Certain products contain WEEE waste which should not be disposed of in your domestic waste.

-

Page 29: Declaration Of Conformity

13. DECLARATION OF CONFORMITY Genpower Ltd confirms that these Hyundai products conform to the following CE Directives. 97/68/EC Non Road Mobile Machinery Directive 2000/14/EC Outdoor Noise Directive 2004/108/EC Electro Magnetic Compatibility Device 2006/42/EC Machinery Directive... -

Page 30: Contact Details

14. CONTACT DETAILS 11.0 POSTAL ADDRESS Genpower Ltd, Isaac Way, London Road, Pembroke Dock, Pembrokeshire. SA72 4RW. UK. 11.1 TELEPHONE +44 (0) 1646 687880 11.2 FAX +44 (0) 0164 686198 11.3 TECHNICAL EMAIL service@genpower.co.uk 11.4 WEBSITE www.hyundaipowerequipment.co.uk MANUAL UPDATES 12.0 Our manuals are constantly being reviewed and updated. - Page 31 NOTES...

Need help?

Do you have a question about the HYC6220 and is the answer not in the manual?

Questions and answers