Summary of Contents for Fromm P325.0001.01

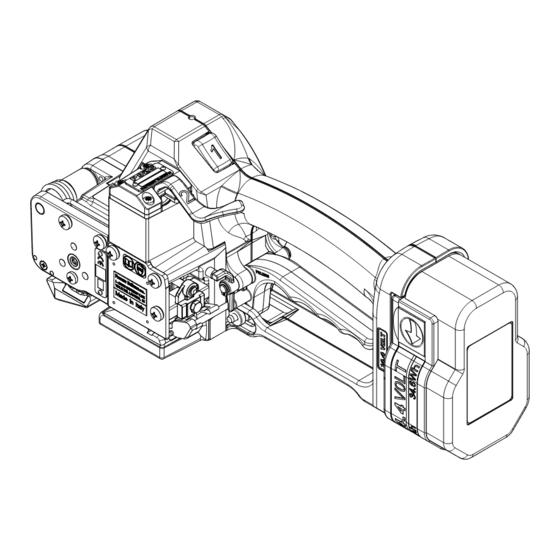

- Page 1 SERVICE MANUAL BATTERY - POWERED PLASTIC STRAPPING TOOL MODEL P325.0001.01 Manual for authorized dealers and service points...

-

Page 2: Table Of Contents

INDEX PAGE ACCESSORIES 5.1.1 Battery ............5-3 5.1.2 Battery chargers . -

Page 3: Accessories

5.1 ACCESSORIES 5.1.1 Battery Use only original Fromm batteries N5.4309 (NiCd) or N5.4316 (NiMH) for the P325 tool. In case of a damaged battery housing, it can be ordered separately under item no. N5.4318. 5.1.2 Battery chargers The battery charger must be ordered separately according to the table mentioned below. -

Page 4: Technical Details

5.2 TECHNICAL DETAILS 5.2.1 Electric schematic black 14,4VDC white 5.2.2 Connecting plan black (-) N5.2359 red (+) red (+) N5.2322 white (-) 5.2.3 Strap tension The tension force values mentioned in the P325 operation manual (600-3500N) are not achievable with each strap. -

Page 5: Conversion Parts P325

5.3 CONVERSION PARTS P325 By converting to an other tool type the following parts must be changed: 43.0701 43.0711 43.0721 43.0722 43.0731 43.0732 43.0733 12.7 X 13 X 16 X 16 X 19 X 19 X 19 X 0.65-1.05 0.65-1.05 0.65-1.05 1.06-1.35 0.40-0.64... -

Page 6: Periodic Maintenance And Control

5.4 PERIODIC MAINTENANCE AND CONTROL (Carry out 12- months cycles doing one shift work. Doing more shift work respectively more often.) 5.4.1 Procedure Before using check tool for following possible faults: • Visual test of the tool for loose, lost or damaged parts •... -

Page 7: Troubleshooting

5.4.2 Troubleshooting Ensure before each tool repair that the battery is charged and the tool’s specific strap is used SYMPTOM CAUSE REMEDY Tool doesn’t work at all Battery is empty or defective Charge or replace battery Contact problems caused by a broken Replace battery housing battery housing N5.4318. - Page 8 SYMPTOM CAUSE REMEDY Tensioning wheel turns Defective needle free wheeling Check parts and replace if necessary back immediately after the N3.4509 in P32.0156 tensioning cycle Tool doesn’t weld Welding gripper P32.1511 is dirty or Replace or clean welding gripper, don’t worn use any hard objects for this (see operation manual P325)

-

Page 9: Battery Test

5.4.3 Battery test The battery should be checked while each maintenance by using the battery tester N7.5127. The use is described in the instruction manual of the battery tester. • NiCd-Batteries 14,4V / (2,4Ah) must be replaced at a capacity less than 70% (1,7 Ah). •... -

Page 10: Lubrication Rules

Additional the screws N1.2112 have to be glued with the idler step P35.0130 using LOCTITE 222. Don’t clamp the planet shaft on the pinion while loosening or tightening the screws N1.2112. Clamp here N1.2112 P35.0130 5.4.6 Lubrication rules All gear parts have to be lubricated with MOLYKOTE BR 2 PLUS grease. Lubrication interval: While each maintenance or after 12 months at the latest. - Page 11 Like imaged the connections of the motor P32.2065 must be adjusted 90° to the sheet P32.2064. The mounting of the sheet happens by fixation of the disk P32.2063 with the screws N1.2216. To adjust the sheet the motor could be placed into the housing. P32.2065 view X P32.2064...

- Page 12 Pay attention to the mounting position of the eccentric (P32.2034). (P325) Eccentric down Adjustment of the lever P32.1414 If the handle lever after welding and cooling of the strap can be pulled up difficult or not at all, the adjustment of the lever P32.1414 must be checked.

- Page 13 Connection of the electronic to the motor In order to prevent a cracking of the terminals on the motor, the connection cables of the electronic are laid with a light bend before soldered to the motor. This method is used for all battery powered plastic strapping tools. 5-13...

-

Page 14: Repair Kit For Electronic P32.2043

5.4.8 Repair kit for electronic P32.2043 The repair kit can be ordered with the article number P32.2075. With the repair kit defective plugs on the connection cables of the electronic can be changed. Procedure: • Cut the cables to a length of 126 mm (see drawing). •... -

Page 15: Recommended Spare Parts

5.5 RECOMMENDED SPARE PARTS Following spare parts are recommended for stock keeping: Item-No. Description Pieces per tool N1.1305 Screw N1.1904 Screw N1.1909 Flat head screw N1.1925 Screw N1.1927 Flat head screw N1.1929 Screw N1.1934 Flat head screw N1.6503 Safety washer N1.6504 Safety washer N1.6505... -

Page 16: Accessory Tools

5.6 ACCESSORY TOOLS Item Description Application number N71.3235 *a,b,c,d,e,f,g Press in and press out arbor N3.4509/P32.2036; N3.4509/P32.2015 N71.3237 *a,b,c,d,e,f,g Press in and press out arbor N3.1159/P32.2016; N3.2356/P35.3211 N71.3239 *a,b,c,d,e,f,g Press in arbor N3.2347/P32.1510 N71.3240 *a,b,c,d,e,f,g Press out arbor N3.2347/P32.1510 N71.3241 *a,b,c,d,e,f,g Press in and press out pressure pad N3.2347/P32.1510... -

Page 17: Use Of Accessory Tools

5.7 USE OF ACCESSORY TOOLS N7.5108 Accessory tools should only be used with the suitable arbor press N7.5108 to prevent a jam of the parts have to be pressed in. Additional a retainer (N7.3215) is necessary. N7.3215 Part Disassembly Assembly N3.1157/ P35.3103 N71.3264... - Page 18 Part Disassembly Assembly N3.2347/ N71.3239 P32.1510 N71.3240 N3.2347 P32.1510 N71.3241 The seal of the needle bushing (N3.2347) has to face to the outside. N3.3172/ P32.2003 N71.3250 P32.2045 N3.3172 P32.2003/45 N3.4509/ P32.2036 N71.3235 N3.4509* P32.2036 N71.3282 *Pay attention to the assembling direction see assembly informations 5-18...

- Page 19 Part Disassembly Assembly N3.3150/ N71.3248 P35.3204 N71.3267 P35.3205 N3.3150 N71.3268 P35.3204/05 P32.1023/ N3.1134/ N71.3243 N71.3244 P32.1022 P32.1022 N3.1134 N71.3245 P32.1023 P32.2016/ N3.1159 N71.3237 N3.1159 P32.2016 N71.3283 5-19...

- Page 20 Part Disassembly Assembly P32.2015/ N3.1137 N71.3286 N3.1137 N71.3285 P32.2015 P32.2018/ N3.4520 N71.3284 N3.4520 N71.3282 P32.2018 P32.2015/ N3.4509 N71.3235 N3.4509 P32.2015 N71.3282 5-20...

-

Page 21: Ordering Spare Parts

"de" (see table). Swedish Finnish Spanish 5.8.2 Ordering address Russian Spare parts and manuals can be ordered at: Czech Fromm Holding AG Tel.: +41(0) 41 741 57 41 Hungarian Hinterbergstrasse 26 Fax: +41(0) 41 741 57 60 CH-6330 Cham e-mail: orders@fromm-pack.com... -

Page 22: Service Address

5.9 SERVICE ADDRESS You will get further assistance and information at: Post address Physical address: Fromm System GmbH Fromm System GmbH Technical customer support Technical customer support Postfach 12 46 Neulandstr. 10 D-77843 Achern D-77855 Achern Germany Germany Phone:+49(0)7841 / 62 94-22 Fax: +49(0)7841 / 62 94-11 e-mail:de@fromm-pack.com... - Page 23 DRAWINGS P325.0001.01 *See 5.8 Ordering spare parts P325.0001.01.en.z...

- Page 24 *See 5.8 Ordering spare parts P325.0001.01.en.z...

- Page 25 *See 5.8 Ordering spare parts P325.0001.01.en.z...

- Page 26 *See 5.8 Ordering spare parts P325.0001.01.en.z...

- Page 27 SPARE PARTS LIST P325 7.1 Type independent spare parts P325.0001.01 Item-No. in group Pcs. Description Dimension Field N1.1305 P32.0157/61/65 2 SCREW M4 X 7.8 N1.1553 P32.1701/P35.0146 1 HEXAGON SCREW M4 X 8 N1.1904 4 SCREW M5 X 20 N1.1909 2 FLAT HEAD SCREW M3 X 5 N1.1922...

- Page 28 Item-No. in group Pcs. Description Dimension Field N2.5296 P32.0157/61/65 1 PRESSURE SPRING 0.5 X 4 X 24/16.5 N2.5822 P32.0157/61/65 1 TORSION SPRING 1.25 X 12/3.75 N2.5823 1 TORSION SPRING 2.8 X 17/4 N31.1118 P32.0158 2 BALL BEARING 10 X 19 X 5 N31.1120 P32.0158 1 BALL BEARING...

- Page 29 Item-No. in group Pcs. Description Dimension Field P32.1029 P32.0157/61/65 1 THRUST PIECE P32.1032 P32.0157/61/65 1 DRIVING PIN P32.1035 P32.0157/61/65 2 DRIVER P32.1050 P32.0157/61/65 1 FRONT TOGGLE LINK P32.1051 P32.0157/61/65 1 LEVER P32.1210 2 CENTERING SLEEVE C11+ P32.1216 1 PRESSURE ROLLER P32.1251 P32.1701/P35.0146 1 COUPLER...

- Page 30 Item-No. in group Pcs. Description Dimension Field P35.3127 P32.0157/61/65 1 STEEL INSERT P35.3128 P32.0157/61/65 1 WELDING STOP GRIPPER P35.3201 3 IDLER GEAR P35.3211 P35.0145 1 END COVER [ ] = Group * = Wearing parts...

- Page 31 7.2 Type dependent spare parts P325.0001.001 43.0701.01 P325/12.7/0.65-1.05 P325.0001.01 07.11.08 Item-No. in group Pcs. Description Dimension Field N2.5237 1 PRESSURE SPRING 0.8 X 4.8 X 25/18.5 P30.1156 2 GUIDE PIN [P32.0139] P32.0161 1 SPRING PACKAGE [P32.0160] P32.0161 1 BODY [P32.0161]...

- Page 32 43.0721.01 P325/16/0.65-1.05 P325.0001.01 07.11.08 Item-No. in group Pcs. Description Dimension Field N2.5237 1 PRESSURE SPRING 0.8 X 4.8 X 25/18.5 [P32.0139] P32.0161 1 SPRING PACKAGE [P32.0160] P32.0161 1 BODY [P32.0161] 1 BASE MODEL A10+ P32.1228 1 HOLDER P32.1229 1 HOLDER P32.1246...

- Page 33 43.0731.01 P325/19/0.40-0.64 P325.0001.01 07.11.08 Item-No. in group Pcs. Description Dimension Field N2.5237 1 PRESSURE SPRING 0.8 X 4.8 X 25/18.5 [P32.0139] P32.0165 1 SPRING PACKAGE [P32.0164] P32.0165 1 BODY [P32.0165] 1 BASE MODEL A10+ P32.1228 1 HOLDER P32.1229 1 HOLDER P32.1403...

- Page 34 43.0733.01 P325/19/1.06-1.35 P325.0001.01 07.11.08 Item-No. in group Pcs. Description Dimension Field N2.5282 1 PRESSURE SPRING 0.8 X 4.8 X 27/17.5 [P32.0146] P32.0157 1 SPRING PACKAGE [P32.0157] 1 BASE MODEL A10+ [P32.0160] P32.0157 1 BODY P32.1723 1 STRAP STOP P32.1910 P32.0146 1 SPRING BOLT P32.2003...

- Page 35 OPERATION MANUAL BATTERY - POWERED PLASTIC STRAPPING TOOL MODEL P325.0001.01...

- Page 36 INDEX PAGE GENERAL SAFETY RULES SAFETY RULES FOR STRAPPING TOOLS TECHNICAL DATA ACCESSORIES Battery ............8-7 Battery - chargers .

-

Page 37: General Safety Rules

GENERAL SAFETY RULES WARNING! Read all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury. The term "power tool" in all of the warnings listed below refers to your mains operated (corded) power tool or battery operated (cordless) power tool. SAVE THESE INSTRUCTIONS. -

Page 38: Power Tool Use And Care

1.4 Power tool use and care a) Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed. b) Do not use the power tool if the switch does not turn it on and off. -

Page 39: Safety Rules For Strapping Tools

Use only cutters designed for strap and never hammers, pliers, hacksaws, axes, etc. 2.6 Environment protection Do not dispose of used batteries in the household refuse, water or by burning them. FROMM distributors offer an environment friendly battery disposal service. P325mane.fm... -

Page 40: Technical Data

TECHNICAL DATA Description of the tool The tool model P325 has been designed to strap packages with plastic strapping. The plastic strapping is fed around the package manually or in combination with a strap feeder. The straps are inserted in the tool, automatically tensioned, sealed by friction welding and separated. -

Page 41: Accessories

ACCESSORIES Use only parts and accessories mentioned in the operating instruction. Using other parts or accessories can cause injuries to you and other persons. Battery Since the tool can be operated with NiCd or NiMH batteries, the battery is not automatically supplied with the tool. -

Page 42: Wearing Plate

Wearing plate In order to protect the P325 when using on packages with hard and rough surface, the tool can be equipped with a wearing plate and a disk for level compensation. The complete wearing plate together with disk and fastening screws can be ordered under item number P32.2031 P32.0171. -

Page 43: Turning Button Kit

For working in alternating positions a turn able suspension bracket with screws and washers can be ordered under item number P32.0137. P32.0137 N1.1904 N1.6503 P32.1307 P32.1310 P35.2069 P35.2073 N2.5623 Mobilux EP2 N1.5105 Turning button kit For a remaining adjustment of tension force and welding time. After exchanging of the turning buttons the adjustment can only be changed with the allen key (2mm) that comes with the kit. -

Page 44: Operating Elements

OPERATING ELEMENTS Tension button LED - Indication Sealing lever Green During tensioning the LED lights green. Green During welding the LED lights green. Yellow Cooling time is running, the tool must not be removed from the strap. Green Cooling time is finished, the tool can be removed from the strap. -

Page 45: Adjustments

Removing the empty battery If the red LED starts lighting while a tensioning or welding procedure, the capacity of the battery is exhausted. All electric functions of the tool are blocked. The seal efficiency is insufficient. Warning! Straps with insufficient seal strength must be removed from the package! The battery must be recharged. -

Page 46: Feeding The Strap Around The Package

Feeding the strap around the package The strapping is fed around the package as illustrated. Warning! The plastic strap which will be welded must be free from oil, grease and other dirt. Dirty plastic straps can't be welded correct! Inserting the strap Pull up the handle lever firmly with your right hand. -

Page 47: Sealing Of The Joint

Sealing of the joint Press sealing lever down until it locks and let it go immediately. The plastic strap is welded and cut off from the rest of the strap. During the welding the LED lights green. After elapsing of the adjusted welding time (see 6.2.2) the cooling time begins (LED lights yellow). -

Page 48: Chart Of Types

CHART OF TYPES Item No. Model Strap width Strap thickness 43.0701 P325/12.7/0.65-1.05 12.7 mm / 1/2" 0.65-1.05 mm / .026 - .041" 43.0711 P325/13/0.65-1.05 13.0 mm 0.65-1.05 mm / .026 - .041" 43.0721 P325/16/0.65-1.05 16 mm / 5/8" 0.65-1.05 mm / .026 - .041" 43.0722 P325/16/1.06-1.35 16 mm / 5/8"... -

Page 49: Exchange Of Wearing Parts

EXCHANGE OF WEARING PARTS Remove always the battery from the tool before starting maintenance works. Exchange of tensioning wheel and grippers Disassembling • Unscrew end cover P35.3211 and remove it; • Remove the torsion spring N2.5823; • Remove the tensioning body; •... -

Page 50: Exchange Of Cutter, Welding Stop Gripper And Welding Gripper

Exchange of cutter, welding stop gripper and welding gripper Disassembling • Unscrew cover P32.2066 and remove it; • Unscrew end cover P35.3211 and remove it; • Remove the torsion spring N2.5823 and the tensioning body; • Remove the tensioning wheel together with the bearing N3.1172 from the tool; •... -

Page 51: Adjustment Of The Coupler

Assembling Assembling in opposite order. Observe the following: Pay attention to the fitting position of the cutter (see drawing). Safe the screws N1.1305 with Loctite 222. Observe the position of the tensioning wheel. The direction of rotation of the tensioning wheel is marked at the front of the tensioning wheel (see 9.1). Lubrication •... -

Page 52: Disposal

12 DISPOSAL The machine, accessories and packaging should be sorted for environmental-friendly recycling. Only for EC countries: Do not dispose of power tools into household waste! According the European Guideline 2002/96/EC for Waste Electrical and Electronic Equipment and its implementation into national right, power tools that are no longer usable must be collected separately and disposed of in an environmentally correct manner.

Need help?

Do you have a question about the P325.0001.01 and is the answer not in the manual?

Questions and answers