Summary of Contents for Beckhoff EL7201-0010

- Page 1 Documentation EL72x1-0010 Servo Motor Terminals with OCT (One Cable Technology) Version: Date: 2015-11-30...

-

Page 3: Product Overview Servomotor Terminal

Product overview Servomotor terminal Product overview Servomotor terminal EL7201-0010 [} 12] Servomotor terminal 50 V with OCT, 2.8 A EL7211-0010 [} 12] Servomotor terminal 50 V with OCT, 4.5 A EL72x1-0010 Version: 2.0... -

Page 4: Table Of Contents

Table of contents Table of contents 1 Product overview Servomotor terminal .................... 3 2 Foreword .............................. 6 Notes on the documentation...................... 6 Safety instructions .......................... 7 Documentation issue status...................... 8 Version identification of EtherCAT devices.................. 8 3 Product overview............................. 12 Introduction ............................. 12 Technical data .......................... - Page 5 Table of contents Modes of operation ........................ 121 6.3.1 Overview ........................... 121 6.3.2 CSV........................... 121 6.3.3 CST........................... 125 6.3.4 CSTCA.......................... 128 6.3.5 CSP........................... 132 Profile MDP 742 or DS 402 ...................... 137 MDP742 process data ......................... 137 DS402 process data ........................ 141 7 EL72x1-0010-DS402 - Object description and parameterization............ 146 Configuration data ........................

-

Page 6: Foreword

The TwinCAT Technology is covered, including but not limited to the following patent applications and patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries. ® EtherCAT is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany Copyright © Beckhoff Automation GmbH & Co. KG, Germany. -

Page 7: Safety Instructions

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG. Personnel qualification This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national standards. -

Page 8: Documentation Issue Status

Associated and synonymous with each revision there is usually a description (ESI, EtherCAT Slave Information) in the form of an XML file, which is available for download from the Beckhoff website. The revision has been applied to the IP20 terminals on the outside since 2014/01, see fig. 1. - Page 9 Identification number Beckhoff EtherCAT devices from the different lines have different kinds of identification numbers: Production lot/batch number/serial number/date code/D number Serial number is the name generally given to the 8-digit number that is printed on the device or attached to it on a sticker.

-

Page 10: Fig. 1 El5021 El Terminal, Standard Ip20 Io Device With Batch Number And Revision Id (Since 2014/01)

Foreword Examples of markings: Fig. 1: EL5021 EL terminal, standard IP20 IO device with batch number and revision ID (since 2014/01) Fig. 2: EK1100 EtherCAT coupler, standard IP20 IO device with batch number Fig. 3: CU2016 switch with batch number Version: 2.0 EL72x1-0010... -

Page 11: Fig. 4 El3202-0020 With Batch Numbers 26131006 And Unique D-Number 204418

Foreword Fig. 4: EL3202-0020 with batch numbers 26131006 and unique D-number 204418 Fig. 5: EP1258-00001 IP67 EtherCAT Box with batch number 22090101 and serial number 158102 Fig. 6: EP1908-0002 IP76 EtherCAT Safety Box with batch number 071201FF and serial number 00346070 Fig. 7: EL2904 IP20 safety terminal with batch number/date code 50110302 and serial number 00331701 EL72x1-0010 Version: 2.0... -

Page 12: Product Overview

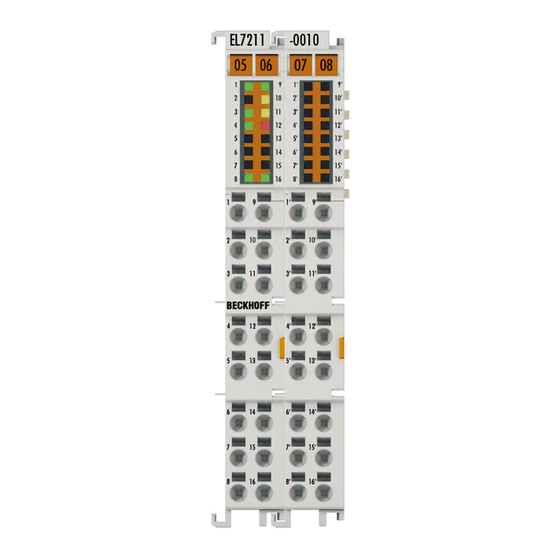

Product overview Product overview Introduction Fig. 8: EL7201 Fig. 9: EL7211 Version: 2.0 EL72x1-0010... - Page 13 The EL72x1-0010 was designed for the motor types of the AM81xx series from Beckhoff Automation. The fast control technology, based on field-orientated current and PI speed control, supports fast and highly dynamic positioning tasks.

-

Page 14: Technical Data

Product overview Technical data Prerequisites Technical data EL7201-0010 EL7211-0010 Number of outputs 3 motor phases, 2 motor holding brake Number of inputs 2 (4) DC link voltage, 2 absolute feedback, 2 digital inputs DC link supply voltage 8...50 V Supply voltage 24 V... -

Page 15: Fig. 10: Three Synchronous Motor Coils, Each Offset By 120

The EtherCAT servomotor terminal offers users the option to configure compact and cost-effective systems without having to give up the benefits of a servomotor. The Beckhoff servo terminal The EL72x1-0010 is a fully capable servo drive for direct connection to servomotors in the lower performance range. - Page 16 With the integration of a complete servo drive into a standard EL7201-0010 EtherCAT Terminal only 12 mm wide, Beckhoff is setting new standards in matters of size. This small manufactured size is possible thanks to the latest semiconductor technology and the resulting very high power factor. And yet, despite the small dimensions, nothing has to be sacrificed.

-

Page 17: Start

Product overview Fig. 11: Limitation to the rated motor current Start For commissioning: • mount the EL72x1-0010 as described in the chapter Mounting and wiring [} 29] • configure the EL72x1-0010 in TwinCAT as described in the chapter Commissioning [} 44]. EL72x1-0010 Version: 2.0... -

Page 18: Basics Communication

Due to automatic cable detection (auto-crossing) symmetric (1:1) or cross-over cables can be used between EtherCAT devices from Beckhoff. Recommended cables Suitable cables for the connection of EtherCAT devices can be found on the Beckhoff web- site! Note E-Bus supply A bus coupler can supply the EL terminals added to it with the E-bus system voltage of 5 V;... -

Page 19: General Notes For Setting The Watchdog

Basics communication Fig. 12: System manager current calculation Caution! Malfunction possible! The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in a terminal block! Attention General notes for setting the watchdog ELxxxx terminals are equipped with a safety feature (watchdog) that switches off the outputs after a specifiable time e.g. -

Page 20: Fig. 13 Ethercat Tab -> Advanced Settings -> Behavior -> Watchdog

Basics communication Fig. 13: EtherCAT tab -> Advanced Settings -> Behavior -> Watchdog Notes: • the multiplier is valid for both watchdogs. • each watchdog has its own timer setting, the outcome of this in summary with the multiplier is a resulting time. -

Page 21: Ethercat State Machine

Basics communication Example "Set SM watchdog" This checkbox enables manual setting of the watchdog times. If the outputs are set and the EtherCAT communication is interrupted, the SM watchdog is triggered after the set time and the outputs are erased. This setting can be used for adapting a terminal to a slower EtherCAT master or long cycle times. -

Page 22: Fig. 14 States Of The Ethercat State Machine

Basics communication Fig. 14: States of the EtherCAT State Machine Init After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible. The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication. Pre-Operational (Pre-Op) During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized correctly. -

Page 23: Coe Interface

Basics communication In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox communication is possible. Boot In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state. In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no other mailbox communication and no process data communication. -

Page 24: Fig. 15 "Coe Online " Tab

This is recommended for modifications while the system is running or if no System Manager or operating staff are available. If slave CoE parameters are modified online, Beckhoff devices store any changes in a fail-safe manner in the EEPROM, i.e. the modified CoE parameters are still available after a restart. The situation may be different with other manufacturers. -

Page 25: Fig. 16 Startup List In The Twincat System Manager

Startup list Changes in the local CoE list of the terminal are lost if the terminal is replaced. If a terminal is replaced with a new Beckhoff terminal, it will have the default settings. It is therefore ad- Note visable to link all changes in the CoE list of an EtherCAT slave with the Startup list of the slave, which is processed whenever the EtherCAT fieldbus is started. -

Page 26: Fig. 17 Offline List

Basics communication Fig. 17: Offline list • If the slave is online ◦ The actual current slave list is read. This may take several seconds, depending on the size and cycle time. ◦ The actual identity is displayed ◦ The firmware and hardware version of the equipment according to the electronic information is displayed ◦... - Page 27 • Channel 1: parameter range 0x8010:00 ... 0x801F:255 • Channel 2: parameter range 0x8020:00 ... 0x802F:255 • ... This is generally written as 0x80n0. Detailed information on the CoE interface can be found in the EtherCAT system documentation on the Beckhoff website. EL72x1-0010 Version: 2.0...

-

Page 28: Distributed Clock

Basics communication Distributed Clock The distributed clock represents a local clock in the EtherCAT slave controller (ESC) with the following characteristics: • Unit 1 ns • Zero point 1.1.2000 00:00 • Size 64 bit (sufficient for the next 584 years; however, some EtherCAT slaves only offer 32-bit support, i.e. -

Page 29: Installation

Installation Installation Installation on mounting rails Risk of electric shock and damage of device! Bring the bus terminal system into a safe, powered down state before starting installation, disassembly or wiring of the Bus Terminals! WARNING Assembly Fig. 19: Attaching on mounting rail The Bus Coupler and Bus Terminals are attached to commercially available 35 mm mounting rails (DIN rails according to EN 60715) by applying slight pressure: 1. -

Page 30: Fig. 20 Disassembling Of Terminal

Installation Disassembly Fig. 20: Disassembling of terminal Each terminal is secured by a lock on the mounting rail, which must be released for disassembly: 1. Pull the terminal by its orange-colored lugs approximately 1 cm away from the mounting rail. In doing so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of the bus terminal block easily without excessive force. -

Page 31: Installation Instructions For Enhanced Mechanical Load Capacity

Installation Fig. 21: Power contact on left side Possible damage of the device Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the mounting rail. This may lead to incorrect results during insulation testing or Attention to damage on the terminal (e.g. -

Page 32: Connection System

Installation Additional installation instructions For terminals with enhanced mechanical load capacity, the following additional installation instructions apply: • Any installation position is permitted • Use a mounting rail according to EN 60715 TH35-15 • Fix the terminal segment on both sides of the mounting rail with a mechanical fixture, e.g. an earth terminal or reinforced end clamp •... -

Page 33: Fig. 23 Pluggable Wiring

Installation Pluggable wiring Fig. 23: Pluggable wiring The terminals of KSxxxx and ESxxxx series feature a pluggable connection level. The assembly and wiring procedure for the KS series is the same as for the KLxxxx and ELxxxx series. The KS/ES series terminals enable the complete wiring to be removed as a plug connector from the top of the housing for servicing. -

Page 34: Fig. 24 High Density Terminals

Installation Wiring Terminals for standard wiring ELxxxx / KLxxxx and terminals for steady wiring ESxxxx / KSxxxx Fig. 25: Mounting a cable on a terminal connection Up to eight connections enable the connection of solid or finely stranded cables to the Bus Terminals. The terminals are implemented in spring force technology. -

Page 35: Mounting Of Passive Terminals

Installation Shielding Shielding Analog sensors and actors should always be connected with shielded, twisted paired wires. Note Mounting of Passive Terminals Hint for mounting passive terminals EtherCAT Bus Terminals (ELxxxx / ESxxxx), which do not take an active part in data trans- fer within the bus terminal block are so called Passive Terminals. -

Page 36: Installation Positions

Installation Installation positions Constraints regarding installation position and operating temperature range Please refer to the technical data for a terminal to ascertain whether any restrictions re- garding the installation position and/or the operating temperature range have been speci- Attention fied. When installing high power dissipation terminals ensure that an adequate spacing is maintained between other components above and below the terminal in order to guarantee adequate ventilation! Optimum installation position (standard) -

Page 37: Shielding Concept

Installation Fig. 29: Other installation positions Shielding concept Together with the shield busbar, the prefabricated cables from Beckhoff Automation offer optimum protection against electromagnetic interference. Connection of the motor cable to the shield busbar Fasten the shield busbar supports 1 to the DIN rail 2. The DIN rail 2 must be in contact with the metallic rear wall of the control cabinet over a wide area. -

Page 38: Notes On Current Measurements Using Hall Sensors

Installation Fig. 30: Shield busbar Connect the cores 4 of the motor cable 5, then attach the copper-sheathed end 6 of the motor cable 5 with the shield clamp 7 to the shield busbar 3. Tighten the screw 8 to the stop. Fasten the PE clamp 9 to the shield busbar 3. - Page 39 Installation Fig. 32: Note Background A current-carrying conductor generates a magnetic field around it according to B = µ * I / (2π * d) with B [Tesla] magnetic field µ0 = 4*π*10 [H/m] (assumption: no magnetic shielding) I [A] current d [m] ...

-

Page 40: El72X1-0010 - Leds And Connection

Installation EL72x1-0010 - LEDs and connection EL7201-0010 Fig. 33: EL7201-0010 - LEDs LEDs Color Meaning green This LED indicates the terminal's operating state: State of the EtherCAT State Machine [} 77]: INIT = initialization of the terminal flashing State of the EtherCAT State Machine: BOOTSTRAP = function for firmware updates rapidly [} 192] of the terminal... -

Page 41: Fig. 34 El7201-0010 - Connection

Installation Connection Fig. 34: EL7201-0010 - Connection Terminal point Name Comment OCT + Positive input of the absolute feedback Input 1 Digital input 1 +24 V Power contact +24 V Motor phase U Motor phase W Brake + Motor brake + 50 V DC link supply + (8...50 V) - Page 42 Installation LEDs Color Meaning green This LED indicates the terminal's operating state: State of the EtherCAT State Machine [} 77]: INIT = initialization of the terminal flashing State of the EtherCAT State Machine: BOOTSTRAP = function for firmware updates rapidly [} 192] of the terminal flashing State of the EtherCAT State Machine: PREOP = function for mailbox communication and different standard-settings set...

-

Page 43: Fig. 36 El7211-0010 - Connection

Installation Connection Fig. 36: EL7211-0010 - Connection Terminal point Name Comment OCT + Positive input of the absolute feedback Input 1 Digital input 1 +24 V Power contact +24 V Motor phase U Motor phase W Brake + Motor brake + 50 V DC link supply + (8...50 V) OCT -... -

Page 44: Commissioning

6.1.1 Installation of the TwinCAT real-time driver In order to assign real-time capability to a standard Ethernet port of an IPC controller, the Beckhoff real-time driver has to be installed on this port under Windows. This can be done in several ways. One option is described here. -

Page 45: Fig. 40 Windows Properties Of The Network Interface

Commissioning After the installation the driver appears activated in the Windows overview for the network interface (Windows Start -->System Properties -> Network) Fig. 40: Windows properties of the network interface Other possible settings are to be avoided: EL72x1-0010 Version: 2.0... -

Page 46: Fig. 41 Incorrect Driver Settings For The Ethernet Port

Commissioning Fig. 41: Incorrect driver settings for the Ethernet port IP address of the port used IP address/DHCP In most cases an Ethernet port that is configured as an EtherCAT device will not transport general IP packets. For this reason and in cases where an EL6601 or similar devices are Note used it is useful to specify a fixed IP address for this port via the “Internet Protocol TCP/IP”... -

Page 47: Fig. 42 Tcp/Ip Setting For The Ethernet Port

Commissioning Fig. 42: TCP/IP setting for the Ethernet port EL72x1-0010 Version: 2.0... -

Page 48: Notes Regarding Esi Device Description

\EtherCAT). The files are read (once) when a new System Manager window is opened, if they have changed since the last time the System Manager window was opened. A TwinCAT installation includes the set of Beckhoff ESI files that was current at the time when the TwinCAT build was created. - Page 49 1018 in the configuration. This is also stated by the Beckhoff compatibility rule. Refer in particular to the chapter ‘General notes on the use of Beckhoff EtherCAT IO components’ and for manual configuration to the chapter ‘Configuration creation – manual’...

- Page 50 In addition to the file described above "OnlineDescription0000...xml" , a so called EtherCAT cache with new discovered devices is created by TwinCAT 3.x (e.g. under Windows 7)C: Note \User\[USERNAME]\AppData\Roaming\Beckhoff\TwinCAT3\Components\Base\EtherCAT- Cache.xml (Please note the language settings of the OS!)You have to delete this file, too. Faulty ESI file If an ESI file is faulty and the System Manager is unable to read it, the System Manager brings up an information window.

- Page 51 Commissioning • Structure of the *.xml does not correspond to the associated *.xsd file --> check your schematics • Contents cannot be translated into a device description --> contact the file manufacturer EL72x1-0010 Version: 2.0...

-

Page 52: Offline Configuration Creation (Master: Twincat 2.X)

The ESI files should be saved in the TwinCAT installation directory (default: C:\TwinCAT\IO\EtherCAT ). The files are read (once) when a new System Manager win- dow is opened.A TwinCAT installation includes the set of Beckhoff ESI files that was cur- rent at the time when the TwinCAT build was created. - Page 53 Commissioning Fig. 52: Selecting the EtherCAT connection (TwinCAT 2.11) Fig. 53: Selecting the EtherCAT connection (TwinCAT 2.11 R2) Then assign a real Ethernet port to this virtual device in the runtime system. Fig. 54: Selecting the Ethernet port This query may appear automatically when the EtherCAT device is created, or the assignment can be set/ modified later in the properties dialog (see Fig.

- Page 54 Commissioning Fig. 55: EtherCAT properties dialog Selecting the Ethernet port Ethernet ports can only be selected for EtherCAT devices for which the TwinCAT real-time driver is installed. This has to be done separately for each port. Please refer to the respec- Note tive installation page.

- Page 55 (i.e. highest) revision and therefore the latest state of production is displayed in the selection dialog for Beckhoff devices. To show all device revisions available in the system as ESI descriptions tick the “Show Hidden Devices” check box, see Fig. “Display of previous revisions”.

- Page 56 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 57 Commissioning Fig. 61: EtherCAT terminal in the TwinCAT tree EL72x1-0010 Version: 2.0...

-

Page 58: Online Configuration Creation 'Scanning' (Master: Twincat 2.X)

The ESI files should be saved in the TwinCAT installation directory (default: C:\TwinCAT\IO\EtherCAT ). The files are read (once) when a new System Manager win- dow is opened.A TwinCAT installation includes the set of Beckhoff ESI files that was cur- rent at the time when the TwinCAT build was created. - Page 59 Commissioning Fig. 63: TwinCAT CONFIG mode display Online scanning in Config mode The online search is not available in RUN mode (production operation). Note the differenti- ation between TwinCAT programming system and TwinCAT target system. Note The TwinCAT icon next to the Windows clock always shows the TwinCAT mode of the local IPC. The System Manager window shows the TwinCAT state of the target system.

- Page 60 [} 64] with the defined initial configura- tion.Background: since Beckhoff occasionally increases the revision version of the deliv- ered products for product maintenance reasons, a configuration can be created by such a scan which (with an identical machine construction) is identical according to the device list;...

- Page 61 Likewise, A might create spare parts stores worldwide for the coming series-produced machines with EL2521-0025-1018 terminals. After some time Beckhoff extends the EL2521-0025 by a new feature C. Therefore the FW is changed, outwardly recognizable by a higher FW version and a new revision -1019. Nevertheless the new device naturally supports functions and interfaces of the predecessor version(s);...

- Page 62 Commissioning Fig. 72: Manual triggering of a device scan on a specified EtherCAT device In the System Manager the scan process can be monitored via the progress bar at the bottom of the screen. Fig. 73: Scan progress The configuration is established and can then be switched to online state (OPERATIONAL). Fig. 74: Config/FreeRun query In Config/FreeRun mode the System Manager display alternates between blue and red, and the EtherCAT device continues to operate with the idling cycle time of 4 ms (default setting), even without active task (NC,...

- Page 63 Commissioning The EtherCAT system should then be in a functional cyclic state, as shown in Fig. “Online display example”. Fig. 77: Online display example Please note: • all slaves should be in OP state • the EtherCAT master should be in “Actual State” OP •...

- Page 64 A ‘ChangeTo’ or ‘Copy’ should only be Attention carried out with care, taking into consideration the Beckhoff IO compatibility rule (see above). The device configuration is then replaced by the revision found; this can affect the supported process data and functions.

- Page 65 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 66 This function is preferably to be used on AX5000 devices. If called, the System Manager suggests the devices that it finds in the associated sub-folder; in the case of the AX5000, for example, in \TwiNCAT\IO \EtherCAT\Beckhoff AX5xxx. Change to Alternative Type The TwinCAT System Manager offers a function for the exchange of a device: Change to Alternative Type Version: 2.0...

-

Page 67: Ethercat Slave Process Data Settings

To this end the EtherCAT master (Beckhoff TwinCAT) parameterizes each EtherCAT slave during the start-up phase to define which process data (size in bits/bytes, source location, transmission type) it wants to transfer to or from this slave. -

Page 68: General Notes - Ethercat Slave Application

Commissioning Fig. 85: Configuring the process data Manual modification of the process data According to the ESI description, a PDO can be identified as “fixed” with the flag “F” in the PDO overview (Fig. “Configuring the process data”, J). The configuration of such PDOs Note cannot be changed, even if TwinCAT offers the associated dialog (“Edit”). - Page 69 Fig. “Basic EtherCAT Slave Diagnosis in the PLC” shows an example of an implementation of basic EtherCAT Slave Diagnosis. A Beckhoff EL3102 (2-channel analogue input terminal) is used here, as it offers both the communication diagnosis typical of a slave and the functional diagnosis that is specific to a channel.

- Page 70 Commissioning Fig. 87: Basic EtherCAT Slave Diagnosis in the PLC The following aspects are covered here: Version: 2.0 EL72x1-0010...

- Page 71 Commissioning Code Function Implementation Application/evaluation The EtherCAT Master's At least the DevState is to be diagnostic information evaluated for the most recent cycle in the PLC. updated acyclically (yellow) or provided acyclically (green). The EtherCAT Master's diagnostic information offers many more possibilities than are treated in the EtherCAT System Documentation.

- Page 72 Commissioning Code Function Implementation Application/evaluation Diagnostic information of the State Information variables for the EtherCAT Master which, while it is EtherCAT Master that are updated current Status (INIT..OP) of represented at the slave for acyclically. This means that it is the Slave.

- Page 73 Commissioning EtherCAT System Documentation The comprehensive description in the EtherCAT System Documentation (EtherCAT Basics --> CoE Interface) must be observed! Note A few brief extracts: • Whether changes in the online directory are saved locally in the slave depends on the device. EL terminals (except the EL66xx) are able to save in this way.

- Page 74 Commissioning • SAFEOP • OP to ensure sound operation. The EtherCAT Master directs these statuses in accordance with the initialization routines that are defined for commissioning the device by the ES/XML and user settings (Distributed Clocks (DC), PDO, CoE). See also the section on "Principles of Communication, EtherCAT State Machine [} 21]" in this connection.

- Page 75 Commissioning Fig. 91: Default target state in the Slave Manual Control There are particular reasons why it may be appropriate to control the states from the application/task/PLC. For instance: • for diagnostic reasons • to induce a controlled restart of axes •...

- Page 76 Commissioning Note regarding E-Bus current EL/ES terminals are placed on the DIN rail at a coupler on the terminal strand. A Bus Coupler can supply the EL terminals added to it with the E-bus system voltage of 5 V; a coupler is thereby loadable up to 2 A as a rule.

-

Page 77: Configuration By Means Of The Twincat System Manager

Commissioning 6.1.7 Configuration by means of the TwinCAT System Manager (with TwinCAT from version 2.10.0 (Build 1241), using EL5001 from firmware version 0.7 as an example) In the left-hand window of the TwinCAT System Manager, click on the branch you wish to configure (in the example: EL5001 Terminal 6). - Page 78 Commissioning „EtherCAT“ tab Fig. 97: „EtherCAT“ tab Type EtherCAT device type Product/Revision Product and revision number of the EtherCAT device Auto Inc Addr. Auto increment address of the EtherCAT device. The auto increment address can be used for addressing each EtherCAT device in the communication ring through its physical position.

- Page 79 Commissioning Fig. 98: “Process Data” tab Sync Manager Lists the configuration of the Sync Manager (SM). If the EtherCAT device has a mailbox, SM0 is used for the mailbox output (MbxOut) and SM1 for the mailbox input (MbxIn). SM2 is used for the output process data (outputs) and SM3 (inputs) for the input process data. If an input is selected, the corresponding PDO assignment is displayed in the PDO Assignment list below.

- Page 80 Commissioning Column Description Index PDO index. Size Size of the PDO in bytes. Name Name of the PDO. If this PDO is assigned to a Sync Manager, it appears as a variable of the slave with this parameter as the name. Flags Fixed content: The content of this PDO is fixed and cannot be changed by the System Manager.

- Page 81 Commissioning Column Description Transition Transition to which the request is sent. This can either be • the transition from pre-operational to safe-operational (PS), or • the transition from safe-operational to operational (SO). If the transition is enclosed in "<>" (e.g. <PS>), the mailbox request is fixed and cannot be modified or deleted by the user.

- Page 82 Commissioning Fig. 100: “CoE – Online” tab Object list display Column Description Index Index and sub-index of the object Name Name of the object Flags The object can be read, and data can be written to the object (read/write) The object can be read, but no data can be written to the object (read only) An additional P identifies the object as a process data object.

- Page 83 Commissioning Update List The Update list button updates all objects in the displayed list Auto Update If this check box is selected, the content of the objects is updated automatically. Advanced The Advanced button opens the Advanced Settings dialog. Here you can specify which objects are displayed in the list.

- Page 84 Commissioning „Online“ tab Fig. 102: „Online“ tab State Machine Init This button attempts to set the EtherCAT device to the Init state. Pre-Op This button attempts to set the EtherCAT device to the pre-operational state. This button attempts to set the EtherCAT device to the operational state.

-

Page 85: Start-Up And Parameter Configuration

(Master: TwinCAT 2.11 R3) Installation of the latest XML device description Please ensure that you have installed the corresponding latest XML device description in TwinCAT. This can be downloaded from the Beckhoff Website and installed according to Note the installation instructions. - Page 86 Commissioning Fig. 103: Axis detected • Several parameters have to be set before the motor can be started up. The values can be found in section "Configuration of the main parameters [} 93]". Please set these parameters before continuing with the motor commissioning procedure. Adding an axis manually •...

- Page 87 Commissioning • Right-click on Axes, then add a new axis (see Fig. Adding a new axis). Fig. 105: Adding a new axis • Select Continuous Axis type and confirm with OK (see Fig. Selecting and confirming the axis type). Fig. 106: Selecting and confirming the axis type •...

-

Page 88: Settings With The Drive Manager

6.2.2 Settings with the Drive Manager (Master TwinCAT 2.11 R3) The data given here serve as an example for a servomotor type AM8131-0F20-0000 from Beckhoff Automation. For other motors the values may vary, depending on the application. Version: 2.0 EL72x1-0010... - Page 89 Commissioning Using the Drive Manager from revision -0019 The Drive Manager is only supported from revision -0019 [} 191] of the EL72x1-0010. If you use an older version, the settings have to be made manually. See sections "CoE settings Note [} 93]" and "NC settings [} 97]" Table of contents •...

- Page 90 Commissioning Fig. 111: Automatic scanning of the connected motor • If you decide to manually input the connected motor, please click on Select Motor. Fig. 112: Selecting the connected motor • Select the suitable motor in the selection window and confirm with Ok. Version: 2.0 EL72x1-0010...

- Page 91 Commissioning Fig. 113: List of available motors • Confirm the next dialog box with OK. All required parameters are automatically entered in the NC, and the scaling factor is calculated. If this is not confirmed, these settings have to be entered manually. See section "NC settings [} 97]".

- Page 92 All main parameters for the commissioning the motor are now set. The motor can now be commissioned with the NC, for example. A brief description can be found in section "Commissioning the motor with the NC [} 102]". Or the NC can be addressed from the PLC. A small http://infosys.beckhoff.com/content/1033/ el72x1-0010/Resources/zip/1859339787.zip is included in the documentation.

-

Page 93: Settings In The Coe Register

6.2.3 Settings in the CoE register (Master TwinCAT 2.11 R3) The data given here serve as an example for a servomotor type AM8131-0F20-0001 from Beckhoff Automation. For other motors the values may vary, depending on the application. EL72x1-0010 Version: 2.0... - Page 94 - Proportional velocity controller component Kp [} 97] Inserting the motor XML file Downloading the EL72x1-0010 motor XML files The motor XML files are available for download from the Beckhoff website. Note To facilitate commissioning of the EL72x1-0010 servo terminal, motor XML files are provided for the servomotors that are supported by the EL72x1-0010.

- Page 95 Commissioning Fig. 119: Selecting the correct motor XML file • All required parameters are then set, and the motor can be put into operation (see Fig. CoE parameters of the motor XML file). Fig. 120: CoE parameters of the motor XML file Startup list Any further application-specific settings should also be implemented in the Startup list.

- Page 96 Commissioning Adaptation of current and voltage The motor may overheat! In order to prevent overheating of the connected motor, it is important to adjust the voltage of the servo terminal to the actually connected voltage. Attention This requires the index 0x8010:19 [} 166] (0x2002:19 [} 147], DS402 profile) "Nominal DC Link Voltage" of the connected voltage to be set accordingly Setting further parameters Single-turn Bits (MDP742: Index 0x8000:12 [} 165] / DS402: Index 0x2010:12...

-

Page 97: Nc Settings

6.2.4 NC settings (Master TwinCAT 2.11 R3) The data given here serve as an example for a servomotor type AM8122-0F20-0000 from Beckhoff Automation. For other motors the values may vary, depending on the application. Table of contents • Definition of the unit [} 97] •... - Page 98 Commissioning Fig. 122: Definition of the unit Selecting the maximum velocity The maximum permitted velocity is calculated based on the maximum motor speed (name plate) and the distance, in this case in relation to 360° per second. Fig. 123: Adjusting the reference velocity Version: 2.0 EL72x1-0010...

- Page 99 Commissioning The reference velocity matches the maximum permitted velocity. Below that separate values for the maximum and minimum velocity for manual NC mode can be set. Dead time compensation The dead time compensation can be found further below. Open Further settings. The dead time compensation should, in theory, be 3 cycles of the NC cycle time, although in practice 4 cycles were found to be preferable.

- Page 100 Commissioning The parameter Encoder Sub Mask (absolute range maximum value) indicates how many bits of the maximum encoder value are single-turn bits. The default setting is 20 (and therefore 12 multi-turn bits). The calculation is based on the following equation. Further calculation example with 13 single-turn bits and 8 multi-turn bits.

- Page 101 Commissioning Fig. 127: Setting the Scaling Factor Scaling output Enter the value 32 in the Parameter tab for the drive settings under Output Scaling (Velocity). Fig. 128: Output scaling Position lag monitoring The position lag monitoring function checks whether the current position lag of an axis has exceeded the limit value.

- Page 102 Commissioning Fig. 129: Lag monitoring Commissioning the motor with the NC • Once the parameters are set, the motor is basically ready for operation. Individual further parameters have to be adapted to the respective application. • To commission the axis, activate the configuration (Ctrl+Shift+F4), select the axis, select tab Online and enable the axis under Set.

- Page 103 Commissioning Fig. 130: Enabling an axis You can now move the axis with the function keys F1, F2 (Backward) or F3, F4 (Forward). You can adjust the Kv factor in order to approach a suitable factor. Set the value to 0 initially in order to set the correct reference velocity.

-

Page 104: Application Example

Application example Installation of the latest XML device description Please ensure that you have installed the corresponding latest XML device description in TwinCAT. This can be downloaded from the Beckhoff Website and installed according to Note the installation instructions. Motor control with visualization Download (http://infosys.beckhoff.com/content/1033/el72x1-0010/Resources/zip/1859339787.zip):... - Page 105 Commissioning Fig. 132: Selection of the target platform Please note the following for the System Manager file: • Start the System Manager in Config mode. • Please ensure that the I/O configuration matches your actual configuration. In the sample program only one EL7041 is integrated.

-

Page 106: Fig. 134 Changing The Plc Path

Commissioning • In the PLC configuration you have to adjust the path for the PLC program. Click on the appended PLC program and select the tab IEC1131 (see Fig. Changing the PLC path). Select Change and enter the correct path. Fig. 134: Changing the PLC path •... -

Page 107: Fig. 136 Global Variables

Commissioning Fig. 136: Global variables Once the global variables have been declared, programming can commence. Start with declaring local variables (see Fig. Local variables). MC_Direction is an enumeration type that specifies the direction of travel for the block MC_MoveVelocity, which in turn initiates continuous travel of the motor. An axis reset is carried out with the function block MC_Reset. -

Page 108: Fig. 138 Program Code

Commissioning Fig. 138: Program code The motor can then be operated with the aid of the following visualization (see Fig. Visualization). Press Enable to enable the axis. In "Free run mode" you can now use the Left or Right buttons, and the motor will run with a speed defined under fbMoveVelocity_Axis_1 in the selected direction. -

Page 109: Commissioning Without Nc, Status Word/Control Word

Commissioning Fig. 139: Visualization Information on function blocks and data types Further information on the function blocks and data types used can be found in the Beck- hoff Information System. Note 6.2.6 Commissioning without NC, status word/control word (Master: TwinCAT 2.11 R3) In principle, the operating modes CST, CSTCA, CSV and CSP can be used without TwinCAT NC. -

Page 110: Fig. 140 Ds402 State Machine

Commissioning (Fault reset) (Shutdown) (Switch on) (Enable operation) Fig. 140: DS402 State Machine Version: 2.0 EL72x1-0010... - Page 111 Commissioning CST - cyclic synchronous torque Select Cyclic synchronous torque mode in index 0x7010:03 [} 173] Modes of operation (MDP) or 0x6060:0 [} 151] Modes of operation (DS402). The Predefined PDO Assignment: 'Cyclic synchronous torque mode (CST)' should also be selected in the respective process data (see CoE process data [} 137] or DS402 process data [} 141]).

-

Page 112: Settings For The Automatic Configuration

Commissioning 6.2.7 Settings for the automatic configuration (Master TwinCAT 2.11 R3) The EL72x1-0010 offers the user the possibility to automatically configure the connected motor from the AM81xx series. The electronic type plate integrated in the motor is read and the necessary parameters of the terminal are adapted accordingly. -

Page 113: Fig. 141 Flow Chart For The Automatic Configuration

Commissioning Fig. 141: Flow chart for the automatic configuration Parameter list of the automatic configuration The following parameters are affected by the automatic configuration. EL72x1-0010 Version: 2.0... -

Page 114: Configuring The Limit Switch

Commissioning Index (hex) Name Meaning MDP 407 Profile DS402 Profile Current loop integral time is calculated according to the symmetrical optimum 8010:12 [} 166] 2002:12 [} 147] Current loop proportional gain is calculated according to the symmetrical optimum 8010:13 [} 166] 2002:13 [} 147] Max. -

Page 115: Homing

Commissioning 6.2.9 Homing (Master TwinCAT 2.11 R3) The data given here serve as an example for a servomotor type AM8131-0F20-0000 from Beckhoff Automation. For other motors the values may vary, depending on the application. Table of contents • Referencing [} 115] - Function block "MC_Home"... -

Page 116: Fig. 144 Configuration Of The Mc_Home Block

Commissioning Fig. 144: Configuration of the MC_Home block • The following figure Extract from the functional description for MC_Home shows an extract from the functional description of MC_Home. Full information can be found in the corresponding functional description. Fig. 145: Extraction from the functional description for MC_Home Reference modes •... -

Page 117: Fig. 146 Selection Of The Reference Modes In The Nc

Commissioning Fig. 146: Selection of the reference modes in the NC The velocity to be used for homing can also be set in the NC (Fig. Setting the reference velocity). Fig. 147: Setting the reference velocity EL72x1-0010 Version: 2.0... -

Page 118: Touch Probe

6.2.10 Touch Probe (Master TwinCAT 2.11 R3) The data given here serve as an example for a servomotor type AM8131-0F20-0000 from Beckhoff Automation. For other motors the values may vary, depending on the application. Functional description The Touch Probe function implemented in the EL72x1-0010 provides the user with the possibility to save the current position of the connected motor at a defined point in time. -

Page 119: Fig. 148 Touch Probe Inputs

Commissioning Fig. 148: Touch Probe inputs EL72x1-0010 Version: 2.0... -

Page 120: Fig. 149 Touch Probe Outputs

Commissioning Fig. 149: Touch Probe outputs Step-by-step • TP1 Enable must be set to true in order to generally activate the Touch Probe function. • Subsequently, you must decide whether the position is to be saved on a positive edge at input 1 (TP1 Enable pos edge = true), on a negative edge (TP1 Enable neg edge = true), or in both cases (both set to ‘true’). -

Page 121: Modes Of Operation

Commissioning edge at input 1 of the terminal. If TP1 Enable neg edge is set and TP1 Continuous is not set, the position will only be saved on the first negative edge at input 1 of the terminal. If you wish to repeat this procedure, you must first deactivate TP1 Enable and then activate it again. -

Page 122: Fig. 150 Selection Of The Mode Of Operation

Commissioning Step-by-Step • Add the terminal to the configuration as described in the chapter TwinCAT configuration settings [} 52] - manual or - Online scan [} 58]. • Link the terminal with the NC as described in the chapter Integration in the NC configuration [} 85]. •... -

Page 123: Fig. 151 Selecting A Predefined Pdo Assignment

Commissioning Fig. 151: Selecting a predefined PDO assignment • Activate the configuration (Ctrl+Shift+F4). • Run through the State Machine of the terminal. There are two ways to do this: ◦ If you use the TwinCAT NC. The State Machine is run through automatically by the NC. You can enable the axis in the On- line tab of the axis. -

Page 124: Fig. 152 Set Enables

Commissioning Fig. 152: Set enables ◦ If you don’t use the TwinCAT NC. In this case you must run through the State Machine manually. To do this, follow the instruc- tions in the chapter Commissioning without the NC [} 109]. • The cyclic variable Target velocity (Fig. Torque specification) can be used to specify a defined velocity. The value in the index 0x9010:14 Velocity encoder resolution corresponds to 1 rpm. -

Page 125: Cst

Commissioning 6.3.3 CST - cyclic synchronous torque (torque control) In CST mode the EL72x1-0010 operates in the cyclic torque interface. A defined torque can be set via the Target torque variable. Step-by-Step • Add the terminal to the configuration as described in the chapter TwinCAT configuration settings [} 52] - manual or - Online scan [} 58]. -

Page 126: Fig. 155 Selecting A Predefined Pdo Assignment

Commissioning Fig. 155: Selecting a predefined PDO assignment • Activate the configuration (Ctrl+Shift+F4). • Run through the State Machine of the terminal. There are two ways to do this: ◦ If you use the TwinCAT NC. The State Machine is run through automatically by the NC. You can enable the axis in the On- line tab of the axis. -

Page 127: Fig. 156 Set Enables

Commissioning Fig. 156: Set enables ◦ If you don’t use the TwinCAT NC. In this case you must run through the State Machine manually. To do this, follow the instruc- tions in the chapter Commissioning without the NC [} 109]. • The cyclic variable Target torque (Fig. Torque specification) can be used to specify a defined torque. The value is specified in 1000ths of the rated current and the torque is calculated according to the following equation, where the rated current refers to the value in the index 0x8011:12 [} 168] (rated current). -

Page 128: Cstca

Commissioning Fig. 157: Torque specification 6.3.4 CSTCA CSTCA - cyclic synchronous torque with commutation angle (torque control with commutation angle) This mode of operation is also intended for use with the cyclic torque interface. In addition the user can specify the commutation angle. The variable Commutation angle can be used to set an angle which is to be maintained with a defined torque set in variable Target torque. -

Page 129: Fig. 158 Selection Of The Mode Of Operation

Commissioning Fig. 158: Selection of the mode of operation • Under Predefined PDO assignment, also select Cyclic synchronous torque mode with commutation angle (CSTCA), Fig. Selecting a predefined PDO assignment. EL72x1-0010 Version: 2.0... -

Page 130: Fig. 159 Selecting A Predefined Pdo Assignment

Commissioning Fig. 159: Selecting a predefined PDO assignment • Activate the configuration (Ctrl+Shift+F4). • Run through the State Machine of the terminal. There are two ways to do this: ◦ If you use the TwinCAT NC. The State Machine is run through automatically by the NC. You can enable the axis in the On- line tab of the axis. -

Page 131: Fig. 160 Set Enables

Commissioning Fig. 160: Set enables ◦ If you don’t use the TwinCAT NC. In this case you must run through the State Machine manually. To do this, follow the instruc- tions in the chapter Commissioning without the NC [} 109]. • You can specify a defined torque via the cyclic variable Target torque. The value is specified in 1000ths of the rated current and the torque is calculated according to the following equation, where the rated current refers to the value in the index 0x8011:12 [} 168] (rated current). -

Page 132: Csp

Commissioning Fig. 161: Specification of torque and commutation angle 6.3.5 CSP - cyclic synchronous position (position control) In the CSP operating mode the EL72x1-0010 operates in the cyclic position interface. A defined position can be set via the Target position variable. Minimum cycle time The cycle time in CSP mode should be at least 250 µs. -

Page 133: Fig. 162 Selection Of The Mode Of Operation

Commissioning Fig. 162: Selection of the mode of operation • Under Predefined PDO assignment, also select Cyclic synchronous position mode (CSP), Fig. Selecting a predefined PDO assignment. EL72x1-0010 Version: 2.0... -

Page 134: Fig. 163 Selecting A Predefined Pdo Assignment

Commissioning Fig. 163: Selecting a predefined PDO assignment • Activate the configuration (Ctrl+Shift+F4). • Run through the State Machine of the terminal. There are two ways to do this: ◦ If you use the TwinCAT NC. The State Machine is run through automatically by the NC. You can enable the axis in the “On- line”... -

Page 135: Fig. 164 Set Enables

Commissioning Fig. 164: Set enables ◦ If you don’t use the TwinCAT NC. In this case you must run through the State Machine manually. To do this, follow the instruc- tions in the chapter Commissioning without the NC [} 109]. • You can specify a defined position via the cyclic variable Target position (fig. Position specification). The value must be multiplied by the calculated scaling factor [} 100] in order to obtain the correct position. -

Page 136: Fig. 165 Position Specification

Commissioning Fig. 165: Position specification Following error monitor Furthermore, there is an option in CSP mode to activate a following error monitor. The following error monitor is switched off on delivery. In all other modes this is not used and is ignored. •... -

Page 137: Profile Mdp 742 Or Ds 402

The CoE objects in the MDP 742 profile (Modular Device Profile) are allocated in the way that is common for the Beckhoff EtherCAT Terminals. The DS402 drive profile is specified in IEC61800-7-200 (CiA402). It uses a different object directory structure. -

Page 138: Fig. 168 Process Data Tab Sm2, El72X1-0010 (Default)

Commissioning Fig. 168: Process Data tab SM2, EL72x1-0010 (default) Version: 2.0 EL72x1-0010... -

Page 139: Fig. 169 Process Data Tab Sm3, El72X1-0010 (Default)

Commissioning Fig. 169: Process Data tab SM3, EL72x1-0010 (default) PDO Assignment To configure the process data, select the required Sync Manager (SM 2 or SM 3) in the "Sync Manager" field at the top left (see Fig. Process Data tab SM3, EL72x1-0010). The process data assigned to this Sync Manager can then be switched on or off in the “PDO Assignment”... - Page 140 Commissioning SM2, PDO assignment 0x1C12 Index Size (byte.bit) Name PDO content 0x1600 (default) DRV Controlword Index 0x7010:01 [} 173] 0x1601(default) DRV Target velocity Index 0x7010:06 [} 173] 0x1602 DRV Target torque Index 0x7010:09 [} 173] 0x1603 DRV Commutation angle Index 0x7010:0E [} 173] 0x1604 DRV Torque limitation Index 0x7010:0B [} 173] 0x1605...

-

Page 141: Ds402 Process Data

Commissioning Name SM2, PDO assignment SM3, PDO assignment Cyclic synchronous velocity mode (CSV) 0x1600 [} 178] (DRV Controlword) 0x1A00 [} 179] (FB Position) 0x1601 [} 178] (DRV Target velocity) 0x1A01 [} 179] (DRV Statusword) Cyclic synchronous torque mode (CST) 0x1600 [} 178] (DRV Controlword) 0x1A00 [} 179] (FB Position) 0x1602 [} 178] (DRV Target torque) 0x1A01 [} 179] (DRV Statusword) 0x1A03 [} 180] (DRV Torque actual value) -

Page 142: Fig. 171 Process Data Tab Sm2, El72X1-0010 (Default)

Commissioning Fig. 171: Process Data tab SM2, EL72x1-0010 (default) Version: 2.0 EL72x1-0010... -

Page 143: Fig. 172 Process Data Tab Sm3, El72X1-0010 (Default)

Commissioning Fig. 172: Process Data tab SM3, EL72x1-0010 (default) PDO Assignment In order to configure the process data, select the desired Sync Manager (SM 2 & 3 can be edited) in the upper left-hand "Sync Manager" box (see fig.). The process data assigned to this Sync Manager can then be switched on or off in the “PDO Assignment”... - Page 144 Commissioning SM2, PDO assignment 0x1C12 Index Size (byte.bit) Name PDO content 0x1600 (default) DS402 Controlword Index 0x6040 [} 151] 0x1601 (default) DS402 Target velocity Index 0x60FF [} 154] 0x1602 DS402 Target torque Index 0x6071 [} 152] 0x1603 DS402 Commutation angle Index 0x60EA [} 154] 0x1604 DS402 Torque limitation Index 0x6072 [} 152]...

-

Page 145: Fig. 173 Process Data Tab - Predefined Pdo Assignment, El72X1-0010

Commissioning Name SM2, PDO assignment SM3, PDO assignment Cyclic synchronous velocity mode (CSV) 0x1600 [} 159] (DS402 Controlword) 0x1A00 [} 160] (DS402 Statusword) 0x1601 [} 159] (DS402 Target velocity) 0x1A01 [} 160] (DS402 Position actual value) Cyclic synchronous torque mode (CST) 0x1600 [} 159] (DS402 Controlword) 0x1A00 [} 160] (DS402 Statusword) 0x1602 [} 159] (DS402 Target torque) 0x1A01 [} 160] (DS402 Position actual... -

Page 146: El72X1-0010-Ds402 - Object Description And Parameterization

EtherCAT XML Device Description The display matches that of the CoE objects from the EtherCAT XML Device Description. We recommend downloading the latest XML file from the download area of the Beckhoff Note website and installing it according to installation instructions. -

Page 147: Configuration Data

EL72x1-0010-DS402 - Object description and parameterization Configuration data Index 2002 Amplifier Settings Index (hex) Name Meaning Data type Flags Default 2002:0 Amplifier Settings Maximum subindex UINT8 0x49 (73 2002:11 Device type 1: Servo drive (cannot be changed) UINT32 0x00000001 2002:12* Current loop integral Integral component of current controller UINT16... - Page 148 EL72x1-0010-DS402 - Object description and parameterization Index 2003 Motor Settings Index (hex) Name Meaning Data type Flags Default 2003:0 Motor Settings Maximum subindex UINT8 0x2D (45 2003:11* Max current Peak current UINT32 0x00001770 Unit: mA (6000 This value is affected by automatic scanning. (see Au- tomatic scanning of the electronic type plates [} 112]) 2003:13* Motor pole pairs...

- Page 149 EL72x1-0010-DS402 - Object description and parameterization Index 2004 Brake Settings Index (hex) Name Meaning Data type Flags Default 2004:0 Brake Settings Maximum subindex UINT8 0x14 (20 2004:01 Manual override (re- Manual release of the motor holding brake BOOLEAN 0x00 (0 lease) 2004:11* Release delay...

-

Page 150: Configuration Data (Vendor-Specific)

EL72x1-0010-DS402 - Object description and parameterization Configuration data (vendor-specific) Index 2020 Vendor data Index Name Meaning Data type Flags Default (hex) 2020:0 Vendor Maximum subindex UINT8 0x14 data 2020:11 Amplifier Peak current of the amplifier (peak value) UINT32 0x00001F peak Unit: mA current (8000... - Page 151 EL72x1-0010-DS402 - Object description and parameterization Index 6040 Controlword Index Name Meaning Data type Flags Default (hex) 6040:0 Control- UINT16 0x0000 DS402 Controlword [} 109] word Bit 0: Switch on Bit 1: Enable voltage Bit 2: reserved Bit 3: Enable operation Bit 4 - 6: reserved Bit 7: Fault reset Bit 8 - 15: reserved...

- Page 152 EL72x1-0010-DS402 - Object description and parameterization Index 6065 Following error window Index Name Meaning Data type Flags Default (hex) 6065:0 Follow- Following error monitor: Following error window UINT32 0xFFFFFF ing error FF (-1 Unit: the given value must be multiplied by the corresponding scaling factor window [} 100] 0xFFFFFFFF (-1...

- Page 153 EL72x1-0010-DS402 - Object description and parameterization Index 6077 Torque actual value Index Name Meaning Data type Flags Default (hex) 6077:0 Torque This object shall provide the actual value of the torque. INT16 0x0000 actual The value is specified in 1000th of the rated current value Formula:l: Index 6079 DC link circuit voltage...

- Page 154 EL72x1-0010-DS402 - Object description and parameterization Index 60BC Touch probe 2 positive edge Index (hex) Name Meaning Data type Flags Default 60BC:0 Touch probe 2 positive Positive position value of TP 2 INT32 0x00000000 edge Unit: the given value must be multiplied by the corre- sponding scaling factor [} 100] Index 60BD Touch probe 2 negative edge Index (hex) Name...

-

Page 155: Information / Diagnosis Data

EL72x1-0010-DS402 - Object description and parameterization Index 6502 Supported drive modes Index (hex) Name Meaning Data type Flags Default 6502:0 Supported drive This object shall provide information on the supported UINT32 0x00000000 modes drive modes. (DS402 Object 0x6502) Only modes CSV, CST, CSTCA and CSP are sup- ported Bit 0: PP Bit 1: VL... - Page 156 EL72x1-0010-DS402 - Object description and parameterization Index 2040 Amplifier Info data Index (hex) Name Meaning Data type Flags Default 2040:0 Amplifier Info data Maximum subindex UINT8 0x12 (18 2040:11 Amplifier temperature Internal terminal temperature UINT16 0x0000 (0 Unit: 0.1 °C 2040:12 DC link voltage DC link voltage...

- Page 157 EL72x1-0010-DS402 - Object description and parameterization Index (hex) Name Meaning Data type Flags Default 2059:0 OCT Nameplate Maximum subindex UINT8 0x24 (36 2059:01 Motor vendor Motor vendor STRING 2059:02 Electric motor type Motor type STRING 2059:03 Serial No Serial number STRING 2059:04 Order code...

-

Page 158: Standard Objects

EL72x1-0010-DS402 - Object description and parameterization Index (hex) Name Meaning Data type Flags Default 2059:13 Max speed Maximum speed UINT32 0x00000000 Unit: rpm 2059:14 Moment of inertia Mass moment of inertia UINT16 0x0000 (0 Unit: g cm^2 2059:15 T motor warn limit Motor temperature warning threshold UINT16 0x0000 (0... - Page 159 EL72x1-0010-DS402 - Object description and parameterization Index 100A Software version Index (hex) Name Meaning Data type Flags Default 100A:0 Software version Firmware-Version des EtherCAT-Slaves STRING Index 1018 Identity Index (hex) Name Meaning Data type Flags Default 1018:0 Identity Information for identifying the slave UINT8 0x04 (4 1018:01...

- Page 160 EL72x1-0010-DS402 - Object description and parameterization Index 1606 DS402 RxPDO-Map Target position Index (hex) Name Meaning Data type Flags Default 1606:0 DS402 RxPDO-Map PDO Mapping RxPDO 7 UINT8 0x01 (1 Target position 1606:01 SubIndex 001 1. PDO Mapping entry UINT32 0x607A:00, 32 Index 1607 DS402 RxPDO-Map Touch probe function Index (hex) Name...

- Page 161 EL72x1-0010-DS402 - Object description and parameterization Index 1A07 DS402 TxPDO-Map Touch probe 1 negative edge Index (hex) Name Meaning Data type Flags Default 1A07:0 DS402 TxPDO-Map PDO Mapping TxPDO 8 UINT8 0x01 (1 Touch probe 1 nega- tive edge 1A07:01 SubIndex 001 1.

- Page 162 EL72x1-0010-DS402 - Object description and parameterization Index 1C13 TxPDO assign Index Name Meaning Data type Flags Default 1C13:0 TxPDO assign PDO Assign Inputs UINT8 0x02 (2 1C13:01 Subindex 001 1. allocated TxPDO (contains the index of the associ- UINT16 0x1A00 ated TxPDO mapping object) (6656 1C13:02...

- Page 163 EL72x1-0010-DS402 - Object description and parameterization Index 1C32 SM output parameter Index (Hex) Name Meaning Data type Flags Default 1C32:0 SM output parameter Synchronization parameters for the outputs UINT8 0x20 (32 1C32:01 Sync mode Current synchronization mode: UINT16 0x0000 (0 •...

- Page 164 EL72x1-0010-DS402 - Object description and parameterization Index 1C33 SM input parameter Index (hex) Name Meaning Data type Flags Default 1C33:0 SM input parameter Synchronization parameters for the inputs UINT8 0x20 (32 1C33:01 Sync mode Current synchronization mode: UINT16 0x0000 (0 •...

-

Page 165: El72X1-0010-Mdp742 - Object Description And Parameterization

EtherCAT XML Device Description The display matches that of the CoE objects from the EtherCAT XML Device Description. We recommend downloading the latest XML file from the download area of the Beckhoff Note website and installing it according to installation instructions. - Page 166 EL72x1-0010-MDP742 - Object description and parameterization Index 8008 FB OCT Settings Index (hex) Name Meaning Data type Flags Default 8008:0 FB OCT Settings Maximum subindex UINT8 0x00 (0 8008:01 Enable autoconfig Configuration takes place automatically after the read- BOOLEAN 0x00 (0 ing of the electronic type plate (see Automatic scanning of the electronic type plates [} 112])

-

Page 167: Fig. 166 Following Error Window

EL72x1-0010-MDP742 - Object description and parameterization Index (hex) Name Meaning Data type Flags Default 8010:39 Select info data 1 Selection "Info data 1" UINT8 0x01 (1 Optional display of additional information in the cyclic process data. Permitted values: Torque current (filtered 1ms) DC link voltage (mV) PCB temperature (0.1 °C) - Page 168 EL72x1-0010-MDP742 - Object description and parameterization Index 8011 DRV Motor Settings Index (hex) Name Meaning Data type Flags Default 8011:0 DRV Motor Settings Maximum subindex UINT8 0x2D (45 8011:11* Max current Peak current UINT32 0x00001770 Unit: mA (6000 This value is affected by automatic scanning. (see Automatic scanning of the electronic type plates [} 112]) 8011:12*...

- Page 169 EL72x1-0010-MDP742 - Object description and parameterization Index (hex) Name Meaning Data type Flags Default 8011:29 I2T warn level I2T model warning threshold UINT8 0x50 (80 Unit: % 8011:2A I2T error level I2T model error threshold UINT8 0x69 (105 Unit: % 8011:2B* Motor Temperature Overtemperature warning threshold...

-

Page 170: Configuration Data (Vendor-Specific)

EL72x1-0010-MDP742 - Object description and parameterization Configuration data (vendor-specific) Index 801F DRV Vendor data Index (hex) Name Meaning Data type Flags Default 801F:0 DRV Vendor data Maximum subindex UINT8 0x14 (20 801F:11 Amplifier peak current Peak current of the amplifier (peak value) UINT32 0x00001F40 Unit: mA... - Page 171 EL72x1-0010-MDP742 - Object description and parameterization Index 6001 FB Touch probe inputs Index (hex) Name Meaning Data type Flags Default 6001:0 FB Touch probe inputs Maximum subindex UINT8 0x14 (20 6001:01 TP1 Enable Touchprobe 1 switched on BOOLEAN 0x00 (0 6001:02 TP1 pos value stored Positive value of Touchprobe 1 saved...

-

Page 172: Output Data

EL72x1-0010-MDP742 - Object description and parameterization Output data Index 7001 FB Touch probe outputs Index (hex) Name Meaning Data type Flags Default 7001:0 FB Touch probe out- Maximum subindex UINT8 0x0E (14 puts 7001:01 TP1 Enable Switch on Touchprobe 1 BOOLEAN 0x00 (0 7001:02... - Page 173 EL72x1-0010-MDP742 - Object description and parameterization Index 7010 DRV Outputs Index Name Meaning Data type Flags Default (hex) 7010:0 Maximum subindex UINT8 0x0E Outputs 7010:01 Control- Controlword UINT16 0x0000 word Bit 0: Switch on Bit 1: Enable voltage Bit 2: Quick stop (inverse) Bit 3: Enable operation Bit 4 - 6: reserved Bit 7: Fault reset...

-

Page 174: Information / Diagnosis Data

EL72x1-0010-MDP742 - Object description and parameterization Information / diagnosis data Index 10F3 Diagnosis History Index (hex) Name Meaning Data type Flags Default 10F3:0 Diagnosis History Maximum subindex UINT8 0x37 (55 10F3:01 Maximum Messages Maximum number of stored messages. A maximum of UINT8 0x00 (0 50 messages can be stored... - Page 175 EL72x1-0010-MDP742 - Object description and parameterization Index 9009 FB OCT Nameplate The parameters described in this index are always read from the electronic type plate of the connected motor. These parameters automatically lead to the parameters marked with an asterisk (*) in this chapter, if automatic scanning of the electronic type plate is switched on (index 8001 [} 165]).

- Page 176 EL72x1-0010-MDP742 - Object description and parameterization Index (hex) Name Meaning Data type Flags Default 9009:13 Max speed Maximum speed UINT32 0x00000000 Unit: rpm 9009:14 Moment of inertia Mass moment of inertia UINT16 0x0000 (0 Unit: g cm^2 9009:15 T motor warn limit Motor temperature warning threshold UINT16 0x0000 (0...

-

Page 177: Standard Objects

EL72x1-0010-MDP742 - Object description and parameterization Index 9018 DRV Info data Index (hex) Name Meaning Data type Flags Default 9018:0 DRV Info data Maximum subindex UINT8 0x11 (17 9018:11 Auxiliary voltage (10 Auxiliary voltage UINT32 0x00000000 Unit: mV Index A010 DRV Amplifier Diag data Index (hex) Name Meaning Data type... - Page 178 EL72x1-0010-MDP742 - Object description and parameterization Index 1018 Identity Index (hex) Name Meaning Data type Flags Default 1018:0 Identity Information for identifying the slave UINT8 0x04 (4 1018:01 Vendor ID Vendor ID of the EtherCAT slave UINT32 0x00000002 1018:02 Product code Product code of the EtherCAT slave UINT32 0x1C213052...

- Page 179 EL72x1-0010-MDP742 - Object description and parameterization Index 1605 DRV RxPDO-Map Torque offset Index (hex) Name Meaning Data type Flags Default 1605:0 DRV RxPDO-Map PDO Mapping RxPDO 6 UINT8 0x01 (1 Torque offset 1605:01 SubIndex 001 1. PDO Mapping entry (object 0x7010 (DRV Outputs), UINT32 0x7010:0A, 16 entry 0x0A (Torque offset))

- Page 180 EL72x1-0010-MDP742 - Object description and parameterization Index 1A02 DRV TxPDO-Map Velocity actual value Index (hex) Name Meaning Data type Flags Default 1A02:0 DRV TxPDO-Map Ve- PDO Mapping TxPDO 3 UINT8 0x01 (1 locity actual value 1A02:01 SubIndex 001 1. PDO Mapping entry (object 0x6010 (DRV Inputs), UINT32 0x6010:07, 32 entry 0x07 (Velocity actual value))

- Page 181 EL72x1-0010-MDP742 - Object description and parameterization Index 1A08 FB TxPDO-Map Touch probe 1 pos position Index (hex) Name Meaning Data type Flags Default 1A08:0 FB TxPDO-Map Touch PDO Mapping TxPDO 9 UINT8 0x01 (1 probe 1 pos position 1A08:01 SubIndex 001 1.

- Page 182 EL72x1-0010-MDP742 - Object description and parameterization Index 1C13 TxPDO assign Index (hex) Name Meaning Data type Flags Default 1C13:0 TxPDO assign PDO Assign Inputs UINT8 0x03 (3 1C13:01 Subindex 001 1. allocated TxPDO (contains the index of the associ- UINT16 0x1A00 ated TxPDO mapping object) (6656...

- Page 183 EL72x1-0010-MDP742 - Object description and parameterization Index 1C32 SM output parameter Index (hex) Name Meaning Data type Flags Default 1C32:0 SM output parameter Synchronization parameters for the outputs UINT8 0x20 (32 1C32:01 Sync mode Current synchronization mode: UINT16 0x0000 (0 •...

- Page 184 EL72x1-0010-MDP742 - Object description and parameterization Index 1C33 SM input parameter Index (hex) Name Meaning Data type Flags Default 1C33:0 SM input parameter Synchronization parameters for the inputs UINT8 0x20 (32 1C33:01 Sync mode Current synchronization mode: UINT16 0x0000 (0 •...

- Page 185 EL72x1-0010-MDP742 - Object description and parameterization Index FB40 Memory interface Index (hex) Name Meaning Data type Flags Default FB40:0 Memory interface Maximum subindex UINT8 0x03 (3 FB40:01 Address reserved UINT32 0x00000000 FB40:02 Length reserved UINT16 0x0000 (0 FB40:03 Data reserved OCTET- STRING[8] EL72x1-0010...

-

Page 186: Error Correction

The DiagMessages are explained in text form in the ESI/XML file belonging to the EtherCAT device: on the basis of the Text ID contained in the DiagMessage, the corresponding plain text message can be found in the languages contained in the ESI/XML. In the case of Beckhoff products these are usually German and English. -

Page 187: Fig. 174 Diagmessages In The Coe

Error correction Fig. 174: DiagMessages in the CoE The subindex of the latest DiagMessage can be read under x10F3:02. Support for commissioning The DiagMessages system is to be used above all during the commissioning of the plant. The diagnostic values e.g. in the StatusWord of the device (if available) are helpful for on- Note line diagnosis during the subsequent continuous operation. - Page 188 Structure of the Text ID The structure of the MessageID is not subject to any standardization and can be supplier-specifically defined. In the case of Beckhoff EtherCAT devices (EL, EP) it usually reads according to xyzz: 0: Systeminfo 1: General...

- Page 189 Error correction Overview of text IDs Text ID Type Place Text (English only) Cause 0x0001 Information System No error No error 0x0002 Information System Communication estab- Communication established lished 0x0003 Information System Initialization: 0x%X, 0x General information; parameters depend on event. See %X, 0x%X device documentation for interpretation.

- Page 190 Error correction Text ID Type Place Text (English only) Cause 0x8103 Error General No variable linkage No variables linked 0x8104 Error General Terminal-Overtempera- The internal temperature of the terminal exceeds the pa- ture rameterized error threshold. Activation of the terminal is prevented 0x8105 Error...

-

Page 191: Appendix

Note • It is recommended to use the newest possible firmware for the respective hardware • Beckhoff is not under any obligation to provide customers with free firmware updates for delivered products. Risk of damage to the device! Pay attention to the instructions for firmware updates on the separate page. -

Page 192: Ethercat Al Status Codes

For detailed information please refer to the EtherCAT system description. 10.3 Firmware Update EL/ES/EM/EPxxxx This section describes the device update for Beckhoff EtherCAT slaves from the EL/ES, EM, EK and EP series. A firmware update should only be carried out after consultation with Beckhoff support. Storage locations An EtherCAT slave stores operating data in up to 3 locations: •... -

Page 193: Fig. 176 Device Identifier Consisting Of Name El3204-0000 And Revision -0016

Corresponding updates Note should only be carried out in consultation with Beckhoff support. Display of ESI slave identifier The simplest way to ascertain compliance of configured and actual device description is to scan the EtherCAT boxes in TwinCAT mode Config/Freerun: Fig. 177: Scan the subordinate field by right-clicking on the EtherCAT device in Config/FreeRun mode... -

Page 194: Fig. 177 Scan The Subordinate Field By Right-Clicking On The Ethercat Device In Config/Freerun Mode 193 Fig. 178 Configuration Is Identical

Appendix Fig. 178: Configuration is identical otherwise a change dialog for entering the actual data in the configuration. Fig. 179: Change dialog In the example shown in Fig. “Change dialog”. an EL3201-0000-0017 was found, while an EL3201-0000-0016 had been configured. In this case it makes sense to adapt the configuration with the Copy Before button. - Page 195 Determining the firmware version Determining the version on laser inscription Beckhoff EtherCAT slaves feature serial numbers applied by laser. The serial number has the following structure: KK YY FF HH KK - week of production (CW, calendar week) YY - year of production...

- Page 196 • offline: The EtherCAT Slave Information ESI/XML may contain the default content of the CoE. This CoE directory can only be displayed if it is included in the ESI (e.g. "Beckhoff EL5xxx.xml"). The Advanced button must be used for switching between the two views.

- Page 197 Appendix Fig. 183: Firmware Update Proceed as follows, unless instructed otherwise by Beckhoff support. • Switch slave to INIT (A) • Switch slave to BOOTSTRAP • Check the current status (B, C) • Download the new *efw file • After the download switch to INIT, then OP •...

- Page 198 Appendix Fig. 184: FPGA firmware version definition If the column Reg:0002 is not displayed, right-click the table header and select Properties... in the context menu. Fig. 185: Context menu Properties The Advanced Settings dialog appears where the columns to be displayed can be selected. Under Diagnosis/Online View select the '0002 ETxxxx Build' check box in order to activate the FPGA firmware version display.

- Page 199 Appendix Fig. 186: Dialog Advanced Settings Update For updating the FPGA firmware • of an EtherCAT coupler the coupler must have FPGA firmware version 11 or higher; • of an E-Bus Terminal the terminal must have FPGA firmware version 10 or higher. Older firmware versions can only be updated by the manufacturer! Updating an EtherCAT device In the TwinCAT System Manager select the terminal whose FPGA firmware you want to update (in this...

- Page 200 Appendix Fig. 187: Select dialog Advanced Settings The Advanced Settings dialog appears. Under ESC Access/E²PROM/FPGA click on Write FPGA button, Fig. 188: Select dialog FPGA Version: 2.0 EL72x1-0010...

- Page 201 Appendix Fig. 189: Write FPGA select the file (*.rbf) with the new FPGA firmware, and transfer it to the EtherCAT device. Risk of damage to the device! A firmware download to an EtherCAT device must never be interrupted! If this process is cancelled, the supply voltage switched off or the Ethernet connection interrupted, the Ether- Attention CAT device can only be recommissioned by the manufacturer!

-

Page 202: Restoring The Delivery State

Appendix 10.4 Restoring the delivery state Restoring the delivery state To restore the delivery state for backup objects in ELxxxx terminals, the CoE object "Restore default parameters", SubIndex 001 can be selected in the TwinCAT System Manager (Config mode) (see Fig. “Selecting the ‘Restore default parameters’ PDO”) Fig. 191: Selecting the "Restore default parameters"... -

Page 203: Support And Service

Beckhoff's branch offices and representatives Please contact your Beckhoff branch office or representative for local support and service on Beckhoff products! The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages: http://www.beckhoff.com You will also find further documentation for Beckhoff components there. - Page 204 Other installation positions ......................Fig. 30 Shield busbar..........................Fig. 31 Shield connection ........................Fig. 32 Note ............................Fig. 33 EL7201-0010 - LEDs ......................... Fig. 34 EL7201-0010 - Connection......................Fig. 35 EL7211-0010 - LEDs ......................... Fig. 36 EL7211-0010 - Connection......................Fig. 37 System Manager option ......................

- Page 205 List of illustration Fig. 43 For TwinCAT 2.11 and higher, the System Manager can search for current Beckhoff ESI files automatically, if an online connection is available ..............Fig. 44 Identifier structure ........................Fig. 45 OnlineDescription information window ..................Fig. 46 Information window OnlineDescription, TwinCAT 3.x..............

- Page 206 List of illustration Fig. 88 EL3102, CoE directory ......................Fig. 89 Example of commissioning aid for a EL3204 ................Fig. 90 Default behaviour of the System Manager ................Fig. 91 Default target state in the Slave ....................Fig. 92 PLC function blocks ........................Fig.

- Page 207 List of illustration Fig. 134 Changing the PLC path ......................106 Fig. 135 Required libraries........................106 Fig. 136 Global variables ......................... 107 Fig. 137 Local variables........................... 107 Fig. 138 Program code ..........................108 Fig. 139 Visualization..........................109 Fig. 140 DS402 State Machine........................ 110 Fig.

- Page 208 List of illustration Fig. 180 EEPROM Update........................195 Fig. 181 Selecting the new ESI........................ 195 Fig. 182 Display of EL3204 firmware version ..................196 Fig. 183 Firmware Update ........................197 Fig. 184 FPGA firmware version definition ....................198 Fig. 185 Context menu Properties ......................

Need help?

Do you have a question about the EL7201-0010 and is the answer not in the manual?

Questions and answers