Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Henny Penny 6.10

-

Page 1: Service Instructions

Service instructions Combi Steamer Unit Model Type of Unit type energy Space$afer Electric Tabletop Plus Platnium 6.10 unit Space$afer 6.23 Electric Tabletop Platnium unit 10015160-0ASAE-A en-US R E G I S T E R W A R R A N T Y O N L I N E AT W W W. H E N N Y P E N N Y. C O M... - Page 2 Manufacturer Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG Halberstaedter Strasse 2a D-38300 Wolfenbuettel Telephone 0 53 31 / 89-0 Telefax 0 53 31 / 89-280 Service instructions...

-

Page 3: Table Of Contents

Directory of contents 1 Password overview ............ 5 2 Introduction ................. 6 2.1 About this manual ................ 6 2.2 Warranty .................... 6 3 Safety instructions ............. 7 4 Opening the appliance ............ 8 4.1 Unit cover and rear wall .............. 8 5 Service menu - appliance test ........... 9 5.1 Service menu ... - Page 4 Directory of contents 7 Trade show mode ............. 37 8 Electronics ................ 38 8.1 Block diagram for the control ............ 38 8.1.1 Unit size 6.23 ................... 38 8.1.2 Unit size 6.1 ..................... 38 8.2 Control board .................. 39 8.2.1 Layout ...................... 39 8.2.2 Configuration ................... 40 8.3 Safety overview ................ 43 8.3.1 Unit size 6.23 ...................

-

Page 5: 1 Password Overview

Password overview 1 Password overview Range Pass- Description Described in word Installation / com- 2100 Setting all basic parameters Installation in- missioning (for example time / date). structions gas calibra- Verification and calibration of Installation in- tion exhaust emissions. Only for structions energy type - gas. -

Page 6: 2 Introduction

Introduction 2 Introduction 2.1 About this manual This service manual contains information needed by the service technician for professional and correct fault isolation, repair and maintenance of the unit. The service technician must also observe the contents of the installation instructions and the user manual. Target group Target group for this service manual is trained specialists who are familiar with the technical functioning and operation of the unit. -

Page 7: 3 Safety Instructions

Safety instructions 3 Safety instructions For servicing tasks, the service technician must be familiar with and observe regional regulations. In addition, the notes in the service manual must be observed. Danger to life due to electric current DANGER ü Disconnect power prior to performing gas and electrical work. •... -

Page 8: 4 Opening The Appliance

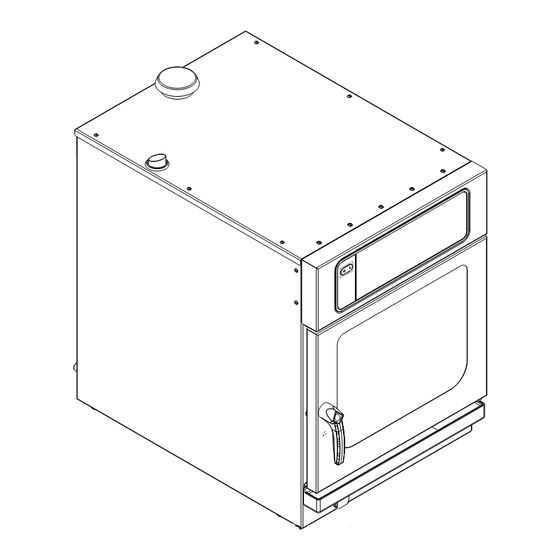

Opening the appliance 4 Opening the appliance 4.1 Unit cover and rear wall Overview a Rear panel c Unit cover b Air inlet nozzle cover Remove unit cover Remove cover from air inlet nozzles by turning it. Remove the screws from the unit cover. Remove the unit cover. -

Page 9: 5 Service Menu - Appliance Test

Service menu - appliance test 5 Service menu - appliance test 5.1 Service menu Description • Functional testing of individual components • Error analysis • Maintenance • Change basic settings • Software update The graphics shown may deviate due to changes and different software versions. -

Page 10: Appliance Information

Service menu - appliance test 5.2 Appliance information Description Display of the appliance-specific information Installed software Appliance configuration Cookbook version Serial number Contact data Overview Exiting the appliance Touch the Back field. information Service instructions... -

Page 11: Status Overview

Service menu - appliance test 5.3 Status overview Status 1 Heating circuit PWM: heat requirement in %. POS: power optimization system (option). Temperature sensors B1, B3, B6, B7 are not present. Status 2 Climate control system, fan B14: Pressure switch on the DynaSteam unit PWM: heat requirement in %. -

Page 12: Combidoctor

Service menu - appliance test Status 4 Miscellaneous K3: Manual rinse K10: Motor M1 On/Off. Only for unit size 6.23. B15: Reed contact switch K07, K13, K14: Not used Temperature sensors B1, B3, B6, B7 are not present. 5.4 CombiDoctor Description The CombiDoctor offers an automatic check of the climate control and the WaveClean automatic cleaning. - Page 13 Service menu - appliance test 2 WaveClean • Automatic checking of the WaveClean cleaning – WaveClean pump (circulation pump) – Siphon pump (drainage pump) – Magnetic valve for water vapor elimination & siphon filling – Reed contact switch of the cooking chamber door Starting the program Touch the "START"...

-

Page 14: Relay Test

Service menu - appliance test 5.5 Relay test Description Separate control of the relay. Testing the relay. Testing the connected components. Relays K1 and K16 are switched on permanently. INFORMATION A plurality of relays are switched on simultaneously. Overview Image: Relay test page 1 Image: Relay test page 2 Activating relay test Touch field of relay to be tested. - Page 15 Service menu - appliance test Relay overview Relay Connec- Description Informa- tion Main contactor Q1 230V AC POS A 230V AC POS B 230V AC Magnetic valve K23 for manual 230V AC rinse Magnetic valve for water vapor 230V AC elimination K12 Siphon pump G24 230V AC...

-

Page 16: Waveclean Test (Option)

Service menu - appliance test 5.6 WaveClean test (option) Overview Description WaveClean test program for function check. Circulation pump Siphon pump Magnetic valve for water filling Door seal / leak tightness in door area Follow the instructions on the touch screen. INFORMATION The test is used exclusively for functional testing and not to clean the cooking chamber. -

Page 17: 100°C + Core Temperature Calibration

Service menu - appliance test 5.7 100°C + core temperature calibration Description Calibration for cooking chamber sensor and core temperature sensor. Testing the calibration. Performing the calibration. The cooking chamber sensor and core temperature sensor calibration is performed in one step. The units are factory calibrated. -

Page 18: Check Calibration

Service menu - appliance test 5.7.1 Check calibration Prerequisite Calibrated digital temperature measurement device. The temperature in the cooking chamber is < 100°C. Fix internal core temperature sensor and temperature sensor of external measurement device in the cooking chamber. Use a grill rack for this. Point the sensor tips upward in order to prevent measurement errors. -

Page 19: Calibrate Cooking Chamber Sensor

Service menu - appliance test 5.7.2 Calibrate cooking chamber sensor Prerequisite Execute Check calibration and do not switch appliance off. (see „5.7.1 Check calibration‟, Page 18) Temperature display on the touch screen indicates 100°C. Calibration Adjust offset value by adjusting the roller. Let 10 minutes adjustment time elapse. -

Page 20: Dynasteam Test

Service menu - appliance test 5.8 DynaSteam test Description The DynaSteam test allows the function test of the DynaSteam steaming unit. Calibration of the steaming unit is not possible / necessary. Prerequisite Access to the water supply pipe in the cooking chamber. Remove both hook-in points. -

Page 21: Emptying The Water

Service menu - appliance test 5.9 Emptying the water Description Water drainage removes water residue from the unit to prevent frost damage during transport and idle period. Requirement Both water connections are connected to compressed air. The pressure may not exceed 6 bar. The cooking chamber temperature is <... -

Page 22: Audio Settings

Service menu - appliance test 5.11 Audio settings Overview Setting the volume Set the desired volume using the sliders. Touch the "OK" field. Changes saved. Canceling the selection Touch the "Back" field. Service instructions... -

Page 23: Select Signal Tones

Service menu - appliance test 5.12 Select signal tones Overview Set signal tones Set the signal tone by adjusting the rollers. Touch the "OK" field. Changes saved. Canceling the selection Touch the "Back" field. 5.13 POS activation Description Software activation for the optional connection to a customer-supplied performance optimization system. - Page 24 Service menu - appliance test Overview Exporting log data Perform according to instructions on the touch screen. Touch the Confirmation field. Log data export begins. Service instructions...

-

Page 25: Software Update

Service menu - appliance test 5.15 Software update Description Update of the software via the USB interface. Additional content (help texts, cookbooks, videos) will not be updated. Overview Performing the update Perform according to instructions on the touch screen and description . -

Page 26: Restoring Data

Service menu - appliance test 5.17 Restoring data Description Import function of parameters stored on the SD card. Required after change of control board or control panel. Overview Restoring data Touch the Confirmation field. Restoring of the data from the SD card. Touch the "OK"... -

Page 27: Water Filter Maintenance

Service menu - appliance test 5.19 Water filter maintenance Description With use of a water filter on the soft water connection of the unit, a maintenance note may appear after the stored flow quantity has been reached. For this, the appropriate filter capacity must be determined and entered. -

Page 28: Setting Units

Service menu - appliance test Importing data Perform according to instructions on the touchscreen. Touch the Confirmation field. Import the created contact data. Then a confirmation appears on the touchscreen. 5.21 Setting units Overview To convert the units 1. Select the desired temperature and volume. 2. -

Page 29: Status Overview Direct Access

Service menu - appliance test Touch the "OK" field. Changes saved. Canceling the selection Touch the "Back" field. Relay overview Relay Connec- Description Instruction Main contactor Q1 Reconnect the line from X10.2 to X12.5 and to as- sign a reserve relay to it. POS A Reconnect the line from X11.1 to X12.5 and to as- sign a reserve relay to it. - Page 30 Service menu - appliance test Overview Calling up status overview Touch the invisible field three times quickly. Change of the display to the multi-page status overview . Exiting the status overview Touch the Back field. Change to the display of the cooking process. The status overview is intended only for the service technician.

-

Page 31: 6 Software

Software 6 Software 6.1 Software update Prerequisite USB stick. Maximum size 32 GB. FAT formatting (default). The disk should be empty if possible. Current software update. The update is provided as packed ZIP file. Preparing the USB stick Open and download the .ZIP file and unzip. In general, the unzipped folder is in the same directory as the previously compressed one. - Page 32 Software Performing the update Switch the unit on. Tap the "Appliance functions" field. Display of Appliance functions menu. Tap "Settings" field. Display of " PIN " window. Enter password and tap the Confirmation field. The password for the Settings menu is 111. Select the "Software update"...

-

Page 33: Importing Additional Content

Software 6.2 Importing additional content Description Import function for manufacturer contents: • Cookbook graphics • Help information • Sound files Prerequisite USB stick. Maximum size 32 GB. FAT formatting (default). The disk should be empty if possible. Current additional content. Additional contents are provided as packed .ZIP file. - Page 34 Software Importing additional Switch the unit on. content Tap the "Appliance functions" field. Display of Appliance functions menu. Tap "Settings" field. Display of " PIN " window. Enter password and tap the Confirmation field. The password for the Settings menu is 111. Select the field "Import additional contents"...

-

Page 35: Importing The Manufacturer's Cookbook

Software 6.3 Importing the manufacturer's cookbook Prerequisite USB stick. On the unit, the software version 1.29 (from 04/2014) or higher is installed. Check of the software version in the unit's information (see „5.2 Appliance information‟, Page 10). If necessary, perform software update . Preparing the USB stick TouchClassicDB.sdf FCImport... -

Page 36: Tap The "Ok" Field

Software Tap the Confirmation field. Import begins. Then a confirmation appears on the touchscreen. Exiting selection Tap the Back field. Service instructions... -

Page 37: 7 Trade Show Mode

Trade show mode 7 Trade show mode Description Trade show mode allows appliance operation for demonstration purposes. Prerequisite A single-phase power supply is required for operation. Unit is connected to L3 and N. See also installation instructions. Calling up the selection Switch unit to "I"... -

Page 38: 8 Electronics

Electronics 8 Electronics 8.1 Block diagram for the control 8.1.1 Unit size 6.23 18V AC 230V AC 24V DC 230V AC Legend Control board Transformer Control panel Digital key Fan motor 8.1.2 Unit size 6.1 18V AC 230V AC 24V DC CAN X5 230V AC Legend... -

Page 39: Control Board

Electronics 8.2 Control board 8.2.1 Layout Service instructions... -

Page 40: Configuration

Electronics 8.2.2 Configuration Connector X1 Description Conductor number Input 10.7 V AC for lighting Power supply I/O board 18V AC Connector X2, X3, X4 Not assigned Connector X5 CAN bus line to motor M10 (only for unit size 6.1) Connector X6 Not assigned Connector X7 MMI communication Connector X8 Digital key contains device-specific information. - Page 41 Electronics Description Conductor number Supply voltage fan motor M1 Output K10, fan motor on/off Connector X14 (potential- Description Conductor free) number Input K11, cooling fan G7 (230V AC) Output K11, cooling fan G7 (230V AC) Connector X15 Not assigned Connector X16 (potential- Only assigned for unit size 6.23.

- Page 42 Electronics Connector X32 (24V DC) Description Conductor number Output, SSR Q2, Q3 Connector X35 Not assigned Button The buttons have no function and are intended for internal use. Service instructions...

-

Page 43: Safety Overview

Electronics 8.3 Safety overview 8.3.1 Unit size 6.23 T1-F2 10,7V AC 3,15A T1-F1 6,3A 18V AC 3,15A 230V AC A1-F3 230V AC 3,15A A1-F5 230V AC 3,15A A1-F2 24V DC 3,15A 6,3A Legend Control board Backup relay Control panel Magnetic valve extinguishing Cooking chamber STL Magnetic valve manual rinse Thermal switch... -

Page 44: Unit Size 6.1

Electronics 8.3.2 Unit size 6.1 T1-F2 10,7V AC 3,15A T1-F1 6,3A 18V AC 3,15A 230V AC A1-F3 230V AC 3,15A A1-F5 230V AC 3,15A A1-F2 24V DC 3,15A 6,3A Legend Control board Backup relay Control panel Magnetic valve extinguishing Cooking chamber STL Magnetic valve manual rinse Thermal switch Solenoid... -

Page 45: 9 Error Messages

Error messages 9 Error messages 9.1 Emergency operation Description In order to allows limited use in case of error, the appliance has various emergency programs. Emergency operation is activated automatically and displayed. After elimination of the error indicated, the controller switches back into regular operation automatically. A reset is not necessary. -

Page 46: Cooking Chamber Sensor Defective (694, 695)

Error messages 9.2 Cooking chamber sensor defective (694, 695) Description Emergency operation is activated automatically and displayed. The core temperature sensor takes over the function of the cooking chamber sensor. Cooking program with core temperature sensor is no longer available. Location The cooking chamber sensor is in the top right of the cooking chamber. -

Page 47: Core Temperature Sensor Defective (699, 700)

Error messages 9.3 Core temperature sensor defective (699, 700) Description The core temperature sensor in the cooking chamber is deactivated. Location The core temperature sensor is in the front area of the cooking chamber. Naming on the circuit diagram Troubleshooting Dismount unit cover. Check contacting on control board A X24. -

Page 48: Water Vapor Sensor Defective (710)

Error messages 9.4 Water vapor sensor defective (710) Description The temperature sensor on the control board is measuring a temperature of >70°C. The unit is no longer operational until it cools down. Troubleshooting Check air intake area of fan. Clean dirty air intake area. Check that cooling fan is functioning properly. -

Page 49: Excess Temperature In The Cooking Chamber (Id73)

Error messages 9.5 Excess temperature in the cooking chamber (ID73) Description The measured temperature in the cooking chamber is outside the allowable range (electric power supply > 310°C). The unit is no longer operational until the cooking chamber cools down. The measurement is taken by the cooking chamber sensor, core temperature sensor and the moisture sensor. -

Page 50: Overtemperature Control (Tmp_Id2)

Error messages 9.6 Overtemperature control (TMP_ID2) Description The temperature sensor on the control board is measuring a temperature of >70°C. The unit is no longer operational until it cools down. Troubleshooting Check air intake area of fan. Clean dirty air intake area. Check that cooling fan is functioning properly. -

Page 51: Fan Defective Or Temperature Limiter Triggered (702) Only For Compact

Error messages 9.8 Fan defective or temperature limiter triggered (702) only for Compact Description The control board A1 does not receive any response via the CAN bus cable from fan motor M10. There is an error in the safety circuit or fan area. - Page 52 Error messages Switch unit on and measure voltage at main contactor Q1, terminals A1 and A2. The main contactor must be energized. No voltage present. There is an error in the STL circuit. Troubleshooting according to "Troubleshooting safety circuit". Voltage present. There is an fault in the fan area. Troubleshoot according to "Troubleshooting the fan".

-

Page 53: Fan Defective. Cooking Program Was Cancelled (701)

Error messages 9.9 Fan defective. Cooking program was cancelled (701) Description The control board A1 does not receive any response via the CAN bus cable from fan motor M10. Troubleshooting (see „9.8 Fan defective or temperature limiter triggered (702) only for Compact‟, Page 51) 9.10 Water pressure too low (709) Description This fault message is displayed if the pressure switch registered a... - Page 54 Error messages Perform DynaSteam test again and check water quantity with measurement container. The water quantity corresponds to the set quantity (±10%). Replace pressure switch. The water quantity does not correspond to the set quantity (±10%). Ensure that the supply pipe is not clogged. Replace steaming unit.

-

Page 55: Faulty Can Connection

Error messages 9.11 Faulty CAN connection Description There is a communication fault between the operating panel and control panel. In addition, temperature sensor and fan fault messages appear on the touchscreen. Fault message displayed Troubleshooting Replace communication cable between operating panel and control panel circuit board. - Page 56 Error messages Service instructions...

- Page 58 Manufacturer Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG Halberstaedter Strasse 2a D-38300 Wolfenbuettel Telephone 0 53 31 / 89-0 Telefax 0 53 31 / 89-280 *10015160-0ASAE-A*...

Need help?

Do you have a question about the 6.10 and is the answer not in the manual?

Questions and answers