Summary of Contents for Retsch MM400

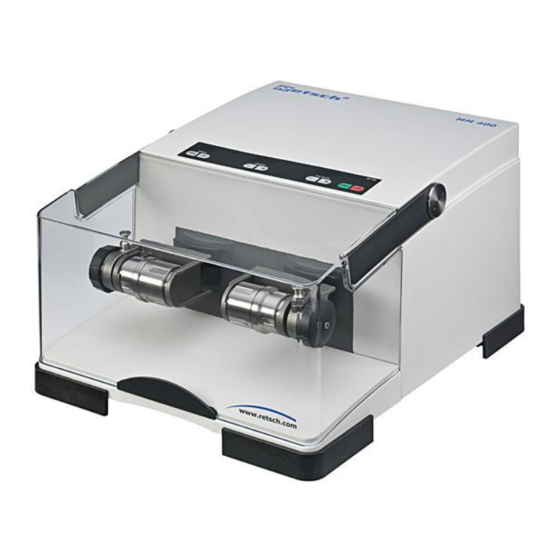

- Page 1 Operating Instructions for Oscillating Mill MM400 Retsch GmbH, 42781 Haan, Retsch-Allee 1-5, Germany 12/20/2016 0004...

-

Page 2: Notes On These Operating Instructions

Notes on these operating instructions These operating instructions for the oscillating mill, type MM400, give all the necessary information on the areas mentioned in the contents. They instruct the target group(s) for each of the defined areas, in order to ensure safe handling of the MM 400 when used for the intended purpose. -

Page 3: Table Of Contents

Wear ..................... 24 Wearing parts ................. 24 Checks ................... 24 Copyright ..................24 Alterations ..................25 Accessories for MM 400 ..............25 Safety regulations for the MM 400 - summary ........26 Appendix ............following pages 12/20/2016 Retsch GmbH... -

Page 4: Safety

The MM 400 is a modern, highly efficient product of Retsch GmbH, corresponding to state of the art. If the machine is used according to the intended purpose with a knowledge of this technical documentation it is completely safe and reliable to operate. -

Page 5: Warning Signs

Observe instructions for use Repairs These operating instructions do not include repair instructions. For your own safety repairs must be carried out only by Retsch GmbH or an authorised agent (service technicians). In this case please contact: The Retsch agency in your country... - Page 6 Do not make any alterations to the machine and use only spare parts and accessories approved by Retsch. Otherwise the Declaration of Conformity with European directives made by Retsch will lose its validity. Furthermore this will also lead to the loss of any guarantee claims.

- Page 7 Follow the safety regulations of the cooling liquid supplier. Retsch GmbH accepts no liability whatsoever arising from the use of liquid nitrogen or similar materials. Cleaning Do not clean the MM 400 under running water. Danger to life through current surge.

-

Page 8: Confirmation

Confirmation I have taken note of the sections „Notes on these operating instructions” and “Safety” _______________________________________ Signature of operating authority _______________________________________ Signature of service technician 12/20/2016 Retsch GmbH... -

Page 9: Technical Data

The milling ball/s may otherwise damage the milling cups. Do not make any alterations to the machine and use only spare parts and accessories approved by Retsch. Otherwise the Declaration of Conformity with the European directives by Retsch loses its validity. -

Page 10: Protective Equipment

L = 65 dB(A) pAeq Operating conditions: Container: 2 steel milling cups of 5 ml Milling organ: 2 tungsten carbide balls 8 mm Quartz crushed pebbles approx. Material charged: 1.0 – 1.5 mm Charged quantity: 1.5ml 12/20/2016 Retsch GmbH... -

Page 11: Protective Systems

If temperature variations are high (e.g. during air transport) the MM 400 must be protected against condensed water. Otherwise the electronic components can become damaged. Intermediate storage Ensure that the MM 400 is also stored dry during intermediate storage. 12/20/2016 Retsch GmbH... -

Page 12: Conditions For The Place Of Installation

The voltage and frequency for the MM 400 are given on the type plate. Ensure that these values correspond to the available power supply system. Connect the MM 400 to the power supply system using the supplied connection cable. 12/20/2016 Retsch GmbH... - Page 13 If the values on the type plate are not observed this can result in damage to the electrical and mechanical components. 12/20/2016 Retsch GmbH...

-

Page 14: Operation

Operation Target group: operators Operating elements and operation Graphical representation Plan view Front view 12/20/2016 Retsch GmbH... -

Page 15: General Table

Connection for power cable of machine Interface RS232 Enables operating software to be updated Sign – Caution! unplug mains Safety instruction plug Type plate Information on the machine and connected loads Sign – Follow operating Safety instruction instructions 12/20/2016 Retsch GmbH... -

Page 16: Display And Operating Unit

Continuous pressing switches on the digits fast running. Start – button Starts the milling operation Green LED Indicates milling operation Stop – button Interrupts or ends the milling operation, Red LED and ON Puts the machine into stand-by mode 12/20/2016 Retsch GmbH... -

Page 17: Inserting / Replacing The Milling Cups

• Short pressing of N+ or N- adjusts the time by one second or one minute. When pressed for longer the display runs continuously without a pause. If 99.0 minutes is exceeded the display L shows 0.10 seconds again. 12/20/2016 Retsch GmbH... -

Page 18: Setting The Frequency

During the milling process the time can be adjusted by pressing the N+ or N- button. When the milling time has elapsed the milling process is automatically ended. The display is reset to the last started value. 12/20/2016 Retsch GmbH... -

Page 19: Storing The Milling Parameters

Display operating hours : Press buttons "frequency 1/s" ( M) and SET simultaneously and keep pressed. “bS” appears in the display “memory”. Leave operating hours : Press STOP button. 12/20/2016 Retsch GmbH... -

Page 20: Operating Software Display

Target group: operators General The MM 400 is an ultramodern, high performance product from Retsch GmbH. Owing to the large selection of accessories the oscillation mill, type MM 400, is a machine with many different application possibilities in laboratories in industry and research. -

Page 21: The Milling Process

Please take any necessary measures to prevent danger to persons, depending on the dangerous nature of your sample. Please note that the properties, and therefore the dangerous nature of your sample, can change during the milling process. 12/20/2016 Retsch GmbH... -

Page 22: Safety Instructions For Handling Liquid Nitrogen

Please follow the safety regulations of the cooling liquid supplier. Retsch GmbH excludes any liability claims whatsoever which may arise through the use of liquid nitrogen or similar materials. ... -

Page 23: Safety Functions And Fault Displays

If the magnetic switch which monitors hood opening has a defect in the supply line this is recognised by the control unit and causes the machine to be switched off. “F07” appears in the display. To eliminate this fault repair by an authorised Retsch service agent is necessary. 12/20/2016... -

Page 24: General

Do not make any alterations to the machine and use only spare parts and accessories approved by Retsch. Otherwise the declared conformity with the European directives by Retsch will lose its validity. Furthermore this will lead to loss of any kind of guarantee claims. Wear... -

Page 25: Alterations

Milling balls dia. Zirconium oxide 12,15,20 mm Milling balls dia. Teflon with steel core 10,12,20 mm Milling balls dia. Polyamide for mixed 5,7,9,12 mm vessels Further accessories are given in our price list or in internet under www.retsch.de 12/20/2016 Retsch GmbH... -

Page 26: Safety Regulations For The Mm 400 - Summary

If the delivery is incomplete and / or there is Later complaints may possibly no transport damage you must inform the longer be considered. transporter and Retsch GmbH immediately (within 24 hrs). Ambient Temperature drops below 5°C Electronic and mechanical components can be damaged. -

Page 29: Eu Declaration Of Conformity

Annex VII Part B of the Machinery Directive, and we undertake to submit this documentation on request to the market surveillance authorities. In case of a modification of the device not previously agreed with Retsch GmbH, as well as the use of unauthorised spare parts or accessories, this declaration will lose its validity. - Page 32 Copyright ® Copyright by Retsch GmbH Haan, Retsch-Allee 1-5 D-42781 Haan Federal Republic of Germany...

Need help?

Do you have a question about the MM400 and is the answer not in the manual?

Questions and answers