Skipper DL850 Operation And Installation Manual

2 axis doppler log

Hide thumbs

Also See for DL850:

- Operation and installation manual (92 pages) ,

- Operation and installation manual (80 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Skipper DL850

- Page 1 SKIPPER DL850 2 Axis Doppler Log Operation And Installation Manual Edition 20030401Bsw3.26 Skipper Electronics A/S Telphone +47 23 30 22 70 Ryensvingen 5 Telefax +47 23 30 22 71 P.O.Box 151, Manglerud E-mail: skipper@skipper.no 0612 Oslo, Norway Co.reg.no: NO-965378847 -MVA...

- Page 2 Copying of this document, and giving it to others and the use or Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und Mitteilung ihres Inhaltes nicht gestattet, soweit nicht ausdrücklich Communication of contents therof, are forbidden without express Authority. Offenders are liable to the payment of damages. zugestanden.

- Page 3 CONTENTS 1. INTRODUCTION..........................5 ............................... 5 YSTEM UMMARY ........................... 5 RANSDUCER AND RANSCEIVER ..............................5 PERATOR Data Entry..................................5 ............................... 6 NTERFACING Outputs..................................6 Inputs....................................6 Alarms..................................6 2. OPERATION..........................7 .............................. 7 ARAMETER ENTRY Fig. 2.1 Setting and Parameter Entry Flowchart .....................7 Example of parameter entry.

- Page 4 NMEA Setup................................46 DL850 T ) NMEA0183 M ................47 RANSMITTED RIGINATED ESSAGES 6.DL850 CALIBRATION PROCEDURE ..................48 ......................48 CTIVATION OF THE CALIBRATION MODE ..................... 49 NSTALLATION ANGULAR ERROR CORRECTION ........................... 49 PEED CALIBRATION TRIP ....................51 ANUAL ADJUSTMENT OF CALIBRATION TABLE .

-

Page 5: Introduction

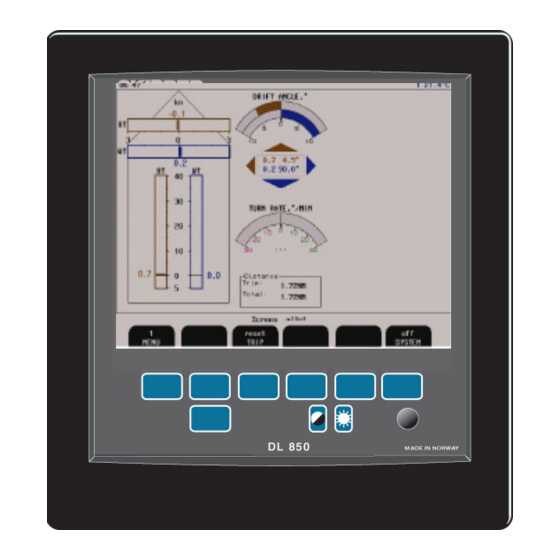

YSTEM UMMARY DL850 is a navigation, 2 Axis Doppler Log with a large, high resolution graphic LCD. An auxiliary, shallow water echo sounder function is included. The display graphics is continuously shown on the LCD along with complete navigation details. All IMO requirements are met or exceeded. Comprehen- sive interfaces are available including NMEA0183 input and output. -

Page 6: I Nterfacing

NMEA0183 Interface Input of Position, Heading, Depth, UTC. “Rate of turn” analogue input. (OPTION) Alarms. High and low speed alarms may be selected from the menus. A potential free relay contact is provided in DL850 for interface to external alarm systems. -

Page 7: Operation

2. Operation 2. OPERATION When the installation is complete, and power is connected to the Operator Unit, the system When the installation is complete, and power is connected to the Operator Unit, the system is switched is switched on by pressing any button. The unit is switched off by pressing the “SYSTEM on by pressing any button. -

Page 8: O Peration S Creens

PERATION CREENS Each of the operation screens contains a graphic picture and one or more Menu sets configured on the 6 soft key buttons. The various screens are selected by keeping the SCREEN SELECT button pressed and rotating the encoder in either direction. Turning the encoder clockwise cycle the screens in the sequence 1 to 7, and counter clockwise rotation cycles the screens in the sequence 7 - 1. - Page 9 CREEN Screen Pilot ILOT The various soft key menus are selected by pressing repeatedly the MENU button on the left side of the soft key menu. The number on the button (1 –3) indicates which of the The various soft key menus are selected by pressing repeatedly the MENU button on the left side of the menus are active.

- Page 10 Screen Pilot, Menu 2: Soft key 1 : MENU Chosen menu number 2 Soft key 2 : Not used Soft key 3 : Not used Soft key 4 : ES GAIN Echosounder Gain Soft key 5 : ES TVG Echosounder TVG (Time Variable Gain) Soft key 6 : SYSTEM System OFF Screen Pilot, Menu 3:...

- Page 11 Screen Shallow Water CREEN HALLOW ATER The various soft key menus are selected by pressing repeatedly the MENU button on the left side of the soft key menu. The number on the button (1 –3) indicates which of the menus are active. The various soft key menus are selected by pressing repeatedly the MENU button on the left side of the soft key menu.

- Page 12 Screen Open Sea CREEN Screen Open Sea, Menu: Soft key 1 : TRIP Trip Distance Counter Reset Screen Open Sea, Menu: 1 Soft key 2 : Not used Soft key 3 : Not used Soft key 1 : TRIP Trip Distance Counter Reset Soft key 4 : Not used Soft key 2 : Not used Soft key 5 : Not used...

- Page 13 ETUP AND UNCTION ONTROL CREENS Each of the setupscreens contains a graphic picture and one or more Menu sets configured on the 6 soft key buttons. The various screens are selected by keeping the SCREEN SELECT button pressed and rotating the encoder in either direction.

-

Page 14: S Creen Nmea/C Ommunication

Note : To configure the serial output of the system go Soft key 6 : DISPLAY Selects the information (received from the external source or transmit- ted by the DL850) to be displayed in the “TEXT” window. [Input, output, off]. - Page 15 Screen COM. Menu2. Soft key1. Menu 2…. Soft key2 COM ERROR reset. The program memorizes the latest occurred NMEA input error for further analysis (error code presented on the Status and Com screens). By the mean of this soft key it is possible to reset the error.

-

Page 16: S Creen Status

CREEN STATUS The status screen contains information that will facilitate analysis and correction of several problems. All installation settings are displayed on this screen. Refer trouble-shooting guide, describing status information, indicated in the first column. Screen status, Menu 1 Soft key 1: MENU 1 Chosen Menu number 1 Soft key 2: SIMULATOR Simulator on/off... - Page 17 Screen status, Menu 3 Soft key 1: MENU 3 Chosen Menu number 3 Soft key 2: Not used Soft key 3: YR.MONTH Year and month setting Soft key 4: DAY Day setting Soft key 5: HOURS Hours setting Soft key 6: MINUTES Minutes setting Note: if time and data information provided on the NMEA input, it has highest priority and all above time &...

- Page 18 Screen Status. Menu 6. Described below functions can be used during commissioning period to exercise different DL850 outputs with a constant, user adjustable speed values. Note: when the test mode is activated, this will be indicated by flashing “TEST” label in the lower right part of the screen.

-

Page 19: S Creen Calibration

The various soft key menus are selected by pressing repeatedly the MENU button on the left side of the soft key menu. The number on the button indicates which of the menus is active. For calibration see : DL850 calibration procedure Screen calibration, Menu 1... - Page 20 Screen calibration, Menu 2 Soft key 1: MENU 2 Chosen Menu number 2 Soft key 2: CALIBR NUM Number of the calibration, data set currently available for adjustments. In the calibration table it is marked by the frame. Soft key 3: WT REAL Real ship’s WT speed ( Reference speed ) Soft key 4: WT MEASUR.

-

Page 21: Creen Cope

CREEN COPE Scope screen layout Screen Scope, Menu1 Soft key 1: MENU Chosen Menu number 1 Soft key 2: WT GAIN [0-255 of relative Water Track start Gain (at a time, when receiver is open) units] Soft key 3: WT AUTOG Toggle Water track autogain mode [on/off] Soft key 4: BT GAIN Bottom Track start Gain (at a time when receiver is open) - Page 22 Screen Scope, Menu2 Soft key 1: MENU Chosen Menu number 2. Soft key 2: SL RANGE Select speedlog range for adjustments of the transceiver parameters, which will be activated, when speedlog turns automatically selects this range during operation. [1-5m, 5-10m, 10-15m, 15-25m, 25-40m, 40-64m, 64…] Note, that when the operator changes SL RANGE, the rest of the soft keys will change their values according to the currently set SL RANGE.

- Page 23 Screen Scope, Menu3 Soft key 1: MENU Chosen Menu number 3. Soft key 2: SL RANGE Select speedlog range for adjustments of the transceiver parameters, which will be activated, when speedlog turns automatically selects this range during operation. [1-5m, 5-10m, 10-15m, 15-25m, 25-40m, 40-64m, 64…] Note, that when the operator changes SL RANGE, the rest of the soft keys will change their values according to the currently set SL RANGE.

- Page 24 If AUTO BT is switched off, bottom track will operate continuously, but no BT speed indications provided on the screen Note: In case of loosing BT indications, DL850 will provide (D)GPS speed value on the NMEA output, if (D)GPS is connected.

-

Page 25: Doppler Log Principle

Bottom Track Characteristics DL850 will try to aquire a bottom track when the depth is between 2 and appx. 70 m, depending on the bottom conditions. If conditions for Water Track operations are also within the operation param- eters, both Bottom Track and Water Track data will be aquired. -

Page 26: Power On/Off

If no bottom is detected in the calculated window, the window is gradually increased in size until the full time and strength window is used. Power ON/OFF During normal daily operation, the system may be switched off from all operation menus. This operation does not disconnect the system from the power supply, but all power consuming compo- nents are switched off. -

Page 27: Screen Select

IXED UNCTIONS Screen Select The SCREEN SELECT button facilitates selection of one of the 6 screen and soft key layouts. The 3 primary operation screens may be cycled by repeatedly pressing the SCREEN SELECT button. Access to the remaining screens is through encoder operation. The screens are cycled in an endless, bi-directional loop, e.g. -

Page 28: Clock And Calendar Settings

UNCTIONS Menu The leftmost softkey is always used for selecting the desired menu, i.e. softkey layout within a screen. The different screens have a different number of menues, and some of the menu functions may be available on more than one menu. Below is a list of all menu functions, not neccessarily in the sequence the appear with the screens. -

Page 29: Simulator

Simulator The DL850 contains a built in simulator to exercise the screen and various interface signals. The simulator may be switched on and off on several screens by the Simulate softkey. When the simulator is operating, “Demo” is flashing at the bottom of the screen. -

Page 30: User Maintenance

3. USER MAINTENANCE Transducer Maintenance. The transducers are virtually maintenance free, but occasional cleaning may be necessary depending on sea water conditions. Operator Unit Maintenance. The operator unit contains no user serviceable parts, and requires no maintenance apart from occasional cleaning of the front panel. -

Page 31: T Rouble S Hooting

ROUBLE HOOTING Trouble Shooting... -

Page 32: T Ypical S Tatus S Creen C Ontents

YPICAL TATUS CREEN ONTENTS The Status Screen contain information that will facilitate analysis and correction of several problems. Information from the Status and Oscilloscope Screens should be sent by fax with any report about func- tional Disturbances. This will greatly facilitate remote failure Analysis. Typical Status Screen Contents. - Page 33 DL850 System. Although some of the subsystems necessary for this basic system operation may still suffer from minor or intermittent operation disorders, the fact that it is possible to select and observe this screen, indicate correct operation of the following DL850 Subsystems: If it is at all possible to cycle through the screens and observe this information, several assumptions may be made regarding operation of the DL850 System.

-

Page 34: T Ypical O Scilloscope S Creen C Ontents

YPICAL SCILLOSCOPE CREEN ONTENTS Typical Oscilloscope Screen Contents. This Oscilloscope Screen show oscillograms from the varios transducers. The horisontal axis represent time for the sound to travel down and back from an object or water layer. The vessel is located at the edge of the grid, and the right edge represent the range. - Page 35 i t c i t t i t t i t t t t e i t c , n i t t e e t t t t e i t s , n i t t e l l a i t a l l i i t t...

- Page 36 . c t t s i a i t s i l i t a t s i i t c r r I t t e & i t c s t i i t t t t e t t e i t c i t c...

-

Page 37: Installation

If a flat, horizontal section is not available for transducer fitting, the shipyard must construct a suit- able bed. do not paint the surface. Protect the active element of the transducer and Installation Details. Refer to SKIPPER´s standard installation procedures in the appendix regarding hull valve installa- tion, welding, Cable glands etc. - Page 38 Power supply may be either 230V/115V AC or 24V DC. Power consumption is appx. 50 W at 24V, appx. 70W at 115/230V. If the AC power system is 115V, DL850 may be prepared for 115V AC by re-connecting the connectors J102, J103 as shown in appendix drawing DL8-B-002 Fuses is shown in fig.4.4 for 230/115 VAC and 24 V DC.

-

Page 39: Fig.4.4 Voltage Selection Connectors And Fuses, Terminal Board

Fig.4.4 Voltage selection connectors and fuses, Terminal Board AC Voltage selection : Transformer Primary to : J102 for 230V and J103 for 115V Fit dummy Plug on opposte Connector for Protection Fuses : 230VAC FS100 and FS101 must be 0,5 Amp.slow blow 115VAC FS100 and FS101 must be 1,0 Amp.slow blow 24VDC FS102 must be 3,15 Amp. -

Page 40: Back-Up Battery Jumper 200

Fig. 4.5 History Memory Battery Jumper, I/O Board. Back-up Battery Jumper 200 After installation is complete and system power is applied, it is necessary to connect the history memory battery to provide power to the user parameters during system power failure. Refer to Fig. 4.5 for the correct setting of the battery jumper “ON”... -

Page 41: Power Indication And Function Led´s

Fig. 4.6 Function LED´s, on Terminal board . Power Indication and function LED´s. The following LED´s are located on the Terminal Board: LD700 +5V#1/VCC (Board External and CPU) LD701 +12V#1/VDD (Board External) LD702 +5V#2 (Board Internal) LD703 +12V#2 (Board Internal) LD704 -12V LD705... - Page 42 NPUT UTPUT IRCUITRY...

-

Page 43: I Nterfacing

Analogue interfaces DL850 is equipped with 3 analogue outputs to supply analogue repeaters or other equipment with analogue inputs. The signals are galvanically connected to the DL850. Standard range is 0 - 10V or 4 - 20mA. The velocity vectors and output modes are programmable from Status Screen, Menu 5:... -

Page 44: Nmea Interface

NMEA interface The NMEA output provides NMEA0183 format depth information for other equipment with NMEA0183 inputs. Baud rate is 4800 or 9600, 8 bit, No parity. Several messages may be selected on Screen 7 and the enabled messages are transmitted with maximal internal of 1.8 seconds. The NMEA inputs accept position, heading and UTC time messages from various navigators and compasses. -

Page 45: I Nstallation Trouble Shooting

NSTALLATION TROUBLE SHOOTING If the problem with communication between cabinet and transceiver unit occurs, the display unit will always come up with Status Screen after switching on power, and red color message is displayed, following “Link” text in the left column of the status screen. -

Page 46: Start-Up And System Adaption

Screen 7 is used for verification of received NMEA messages and control of transmitted NMEA depth messages. The baud-rate may be set to 4800 or 9600, 4800 being the more common. When a NMEA talker is connected to one of the DL850 inputs, all received messages will be dis- played on the screen. - Page 47 Heading, compass HCC,xxx. Composite Loran C specific RMA,a,xxxx.xx,N,xxxxx.xx,W,,,xx.x,xxx.,,*xx GPS, Transit specific RMC,xxxxxx,a,xxxx.xx,N,xxxxx.xx,W,xx.x,xxx., xxxxxx,,*xx Vessel Identification IMA,aaaaaaaaaaaa,aaaxxxx,xxxx.xx,N,xxxxx.xx,W, xxx.x,T,xxx.,M,xx.x,N DL850 T ) NMEA0183 M RANSMITTED RIGINATED ESSAGES Depth & Draught $SDDPT,x.x,x.x<CR><LF> Depth Below Surface $SDDBS,x.x,f,x.x,M,x.x,F<CR><LF> Depth Below Transducer $SDDBT,x.x,f,x.x,M,x.x,F<CR><LF> Depth Below Keel $SDDBK,x.x,f,x.x,M,x.x,F<CR><LF>...

-

Page 48: Dl850 Calibration Procedure

6.DL850 CALIBRATION PROCEDURE DL850 speed error can be caused basically by 2 reasons: angular sensor installation error and different way of water propagation along the hull, which depends on the hull’s shape and vessel’s speed. All calibration functions are concentrated on the Calibration screen. In order to select this screen, push “screens”... -

Page 49: I Nstallation Angular Error Correction

NSTALLATION ANGULAR ERROR CORRECTION Before conducting speed calibration trips, it is recommended to set compensation for installation angular error. To do this, the vessel should go with a constant speed (preferably 50% of full speed or higher) at constant direction for 2-3 minutes. The impact of wind and waves must be minimal. The averaged meas- ured drift angle is indicated in the lower/right part of the calibration screen. - Page 50 and FINISH/leg2 when passing the start and finish marks accordingly. Note: if for some reason only one leg is used, it is necessary to skip the second one just by pressing 2 times mentioned above button. Note: if it is necessary to repeat backward leg, while keeping forward leg information unchanged, press START/leg1 button and keep it pressed 3-4 seconds until the button changes its status to leg2.

-

Page 51: M Anual Adjustment Of Calibration Table

ANUAL ADJUSTMENT OF CALIBRATION TABLE If it is required to make changes in the calibration table, received after calibration trips, or for some reason calibration trips haven’t been conducted, it is possible to adjust calibration settings manually. In last case, DGPS speed can be used as a referenced (real) speed, but the impact of wind, waves and current must be insignificant. -

Page 52: Specifications

NMEA 0183 for Speed. Alarm Relay. Output for VGA Repeater. 232 C as option. Interface Inputs NMEA0183 for Position, Heading and Time. Rate of turn Sensor Input. Languages English, French, Spanish, Russian, German and Norwegian. Options SKIPPER IR300 digital Repeater. -

Page 53: P Erformance

ERFORMANCE 1. Speed range +/- 50 kts (under favourable installation and sea conditions up to +/- 50 kts) Depth range for Water track 2.5m - 6m Maximum roll angel +/- 10 degrees Maximun pitc angel +/- 5 degrees Depth Range for Bottom Track: 2 - 70 m Depth Range for Echosounder: 2 - 100 m... -

Page 54: Service

8. SERVICE All service requests should be made to the local SKIPPER representative. Adjustments and repairs should only be performed by qualified service engineers, and unqualified repair attempts will void the warranty. -

Page 55: Appendix

9. APPENDIX ISCELLANOUS NSTALLATION RAWINGS... -

Page 63: Gate Valve Operation And Installation Manual

10. GATE VALVE OPERATION AND INSTALLATION MANUAL SKIPPER ETNSLJ 100mm GATE VALVE Operation And Installation Manual Edition 20030328 Skipper Electronics A/S Telphone +47 23 30 22 70 Ryensvingen 5 Telefax +47 23 30 22 71 P.O.Box 151, Manglerud E-mail: skipper@skipper.no 0612 Oslo, Norway Co.reg.no: NO-965378847 -MVA... - Page 64 Weitergabe sowie Vervielfältigung dieser Unterlage, Verwertung und Copying of this document, and giving it to others and the use or Mitteilung ihres Inhaltes nicht gestattet, soweit nicht ausdrücklich Communication of contents therof, are forbidden without express zugestanden. Zuwiderhandlungen verpflichten zu Schadenersatz. Authority.

- Page 65 Doppler Log: DL 850 Sensor unit complete. The SKIPPER 100 mm Gate Valve is delivered for Echo Sounder or Doppler Log, assembled for transport. The parts necessary for final assembly will be found on the gate valve itself, or packed in a box, delivered with the gate valve.

- Page 66 Check that the transducer sensor housing, when fully inserted, is flush with the lower surface of the bottom flange. Check that the outer edges of the speed log sensor, when fully inserted, are flush with the lower surface of the bottom flange, leaving only the rounded part of the sensor “head” protruding below the bottom flange. If the two above points are not met exactly, it is possible to adjust the height of the gate valve by inserting thicker or more than one “Klingersil”...

- Page 67 SKIPPER 100 MM GATE VALVE. OPERATION. REMOVAL OF ECHO SOUNDER TRANSDUCER UNIT / SPEED LOG SENSOR UNIT. The transducer unit / sensor unit is secured with 6 each 16 mm pinbolts with nuts and washers, and two each 16 x 40 mm hexagon bolts.

- Page 68 SKIPPER 100 MM GATE VALVE. OPERATION. REINSTALLATION OF ECHO SOUNDER TRANSDUCER UNIT / SPEED LOG SENSOR UNIT. Before the transducer unit / sensor unit is reinstalled , please check that the O-ring on top of the intermedi- ate element and also the water blocking O-ring inside the intermediate element, is free of damage and well greased.

- Page 72 NOTE! The two shorter bolts should be placed below and above the housing of the gate valve closing mechanism. NOTE! Intermediate element has two shorter bolts NOTE! Bottom flange has two shorter bolts DL 850 Sensor : The arrow on the sensor must point Ahead.

Need help?

Do you have a question about the DL850 and is the answer not in the manual?

Questions and answers