Summary of Contents for Balluff BES M30EP-PFC12F-S04G-D12

- Page 1 BES M30EP-PFC12F-S04G-D12 BES Q40ZU-PFC15B-S04G-D12 BES Q40ZU-PFC20F-S04G-D12 Inductive Safety Sensors User's Manual english...

- Page 2 Some of these trademarks may be registered trademarks of the respective owners. Balluff is not liable for any technical or printing errors, removal of the text contained herein or unintended damage resulting from use of the material.

-

Page 3: Table Of Contents

Measures against simple circumvention Electrical Connection Operation as 4-conductor Startup Calibration aid Determining the Release zone Disabling the calibration aid Switching state of the outputs Operation Operating mode Response times LED display Technical Data Maintenance, Care, and Disposal Troubleshooting www.balluff.com... -

Page 4: About This User's Guide

Note In the interest of continual product improvements the technical data for this product and the contents of this user's guide are subject to change without notice. The latest status of this user's guide is available on Balluff website www.balluff.com. -

Page 5: Typographical Conventions

► Action instruction 2 Action sequences are numbered in order: 1. Step 1 2. Step 2 3. Step 3 Symbols Note The symbol and the word Note indicate information which is helpful or important for use of the product. www.balluff.com... -

Page 6: Abbreviations

BES M/Q…-D12 Inductive Safety Sensors Abbreviations Common Cause Failure Failure as a consequence of as common cause Diagnostic Coverage Diagnostic Coverage MTTF D Mean Time To Dangerous Failure Mean Time To Dangerous Failure Probability of (dangerous) Failure per Hour (PFH D) Probability of (dangerous) Failure per Hour Performance Level PL according to EN ISO 13849-1... - Page 7 The general warning symbol combined with the signal word WARNING indicates a risk which can result in serious injury or death. DANGER The general warning symbol combined with the signal word DANGER indicates a risk which can result directly in serious injury or death. www.balluff.com...

-

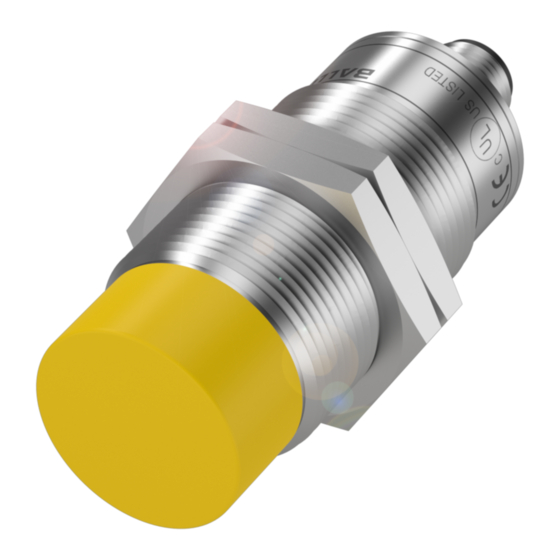

Page 8: About This Product

– 1 Safety sensor BES0577 – 2 Mounting nuts M30 – 1 Original user's guide Figure 1 Scope of delivery by type Note Should one of the components listed be missing or damaged, please contact one of the Balluff subsidiaries. -

Page 9: Funktion

"0" Damping element Yellow signal LED: Switching state Green power LED: Operating voltage BES057C: Safety sensor Close zone Release zone Assured turn-off distance s ar "0" "1" Damping element Yellow signal LED: Switching state Green power LED: Operating voltage www.balluff.com... -

Page 10: Release Zone

BES M/Q…-D12 Inductive Safety Sensors BES0577: Safety sensor LEDs Close zone Release zone Assured turn-off distance s ar "0" "1" Damping element Yellow signal LED: Switching state Green power LED: Operating voltage Figure 2 Function overview Release zone The outputs (OSSDs) are only released when damping occurs in the release zone. - Page 11 BES057A: 45 x 45 x 1 mm and non-flush mounting – BES057C: 60 x 60 x 1 mm and non-flush mounting – BES0577: 45 x 45 x 1 mm and non-flush mounting Note Depending on the composition of the damping element the close zone may be absent. www.balluff.com...

-

Page 12: Relevant Standards

BES M/Q…-D12 Inductive Safety Sensors Relevant standards The following directives and standards were applied: 2006/42/EG – European Machine Directive – 2014/30/EU EMC Directive EN ISO 13849-1:2015 – Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design –... -

Page 13: General Safety Notes

The inductive safety sensor has been certified by TÜV NORD. 1-channel operation is included in the certification. Note The EU Declaration of Conformity as well as the certificates for EN/IEC 61508 and EN/ISO 13849-1 from TÜV NORD can be found at www.balluff.com. www.balluff.com... -

Page 14: Non-Approved Use

BES M/Q…-D12 Inductive Safety Sensors Non-approved Use Warranty and liability claims against the manufacturer are rendered void by: – Unauthorized tampering – Improper use – Use, installation or handling contrary to the instructions provided in this User's Guide. – The sensor is not permitted to be used as a mechanical stop. –... - Page 15 Technical Data on page 36). Contact the manufacturer for any special ambient conditions. – Use only within the specified application description. – Safety requirements for the application – The safety requirements for the respective application must agree with the requirements laid out here. www.balluff.com...

- Page 16 BES M/Q…-D12 Inductive Safety Sensors Observe the following conditions:: ► Take measures which prevent metallic objects from unknowingly contacting the active surface. ► For interlocking devices together with guards observe DIN EN ISO 14119. ► Maintain specified application conditions (see Section Technical Data on page 36).

-

Page 17: Installation

BES M/Q…-D12 Inductive Safety Sensors Installation Mounting and installation conditions for BES057A and BES057C Orient sensor face The cable socket can be rotated: Figure 3 Material of sensing surface www.balluff.com... - Page 18 BES M/Q…-D12 Inductive Safety Sensors Installation conditions for BES057A: The device cannot be installed flush in steel per IEC 60947-5-2, Type I2C40SP2. In addition the device may be installed flush on steel on one side. In copper, aluminum and brass the device can be flush mounted per IEC 60947-5-2, Type I1C40SP2.

- Page 19 Secure the device against coming loose. ► Tighten screws to 1 Nm. ► Limit use of slot holes to initial setting. ► Note installation conditions per figures 1 to 5: Angle Channel Figure 5 Minimum distances from metal surfaces for BES057C www.balluff.com...

-

Page 20: Mounting And Installation Conditions: Bes0577

BES M/Q…-D12 Inductive Safety Sensors Mounting and installation conditions: BES0577 The device cannot be installed flush in steel per IEC 60947-5-2, Type I2C40SP2. ► Secure device against loosening (tightening torque ≤ 50 Nm). ► Note installation conditions per figures 1 to 3: Figure 6 Minimum distances from metal surfaces for BES0577 WARNING Failure of the safety function The safety function of the sensor cannot be assured when using... -

Page 21: Measures Against Simple Circumvention

2 sec., the outputs are completely locked and not released when there is damping in the close zone. If the object remains in the close zone longer than 5 sec., the adjustment mode is activated (see Section 6.1 Calibration aid on page 24). www.balluff.com... - Page 22 BES M/Q…-D12 Inductive Safety Sensors The clear zone can be unblocked as follows: – Undamp (> 30 mm) for a time of more than 2 sec Type Undamp BES057A > 30 mm BES057C > 45 mm BES0577 > 30 mm – Voltage interruption (see Section 6.3 Disabling the calibration aid on page 26).

-

Page 23: Electrical Connection

Note The nominal voltage is 24 V DC. This voltage may fluctuate according to EN 61131-2 between 19.2 V and 30 V incl. 5 % ripple. Operation as 4-conductor 1 Safety-relevant logic unit +24 V Figure 7 Electrical connection when operating as a 4-conductor www.balluff.com... -

Page 24: Startup

BES M/Q…-D12 Inductive Safety Sensors Startup Calibration aid For simple and safe installation the sensor has an optical setup aid for visualizing the release zone. BES057A: The setup aid is activated by bringing the metallic object in front of the safety sensor (close zone). -

Page 25: Determining The Release Zone

LED turns off. If the target is located in one of the directions outside the release zone, the LED begins to flash again. > 5 s Signal Power Close zone Release zone Figure 9 Determining the Release zone www.balluff.com... -

Page 26: Disabling The Calibration Aid

BES M/Q…-D12 Inductive Safety Sensors Disabling the calibration aid BES057A: If the sensor is undamped (> 30 mm) for more than 2 sec., the setup aid is turned off and the yellow Signal LED goes out. This can also be accomplished by interrupting the supply voltage. -

Page 27: Switching State Of The Outputs

Output specifications The output specifications are based on the specifications for the input per EN 61131-2 Type 1 or Type 2: Logic "1" ≥ 15 V 2...15 mA ≥ 11 V 15...30 mA Residual current 0.2 mA 1) Logic "0" ≤ 5 V 1) Pull-down current typ. 30 mA www.balluff.com... - Page 28 BES M/Q…-D12 Inductive Safety Sensors Cross-connection / short circuit – Crossing both the outputs (A1 and A2) is detected by the sensor and results in turning off the outputs (OSSDs) at the next safety request. The outputs A1 and A2 remain turned off until the fault is eliminated and a voltage reset has been performed.

-

Page 29: Operation

This makes it no longer possible to turn them back on in the release zone. A release takes place either by undamping (> s ar ) for more than 2 sec. or by a voltage interruption (see Section 4.3 Measures against simple circumvention on page 21). www.balluff.com... - Page 30 BES M/Q…-D12 Inductive Safety Sensors Delayed switching of the Signal LED BES057A: Undamping < 2 s: If the damping element was removed from the sensor for more than approx. 2 sec. (> 30 mm), the yellow Signal LED comes on when damping in the release zone with a delay of approx.

- Page 31 2 sec. (> 30 mm), the yellow Signal LED comes on with no delay when damping in the release zone. ≈ 0 s Signal Power Close zone Release zone *) except for initial startup Figure 12 Non-delayed switching www.balluff.com...

-

Page 32: Response Times

BES M/Q…-D12 Inductive Safety Sensors Response times Type Response time Response time to a safety request ≤ 50 ms (removing from the release zone) Response time when approaching the close zone ≤ 100 ms (non-safety relevant done) Response time when approaching the release zone typ. - Page 33 Type Response time Test pulse interval Tp (2) [pulse packet] min. 2 ms max. 5 ms Response times 1 Test pulse duration 2 Test pulse interval Tp (pulse packet) 3 Test pulse interval T Test pulse interval T (pulse packet repetition) min. 30 ms max. 50 ms www.balluff.com...

-

Page 34: Led Display

BES M/Q…-D12 Inductive Safety Sensors LED display Sensor type BES057A, BES057C: Operating status Outputs (OSSD) (OSSD) Signal No supply voltage Both outputs turned off Power Signal Undervoltage Power Signal Overvoltage Both outputs turned off Power Signal Damping element Both outputs outside the release zone turned off Power... - Page 35 Power within the close zone or very near the release zone Operating mode: Both outputs Signal Damping element released Power within the release zone (operating mode) LED on LED off LED flashing (2 Hz) LED flashing rapidly (5 Hz) www.balluff.com...

-

Page 36: Technical Data

BES M/Q…-D12 Inductive Safety Sensors Technical Data BES057A BES057C BES0577 BES057A BES057C BES0577 Product Features Plug connection Release zone 10…15 mm 4…20 mm 6…12 mm Non-flush mount Meets the EN ISO 13849-1:2015, Category 4 PL e requirements IEC 61508: SIL 3 IEC 62061: SILcl 3 Area of use Operating mode Continuous operation (maintenance-free) - Page 37 4…20 mm 6…12 mm Assured turn-off 30 mm 45 mm 30 mm distance s ar Response time to a safety request Response time to ≤ 50 ms a safety request Response time ≤ 200 ms when approaching the release zone (release time) Risk time (fault ≤ 100 ms response time) www.balluff.com...

- Page 38 BES M/Q…-D12 Inductive Safety Sensors BES057A BES057C BES0577 Environmental conditions Operating Class C per EN 60654-1 Weather-protected conditions Ambient –25...70 °C –25...60 °C –25...70 °C temperature for mission time ≤ 87,600 h 10…40 °C, for mission time ≤ 175,200 h Temperature 0.5 K/min change rate Max. permissible 5…95 %, short-time relative humidity 5…70 %, continuous Air pressure 80...106 kPa...

- Page 39 Unless otherwise indicated, all data in the entire temperature range are based on a reference target per IEC 60947-5-2 (FE360 = ST37K) 45 x 45 x 1 mm 60 x 60 x 1 mm 45 x 45 x 1 mm Packaging unit 1 pc. www.balluff.com...

-

Page 40: Maintenance, Care, And Disposal

BES M/Q…-D12 Inductive Safety Sensors Maintenance, Care, and Disposal No special measures for maintenance and upkeep are necessary when operated properly. The device may be repaired only by the manufacturer. Dispose of the device in accordance with the prevailing national regulations for environmentally safe disposal. - Page 41 BES M/Q…-D12 Inductive Safety Sensors www.balluff.com...

- Page 42 BES M/Q…-D12 Inductive Safety Sensors...

- Page 43 BES M/Q…-D12 Inductive Safety Sensors www.balluff.com...

-

Page 44: Www.balluff.com

Balluff GmbH Schurwaldstraße 9 73765 Neuhausen a.d.F. Germany Phone +49 7158 173-0 Fax +49 7158 5010 balluff@balluff.de www.balluff.com...

Need help?

Do you have a question about the BES M30EP-PFC12F-S04G-D12 and is the answer not in the manual?

Questions and answers