Table of Contents

Advertisement

OPERATOR'S MAN U AL

MODEL #

HDS 3.9/30 Pe Cage

HDS 4.8/30 Pe Cage

HDS 4.8/30 Pe Cage

HDS 4.7/35 Pe Cage

To locate your local Kärcher Commercial Pressure Washer Dealer nearest you,

05/30/17

-

N

h is

per

l

C IO

torc

add

fue

e or

not

A U

n fl

am

E.

Do

per-

E C

K OF

ope

FIR

est

. Ne

P R

y wh

. RIS

ere

me

nue

E DE

rati

FEU

on.

onl

ids

fl am

QU

en

opé

a

T /

. Ope

ble

rate

liqu

s où

une

RIS

est

o o

llam

No

E N

ma

roit

able

s.

chi

ne

el fueg

FUE

GO.

LOS

ION

ay

fl am

rati

ng.

r aux

end

amm

la

ma

de

DE

E M

EXP

spr

is

ope

ise

infl

t que

as

RIE

don

SGO

ar

IS S

K OF

. Do

chi

not

ne

ON

. Util

liqu

pen

ides

dan

to en

áre

s.

.

p cle

rge

RIS

ted

ma

OSI

er

de

sel

duc

able

aja

ndo

NS

. Kee

dis

cha

R T

mit

en

the

E D'E

XPL

vap

oris

ant

die

el pro

s infl

am

e trab

SO

ct

S

V E

wh

QU

pas

car

bur

Use

liqu

na

ido

est

TO

PER

or

dire

E SOU

.

/ A

RIS

Ne

e.

r de

LOS

ION

roc

ie

gui

má

UR

Y

tou

ch

CHA

UD

son

nes

n-

mis

ajo

ute

EXP

s.

No

la

INJ

not

EAU

per

Ma

TE

G

D OP-

E

pas

O DE

SG

ido

a cua

ndo

ERE

ID.

Do

es.

s des

NA

S.

IEN

IN

REA

Y,

OR

RIE

n per

mit

olin

OR

SEV

FLU

bus

au

ver

PER

UA

SO

CAL

son

as.

R N

UR

LLY

BEF

by

sea

dir

gas

ION

AR

GE

loin

des

jet

d'e

S A

AG

s per

W A

K OF

INJ

EFU

d only

aña

INJ

ECT

T DIS

CH

ten

ir

ger

le

SEV

ERA

GA

a o

DE

otra

TIVE

RIS

S CAR

be

use

NT

OF

. HO

s.

. Se

diri

ES

CAR

agu

TEC

E THE

CTI

ON

is

to

AVA

par

RIS

zle

K

per

son

RES

. Ne

pas

O LES

ION

a.

DES

del

ER

PRO

men

ts

UC

TRU

chi

ne

ATE

UR

util

ise

of

noz

at

BLE

SSU

TIE

ÓN

boq

uill

fl ujo

el

OTH

chi

ne.

et

vête

TO

RED

G INS

s ma

rs.

L'O

PER

t être

US-

stre

am

E DE

A LA

SOR

ACI

e de

diri

ja

AR

AND

ma

ion

ERA

. Thi

TIN

rato

DE

il doi

DE

nte

RIS

QU

ON

ETR

alc

anc

ue

ni

WE

ng

this

pro

tect

c-

ade

US

ING

ed

ope

NU

EL

app

are

ANT

ES

me

PRE

SSI

O DE

PEN

del

. No

toq

E

n ope

EYE

rati

s de

su cue

rpo

the

qua

lifi

LE

MA

. Cet

lifi

es.

ION

do

sola

t

SG

e fue

ra

ON

TEC

whe

TIV

lun

ette

ne.

eja

off

LIR

E

ATI

ON

urs

qua

e ser

RAC

usa

pro

duc

RIE

gas

A PR

ESI

PRO

RN

des

chi

ma

ad

y prot

and

ent

s.

s

UTI

LIS

rate

AL

deb

OPE

os.

this

A ALT

tén

INU

RY.

BE

WO

Por

tez

z cet

te

urid

s dry

pon

sec

et

des

ope

MA

NU

e equ

ipo

ifi cad

Use

s un

en-

OF

MU

ST

RE.

s util

ise

de

seg

.

tion

com

inte

nus

es

EL

Est

s cal

TIO

N.

a.

r dan

RIS

K

NG

BLE

SSU

vou

len

tes

e equ

ipo

con

nec

ing

and

ma

pos

ant

LEA

SE.

rad

ore

HY

XIA

ted

are

en

un

CLO

THI

E DE

qua

nd

ES.

Use

est

all

p

cal

wir

t être

com

se-

AR

ope

ll ven

ASP

tila

Uti

lise

to

QU

teu

rs

ION

ope

re

. Kee

ctri

doi

ven

sur

les

cio

nes

560

.0

por

K

OF

a we

YXI

E.

pro

duc

RIS

tec

DE

LES

ndo

ON

s les

ele

r d'e

fi ls

au

con

nec

8.9

23-

RIS

y in

SPH

el

pro

SGO

e cua

OC

UTI

from

ay

Tou

jete

las

cos

.

onl

n aér

D'A

E

é.

. Use

cua

da.

ds.

RIE

ent

am

ELE

CTR

ay

TIO

aw

N.

pro

tod

as

elé

ctri

RIS

QU

it bie

ASF

IXIA

n ade

h han

à

uad

OF

p spr

CU

jam

ais

nga

ent

es

dro

O

DE

tila

ció

bot

. Ten

ir

RIS

K

. Kee

LEC

TRO

. Ne

. Ma

nte

pon

RIE

SG

ven

Hol

d with

SSE

.

gro

und

E D'E

dus

IÓN

ie

com

are

a de

K .

OU

ÓN

ER

RIS

QU

sus

pen

s.

OC

UC

No

roc

KS

BAC

ET

REP

PR

ESI

NG

et

être

ctri

que

ELE

CTR

lo.

KIC

TOL

N

LA

DA

fi ls

éle

O DE

del

sue

AY

GUN

EE

PIS

CO

.

SE

SG

iba

SPR

PO

IGN

.

MU

EVE

ma

nos

CAU

of

RIE

y arr

LA

x ma

ins

A

SE

dos

CAN

g are

as

cas

deu

TOL

las

RFA

CES

pin

les

LA

PIS

ga

con

T SU

ed

grip

ent

.

Sos

ten

Y.

HO

y des

ign

r seu

lem

lan

ces

INJ

UR

onl

che

ts et

e las

K OF

Use

wa

nd.

. Tou

e pis

tole

am

ent

RN

RIS

S.

and

AU

DES

gné

. Use

sol

za.

BU

gun

ay

CH

s des

poi

TES

y la

lan

spr

CES

lée

IEN

illo

SU

RFA

ties

iso

IES

CAL

gat

par

FIC

as

del

PER

SU

ais

lad

áre

as

ORDER #

1.575-600.0

1.575-601.0

1.575-602.0

1.575-603.0

visit www.karchercommercial.com

98000800-1

MODEL #

HDS 4.7/35 Pe Cage

HDS 5.6/35 Pe Cage

HDS 5.6/35 Pe Cage

ORDER #

1.575-604.0

1.575-605.0

1.575-606.0

9.800-080.0-AB

Advertisement

Table of Contents

Summary of Contents for Kärcher HDS 3.9/30

- Page 1 áre 98000800-1 MODEL # ORDER # MODEL # ORDER # HDS 3.9/30 Pe Cage 1.575-600.0 HDS 4.7/35 Pe Cage 1.575-604.0 HDS 5.6/35 Pe Cage 1.575-605.0 HDS 4.8/30 Pe Cage 1.575-601.0 HDS 5.6/35 Pe Cage 1.575-606.0 HDS 4.8/30 Pe Cage...

-

Page 2: Table Of Contents

CONTENTS Introduction & Important Safety Information Component Identifi cation Assembly Instructions Operating Instructions Detergents & Clean Up Tips Shut Down & Clean-Up Storage Maintenance 12-14 Troubleshooting 15-18 Maintenance & Oil Change Charts Exploded Views 20-21 Exploded View, Parts List 22-24 Float Tank Assembly &... -

Page 3: Introduction & Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION WARNING: This machine exceeds Thank you for purchasing this Pressure Washer. We WARNING 85 db appropriate ear protection reserve the right to make changes at any time without must be worn. incurring any obligation. Owner/User Responsibility: The owner and/or user must have an understanding of the manufacturer’s operating instructions and warnings before using this pressure washer. -

Page 4: Important Safety Information

IMPORTANT SAFETY INFORMATION In an overfi lling situation, additional precautions are 14. Never make adjustments on machine while in necessary to ensure that the situation is handled operation. in a safe manner. 15. Be certain all quick coupler fi ttings are secured before using pressure washer. - Page 5 IMPORTANT SAFETY INFORMATION WARNING: Be extremely careful WARNING when using a ladder, scaffolding or any other relatively unstable location. The cleaning area should have adequate slopes and drainage to reduce the pos- sibility of a fall due to slippery RISK OF INJURY surfaces.

-

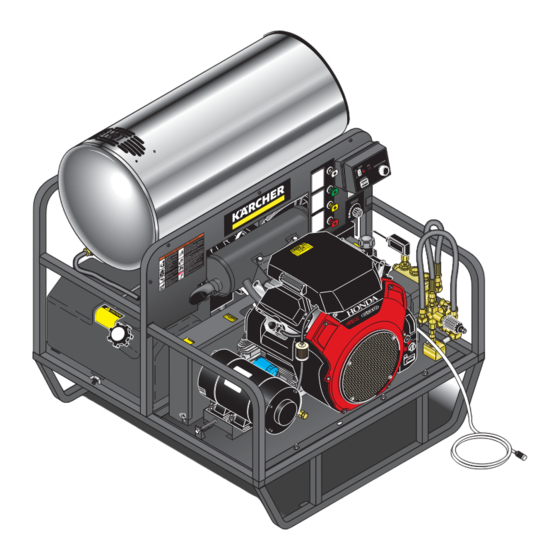

Page 6: Component Identifi Cation

COMPONENT IDENTIFICATION SMALL Flue Adapter Optional 7-10049 Insulation Gasket Optional 7-01471 Water Supply Hose (not included) Detergent Valve 22mm Coupling Adjustable Thermostat Outlet Burner Switch Hour Meter h is C IO e or torc n fl per- K OF . Ne y wh . -

Page 7: Assembly Instructions

ASSEMBLY INSTRUCTIONS Spray Wand High Pressure High Nozzle Pressure Hose 98000800-4 98000800-3 98000800-5 STEP 1: Attach the high pres sure STEP 2: Remove wand end and fi rst STEP 3: Remove shipping cap hose to the spray gun by threading place the o-ring followed by the high and install oil dipstick (Depending twist connect onto spray gun inlet. -

Page 8: Operating Instructions

OPERATING INSTRUCTIONS Dipstick Tank 98000800-9 98000800-10 STEP 1: Check engine oil level. Oil level should be level to the fi ll mark- S T E P 2 : F i l l g a s t a n k w i t h ings on the dipstick. -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS START On-Off Switch Engine Switch 98000800-14 98000800-15 STEP 7: (Electric Start Models) Turn the engine STEP 8: (Electric Start Models) Turn the key to the switch to "Start" po si tion. START position, and hold it there until the engine starts. If the engine fails to start within 5 seconds, release the key, and wait at least 10 seconds before op er at ing the starter again. -

Page 10: Detergents & Clean Up Tips

DETERGENTS & GENERAL CLEANING TECHNIQUES WARNING: Some de ter gents the pump pro tec tor engages and cools the pump by WARNING may be harm ful if in haled or dis charg ing the warm water onto the ground. This in gest ed, caus ing severe nau- ther mal de vice pre vents internal dam age to the pump. -

Page 11: Shut Down & Clean-Up

SHUTTING DOWN AND CLEAN-UP On-Off Switch 98000800-22 98000800- 98000800-24 STEP 1: Re move detergent suc tion STEP 2: Turn off the engine. STEP 3: Tur n off water tube from container and insert into sup ply. one gallon of fresh water. Open de- ter gent metering valve. -

Page 12: Maintenance

MAINTENANCE Winterizing Procedure: PREVENTATIVE MAINTENANCE Damage due to freezing is not covered by warranty. 1. Check to see that water pump is properly Ad here to the following cold weather procedures when- lu bri cat ed. ev er the washer must be stored or operated outdoors 2. -

Page 13: Maintenance

MAINTENANCE tem per a tures and the combustion smoke normally Deliming Coils: as so ci at ed with ma chines in cor po rat ing a spray gun. Periodic flushing of coils or optional float tank is Pe ri od ic in spec tion, to insure that the fuel solenoid rec om mend ed. - Page 14 MAINTENANCE Kärcher ClearFire Oil Burner 6. Remove top tank wrap, bend back insulation tabs and fold back blanket. Burner Air Adjustment: The oil burner on this machine 7. Remove bolts that hold down coil to bottom wrap. is preset for operation at altitudes below 500 feet. If operated at higher altitudes, it may be necessary to 8.

-

Page 15: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Faulty pressure gauge Install new gauge. OPERATING Insuffi cient water supply Use larger supply hose; clean fi lter at water PRESSURE inlet. Old, worn or incorrect spray nozzle Match nozzle number to machine and/or replace with new nozzle. Belt slippage Tighten or replace;... - Page 16 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION BURNER WILL Flex coupling slipping on fuel Replace if needed. NOT LIGHT pump shaft or burner motor shaft (continued from On-Off switch defective Check for electrical current reaching burner assem- previous page) bly with burner switch on. Heavy sooting on coil and burner Clean as required.

- Page 17 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Improper fuel or water in fuel Replace with clean and proper fuel. WATER Low fuel pressure Increase fuel pressure. TEMPERATURE Weak fuel pump Check fuel pump pressure. Replace pump if needed. Fuel fi lter partially clogged Replace as needed.

- Page 18 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Oil seal worn Check and replace if necessary. DRIPPING EXCESSIVE Irregular functioning of the valves Check and replace if necessary. VIBRATION IN DELIVERY LINE DETERGENT Air leak Tighten all clamps. Check detergent lines for NOT DRAWING holes.

-

Page 19: Maintenance & Oil Change Charts

PREVENTATIVE MAINTENANCE This pressure washer was produced with the best avail able ma te ri als and quality craftsmanship. However, you as the own er have certain re spon si bil i ties for the correct care of the equip ment. At ten tion to reg u lar pre ven ta tive main te nance pro ce dures will as sist in preserving the per for mance of your equipment. -

Page 20: Exploded Views

EXPLODED VIEW To Burner Pump From Burner Return 68, 69 h is C IO e or torc n fl per- K OF . Ne y wh . RIS E DE rati fl am opé . Ope rate liqu s où o llam . -

Page 21: Exploded Views

EXPLODED VIEW Vanguard with Heat Shield Engine Carb Port To Float Tank To Detergent Valve 98000800-32 HDS 600-606 • 9.800-080.0-AB... -

Page 22: Exploded View Parts List

EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 9.802-261.0 Hose, 3/4" Push On 2 ft. ITEM PART NO. DESCRIPTION 9.803-014.0 Coil, Rodless 9.802-151.0 Swivel, 1/2" JIC, Push On 9.803-005.0 Top Wrap, SS ▲ Washer, Snubbing ▲ Trim 9.802-099.0 9.802-071.0 2 ft. ▲... - Page 23 EXPLODED VIEW PARTS LIST (w/Generator) Black, w/o Relief (600.0) ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.803-009.0 Bracket, Belt Tension 9.803-000.0 Weldment, Face Plate, Long, Black (w/Generator) (602.0, 604.0, 605.0 - w/Gen) ▲ Nut, 5/16", ESNA, NC 9.802-776.0 ▲ Weldment, Face Plate, Short, 9.803-002.0 (w/Generator) Black (600.0, 601.0, 603.0,...

- Page 24 EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 8.933-006.0 Switch, MV60 ITEM PART NO. DESCRIPTION 8.753-065.0 Clamp, 1 Ear, #10 9.802-781.0 Nut, 3/8", Flange 8.753-270.0 Reducer, Connector Whiz Loc, NC 1/4" x 3/8" Honda 9.802-776.0 Nut, 5/16", ESNA, NC ▲ Vanguard 8.706-168.0 Elbow, 3/8"...

-

Page 25: Float Tank Assembly & Parts List

FLOAT TANK EXPLODED VIEW 8.903-579.0 98000800-33 To Pump FLOAT TANK PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.804-042.0 Tank, Float, 2-1/2 Gallon, 9.803-671.0 Stem, 5" Float Blank 9.802-512.0 Cable, TY, 48" 8.749-328.0 Valve, Float Plastic 9.802-150.0 Anchor, Connector, 1/2" 9.802-162.0 Strainer, 1/2"... -

Page 26: Control Panel, Exploded View & Parts List

CONTROL PANEL EXPLODED VIEW (Reversed View of Label) Detergent Valve Pump h is d fu to rc C IO e or t ad fl am . Do t pe FI RE e es io n. w he . RI e fl ér at e on ui ds... - Page 27 CONTROL PANEL PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 9.803-693.0 Box, Plastic, Back 8.740-345.0 Clamp, Hose, UNI .46-.54 9.802-482.0 Box, Plastic, Front, 9.802-251.0 Hose, 1/4" x 1/2" Fabricated Clear Vinyl 6 ft. 8.750-094.0 Thermostat, 302°F 8.707-058.0 Strainer, 1/4" Brass ▲...

-

Page 28: Hose & Spray Gun Assembly & Parts List

HOSE & SPRAY GUN ASSEMBLY 98000800-35 HOSE & SPRAY GUN PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.739-203.0 Hose, 3/8” x 50’, 2 Wire 9.802-299.0 Nozzle, 0005, Red Tuff Flex (603.0, 604.0) 4.775-054.0 EASY! Force Advanced KNA 9.802-300.0 Nozzle, 1505, Yellow (603.0, 604.0) -

Page 29: Burner Specifi Cations

SPECIFICATIONS KÄRCHER CLEARFIRE BURNER SPECIFICATIONS Fuel Nozzle w/100psi Burner Check Burner Fuel Solenoid Model No. Assy No. Valve Ignitor Motor Pump Coil Electrode 1.575-600.0 8.918-919.0 8.754-889.0 8.919-116.0 8.751-074.0 8.754-705.0 9.802-562.0 8.751-342.0 1.575-601.0 8.918-919.0 8.754-889.0 8.919-116.0 8.751-074.0 8.754-705.0 9.802-562.0 8.751-342.0 1.575-602.0 8.920-645.0 8.754-892.0 8.919-114.0... -

Page 30: Pump Specifi Cations

SPECIFICATIONS PARTS SPECIFICATIONS ENGINE PUMP Machine Pump Part Pulley Bushing Engine Engine Model Model Number Unloader Pulley Part # Bushing Part # Part # Pulley Engine 1.575-600.0 KT4540 8.921-714.0 8.715-483.0 2BK100H 9.802-391.0 25MM 9.802-403.0 GX390 8.750-579.0 2BK34H (389 cc) 1.575-601.0 KT6036 8.921-716.0 8.715-483.0... - Page 31 SPECIFICATIONS ENGINE GENERATOR Pulley Bushing Belt Belt Pulley Belt Model Part # Bushing Part # Size Part # Pulley Part # Belt Part # Bushing Part No. 600.0 9.802-382.0 H x 1 9.802-399.0 BX44(2) 8.715-705.0 601.0 9.802-382.0 H x 1 9.802-399.0 BX42(2) 8.715-703.0...

-

Page 32: Clearfi Re "S" Burner Replacement Parts

CLEARFIRE BURNER "S" REPLACEMENT PARTS For best performance specify genuine KNA replacement parts 8.918-919.0 HDS 600-606 • 9.800-080.0-AB... - Page 33 CLEARFIRE BURNER "S" REPLACEMENT PARTS LIST For best performance specify genuine KNA replacement parts ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.918-454.0 Gasket, Junction Box 8.919-050.0 Burner Housing Assembly 8.750-542.0 Cover, Junction Box 8.751-160.0 Air Guide 8.750-116.0 Block, Terminal, 5 Pole 8.754-705.0 Fuel Pump, Suntec OL35 8.750-817.0...

-

Page 34: Clearfi Re "M/L" Burner Replacement Parts

CLEARFIRE BURNER "M/L" REPLACEMENT PARTS For best performance specify genuine KNA replacement parts 8.920-645.0 54 34 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.752-933.0 Motor, 1/5 HP 13.5VDC 8.919-865.0 BurnerHousing Assembly-ML Ametek N1CPM-156 8.754-905.0 Gasket, KNA Burner Pump 8.752-932.0 Motor, 1/7 HP 115V Suntec Emerson K41... - Page 35 CLEARFIRE BURNER "M/L" REPLACEMENT PARTS For best performance specify genuine KNA replacement parts ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.752-034.0 Flange 1" Tube Assy Burner 8.750-770.0 Screw, 10/32 x 5/8”, Whiz Loc Flange 8.752-035.0 Flange 3" Tube Assy Burner 8.750-816.0 Screw, 10/32 x1/4”...

-

Page 36: Kt.2 Pump Exploded View And Parts List

KT.2 SERIES PUMP EXPLODED VIEW TORQUE SPECS ITEM # FT. LBS. KT.2 PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 8.752-825.0 Crankcase 8.707-262.0 Brass Plug 3/8 See Kit Below Plunger Oil Seal See Kit Below Valve Seat See Kit Below O-Ring Ø1.78 x 37.82... - Page 37 KT.2 SERIES PUMP EXPLODED VIEW PARTS LIST ITEM PART NO. DESCRIPTION 9.803-181.0 Bearing Housing 8.752-841.0 Plunger Bolt 8.752-820.0 Bonded Seal 8.753-819.0 Plunger, 18mm 8.752-823.0 Copper Spacer 8.753-820.0 Plunger Rod 8.752-822.0 Connecting Rod Pin 8.752-821.0 Connecting Rod 9.802-889.0 Spring Washer 9.802-937.0 Connecting Rod Screw 9.803-194.0 O-Ring Ø2.62 x 152.07...

-

Page 38: Vrt3 Unloader Exploded View And Parts List

VRT3 UNLOADER EXPLODED VIEW AND PARTS LIST 8.750-297.0, 8 GPM, 2320 PSI 8.750-298.0, 8 GPM, 3630 PSI 8.750-299.0, 8 GPM, 4500 PSI ITEM PART NO. DESCRIPTION 8.750-713.0 Outlet Fitting 8.750-712.0 Knob, Unloader 8.750-709.0 Repair Kit, VRT3, 2320/3630 PSI 8.750-710.0 Repair Kit, VRT3, 4500 PSI (Kit Items: 3, 4, 6, 9-12, 21, 24) Unloader Adjustment Procedures Remove lock nut (Item 19). - Page 40 www.karchercommercial.com Form # 9.800-080.0 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the HDS 3.9/30 and is the answer not in the manual?

Questions and answers