Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BRONKHORST CEM

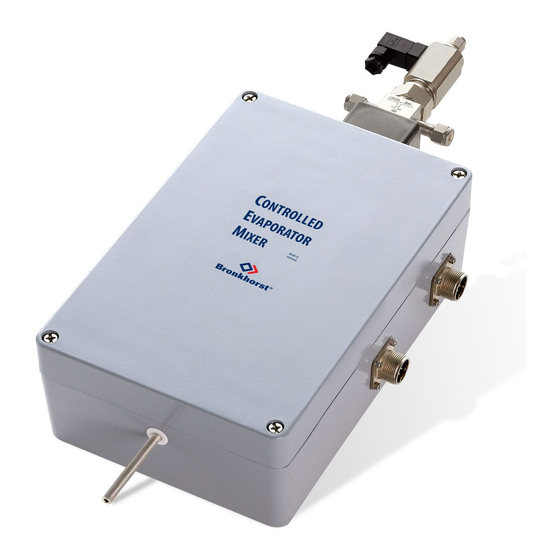

- Page 1 Instruction manual controlled evaporator and mixer Doc. no.: 9.17.010J Date: 19-09-2016 ATTENTION Please read this instruction manual carefully before installing and operating the instrument. Not following the guidelines could result in personal injury and/or damage to the equipment.

- Page 2 ® BRONKHORST page 2 9.17.010...

- Page 3 Re-conditioning of products primarily returned for warranty service that is partly or wholly judged non- warranty may be charged for. Bronkhorst High-Tech B.V. prepays outgoing freight charges when any party of the service is performed under warranty, unless otherwise agreed upon beforehand.

- Page 4 This must be done without flow. Your CEM system is now ready for operation. Be sure that your liquid system is free of gas bubbles. If needed remove the de-aerate plug on top of the CEM control valve for de-aeration. page 4 9.17.010...

-

Page 5: Table Of Contents

BRONKHORST TABLE OF CONTENTS Introduction General ............................page 7 Principle of operation ........................page 7 CEM set-up ........................... page 7 Installation Receipt of equipment ........................page 8 Return shipment ........................... page 8 Service ............................page 8 Mounting position .......................... page 8 Liquid filling ........................... - Page 6 ® BRONKHORST page 6 9.17.010...

-

Page 7: Introduction

A carrier gas, controlled by a MFC* is used to stimulate the evaporation process as a mixing component, and furthermore to transport the vapour. The process is highly repeatable and efficient. Subsequent total evaporation of the liquid is achieved in the "CEM". * For operation of these devices consult the appropriate instruction manuals. 1.3 CEM set-up The “CEM”... -

Page 8: Installation

2.4 Mounting position ® Bronkhorst strongly advises to mount the CEM in a vertical position, with the control valve section pointing upwards and the vapour output pointing downwards. Avoid installation in close proximity of mechanic vibration or strong heat sources. -

Page 9: In-Line Filter

The liquid meter should be installed according to its manual. The outlet of this meter should be connected to the liquid input port of the CEM valve. The CEM valve is controlled by the controller section of the liquid flowmeter. Electrical connections should be made according to the customer system description. -

Page 10: Operation

Operation example: Application: Generation of humid gas The CEM system can be used for generating a certain humidity in a gas stream. The gas flow is controlled ® by the F-201 gas flow controller and the humidity, the water, is controlled by the LIQUI-FLOW controller. - Page 11 ® BRONKHORST At 50% r.h., the (Mole) ratio between gas and water: [mbar] The moleRatio: 1013 so in a gas flow of 2 ln/min, the saturated water flow (50% r.h.) is: ...

-

Page 12: Cables

® BRONKHORST 4 Cables ® The use of standard cables, manufactured by Bronkhorst is recommended. 4.1 EMC and cables All system set-ups described in this manual carry the CE-mark. Therefore they have to comply with the EMC requirements as are valid for this kind of equipment. -

Page 13: Appendix

APPENDIX Recommendations for handling ® the Bronkhorst (CEM) system Vacuum system Non Vacuum system... - Page 14 ® BRONKHORST...

- Page 15 Startup using Vacuum Inertgassupply Vacuum Vacuum Carrier Processgas Liquid Heatedline Liquid Valve Process Vacuum A) To fill the system: Procedure: Actions: A1) Evacuate the lines “Vacuum” Start pumps A2) Evacuate all lines Close: 2,3,5,10 and 9. Connect inert gas on carrier gas inlet. Open : 1,4,7,11.

- Page 16 ® BRONKHORST B) To start the process: Procedure: Actions: B1)Set the CEM heater at right temperature. Give setpoint to the heater, wait until temperature is reached. B2) Start gas flow. Open 9. Give setpoint to gas MFC. B3) Start liquid flow.

- Page 17 Startup without using Vacuum Inertgassupply Atmospheric / waste Carrier Processgas Liquid Heatedline Liquid Valve Process Atmospheric / waste A) To fill the system: Procedure: Actions: A1)Purge all lines Close: 3, 5 and 10. Connect inert gas on carrier gas inlet. Open : 2, 4, 7, 9 and 11.

- Page 18 ® BRONKHORST B) To start the process: Procedure: Actions: B1) Set the CEM heater at right temperature. Give setpoint to the heater, wait until the temperature is stabilized. B2) Start gas flow. Give setpoint to gas MFC. B3) Start liquid flow.

Need help?

Do you have a question about the CEM and is the answer not in the manual?

Questions and answers