Parker 890 Quick Start Manual

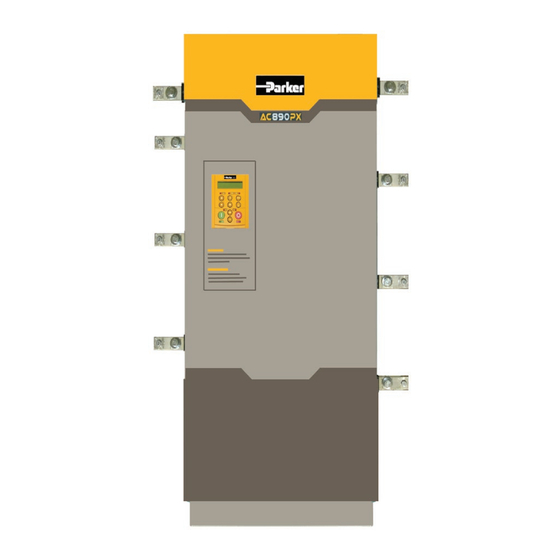

890sd (standalone) drives

frames g, h & j

Hide thumbs

Also See for 890:

- Quick start manual (24 pages) ,

- Owner's manual (32 pages) ,

- Quick start manual (33 pages)

Table of Contents

Advertisement

Quick Links

The full Product Manual is available on line at www.parker.com/ssd

890 QuickStart Manual

890SD (Standalone) Drives

Frames G, H & J

HA471391U000 Issue 6

aerospace

climate control

electromechanical

filtration

fluid & gas handling

hydraulics

pneumatics

process control

sealing & shielding

ENGINEERING

YOUR

SUCCESS.

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Parker 890

- Page 1 The full Product Manual is available on line at www.parker.com/ssd aerospace 890 QuickStart Manual climate control electromechanical filtration fluid & gas handling 890SD (Standalone) Drives hydraulics pneumatics Frames G, H & J process control HA471391U000 Issue 6 sealing & shielding...

- Page 2 All rights strictly reserved. No part of this document may be stored in a retrieval system, or transmitted in any form or by any means to persons not employed by a Parker Hannifin Manufacturing Ltd., without written permission from Parker Hannifin Manufacturing Ltd. Although every effort has been taken to ensure the accuracy of this document it may be necessary, without notice, to make amendments or correct omissions.

- Page 3 Page 2...

-

Page 4: Table Of Contents

C o n t e n t s Page Safety ..................................4 Hazards to Personnel Application Risk • Risk Assessment • Accessibility • Protective Insulation • RCDs Introduction ................................6 About this QuickStart Overview..................................7 Installation .................................. 8 Mounting Dimensions Air Flow Environmental Conditions AC Line Choke... -

Page 5: Safety

The specifications, processes and circuitry described herein are for guidance only and may need to be adapted to the user's specific application. Parker Hannifin Manufacturing Limited does not guarantee the suitability of the equipment described in the Manual for individual applications. -

Page 6: Risk Assessment

Risk Assessment Under fault conditions, power loss or other operating conditions not intended, the equipment may not operate as specified. In particular: • The motor speed may not be controlled • The direction of rotation of the motor may not be controlled •... -

Page 7: Introduction

Show you how to Autotune the drive and start the motor. Because the 890 is a system product and we have no knowledge of your application, we detail the quickest way to power-up the drive using a simple earthing scheme with minimal control wiring. -

Page 8: Overview

Overview Brake Unit DBR Brake Resistor Connection Brake Resistor Connections Negative (-) DC Positive (+) DC Buss Connection Buss Connection PE/Ground PE/Ground Connection Connection Lifting eyes (*See Note 1) Lifting eyes (*See Note 1) Must be left turned in this direction Must be left turned in this direction Power Input Connection (L3) -

Page 9: Installation

Installation A simplified installation is shown below. This installation is not EMC compliant. For European installations and countries with EMC legislation refer to the 890 Engineering Reference Manual, Appendix C. I I T D C D DC 4Q 1 5A... -

Page 10: Mounting Dimensions

Mounting Dimensions The units must be installed in a cubicle. The drive must be securely mounted using all 10 off M8 mounting hole positions. Refer to Chapter 4: Installation Drawings in the Engineering Reference manual for more information. Maximum Weight Models kg/lbs Frame G... -

Page 11: Air Flow

Air Flow Required We strongly recommend that brake/exhaust duct is Air Inlet Location fitted to the drive whether a brake is fitted or not. It is important that the top vent is properly fitted to assure that the exhaust air is not recirculated. We also recommend that these drives are separated from other equipment in a large multifunction cabinet Additional air... -

Page 12: Environmental Conditions

Environmental Conditions Operating ambient temperature 0°C to 40°C (32°F to 104°F) Enclosure rating IP20 – UL(cUL) Open type Atmosphere Dust free, non flammable, non-corrosive, <85% humidity, non-condensing AC Line Choke The drive must be used with an AC Line Choke, however, where a drive is IMPORTANT individually supplied from a dedicated transformer with the required impedance, the AC Line Choke is not required. -

Page 13: 890Sd Power Connections

890SD Power Connections Earth/Ground M10 bolt & washer for compression terminations M3/W M2/V M1/U Auxiliary Power The unit must be permanently earthed. Protect the incoming mains supply using a suitable fuse or circuit breaker (circuit breaker types RCD, ELCB, GFCI are not recommended). Refer to Chapter 5: Circuit Breakers in the Engineering Reference Manual. -

Page 14: 890Sd Control Connections

890SD Control Connections Speed Reference Sequencing Analog • Connect volt-free Connect a 10kΩ potentiometer at • • SPEED FEEDBACK contacts as required terminal block X12 (Analog I/P 3) • 10V = ±100% speed RUN (maintained contact) High (CW): terminal X12/08 at terminal X12/0 6 terminal X14/03 and Wiper:... -

Page 15: 890Sd Feedback Connections

CLOSED-LOOP VEC mode, as the encoder direction must be correct for this mode to operate. Using other types of encoders requires the 890 DSE Configuration Tool and the setting of other parameters. Refer to the 890 Engineering Reference Manual for details of these parameters. -

Page 16: Drive Start-Up

Drive Start-up Before Applying Power : • Read the Safety section at the front of the QuickStart. • Ensure that all local electric codes are met. • Check for damage to equipment. • Check for loose ends, clippings, filings, drilling swarf etc. lodged in the drive and system. -

Page 17: Drive Set-Up

Drive Set-up Appendix A contains information about the 6901 keypad menus and parameter names. Selecting Defaults On first power-up the AC890 prompts whether to load default parameter values for 50Hz or 60Hz. Select either 50Hz or 60Hz then press M then UP to confirm the choice. Motor Data Before attempting to set up the drive, you will need some motor information. -

Page 18: Autotune

Autotune This section is only for operating in Sensorless or Closed-loop Vector modes. If the drive is in V/Hz mode, Autotune is unnecessary and will not Enable. • Ensure that MAX SPEED is greater than NAMEPLATE RPM for a successful autotune. •... -

Page 19: Running In Local

Quick Setup to desired level. If the drive trips on Overvoltage, extend the RAMP DECEL TIME or connect a braking resistor. Refer to the 890 Engineering Reference Manual. Go to SYSTEM::SAVE CONFIG::APPLICATION and UP arrow to save your settings Values are stored during power-down. -

Page 20: Appendix A: Using The 6901 Keypad

Appendix A: Using the 6901 Keypad The 6901 keypad has a two-line backlit LCD display with units and symbols. It can be used to setup and configure the 890 in plain language. It can also be used to operate the drive in Local mode from its Start and Stop buttons, Jog and reverse. -

Page 21: The Menu Structure

The Menu Structure The main menus are shown below. Each menu contains parameters. This is the power-up welcome screen. If a different screen appears, press E a few times to return to this screen. OPERATOR Press the M key to get to the OPERATOR menu menu at level 1 DIAGNOSTICS DOWN arrow to get to the DIAGNOSTICS menu... -

Page 22: Appendix B: Analog And Digital I/O

Appendix B: Analog and Digital I/O The terminal function names apply to the factory shipping configuration. These terminals may have different functions if the configuration has been modified using DSE. Page 21... -

Page 23: 890Sd Control Terminals

890SD Control Terminals Page 22... -

Page 24: Appendix C: Electrical Ratings

Appendix C: Electrical Ratings Notes for Electrical Ratings Tables Page 23... -

Page 25: Electrical Ratings: 890Sd Frame G, 400V

Electrical Ratings: 890SD Frame G, 400V Page 24... -

Page 26: Electrical Ratings: 890Sd Frame H, 400V

Electrical Ratings: 890SD Frame H, 400V Page 25... -

Page 27: Electrical Ratings: 890Sd Frame J, 400V

Electrical Ratings: 890SD Frame J, 400V Page 26... -

Page 28: Appendix D: Compliance

Appendix D: Compliance A comprehensive guide to product compliance is available in the full product manual. Warning Where there is a conflict between EMC and safety requirements personnel safety shall always take precedence. Operation of this equipment requires detailed installation and operation instructions provided in the installation/operation manual intended for use on this product. -

Page 29: Planning Cable Runs

Planning Cable Runs ♦ Use the shortest possible motor cable lengths. ♦ Use a single length of cable to a star junction point to feed multiple motors. ♦ Keep electrically noisy and sensitive cables apart. If this is not possible parallel cable runs should be separated by at least 0.25 meters, for runs longer than 10 meters, separation should be increased proportionally. - Page 30 (from AT, BE, CH, CZ, DE, EE, ES, FI, FR, IE, IL, IS, IT, LU, MT, NL, NO, PT, SE, SK, UK) © 2017 Parker Hannifin Corporation. All rights reserved. Parker Hannifin Manufacturing Limited, Automation Group, Electromechanical Drives Business Unit,...

Need help?

Do you have a question about the 890 and is the answer not in the manual?

Questions and answers