Fujitsu ASU18RMLQ Service Instruction

Split type room air conditioner

Hide thumbs

Also See for ASU18RMLQ:

- Service manual (21 pages) ,

- Manual (80 pages) ,

- Service manual (26 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Fujitsu ASU18RMLQ

- Page 1 SPLIT TYPE ROOM AIR CONDITIONER WALL MOUNTED / DUCT / type CASSETTE INVERTER MULTI SERVICE INSTRUCTION Models Indoor unit Outdoor unit AOU24RML ASU9RMLQ AOU36RML ASU12RMLQ ASU18RMLQ AOU24RML1 AOU36RML1 ARU9RML ARU12RML ARU18RML AUU9RML AUU12RML R410A AUU18RML...

-

Page 2: Table Of Contents

CONTENTS 1. DESCRIPTION OF EACH CONTROL OPERATION 1. CAPACITY CONTROL....................01-01 2. AUTO CHANGEOVER OPERATION................01-01 2-1-1 INDOOR UNIT DISPLAY................... 01-01 2-1-2 INDOOR UNIT DISPLAY................... 01-02 3. INDOOR FAN CONTROL................... 01-03 4. OUTDOOR FAN CONTROL..................01-07 5. LOUVER CONTROL....................01-08 5-1 Wall Mounted (AS) type.................. -

Page 3: Description Of Each Control Operation

R410A WALL MOUNTED / DUCT / CASSETTE type INVERTER (MULTI ) 1 . DESCRIPTION OF EACH CONTROL OPERATION... -

Page 4: Capacity Control

1. CAPACITY CONTROL 1-1 COOLING, HEATING, DRY CAPACITY CONTROL Compressor frequency decides by capacity of an indoor unit, operation number of an indoor unit, set temperature, room temperature and outside temperature. 2. AUTO CHANGEOVER OPERATION 2-1 For AS, AU type When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum mode from among the HEATING, COOLING, DRY and MONITORING modes. - Page 5 2-2 For AR type When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum mode from among the HEATING, COOLING and MONITORING modes. During operation, the optimum mode is automatically swiched in accordance with temperature changes. The temperature can be set between 18°C and 30°C in 1 degC steps.

-

Page 6: Indoor Fan Control

Quiet Cool air Cool air prevention prevention S-Lo S-Lo Cooling 1,200 Cooling 1,380 1,070 1,230 1,050 Quiet Quiet ASU18RMLQ Operation mode Air flow mode Speed (rpm) Heating 1,480 1,480 1,380 1,200 Quiet 1,060 Cool air prevention S-Lo Cooling 1,480 1,380... - Page 7 AUU9RML AUU12RML Operation mode Air flow mode Operation mode Air flow mode Speed (rpm) Speed (rpm) Cooling Cooling Quiet Quiet Heating Heating Quiet Quiet Auto Auto Monitoring Monitoring S- Lo S- Lo AUU18RML Operation mode Air flow mode Speed (rpm) Cooling Quiet Heating...

- Page 8 (4). DRY OPERATION During the dry mode operation, the fan speed setting can not be changed. The indication of the remote controller is fixed in [AUTO]. The fan operates on [S-Lo] mode or OFF. (5). HEATING OPERATION (Fig.3) 5-1. For AU / AS Type airflow change - over ( Heating: AUTO) Switch the airflow [AUTO], and the When the room...

- Page 9 6-2. For AR Type The maximum value of the indoor fan speed is set as shown in Figure 6, based on the detected temperature by the indoor heat exchanger sensor on heating mode. ( Fig.6 : Cool Air Prevention Control ) Indoor heat exchanger Indoor heat exchanger temperature...

-

Page 10: Outdoor Fan Control

4. OUTDOOR FAN CONTROL (1). Fan Speed The speed of outdoor unit fan motor is determined at outside temperature and compressor rotation. ( Table 2 : Target fan speed ) AOU24/36RML Compressor rotation [Hz] < < < < < Frequency rise 10 F<20 20 F<30 30 F<40... -

Page 11: Louver Control

5. LOUVER CONTROL 5-1 Wall Mounted ( AS ) type (1). VERTICAL LOUVER CONTROL (Function Range) Each time the button is pressed, the air direction range will change as follow: (Fig 5: Air Direction Range) (Operation Range) Cooling / Dry mode Heating mode Fan mode Use the air direction adjustments within the ranges shown above. - Page 12 5-2 Cassette (AU) type (Function Range) Each time the button is pressed, the air direction range will change as follows: (Air Direction Range) (Operation Range) During Cooling/Dry mode/Fan mode : During Heating mode Use the air direction adjustments within the ranges shown above. The vertical airflow direction is set automatically as shown, in accordance with the type of operation selected.

-

Page 13: Compressor Control

6. COMPRESSOR CONTROL (1). OPERATION FREQUENCY RANGE The operation frequency of the compressor is different based on the operation mode as shown in the table 4. (Table 4 : Compressor Operation Frequency Range) Cooling Heating AOU24RML 15Hz 90Hz 20Hz 95Hz AOU36RML 15Hz 90Hz... -

Page 14: Timer Operation Control

7. TIMER OPERATION CONTROL 7-1 Wireless Remote Controller For AS type ON / OFF TIMER PROGRAM TIMER SLEEP TIMER (1). OPERATION FREQUENCY RANGE OFF timer : When the clock reaches the set time, the air conditioner will be turned off. Operation mode Stop mode Set time of timer... - Page 15 (3). SLEEP TIMER If the sleep is set, the room temperature is monitored and the operation is stopped automatically. If the operation mode or the set temperature is change after the sleep timer is set, the operation is continued according to the changed setting of the sleep timer from that time ON. In the cooling operation mode When the sleep timer is set, the setting temperature is increased 2°F(1°C).

- Page 16 7-2 Wired Remote Controller For AR / AU type ON / OFF TIMER WEEKLY TIMER TEMPERATURE SET BACK TIMER 1. ON / OFF TIMER OFF timer : When the clock reaches the set time, the air conditioner will be turned off. Operation mode Stop mode Set time of timer...

- Page 17 2-2. DAY OFF setting The DAY OFF setting is only available for days for which weekly settings already exist. If the operating time carries over to the next day (during a next day setting), the effective DAY OFF range will be set as shown below. Normal DAY OFF Operation mode...

-

Page 18: Electronic Expansion Valve Control

8. ELECTRONIC EXPANSION VALVE CONTROL The most proper opening of the electronic expansion valve is calculated and controlled under the present operating condition based on the following values. The compressor frequency, the temperatures detected by the discharge temperature sensor and the outdoor temperature sensor. The pulse range of the electronic expansion valve control is between 30 to 480 pulses. -

Page 19: Manual Auto Operation (Indoor Unit Body Operation)

13. MANUAL AUTO OPERATION (Indoor unit body operation) If MANUAL AUTO Button is set, the operation is controlled as shown in Table 6. If the remote control is lost or battery power dissipated, this function will work without the remote control. -

Page 20: Fresh Air Control (For Ar Type)

16. FRESH AIR CONTROL (For AR type) The fan motor for Fresh Air is operated in synchronization with the indoor fan operation as shown in Figure 11. (Fig.11 : Fresh air control) Operation Fan motor (Indoor unit) Stop Operation Fan motor (for Fresh Air) Stop 17. -

Page 21: Coil Dry And Clean Opeartion Control (For As Type)

Operating COIL DRY : ON ASU12RMLQ 900rpm 480rpm Other indication : OFF ASU18RMLQ 900rpm 480rpm MW09/ 12/ 18Y3FM model (For Friedrich) is only COIL-DRY OPERATION. 20. AIR CLEAN OPERATION (Only for ASU9/ 12/18RMLQ) The air clean operation switches ON and OFF as follows every time it receives AIR CLEAN signal from remote controller. -

Page 22: Energy Save Function (For Ar Type)

21. ENERGY SAVE FUNCTION (For AR type) 1. During Cooling / Dry operation: The thermostat temperature setting increases by 1 degC as soon as the ENERGY SAVE button is pressed, and then increases by 1 degC after 1 hour later. Afterwards, energy consumption is saved by continuing to cool or dry at a thermostat temperature of 2 degC higher than setting temperature. - Page 23 Defrost Flow Chart The defrosting shall proceed by the integrating operation time and outdoor heat exchanger temperature as follows. Heating operation start : Compressor ON (Not defrosted for 6 or 10 minutes) Compressor integrating operation: 45 minutes and over Outdoor temp. > 30.2°F Outdoor temp.

-

Page 24: Various Protections

23. VARIOUS PROTECTIONS (1). DISCHARGE GAS TEMPERATURE OVERRISE PREVENSION CONTROL The discharge gas thermosensor (discharge thermistor : Outdoor side) will detect discharge gas temperature. When the discharge temperature becomes higher than Temperature ,the compressor frequency is decreased 20 Hz, and it continues to decrease the frequency for 20 Hz every 120 seconds until the temperature becomes lower than Temperature . - Page 25 (5). HIGH TEMPERATURE RELEASE CONTROL ( HEATING MODE ) On heating mode, the compressor frequency is controlled as following based on the detection value of the indoor heat exchanger temperature sensor. (Fig 8 : Heating Overload Protection Control) Indoor heat exchange temperature Compressor is OFF 145.4°F...

-

Page 26: Trouble Shooting

R410A WALL MOUNTED / DUCT CASSETTE type INVERTER (MULTI) 2 . TROUBLE SHOOTING... -

Page 27: Error Display

2. TROUBLESHOOTING 2-1 ERROR DISPLAY 2-1-1 INDOOR UNIT DISPLAY For ASU9 - 18RMLQ The OPERATION, TIMER, AIR CLEAN and COIL DRY lamps operate as follows according to the error contents. Error display Trouble Error contents AIR CLEAN COIL DRY TIMER shooting OPERATION or QUIET... - Page 28 For AUU9 - 18RML The OPERATION, TIMER and FILTER lamps operate as follows according to the error contents. Error display Trouble Error contents shooting OPERATION TIMER FILTER (GREEN) (ORANGE) (RED) Communication error 2 times (Serial reverse transfer error) 3 times Outdoor communication signal error 4 times (Forward transfer signal error)

-

Page 29: Outdoor Unit Display

2-1-2 OUTDOOR UNIT DISPLAY 1. ERROR DISPLAY Trouble Error Contents shooting 1 times blink 1 times blink Outdoor communication signal error (Forward transfer signal error) 1 times blink 1 times blink Outdoor discharge pipe temperature 2 times blink thermistor error Outdoor heat exchanger temperature 3 times blink thermistor error... -

Page 30: Wired Remote Controller Display

2-1-3 WIRED REMOTE CONTROLLER DISPLAY For ARU9-18RML (AR-3TA) 1. SELF - DIAGNOSIS When the error indication "E:EE" is displayed, inspection of the air conditioning system is necessary. Please consult authoilzed servise personnel. Run [Self-Diagnosis] if [E:EE] flashes on the clock display of the remote controller. Display Error code SU MO TU WE TH FR SA... - Page 31 2. ERROR CODE HISTORY DISPLAY Up to 16 memorized error codes may be displayed for the indoor unit connected to the remote controller. 1. Stop the air conditioner operation. 2. Press the SET TEMPERATURE buttons simultaneously for 5 seconds or more to start the self-diagnosis.

- Page 32 For AUU09-18RML (AR-6TC) 1. SELF - DIAGNOSIS When "EE" in Temperature Display is displayed, inspection of the air conditioning system is necessary. Please consult authoilzed servise personnel. Unit number (usually 0) Error code SU MOTU WETH FR SA ex. Self-diagnosis check Trouble Error code Error contents...

- Page 33 2. ERROR CODE HISTORY DISPLAY Up to 16 memorized error codes may be displayed for the indoor unit connected to the remote controller. 1. Stop the air conditioner operation. 2. Press the SET TEMPERATURE buttons and the START/STOP button simultaneously for 5 seconds or more to start the self-diagnosis.

-

Page 34: Trouble Shooting With Error Code

2-2 TROUBLE SHOOTING WITH ERROR CODE Trouble shooting 1 Indicate or Display: INDOOR UNIT Error Method: Refer to error code table. Communication Error (Indoor unit Remote control) Detective details: Detective Actuators: When the indoor unit cannot receive the signal from Wired Remote Indoor unit controller PCB circuit more than 10seconds after power ON, or the indoor unit cannot receive Wired Remote Control... - Page 35 Trouble shooting 2 Indicate or Display: OUTDOOR UNIT Error Method: Refer to error code table. Communication Error (Serial Reverse Transfer Error) Detective details: Detective Actuators: When the indoor unit cannot receive the serial signal from Outdoor unit Outdoor Unit Main PCB Circuit more than 10seconds.

- Page 36 Indicate or Display: Trouble shooting 3 INDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Room Temperature Thermistor Error Detective Actuators: Detective details: Indoor Unit Control PCB(AS, AR) , When Room Temperature Thermistor open or short-circuit is detected at power ON. Main PCB(AU) or Room Temperature Thermistor Forecast of Cause :...

- Page 37 Indicate or Display: Trouble shooting 4 INDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Indoor Heat Exchanger Temperature Thermistor Error Detective Actuators: Detective details: When Heat Exchanger Temperature Thermistor open or short-circuit is Indoor Unit Control PCB (AS, AR) , detected at power ON.

- Page 38 Indicate or Display: Trouble shooting 5 OUTDOOR UNIT Error Method: Refer to error code table. Outdoor Heat Exchanger Temperature Thermistor Error Detective Actuators: Detective details: Outdoor Unit Main PCB Circuit When Heat Exchanger Temperature Thermistor open or short-circuit is Heat Exchanger Temperature Thermistor detected at power ON or while running the compressor.

- Page 39 Indicate or Display: Trouble shooting 6 INDOOR UNIT Error Method: Refer to error code table. Water Drain Abnormal Detective Actuators: Detective details: Indoor Unit Main PCB Circuit When Float Switch is ON for more than 3 minutes. Float Switch Forecast of Cause : 1.

- Page 40 Indicate or Display: Trouble shooting 7 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Outdoor Temperature Thermistor Error Detective Actuators: Detective details: Outdoor Unit Main PCB Circuit When Outdoor Temperature Thermistor open or short-circuit is detected at power ON or while running the compressor. Outdoor Temperature Thermistor Forecast of Cause : 1.

- Page 41 Indicate or Display: Trouble shooting 8 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Outdoor Discharge Pipe Temperature Thermistor Error Detective details: Detective Actuators: When Discharge Pipe Temperature Thermistor open or short-circuit Outdoor Unit Main PCB Circuit is detected at power ON or while running the compressor.

- Page 42 Trouble shooting 9 Indicate or Display: Indicate or Display: INDOOR UNIT Error Method: Refer to error code table. Indoor EEPROM abnormal (Model No.) Detective details: Detective Actuators: Indoor Unit Control PCB (AS,AR), When the model information being read from EEPROM has an apparent error.

- Page 43 Indicate or Display: Trouble shooting 10 INDOOR UNIT Error Method: Refer to error code table. Indoor Fan Motor abnormal Detective Actuators: Detective details: Indoor Unit Control PCB (AS,AR), When the condition that actual frequency of Indoor Fan is below 1/3 Main PCB, Power PCB (AU) Circuit.

- Page 44 Indicate or Display: Trouble shooting 11 Indicate or Display: INDOOR UNIT Error Method: Refer to error code table. Outdoor Communication Signal Error (Forward Transfer Signal Error) Detective details: Detective Actuators: Indoor Unit Control PCB (AS,AR), When the outdoor unit cannot receive the serial signal from Indoor unit Main PCB, Power PCB (AU) Circuit more than 10seconds.

- Page 45 Indicate or Display: Trouble shooting 12 OUTDOOR UNIT Error Method: Refer to error code table. Compressor Temperature Thermistor Error Detective Actuators: Detective details: When Compressor Temperature Thermistor open or short-circuit is Outdoor Unit Main PCB Circuit detected at power ON or while running the compressor. Compressor Temperature Thermistor Forecast of Cause : 1.

- Page 46 Indicate or Display: Trouble shooting 13 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Pressure Switch Error Detective details: Detective Actuators: When pressure switch open is detected in 10 seconds Outdoor Unit Main PCB Circuit after the power is turned on. Pressure Switch Forecast of Cause : 1.

- Page 47 Indicate or Display: Trouble shooting 14 OUTDOOR UNIT Error Method: Refer to error code table. IPM error Detective details: Detective Actuators: When more than normal operating current to IPM in Main PCB flows, Outdoor Unit Main PCB Circuit the compressor stops. Compressor After the compressor restarts, if the same operation is repeated within 40sec, the compressor stops again.

- Page 48 Indicate or Display: Trouble shooting 15 OUTDOOR UNIT Error Method: Refer to error code table. CT error Detective Actuators: Detective details: Outdoor Unit Main PCB Circuit When Input Current Sensor has detected lower than 0A Outdoor Unit Filter PCB Circuit while Inverter Compressor is operating at higher than 50Hz, after 1minute upon starting the Compressor.

- Page 49 Indicate or Display: Trouble shooting 16 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Active Filter Module (AFM) error Detective Actuators: Detective details: Outdoor Unit Main PCB Circuit When inverter input DC voltage is higher than 467V or Active Filter Module lower than 237V.

- Page 50 Indicate or Display: Trouble shooting 17 OUTDOOR UNIT Error Method: Refer to error code table. Compressor rotor location cannot detect (Permanent Stop) Detective details: Detective Actuators: While running the compressor, if the detected rotor location is out of Outdoor Unit Main PCB Circuit phase with actual rotor location more than 90 degrees, the compressor stops.

- Page 51 Indicate or Display: Trouble shooting 18 OUTDOOR UNIT Error Method: Refer to error code table. Outdoor Unit Fan Motor Error Detective Actuators: Detective details: When outdoor fan rotation speed is less than 100rpm in 20 seconds Outdoor Unit Main PCB Circuit after fan motor starts, fan motor stops.

- Page 52 Indicate or Display: Trouble shooting 19 OUTDOOR UNIT Error Method: Refer to error code table. Heat Sink Temperature Thermistor Error Detective details: Detective Actuators: When Heat Sink Temperature Thermistor open or short-circuit is Outdoor Unit Main PCB Circuit detected at power ON or while running the compressor. Heat Sink Temperature Thermistor Forecast of Cause : 1.

- Page 53 Indicate or Display: Trouble shooting 20 Refer to error code table. OUTDOOR UNIT Error Method: Compressor Start-up error (Permanent Stop) Detective Actuators: Detective details: The detect rotor position operation is repeat up to 50 times. Outdoor Unit Main PCB Circuit 3min ST operates if the compressor fails on start-up, it start try again of the detect rotor position operation.

- Page 54 Indicate or Display: Trouble shooting 21 OUTDOOR UNIT Error Method: Refer to error code table. 2-way valve Temperature Thermistor Error Detective details: Detective Actuators: When 2-way valve Temperature Thermistor open or short-circuit is Outdoor Unit Main PCB Circuit detected at power ON or while running the compressor. 2-way valve Temperature Thermistor Forecast of Cause : 1.

- Page 55 Indicate or Display: Trouble shooting 22 OUTDOOR UNIT Error Method: Refer to error code table. 3-way valve Temperature Thermistor Error Detective details: Detective Actuators: When 3-way valve Temperature Thermistor open or short-circuit is Outdoor Unit Main PCB Circuit detected at power ON or while running the compressor. 3-way valve Temperature Thermistor Forecast of Cause : 1.

- Page 56 Indicate or Display: Trouble shooting 23 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Connected Indoor unit error Detective Actuators: Detective details: Outdoor Unit Main PCB Circuit When the total capacity of the connected indoor units exceed the connectable range of the total capacity.

- Page 57 Indicate or Display: Trouble shooting 25 INDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Manual auto switch error Detective Actuators: Detective details: Indoor Unit Control PCB Circuit (AS) When the manual auto switch becomes ON for 60 consecutive seconds.(AS) Main PCB Circuit (AU) 30 consecutive seconds.(AU) Display PCB (AU)

- Page 58 Indicate or Display: Trouble shooting 26 INDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Power supply frequency detection error Detective Actuators: Detective details: Indoor Unit Control PCB Circuit (AS,AR) The power supply frequency cannot be recognized after 4sec of power ON. Forecast of Cause : 1.

- Page 59 Indicate or Display: Indicate or Display: Trouble shooting 27 INDOOR UNIT Error Method: Refer to error code table. Communication Error (Main PCB ---> Display PCB) Detective details: Detective Actuators: When the Display PCB cannot receive the signal from the Main PCB. Indoor Unit Main PCB Circuit Display PCB Forecast of Cause:...

- Page 60 Indicate or Display: Indicate or Display: Trouble shooting 28 INDOOR UNIT Error Method: Refer to error code table. Communication Error (Main PCB <--- Display PCB) Detective details: Detective Actuators: When the Main PCB cannot receive the signal from the Display PCB. Indoor Unit Main PCB Circuit Display PCB Forecast of Cause:...

- Page 61 Indicate or Display: Trouble shooting 29 INDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. VDD permanence stop protection (Electric air clean) Detective Actuators: Detective details: Electric air clean unit When the air cleanness monitor trial protection operates 4 times. Indoor Unit Control PCB Circuit Forecast of Cause : 1.

- Page 62 Indicate or Display: Trouble shooting 31 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Discharge temperature error Detective details: Detective Actuators: When the discharge temperature becomes higher than 115°C, Outdoor Unit Main PCB Circuit the compressor stops. Discharge Pipe Temperature Thermistor Forecast of Cause : 1.

- Page 63 Indicate or Display: Trouble shooting 32 OUTDOOR UNIT Error Method: Refer to error code table. Excessive high pressure protection on cooling Detective details: Detective Actuators: Excessive high pressure protection on cooling mode has been Outdoor Unit Main PCB Circuit activated. Outdoor Fan Motor Heat Exchanger Temp.

- Page 64 Indicate or Display: Trouble shooting 33 OUTDOOR UNIT Error Method: INDOOR UNIT Refer to error code table. Compressor temperature error Detective details: Detective Actuators: When the compressor temperature becomes higher than 125°C, Outdoor Unit Main PCB Circuit the compressor stops. Compressor Temperature Thermistor Forecast of Cause : 1.

- Page 65 Indicate or Display: Refer to error code table. Trouble shooting 35 OUTDOOR UNIT Error Method: 4-way valve error Detective Actuators: Detective details: The following condition is monitored every one minute after the Outdoor Unit Main PCB Circuit compressor operates consecutively for 19 minutes, and 7 min ST Heat Exchanger Temperature operates when the condition is detected two times in succession.

-

Page 66: Trouble Shooting With No Error Code

2-3 TROUBLE SHOOTING WITH NO ERROR CODE Forecast of Cause: Trouble shooting 36 1. Power Supply failure 2. External cause Indoor Unit - No Power 3. Electrical Components defective Check Point 1 : Check Installation Condition Isn’t the breaker down? Check loose or removed connection cable. - Page 67 Forecast of Cause: Trouble shooting 37 1. Power Supply failure 2. External cause Outdoor Unit - No Power 3. Electrical Components defective Check Point 1 : Check Installation Condition Isn’t the breaker down? Check loose or removed connection cable. >>If abnormal condition is found, correct it by referring to Installation Manual or Data &...

- Page 68 Forecast of Cause: Trouble shooting 38 1. Setting/ Connection failure 2. External cause No Operation (Power is ON) 3. Electrical Component defective Check Point 1 : Check indoor and outdoor installation condition Indoor Unit - Check incorrect wiring between Indoor Unit - Remote Control, or terminals between Indoor Units. Or, check if there is an open cable connection.

- Page 69 Forecast of Cause: Trouble shooting 39 1. Indoor Unit error 2. Outdoor Unit error No Cooling / No Heating 3. Effect by Surrounding environment 4. Connection Pipe / Connection Wire failure 5. Refrigeration cycle failure Check Point 1 : Check Indoor Unit Does Indoor Unit FAN run on HIGH FAN? Is Air Filter dirty? Is Heat Exchanger clogged?

- Page 70 Forecast of Cause : Trouble shooting 40 1. Abnormal installation (Indoor/ Outdoor) 2. Fan failure(Indoor/ Outdoor) Abnormal Noise 3. Compressor failure (Outdoor) Diagnosis method when Abnormal Noise is occurred Abnormal noise is coming from Indoor Unit. Abnormal noise is coming from Outdoor Unit. (Check and correct followings) (Check and correct followings) Is Main Unit installed in stable condition?

-

Page 71: Service Parts Information

2-4 SERVICE PARTS INFORMATION SERVICE PARTS INFORMATION 1 Compressor Diagnosis method of Compressor ( If Outdoor Unit LED displays Error, refer to Trouble shooting ) Abnormal noise Stops soon after starting up Does not start up Check if vibration noise by Is there open or loose connection Is there open or loose connection cable? - Page 72 SERVICE PARTS INFORMATION 2 Inverter Compressor Check Point 1 : Check Connection Check terminal connection of Compressor Check connection of Main PCB (loose or incorrect wiring) (Loose or incorrect wiring) Terminal cover opened (RED) (RED) W304 MAIN PCB W305 W303 (WHITE) (WHITE) (BLACK)

- Page 73 SERVICE PARTS INFORMATION 3 Active Filter Module Check Point 1 : Check Open or Short-circuit and Diode (D1) Remove connector, check the open or short-circuit and the diode in the module Check the open or short-circuit Terminal Resistance value Tester(+) Tester(-) 360k 720k...

- Page 74 SERVICE PARTS INFORMATION 4 Outdoor unit Electronic Expansion Valve ( EEV ) Check Point 1 : Check Connections Check connection of connector ( Loose connector or open cable ) AOU24RML AOU36RML EXPANSION EXPANSION VALVE COIL VALVE COIL BROWN BROWN BLUE BLUE CN27 CN27...

- Page 75 Check Point 5 : Check Opening and Closing Operation of Valve If it is open, When Valve is closed, it has a temp. difference between Inlet and Outlet. it has no temp. difference between Inlet and Outlet. CLOSE OPEN Example : Hot Gas Example : Hot Gas Pipe (In) Pipe (In)

-

Page 76: Replacement Parts

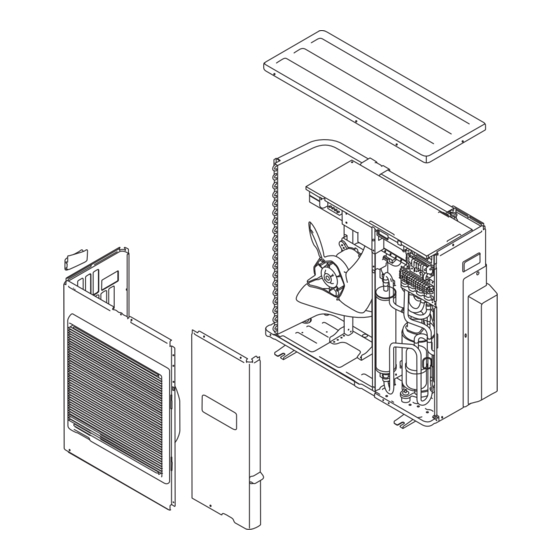

R410A WALL MOUNTED / DUCT / CASSETTE type INVERTER (MULTI) 3 . REPLACEMENT PARTS... - Page 77 R E P L A C E ME N T P ART S Models : ASU9RMLQ ASU12RMLQ ASU18RMLQ INVERTER 03-01...

- Page 78 R E P L A C E ME N T P ART S Models : ASU9RMLQ ASU12RMLQ ASU18RMLQ 03-02...

- Page 79 R E P L ACE ME NT PAR TS Model : ARU9RML 03-03...

- Page 80 R E P L ACEM E NT PAR TS Model : ARU9RML 03-04...

- Page 81 R E P LAC EM ENT P ART S Models : ARU12RML ARU18RML 03-05...

- Page 82 R E PL ACE M ENT P ART S Models : ARU12RML ARU18RML 03-06...

- Page 83 R E PLA CEM ENT P ART S Models : ARU9RML ARU12RML ARU18RML 03-07...

- Page 84 R E P LAC EM ENT P ART S Models: AUU9RML AUU12RML AUU18RML...

- Page 85 R E PL A CEM ENT P ART S Models : AUU9RML AUU12RML AUU18RML CONTROL UNIT...

- Page 86 R E P LACE M ENT P ART S CASSETTE TYPE DECORATION PANEL UTG-UFUB-W...

- Page 87 R E P L ACEM E NT P ART S CASSETTE TYPE DECORATION PANEL UTG-UFUB-W Flap total assy Motor holder assy (connector : white) (connector : red)

- Page 88 R E P L A C E ME N T P A RT S Model : AOU24RML AOU24RML1 03-08...

- Page 89 R E P L A C E ME N T P A RT S Model : AOU24RML AOU24RML1 03-09...

- Page 90 R E P L A C E ME N T P A RT S Model : AOU24RML AOU24RML1 03-10...

- Page 91 R E P L A C E ME N T P A RT S Model : AOU24RML AOU24RML1 Connector : RED WHITE Connector : BLACK GREEN BLUE YELLOW 03-11...

- Page 92 R E P L A C E ME N T P A RT S Model : AOU36RML AOU36RML1 03-12...

- Page 93 R E P L A C E ME N T P A RT S Model : AOU36RML AOU36RML1 03-13...

- Page 94 R E P L A C E ME N T P A RT S Model : AOU36RML AOU36RML1 03-14...

- Page 95 R E P L A C E ME N T P A RT S Model : AOU36RML AOU36RML1 Connector : RED WHITE Connector : BLACK GREEN BLUE YELLOW 03-15...

- Page 96 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED INVERTER BOX A PARTS FILTER PCB PROCESS Assemble PWB ASSY SCREW,TAPPING (FILTER PCB) REGULATION As shown in Fig.1, assemble PWB ASSY to INVERTER BOX A. As shown in Fig.2, pull out the wires of PWB ASSY.

- Page 97 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED INVERTER BOX A PROCESS Assemble PCB ASSY PARTS MAIN PCB (MAIN PWB) SCREW, TAPPING REGULATIONS Certainly set PWB ASSY under the 3 hooks of INVERTER BOX A. Before it is temporary fix of PCB ASSY, As shown in the Fig.2-5, pull out the wires of PCB ASSY.

- Page 98 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.2, pull out the wires. Through this hole. MAIN PCB W12 YELLOW,W13 BLUE (MAIN PCB) WIRE WITH TERMINAL W10 BLACK,W11 WHITE (MAIN PCB) WIRE WITH TERMINAL Through this hole.

- Page 99 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.3, pull out the wires. W201 YELLOW(MAIN PCB) W16 RED (MAIN PCB) WIRE WITH TERMINAL WIRE WITH TERMINAL W200 RED (MAIN PCB) CN1 (MAIN PCB) WIRE WITH TERMINAL WIRE WITH CONNECTOR...

- Page 100 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.4-5, pull out the wires. W17 BLACK (MAIN PCB) WIRE WITH TERMINAL W16 RED (MAIN PCB) WIRE WITH TERMINAL W303 BLACK, W304 WHITE,W305 RED (MAIN PCB)

- Page 101 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.6, pull out the wires. As shown in the Fig.7, pull out the wires and fix them. W303 BLACK, W304 WHITE, W305 RED (MAIN PCB) WIRE WITH TERMINAL...

- Page 102 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.8, pull out the wires. CN1 (MAIN PCB) WIRE WITH CONNECTOR W200 RED (MAIN PCB) WIRE WITH TERMINAL W201 YELLOW(MAIN PCB) WIRE WITH TERMINAL CN50 (MAIN PCB) CN39 (MAIN PCB)

- Page 103 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.9-10, pull out the wires. CN1 (MAIN PCB) CN50 (MAIN PCB) WIRE WITH CONNECTOR WIRE WITH CONNECTOR CN39 (MAIN PCB) WIRE WITH CONNECTOR Fig.9 W201 YELLOW(MAIN PCB)

- Page 104 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED PROCESS Assemble WIRE WITH TERMINAL WIRE WITH TERMINAL PARTS (ACTL, etc) REGULATIONS As shown in Fig.1 assemble WIRE WITH TERMINAL to INVERTER BOX A. Hook WIRE WITH TERMINAL WHITE...

- Page 105 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED EMI FILTER PROCESS Connect wires. (INVERTER BOX A) PARTS BINDER C REGULATIONS As shown in Fig1-2, assemble EMI FILTER. Turn of the wire is according as Fig.1. As shown in Fig.2, certainly fix EMI FILTER to wires by BINDER.

- Page 106 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.3, connect wires. CN34 (from W8 BLACK, W9 WHITE of FILTER PCB) YELLOW Fig.3 03-26...

- Page 107 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.4-5, connect wires. PWB must not warp when you connect CN1. (from CN1 of MAIN PCB) WHITE Fig.4 TM101 TM102 WIRE WITH TERMINAL WIRE WITH TERMINAL...

- Page 108 R E P L A C E ME N T P A RT S MODEL : AOU24RML PROCESS Fix the wires to INVERTER BOX A (HEATSINK THERMISTOR, etc) REGULATIONS As shown in Fig.1,fix the wires to INVERTER BOX A. Fig.2 Hook HEATSINK THERMISTOR...

- Page 109 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.2, fix the wires to INVERTER BOX A. Pull out the wire through this opening. Hook Fig.2 HEATSINK THERMISTOR CN407(MAIN PCB) WIRE WITH CONNECTOR 03-29...

- Page 110 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS Tighten screw as shown in figure. Check no miss tightening ! Check no float of parts ! SCREW WITH WASHER D101 SCREW WITH WASHER DIPIPM IC310 SCREW WITH WASHER...

- Page 111 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED PROCESS Bind WIRE WITH CONNECTOR BINDER C PARTS (COMP WIRE) REGULATIONS As shown in the figures, set WIRE WITH CONNECTOR and bind it to INVERTER BOX A. The wire must not come in contact with the HOLDER(THERMO) SUS304 CSP-H T0.5 INVERTER BOX A Fig.1...

- Page 112 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED EMI FILTER PROCESS Connect wires. PARTS BINDER C (D,PWR(BRIDGE), ACTPM) REGULATIONS As shown in figures, assemble EMI FILTER. Turn of the wire is according as Fig.3. As shown in Fig.2, certainly fix EMI FILTER to wires by BINDER.

- Page 113 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.4, connect wires. WIRE WITH TERMINAL Twist 4 times or more. WHITE W17 BLACK (MAIN PCB) WIRE WITH TERMINAL W16 RED (MAIN PCB) WIRE WITH TERMINAL W12 YELLOW,W13 BLUE...

- Page 114 R E P L A C E ME N T P A RT S MODEL : AOU24RML REGULATIONS As shown in Fig.5, bind 3 types of wires. W12 YELLOW,W13 BLUE (MAIN PWB) BINDER C 50 10mm CN407(MAIN PCB) WIRE WITH CONNECTOR Bind 3 types of wires! Fig.5 (W12 YELLOW,W13 BLUE,CN407)

- Page 115 R E P L A C E ME N T P A RT S MODEL : AOU24RML PROCESS Connect wires. (TERMINAL) REGULATIONS As shown in figures, connect wires. A right picture shows the example of two times of the twist. Twist W4 and W5 2 times or more.

- Page 116 R E P L A C E ME N T P A RT S MODEL : AOU24RML PROCESS Connect wires. (PCB ASSY(MAIN),INVERTER BOX D) REGULATIONS As shown in figures, connect wires. W200 RED (MAIN PCB) WIRE WITH TERMINAL W201 YELLOW(MAIN PCB) WIRE WITH TERMINAL Fig.1 03-36...

- Page 117 R E P L A C E ME N T P A RT S MODEL : AOU24RML USED BINDER C PROCESS Bind wires. PARTS REGULATIONS As shown in figures, bind 4 types of wires. BINDER C Close up Bind 4 types of wires! (W200,W201,W8,W9,CN1) Fig.1 CN1 (MAIN PCB)

- Page 118 R E P L A C E ME N T P A RT S MODEL : AOU36RML USED INVERTER BOX A PARTS FILTER PCB PROCESS Assemble PWB ASSY SCREW,TAPPING (FILTER PCB) REGULATION As shown in Fig.1, assemble PWB ASSY to INVERTER BOX A. As shown in Fig.2, pull out the wires of PWB ASSY.

- Page 119 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Assemble PCB ASSY. INVERTER BOX A USED MAIN PCB MAIN PCB PARTS SCREW,TAPPING REGULATIONS Certainly set PWB ASSY under the 3 hooks of INVERTER BOX A. Before it is temporary fix of PWB ASSY, As shown in the Fig.3-6, pull out the wires of PWB ASSY.

- Page 120 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.2, Twist W21 and W22 10 times or more. A right picture shows the example of two times of the twist. MAIN PCB Fig.2 W21 ORANGE,W22 ORANGE...

- Page 121 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.3, pull out the wires. W12 YELLOW,W13 BLUE (MAIN PCB) Through this hole. MAIN PCB WIRE WITH TERMINAL W10 BLACK,W11 WHITE (MAIN PCB) WIRE WITH TERMINAL Through this hole.

- Page 122 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.4, pull out the wires. W200 RED (MAIN PCB) W202 PINK (MAIN PCB) W201 YELLOW (MAIN PCB) WIRE WITH TERMINAL WIRE WITH TERMINAL WIRE WITH TERMINAL W16 RED (MAIN PCB)

- Page 123 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.5-6, pull out the wires. W17 BLACK (MAIN PCB) WIRE WITH TERMINAL W16 RED (MAIN PCB) WIRE WITH T TERMINAL W303 BLACK, W304 WHITE,W305 RED (MAIN PCB)

- Page 124 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.7, pull out the wires. As shown in the Fig.8, pull out the wires and fix them. W303 BLACK,W304 WHITE, W305 RED (MAIN PCB) WIRE WITH TERMINAL...

- Page 125 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.9, pull out the wires. CN1 (MAIN PWB) WIRE WITH CONNECTOR W200 RED (MAIN PCB) CN50 (MAIN PWB) WIRE WITH TERMINAL WIRE WITH CONNECTOR W201 YELLOW(MAIN PCB) WIRE WITH TERMINAL...

- Page 126 R E P L A CE ME NT PAR TS MODEL : AOU36RML REGULATIONS As shown in Fig.10-11, pull out the wires. CN1 (MAIN PCB) WIRE WITH CONNECTOR CN51 (MAIN PCB) WIRE WITH CONNECTOR CN52 (MAIN PCB) WIRE WITH CONNECTOR CN50 (MAIN PCB) WIRE WITH CONNECTOR CN40 (MAIN PCB)

- Page 127 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Assemble WIRE WITH TERMINAL USED WIRE WITH TERMINAL (ACTL, etc) PARTS REGULATIONS As shown in Fig.1 assemble WIRE WITH TERMINAL to INVERTER BOX A. Hook W IRE WITH TERMINAL WHITE...

- Page 128 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Connect wires. (INVERTER BOX A) USED EMI FILTER PARTS BINDER C REGULATIONS As shown in Fig1-2, assemble EMI FILTER. Turn of the wire is according as Fig.1. As shown in Fig.2, certainly fix EMI FILTER to wires by BINDER.

- Page 129 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.3, connect wires. CN34 (from W8 BLACK, W9 WHITE of FILTER PCB) YELLOW Fig.3 03-49...

- Page 130 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.4-5, connect wires. PCB must not warp when you connect CN1. (from CN1 of MAIN PCB) Fig.4 WHITE THERMISTOR W21 ORANGE,W22 ORANGE (MAIN PCB) WIRE WITH TERMINAL...

- Page 131 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Fix the wires to INVERTER BOX A (HEATSINK THERMISTOR, etc) REGULATIONS As shown in Fig.1 fix the wires to INVERTER BOX A. Fig.2 Hook HEATSINK...

- Page 132 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.2, fix the wires to INVERTER BOX A. Pull out the wire through this opening. Hook Fig.2 HEATSINK THERMISTOR CN407(MAIN PCB) WIRE WITH CONNECTOR 03-52...

- Page 133 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS Tighten screw as shown in figure. SCREW WITH WASHER Check no miss tightening Check no float of parts D101 SCREW WITH WASHER DIPIPM IC310 SCREW WITH WASHER...

- Page 134 R E P L A C E ME N T P A RT S MODEL : AOU36RML USED PROCESS Bind WIRE WITH CONNECTOR. BINDER C PARTS (COMP WIRE) REGULATIONS As shown in the figures, set WIRE WITH CONNECTOR and bind it to INVERTER BOX A. The wire must not come in contact with the HOLDER(THERMO) SUS304 CSP-H T0.5 Fig.1 INVERTER BOX A...

- Page 135 R E P L A C E ME N T P A RT S USED MODEL : AOU36RML EMI FILTER PARTS BINDER C PROCESS Connect wires. D,PWR(BRIDGE), ACTPM REGULATIONS As shown in figures, assemble EMI FILTER. Turn of the wire is according as Fig.3. As shown in Fig.2, certainly fix EMI FILTER to wires by BINDER.

- Page 136 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.4, connect wires. WIRE WITH TERMINAL Twist 4 times or more. WHITE W17 BLACK (MAIN PCB) WIRE WITH TERMINAL W16 RED (MAIN PCB) WIRE WITH TERMINAL W12 YELLOW,W13 BLUE...

- Page 137 R E P L A C E ME N T P A RT S MODEL : AOU36RML REGULATIONS As shown in Fig.5 bind 3 types of wires W12 YELLOW, W13 BLUE (MAIN PCB) WIRE WITH TERMINAL BINDER C CN407(MAIN PCB) WIRE WITH CONNECTOR Bind 3 types of wires! Fig.5...

- Page 138 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Connect wires. (TERMINAL) REGULATIONS As shown in figures, connect wires. A right picture shows the example of two times of the twist. Twist W4 and W5 2 times or more.

- Page 139 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Connect wires. (PWB ASSY(MAIN),INVERTER BOX D) REGULATIONS As shown in figures, connect wires. W200 RED (MAIN PCB) WIRE WITH TERMINAL W201 YELLOW(MAIN PCB) WIRE WITH TERMINAL W202 PINK(MAIN PCB) WIRE WITH TERMINAL...

- Page 140 R E P L A C E ME N T P A RT S MODEL : AOU36RML PROCESS Bind wires. USED PARTS REGULATIONS As shown in figures, bind 6 types of wires. BINDER C Bind 6 types of wires! (W200~W203,W8,W9,CN1) Close up Fig.1 W201 YELLOW(MAIN PCB)

- Page 141 R410A WALL MOUNTED / DUCT / CASSETTE type INVERTER (MULTI) 4 . APPENDING DATA 1. PT CHART...

- Page 142 1. PT CHART MODEL NAME : ASU12RMLQ+ASU12RMLQ+ASU12RMLQ / AOU36RML Outdoor Temperature Dry Bulb (°F) COOLING 32360 31970 31550 22290 16440 13630 12230 10820 CAPACITY (BTU ) 2350 2920 4020 3130 2260 2260 2280 2300 INPUT ( W ) 10.3 12.8 17.7 13.7 10.0...

- Page 143 MODEL NAME : ASU12RMLQ+ASU12RMLQ+ASU9RMLQ / AOU36RML Outdoor Temperature Dry Bulb (°F) COOLING 31430 31040 30570 21400 16030 13360 12030 10700 CAPACITY (BTU ) 2350 2910 4020 3150 2260 2260 2280 2300 INPUT ( W ) 10.3 12.8 17.7 13.8 10.0 10.1 70 / 60 AMPS ( A )

- Page 144 MODEL NAME : ASU18RMLQ+ASU9RMLQ+ASU9RMLQ / AOU36RML Outdoor Temperature Dry Bulb (°F) COOLING 32630 32240 31810 22260 16580 13860 12490 11130 CAPACITY (BTU ) 2350 2920 4020 3140 2260 2260 2280 2300 INPUT ( W ) 10.3 12.8 17.7 13.8 10.0 10.1...

- Page 145 1116, Suenaga, Takatsu-ku, Kawasaki 213-8502, Japan JUN 2006 Printed in Japan GS06082006...

Need help?

Do you have a question about the ASU18RMLQ and is the answer not in the manual?

Questions and answers