Subscribe to Our Youtube Channel

Summary of Contents for Krautzberger MA-1

- Page 1 Operating instructions Mini spray gun MA-1 T-Dok-015-GB-Rev.0 ■ 200-0345 Translation of the original operating instructions...

- Page 2 Thank you for selecting a Krautzberger product. This product has been manufactured following state-of-the-art manufacturing procedures and extensive quality assurance measures. We promise you a product of the highest quality. If you have questions, requests or suggestions, please contact us. We are always glad to assist you.

-

Page 3: Table Of Contents

ENGLISH Mini spray gun MA-1 Table of contents Function and identification....................5 Function........................5 Identification......................... 6 Using this operating manual..................... 7 Symbols in this manual....................7 Personnel requirements....................8 Personal protective equipment..................9 Safety and responsibility....................12 Responsibility of the owner..................12 Intended use...................... - Page 4 Accessories........................37 Disassembly and disposal....................38 12.1 Safety........................38 12.2 Disassembly......................38 12.3 Disposal........................38 Technical data........................39 13.1 Dimensions and weight.................... 39 13.2 General specifications..................... 39 13.3 Dimensions......................40 Declaration of incorporation................... 41 Notes..........................42 Index..........................43 GB–4 mail@krautzberger.com, www.krautzberger.com...

-

Page 5: Function And Identification

ENGLISH Mini spray gun MA-1 1 Function and identification Function The mini spray gun MA-1 is used for: automatic coating/marking of surfaces dosing of fluids placement of adhesive or marking points Typical spray fluids are paints, dyes, adhesives, glazes, enamels, release agents, etc. -

Page 6: Identification

Scope of delivery Type Product number MA-1 with cover 200-0345 MA-1 with needle stroke adjustment 200-0345 Operating manual T-Dok-015 Serial number The serial number of the mini spray gun is located on the main element. It serves as a unique iden- tifier. -

Page 7: Using This Operating Manual

ENGLISH Mini spray gun MA-1 2 Using this operating manual Symbols in this manual Safety instructions This manual uses symbols to identify safety instructions. The safety instructions are preceded by signal words that indicate the severity of the hazard. DANGER! This combination of symbol and signal word indicates an immediate dangerous situation, which will cause death or severe injuries if it is not averted. -

Page 8: Personnel Requirements

References to sections in this manual and other applicable docu- ments Lists without specified order [Pushbutton] Operating elements (e.g. pushbuttons, switches), display ele- ments (e.g. signal lights) ‘Display’ Screen elements (e.g. pushbuttons, assignment of function keys) Personnel requirements GB–8 mail@krautzberger.com, www.krautzberger.com... -

Page 9: Personal Protective Equipment

Description of the personal protective equipment recommended by Krautzberger The personal protective equipment is described below: Protective work clothing ■... - Page 10 Safety goggles are used to protect the eyes from flying parts and splashes of liquid. Protective gloves Protective gloves protect hands from friction, abrasion, puncture wounds, or deeper injuries, as well as from contact with hot surfaces. GB–10 mail@krautzberger.com, www.krautzberger.com...

- Page 11 ENGLISH Mini spray gun MA-1 Safety shoes Safety shoes protect the feet against crushing, falling parts or slipping on slippery ground. Safety helmet The helmet protects the head against injuries from falling parts and oscillating loads as well as in tight spaces.

-

Page 12: Safety And Responsibility

Do not use sharply abrasive, chemically aggressive, very hot or very cold spray media without first consulting with and receiving approval from Krautzberger GmbH. Adhere to the spray media manufacturer's safety data sheets. Only use the manufacturer's OEM parts. -

Page 13: General Safety Instructions

ENGLISH Mini spray gun MA-1 Ä Chapter 13 Only operate the mini spray gun in compliance with the values specified in ( ‘Technical data’ on page 39). Make sure that the connected compressed air is oil-free and free from solid matter. -

Page 14: Residual Risks

Frost, etc. Residual risks Devices, machines or systems made by Krautzberger GmbH have been manufactured based on state-of-the-art technology and in compliance with technical safety regulations. Nonetheless, their use may pose a threat to the life or health of users or third parties, or harm the device, the machine, the system or other material assets. -

Page 15: Transport, Storage, And Packaging

ENGLISH Mini spray gun MA-1 4 Transport, storage, and packaging Transport The mini spray gun is protected by cardboard packaging. The cardboard packaging can be reused for storage. Storage Store the mini spray gun under the following conditions: Store in the original packaging. -

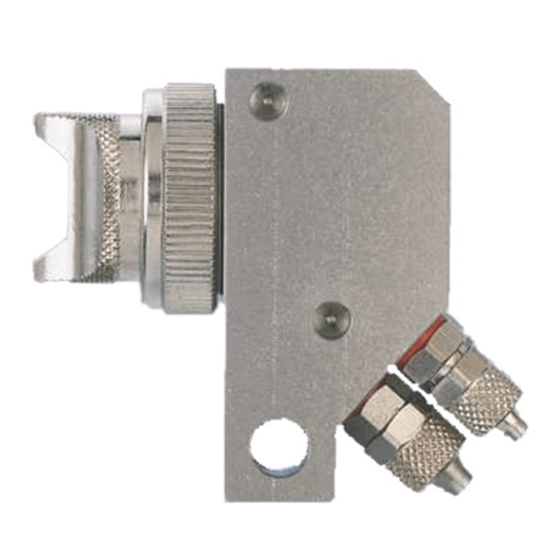

Page 16: Overview

Connection for material supply "M" Connection for round jet air "R" Connection for control air "St" Cover, or optional needle stroke adjustment Main element Air nozzle Installation drill hole for retaining bolts The connections are marked with letter abbreviations. GB–16 mail@krautzberger.com, www.krautzberger.com... -

Page 17: Installation

ENGLISH Mini spray gun MA-1 6 Installation Safety Personnel: Specialised personnel Trained electrician Protective equipment: The selection of the protective equipment depends on the installation conditions on site. Always observe the applicable country-specific safety, accident prevention, occupational safety, and envi- ronmental protection regulations for the proper selection of the protective equipment. -

Page 18: General Installation Information

Operate the mini spray gun with processed, dried compressed air (air quality pursuant to DIN ISO 8573-1: quality class 4). Vibration and recoil forces may occur on the mini spray gun during operation. Ensure suffi- cient fastening. Never point the compressed air at living beings. GB–18 mail@krautzberger.com, www.krautzberger.com... -

Page 19: Installing The Mini Spray Gun

ENGLISH Mini spray gun MA-1 Installing the mini spray gun Changing the installation position of the mini spray gun The mini spray gun can be mounted on one side on the retaining bolts in order to change the installation position. - Page 20 Connect the material line to connection "M" ( Fig. 3/1). Connect the control air to connection "St" ( Fig. 3/2). Connect the round jet air to connection "R" ( Fig. 3/3). Connect the flat jet air to connection "F" ( Fig. 3/4). GB–20 mail@krautzberger.com, www.krautzberger.com...

-

Page 21: Preliminary Air Control

ENGLISH Mini spray gun MA-1 Preliminary air control Fig. 4: Preliminary air control Flat jet air supply (atomizer air) Round jet air supply (atomizer air) Control air (material supply) Air supply open Air supply closed Time Time until the atomiser air is stable... - Page 22 Spray start: First activate atomizer air "R" and possibly "F" and then open control air "St". End: First switch off "St", then close "R" and "F". PDV(e) = Proportional pressure control valve, electrically controlled O/S(E) = Opener/closer with bleed O/S = Opener/Closer GB–22 mail@krautzberger.com, www.krautzberger.com...

-

Page 23: Operation

ENGLISH Mini spray gun MA-1 7 Operation Safety Personnel: User Specialised personnel Protective equipment: The selection of the protective equipment depends on the utilised medium of the system owner. The information provided by the medium manufacturer indicated on the safety data sheet must be adhered to in order to ensure the proper selection of protective equipment. -

Page 24: General Information About Start-Up / Commissioning

Do not use sharply abrasive, chemically aggressive, very hot or very cold spray media without first consulting with and receiving approval from Krautzberger GmbH. Adhere to the spray media manufacturer's safety data sheets. Only operate the mini spray gun in compliance with the values specified in ( Ä... -

Page 25: Shutting Down

ENGLISH Mini spray gun MA-1 Never point the compressed air at living beings. Adhere to the operating manuals for the respective components. Shutting down 7.3.1 Temporary shut-down End the spray process by switching off the control air (connection "St"). 7.3.2 Long-term shut-down End the spray process by switching off the control air (connection "St"). -

Page 26: Adjusting The Needle Stroke

Depending on the optional design of the mini spray gun there are two options for the needle stroke adjustment. Fig. 6: Adjusting the needle stroke Set the needle stroke and then tighten the nut to prevent an accidental change of the needle stroke Set the needle stroke with a knurl nut GB–26 mail@krautzberger.com, www.krautzberger.com... -

Page 27: Maintenance

The use of incorrect or defective spare parts can cause risks for the personnel as well as damage, malfunctions or complete failure. – Only use original spare parts from Krautzberger or spare parts that have been approved by Krautzberger. –... -

Page 28: Maintenance Schedule

Escaping air and spray medium as well as the deterioration of the spray pattern are signs that parts are worn. Contact Krautzberger Customer Care with any questions on maintenance work and maintenance intervals. Interval... -

Page 29: Changing The Material Nozzle And The Air Nozzle

We recommend our brush set. Please contact our Customer Care department for this pur- pose. Slightly grease sliding parts. We recommend Krautzberger special grease. Please contact our Customer Care department for this purpose. Changing the material nozzle and the air nozzle... -

Page 30: Changing The Material Needle

Pull out the control piston ( Fig. 8/3) from the main element ( Fig. 8/5) together with the material needle ( Fig. 8/4). CAUTION! Risk of injury due to material needles! Remove the material needle ( Fig. 8/4) from the control piston ( Fig. 8/3). GB–30 mail@krautzberger.com, www.krautzberger.com... - Page 31 ENGLISH Mini spray gun MA-1 Attaching the material needle WARNING! Risk of injury through the use of incorrect spare parts! CAUTION! Risk of injury due to material needles! Insert new material needle into the control piston ( Fig. 8/3). Ensure that the optional needle stroke adjustment is relaxed. If necessary, release the pressure by turning anti-clockwise.

-

Page 32: Changing The Needle Seals

Reinsert the mounted needle guide ( Fig. 9/2) with the two new seals ( Fig. 9/1 and 3) and the flat seal ( Fig. 9/4) into the main element. Ä Chapter 8.5 ‘Changing the material needle’ on page 30). Reinstall material needle ( GB–32 mail@krautzberger.com, www.krautzberger.com... - Page 33 ENGLISH Mini spray gun MA-1 NOTICE! Lightly grease springs, threads and seals with the "Krautzberger special grease" during instal- lation. "Krautzberger special grease" can be purchased from Krautzberger GmbH. See the last page for contact data. ■ 200-0345 GB–33...

-

Page 34: Troubleshooting

Material too thick Thin material Split spray pattern Insufficient mate- Increase material rial supply Flat jet air pres- Reduce flat jet air sure too high pressure Spray pattern too thin Cap nut loose Tighten cap nut GB–34 mail@krautzberger.com, www.krautzberger.com... -

Page 35: Customer Care

ENGLISH Mini spray gun MA-1 Spray pattern Error Cause Remedy Material jet comes out Insufficient mate- Increase material in spurts or rapid rial supply supply bursts Blocked material Clean ( Ä Chapter 8.3 path ‘Cleaning’ on page 28) Loose or dam- Tighten or replace Ä... -

Page 36: Spare Parts

Designation – Item number according to spare parts list – Quantity – Desired shipping method (post, freight, sea, air, express) – Delivery address A complete spare part overview is available on the website of Krautzberger GmbH: www.krautzberger.de GB–36 mail@krautzberger.com, www.krautzberger.com... -

Page 37: Accessories

Mini spray gun MA-1 Accessories A wide range of accessories is available for the mini spray gun. For further information, visit us on the Internet (www.krautzberger.com) or contact your Krautzberger specialist dealer, consultant or our office staff. ■ 200-0345 GB–37... -

Page 38: Disassembly And Disposal

Sort remaining components based on the respective material and dispose of them accord- ingly. Properly dispose of potential spray media residue separately from the device. If in doubt, obtain information about environmentally-appropriate disposal with the local municipali- ties or specialised disposal companies. GB–38 mail@krautzberger.com, www.krautzberger.com... -

Page 39: Technical Data

ENGLISH Mini spray gun MA-1 Technical data 13.1 Dimensions and weight Specification Value Unit Material connection M5 female or PK-4 " Connection for atomiser air (R and F) M5 female or PK-3 " Connection for control air (St) M5 female or PK-3 "... -

Page 40: Dimensions

Operating instructions T-Dok-015-GB-Rev.0 13.3 Dimensions Fig. 10: Dimensions GB–40 mail@krautzberger.com, www.krautzberger.com... -

Page 41: Declaration Of Incorporation

ENGLISH Mini spray gun MA-1 Declaration of incorporation Fig. 11: Declaration of incorporation ■ 200-0345 GB–41... -

Page 42: Notes

Operating instructions T-Dok-015-GB-Rev.0 Notes ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ GB–42 mail@krautzberger.com, www.krautzberger.com... -

Page 43: Index

ENGLISH Mini spray gun MA-1 16 Index Cleaning ............28 Complete machine . - Page 45 Krautzberger GmbH Stockbornstrasse 13 65343 Eltville am Rhein, Germany Hotline: +49 (0) 6123 698-222 Reception: +49 (0) 6123 698-0 Fax: +49 (0) 6123 698-200 Email: mail@krautzberger.com Internet: www.krautzberger.com © Krautzberger GmbH 2017 © Krautzberger GmbH 2017...

Need help?

Do you have a question about the MA-1 and is the answer not in the manual?

Questions and answers