Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Full Spectrum Laser HL40-5g Hobby Advanced

- Page 1 ...

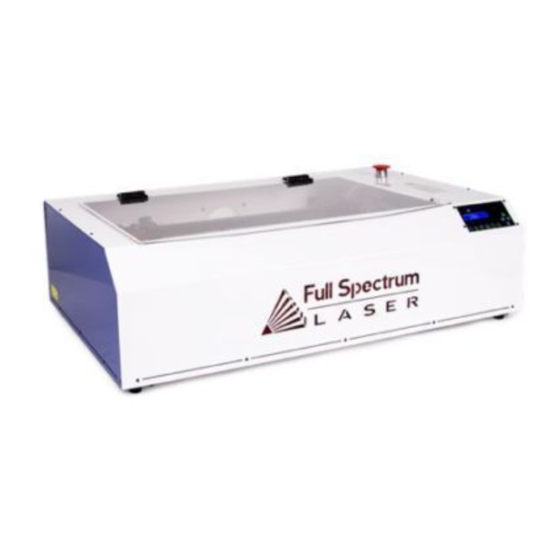

- Page 2 1 HSeries (5th Gen) Hobby Laser User Manual Congratulations on your purchase of a Full Spectrum Laser HSeries (5th Gen) Laser Cutter. With proper usage and upkeep, your hobby laser cutter should provide years of productive output. This user manual will guide you through the safety guidelines and operation of your machine. It is recommended that you familiarize yourself with this manual before using your laser cutter. For more information and product selection, please visit w ww.fslaser.com . Compliance Statement The Full Spectrum Laser HL405g “Hobby Advanced” Laser System is a class 3R laser product, as defined in International Standard IEC 608251. The Full Spectrum HL405g complies with 21 CFR 1040.10 and 1040.11, the Federal Performance Standards for LightEmitting Products, except for deviations pursuant to Laser Notice No. 50, dated July 16, 2001. The Center for Devices and Radiological Health of the US FDA issued Laser Notice No. 50 to permit manufacturers to classify and manufacture their products in accordance with the International Standard. 21 CFR 1040 and IEC 608251 require that certification, identification and warning labels be placed on laser products. Reproductions of the labels found on the Full Spectrum Hobby Advanced Laser System follow, with locations specified: Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

-

Page 3: Table Of Contents

2 TABLE OF CONTENTS SAFETY FIRST Safety Icons General Safety Laser Safety Fire Safety Electrical Safety Safety Stickers UNBOXING HSeries Hobby Laser Parts List Additional Recommended Tools Unboxing Your HSeries Hobby Laser INSTALLATION AND ASSEMBLY Assembly Stage One: Remove Zip Ties Assembly Stage Two: Connect the Exhaust Assembly Stage Three: Connect the Water Pump Assembly Stage Four: Assemble the Air Compressor (Recommended) Assembly Stage Five: Connect Electrical Power Assembly Stage Six: Connecting the Ethernet Cable Assembly Stage Seven: Install RetinaEngrave Software Focus Lens Adjustment Laser Tube Test Mirror Alignment Focusing Laser Head Adjustment USER INTERFACES HSeries Hobby Laser Touchscreen Interface Validating Control Card RetinaEngrave Interface OPERATIONS Engraving Cutting Designating Layers Design Tab Workspace Tools HARDWARE MAINTENANCE Replacing the Laser Tube Replacing the Power Supply Belt Installation Appendix A: Troubleshooting ... -

Page 4: Safety First

3 SAFETY FIRST Safety Icons Familiarize yourself with these icons. They indicate areas that require special attention. Attention Icon: Calls attention to an important point or offers a “Pro Tip” of general usefulness. Caution Icon: Warns of important area of caution not covered by other icons. Fire Icon: Warns of potential fire hazards. Shock Icon: W arns of potential electrical hazards. CO2 Gas icon: Warns of potential gas leaks and associated hazards. Laser Icon: W arns of potential dangers associated with laser usage. Fragile Icon: W arns of fragile parts or materials, such as glass. Laceration Icon: ... -

Page 5: General Safety

4 General Safety ALWAYS have a clean, level and open work space to unbox and place your laser cutter. ALWAYS be aware that the laser tube is made of glass and is therefore extremely fragile and can cause severe lacerations if broken. ALWAYS be aware that the laser tube is filled with CO2 gas. While carbon dioxide is a class 2.2 gas (nonflammable and nontoxic), release of this gas from the laser tube will render your laser inoperable. NEVER modify, disassemble, or in any way alter the construction of the laser and never start up a system that has been modified or disassembled. ALWAYS inspect the laser cutter for damage and breakage before use. It is the responsibility of the user to ensure all safety precautions are correctly assembled and working properly before operating the machine. NEVER leave the laser system unattended during operation. KEEP YOUR LASER SYSTEM CLEAN – A build up of cutting and engraving residue and debris is dangerous and can create a fire hazard. Keep your laser system clean and free ... -

Page 6: Laser Safety

5 Laser Safety The output of the CO2 engraving laser is fully contained in a Class 1 enclosure during normal operation. The laser cabinet has a safety interlock switch that deactivates the laser if the door is opened during operation, and no special precautions are necessary to operate the high power laser safely. However, the output beam of the Alignment Laser (visible red diode laser) is accessible to the operator during normal operation, giving the total system an overall rating of Class 3R. Class 3R lasers have minimal safety concerns when used properly and handled with care. Follow these safety guideline at all times: NEVER operate the machine with any of the panels removed. Be aware that removal of any portion of the cabinet will expose the laser system and greatly increase the risk of injury and/or fire. Personal injury and fire risks are especially pronounced if the machine is operated with the bottom panel removed. Remember that the CO2 laser beam is invisible! NEVER engrave or cut any material containing PVC or vinyl. These materials (along with other chlorine/ chloride containing materials) produce a corrosive vapor that is extremely harmful to humans and will destroy your machine. Your warranty will be void if your machine is damaged by corrosion from engraving or cutting PVC or vinyl. NEVER engrave or cut any unknown material. The vaporization/melting of many materials, including but not limited to PVC and polycarbonates, can give off hazardous fumes. Please refer to the MSDS sheet from the material manufacturer to determine the response of any work material to extreme heat (burning/fire hazard). ALWAYS use the air assist, especially while vector cutting. Vector cutting movements are relatively slow and apply an extremely large amount of heat to the workplace. This buildup of heat can create a significant fire risk. NEVER o perate the Alignment Laser without the focus lens in place. The unfocused beam can be reflected out of the chassis. ... - Page 7 6 NEVER aim any laser towards an aircraft or vehicle that is in motion. The bright light can flashblind, cause glare, or distract the pilot or driver. The standard reference for laser safety is the American Standard for the Safe Use of Lasers, Z136.12000, developed by the American National Standards Institute (ANSI). This reference is the basis for many of the federal regulations for laser and laser system manufacturers, and for the Occupational Safety and Health Administration (OSHA) laser safety guidelines. It contains detailed information concerning proper installation and use of laser systems. While the ANSI standard itself does not have the force of law, its recommendations, including warning signage, training, and the designation of a laser safety officer, may be compulsory under local workplace regulations when operating laser systems above Class I. It is the operator’s responsibility to ensure that the installation and operation of the Full Spectrum Laser Hobby Laser System is performed in accordance with all applicable laws. Copies of ANSI Standard Z136.12000 are available from: LASER INSTITUTE OF AMERICA 12424 RESEARCH PARKWAY, SUITE 125 ORLANDO, FL 32826 (407) 3801553. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com .

-

Page 8: Fire Safety

7 Fire Safety Laser cutting and engraving systems can present a significant fire hazard due to the extremely high temperatures generated by the laser beam. While the objective of most cutting and engraving operations is to vaporize material without burning, most materials capable of being cut or engraved are inherently combustible and can ignite. Usually this is a small flame of burning material issuing from the cut zone which self extinguishes due to the air assist or depowering of the beam. However, it is possible for the flame to propagate and set fire to the machine and its surroundings. Pro Tip! Experience shows that vector cutting with the laser has the most potential to create an open flame. Acrylic in all its different forms has been shown to be especially flammable when vector cutting with a laser. ALWAYS keep a properly maintained and inspected 5lb or larger fire extinguisher on hand. Full Spectrum Laser recommends a Halogen fire extinguisher or a multipurpose dry chemical fire extinguisher. Halogen extinguishers are more expensive than a dry chemical, but offer certain advantages should you ever need to use an extinguisher. The Halogen extinguisher discharges a clean, easily removable substance that is not harmful to the mechanics or wiring of the laser system. The dry chemical extinguisher discharges a sticky, corrosive powder that is very difficult to clean up. BE AWARE t h at stacking materials (especially organic materials such as paper) can lead to increased risk of flame propagation or work piece ignition. NEVER operate your machine unattended. There is a significant risk of fire if the machine is set improperly, or if the machine should experience a mechanical or electrical failure while operating. ALWAYS keep the area around the machine clean and free of clutter, combustible materials, explosives, or volatile solvents such as acetone, alcohol, or gasoline. ALWAYS use air assist when vector cutting. ... - Page 9 8 NEVER CUT PVC (polyvinyl chloride) under any circumstances. NEVER store any flammable materials in the inside of the device or in the immediate vicinity of the device. Debri and leftover produced materials within the machine must to be removed to prevent fire hazard. ALWAYS have on hand a firstaid kit designed for the initial treatment of burns and smoke inhalation. Be sure to store this kit in an area that is outside risk areas. Woodshop Dust Fire Safety Considerations* Before processing materials the user must verify whether harmful materials can be generated and whether the filter equipment of the exhaust system is suitable for the harmful materials. We emphasize that it is the responsibility of the user, to consider the national and regional threshold values for dust, fogs and gases when selecting the filters and the exhaust system. (The values for the maximum workplace concentration must not be exceeded.) Be mindful of large quantities of fuel in the form of wood and wood products, sawdust, and flammable materials such as paints, oil finishes, adhesives, solvents, and liquid propane for internal combustion engines. Preventing the buildup of dust is one of the key means for controlling fire and explosion hazards. The principal engineering control technology for control of dust is exhaust ventilation. The primary work practice control is good housekeeping. Dust collection is best accomplished at the sourceat the point of operation of the equipment, if feasible. For many pieces of equipment, welldesigned ducts and vacuum hoods can collect most of the dust generated before it even reaches the operator. Very fine dust that manages to escape pointofsource collection can be captured from above by general exhaust points located along the ceiling. These control technologies are effective for most equipment, excepting machines that commonly produce the very finest dust or large quantities of dust. *These guidelines come from the U.S. Department of Labor ...

-

Page 10: Electrical Safety

9 Electrical Safety The power supply is capable of outputting DC 20,000V at up to 20mA—always make sure to give the supply capacitors adequate time to discharge before accessing the electronics area. This power is also provided to the discharge terminals on the laser tube itself. Your laser shipped with silicone terminal covers that prevent access to bare wiring—notify Full Spectrum Laser support and immediately cease operations if these covers ever slip and expose bare wir e . DO NOT o pen any of the machine’s access panels while the unit is plugged in. Opening a panel may expose the operator to the unit’s AC input power. The AC input power is potentially lethal and is located on the far right within the cabinet. NEVER m ake or break any electrical connections to the system while the unit is turned on. NEVER a ccess the electronics area with hands or tools unless the unit is disconnected from power for at least one hour. NEVER r eplace the installed 10 amp fuse with a fuse of a higher rating. This will void your warranty and the electronics will not be adequately protected from surges or short circuits. POWER ON/OFF is controlled by the large red button (estop) located on the top of the case in the far right. This is a normallyopen twist to release button. To power the laser down, simply press the button down until it locks. To power the laser up, twist the button clockwise according to the indicating arrows on the surface of the button. ... -

Page 11: Safety Stickers

10 Safety Stickers 1. CERTIFICATION/IDENTIFICATION LABEL. This sticker is located on the rear of the machine. Any updates to the information (date of manufacture and manufacturer address) are added as adhesive overlays. 2. WARNING LABEL. This label is located on the rear of the machine, above the certification label. 3. EXPLANATORY LABEL. This label identifies the classification of the HL405g in accordance with IEC 608251. It is located on the rear of the machine, next to the Warning Label. 4. NONINTERLOCKED PROTECTIVE HOUSING SAFETY LABELS (5). Two exterior labels located on left and bottom panels. Two interior labels located on the bottom of the power supply and the side optics riser #1 so that the labels are visible when the covers have been removed. One label located on the right tube access panel. 5. DEFEATABLYINTERLOCKED PROTECTIVE HOUSING SAFETY LABEL. T his label is located on the machine’s cabinet door, in the lower righthand corner. 6. APERTURE SAFETY LABEL (2). This label is located on the left slider of the Y gantry and on the main aperture of the laser tube. 7. ELECTRICAL SAFETY LABEL. This label is located on the right panel of the machine. 8. FIRE WARNING LABEL.... -

Page 12: Unboxing

11 UNBOXING Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 13 12 Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

-

Page 14: Hseries Hobby Laser Parts List

13 HSeries Hobby Laser Parts List Your laser shipped with the following included parts and accessories: DESCRIPTION (QTY) A. Laser Engraving Machine (1) B. Honeycomb Cutting Table (1) C. Plastic Fitting (1) D. Water Pump (1) E. Water Tubes (2) F. Flat Washer (1) G. Conical Spring Washers (2) H. Tooth Lock Washer (1) Thermal Paper (1 sheet) J. Power Cable (1) K. 2.5 mm Hex Key (1) L. Ethernet Cable (1) M. 2.0 mm Hex Key (1) N. 2” Focusing Bilit (1) O. Adjustment Tool (1) Optional Accessories (not included but recommended): P. 4” Ducting (1) Q. Exhaust Fan (1) R. 4” Hose Clamp (1) S. -

Page 15: Unboxing Your Hseries Hobby Laser

14 Unboxing Your HSeries Hobby Laser When your HSeries (5th Gen) Hobby Laser arrives, it will require careful unboxing and examination of parts. Follow these instructions for best results. FRAGILE PARTS! Be gentle in removing the foam packaging and accessories. Never pull or force the packaging loose from the laser cutter. Be particularly aware that the water inlet and outlet nodes protrude from the tube and are extremely fragile when unboxing your laser tube. UNBOXING STEPS 1. Create a work space. Y ou will need an open, level work space to place your laser cutter. A solid table with adequate room (the machine’s dimensions are 32” x 20” x 8.25”) for the machine is recommended. Be sure the workspace is free of fire hazards and is well ventilated. Always have a fire extinguisher handy in case of emergency. 2. Carefully open the top of the box. Set the box on a flat space near where you will place the machine. Open the box carefully from the top. If you use a cutting tool to open the box, be careful not to allow the cutting edge to touch the machine or any packed accessories. Always use all tools with caution and only as specified by the manufacturer. 3. Remove “honeycomb” cutting table. R emove the honeycomb plate (B) from the box and then remove the bubble wrap surrounding it. Set the honeycomb plate aside for now. Once we have removed the packed accessories we will insert it into the base of the machine. 4. Remove the Machine from the box. W ith the foam packaging intact, gently lift the machine out of the box and place on a clean flat surface such as the table you plan on ... - Page 16 15 7. Insert the Honeycomb. P lace the honeycomb into the laser cutter machine body and lay flat. Be careful not to hit other machine components during this procedure. 8. Inspect the machine. E xamine your laser cutter for defects and breakage. If you find any defects or breakage, contact your sales representative immediately. Have pictures of the damage ready to share. Your machine is now unboxed. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

-

Page 17: Installation And Assembly

16 INSTALLATION AND ASSEMBLY Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... -

Page 18: Assembly Stage One: Remove Zip Ties

17 With your laser cutter unboxed and placed in its permanent work space we can now assemble it. This is a simple process that should take less than half an hour to complete. The following stages will be described in detail. Assembly Stages: 1. Remove the Zip Ties 2. Connect the Exhaust 3. Assemble the Water Pump 4. Assemble the Air Compressor (Recommended) 5. Connect Power 6. Connect the Ethernet Cable 7. Install RetinaEngrave Software In addition, you will need the following tools and accessories (not included with your machine purchase): 1. 35 gallons of distilled water 2. A five gallon bucket 3. Small scissors 4. Aluminum Tape 5. Ducting Tube 6. Exhaust Fan (recommended) 7. Internet connection (to download software) Assembly Stage One: Remove Zip Ties To secure the machine during shipping, zip ties are used to hold the X belt, the Y belts and the ... -

Page 19: Assembly Stage Two: Connect The Exhaust

18 Assembly Stage Two: Connect the Exhaust It is mandatory that an exhaust blower is connected and operating whenever you run a job on your laser. A properly installed exhaust blower removes smoke and fumes from the case and exhausts them to the outside of the building. CAUTION! You should never operate your laser without a working exhaust. Full Spectrum recommends exhaust systems capable of 232 CFM. Keep in mind that exhaust systems with high flow rates may require fixtures for thin materials. FIRE WARNING! It is important that either rigid or flexible metal ducting be used in the exhaust system. Any type of “soft” ducting is potentially flammable and should not be used under any circumstance. CONNECTING THE EXHAUST STEPS: 1. Position Ducting. P lace your 4” ducting (not included) over the installed Exhaust Port located at the back of the machine and hold. 2. Secure with Aluminum Tape. E venly tape, secure and seal the ducting to the Exhaust Port using aluminum tape (not included). 3. Attach Exhaust Fan (recommended). W e recommend using an exhaust fan to ensure maximum air exhaust. Secure the other end of the ducting connected to the machine to a Exhaust Fan (not included). Now repeat the ducting and taping process on the other side of the Exhaust fan creating a sequence of machine to ducting to exhaust fan to second ducting. 4. Ventilate Outside. S et the open end outside of a window or an installed ventilation outlet. Check your system for leaks—most can be remedied with duct tape. Please be aware that ... -

Page 20: Assembly Stage Three: Connect The Water Pump

19 Assembly Stage Three: Connect the Water Pump Your HL405g laser uses a watercooled continuous beam CO2 laser tube. The tube requires a flow of room temperature water to regulate the temperature of the resonance chamber. Your purchase includes a water pump for cooling the laser tube. NEVER FIRE THE LASER WITHOUT A CORRECTLY CONNECTED AND POWERED WATER PUMP. FIRING THE LASER WITHOUT TURNING THE PUMP ON OR, WORSE, WITH NO WATER IN THE SYSTEM, WILL SEVERELY DEGRADE OR DESTROY YOUR LASER TUBE AND VOID YOUR WARRANTY. CONNECTING THE WATER PUMP STEPS: 1. Remove Capping On Water inlet/Outlet. Remove the short silicone tubing capping the water inlet and outlet on the back of the machine. . 2. Attach Water Pump FItting. Remove the water pump (D) from its packaging. Attach the white plastic fitting (C) to the water pump by gently screwing it on. 3. Prep Water Bucket. Fill a clean 5 gallon bucket (not included) with 3 4 gallons of distilled water (not included). ALWAYS use only distilled water and replace often. 4. Attach Inlet Water Tubing. Push one end of one of the two (2) silicone water tubes (E) onto the water pump fitting (C). Now attach the other end of that tubing to the “water inlet” located at the back of machine. Completely submerge the assembled water pump in the bucket of distilled water. ... - Page 21 20 5. Attach Outlet Water Tubing. P ush one end of the other silicone water tubing (E) onto the “water outlet”. Place the other end of the water tubing into bucket of distilled water. PRO TIP! We recommend that you attach the laser and water pump to a power strip and use that to control the mains power to the unit—this ensures that the water pump is always on when the laser is powered. CAUTION! Make sure that there are no air bubbles inside of the water jacket of the laser tube. Air bubbles can create local hot spots in the lasing chamber and reduce the lifetime of your tube. If present, water bubbles typically migrate to the electrodes on either end of the tube. You should visually inspect the laser tube to make sure that bubbles are not present; slightly tilting the laser while powering on the circulation pump is usually sufficient to remove bubbles. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

-

Page 22: Assembly Stage Four: Assemble The Air Compressor (Recommended)

21 Assembly Stage Four: Assemble the Air Compressor (Recommended) Air is used as a pressurized gas to assist in cutting and engraving operations. This pressurized air is critical to safe and efficient cutting operations as it not only helps cut through material more quickly, but also helps prevent the formation of flames. A lowflow air compressor for vector cutting gas assist is available as an optional accessory at h ttp://fslaser.com/Product/HobbyCompressor . ASSEMBLING THE AIR COMPRESSOR STEPS: 1. Attach Push Fitting (Recommended). R emove the air compressor from its packaging. Gently screw on the push fitting to air compressor. 2. Attach Air Hose to Air Compressor (Recommended). P ush one end of the black air inlet hose into the air compressor push fitting until it is snug. 3. Attach Air Hose to Laser Cutter (Recommended). I nsert other end of the black air inlet hose into the “air inlet” slot in the back of laser cutter (A) via the blue push fitting. THIRDPARTY AIR ASSIST SYSTEMS . If you choose to attach your laser to a 3rd party air compressor, make sure to use at least one stage of air drying and air cleaning (5 micron filter recommended) and limit the input pressure to no more than 30 psi. Lowquality compressed air can damage your focus lens. ... -

Page 23: Assembly Stage Five: Connect Electrical Power

22 Assembly Stage Five: Connect Electrical Power The Full Spectrum Hobby Advanced Laser System and available accessories are configured to accept 110VAC at 60Hz. 220VAC units connect to power through an included converter (singlephase 220VAC). CONNECTING ELECTRICAL POWER STEPS: 1. Prepare Power Cord. R emove the electrical cord (J) from its packaging. 2. Plug in Power Cord To Laser Cutter . The power cord plugs into a “C14” power receptacle located on the right side of the machine. 3. Plug in Power Cord to Outlet. F Inally, plug the power cord into any proper outlet socket in your workspace. PRO TIP! Please be aware that the accessories will increase the circuit load; the most significant power draw usually comes from the blower/exhaust system. Consult the manufacturer’s information and manual for the operating parameters of your exhaust system. POWER ON/OFF: the laser’s power is controlled by the large red button (estop) located on the top of the case in the far right. This is an open twist to release button. To power the laser down, simply press the button down until it locks. To power the laser up, twist the button clockwise according to the indicating arrows on the surface of the button. IN CASE OF A BLOWN FUSE: determine the cause of the overload before replacement to protect the machine from damage. The laser system is equipped with a fuse on the power inlet to protect the machine from surges or short circuits. The fuse is userchangeable (machine ships with 10A fuse installed). If problem persists, contact customer support. ... -

Page 24: Assembly Stage Six: Connecting The Ethernet Cable

23 Assembly Stage Six: Connect the Ethernet Cable All Full Spectrum 5th Gen Laser Systems are designed to be used with either 32 or 64 bit versions of Windows 7 or later. Full Spectrum Laser recommends a system with the following minimum specifications: Intel® Core™ or AMD Athlon™ II processor Microsoft® Windows® 7 64bit with Service Pack 1 6GB of RAM CONNECTING ETHERNET CABLE STEPS: 1. Identify the Ethernet Cable. Locate and remove the included Ethernet cable (L) from its packaging. 2. Plug Ethernet Cable into Laser Cutter. Plug in the Ethernet cable into the Ethernet slot on the HSeries Hobby Laser. 3. Plug Ethernet Cable into Computer. C onnect Via Router (Recommended). Router connectivity is more reliable than directly connecting via Ethernet and should be the primary way of connecting. Direct connect from laser to computer should be a secondary choice, if possible. If direct connecting to router is not available (i.e. due to location of router) then we recommend using an Ethernet to WiFi adapter that is connected to the router. If both of those are not possible then direct connection to computer can be utilized via the Ethernet cable. PRO TIP! The Hobby Advanced can connect to your computer via either Ethernet or USB (but not both simultaneously). Full Spectrum includes an Ethernet cable in the laser accessories and recommends the use of Ethernet cables as USB is more prone to electrical interference . ATTENTION! Your laser must be connected to your computer in order to ... -

Page 25: Assembly Stage Seven: Install Retinaengrave Software

24 Assembly Stage Seven: Install RetinaEngrave Software RetinaEngrave v4.420 is a combination of a print driver and control software that communicates with, downloads jobs to, and controls the laser system. It is available on the Full Spectrum software page ( h ttp://fslaser.com/Software ) ATTENTION! The laser must be powered on when operating the software or when connecting the laser via the Ethernet cable. You will need uninterrupted Internet access for this process. INSTALLING RETINAENGRAVE SOFTWARE STEPS: 1. Go to Download Page. T urn on your computer or laptop, now connected to your laser cutter via the Ethernet Cable (J) or a router as demonstrated in Stage Six (above). In your favorite browser (Google Chrome, Firefox, etc) go to h ttp://fslaser.com/RetinaEngrave . 2. Download Installer. You will need to download the RetinaEngrave installer first. Click Download RetinaEngrave Installer to begin the process. 3. Run Installer. O nce the Installer is downloaded click R un . Approve any security warnings. The software will not harm your computer. ... - Page 26 25 6. Select Destination. T his is an optional step where you can place the installed software where you wish on your computer. The default destination is your C drive. If this is acceptable, Click N ext . 7. Select Components. T his is another optional step allowing you to choose what components you want to add with your install. You can selectively click any component on Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 27 26 or off by adding or removing a checkmark next to each one. Or you can choose the default components. After you have made your selections, Click N ext . 8. Select Start Menu Folder. This will name your folder and create a shortcut in your Start Menu folder. It is recommended that you use the default name. Click Next . 9. Select Additional Tasks. T his window allows the options to create a shortcut desktop icon and tell your computer not to firewall (block) running the program. Both are the default options and are recommended. Click N ext. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 28 27 10. Install RetinaEngrave Software. T he RetinaEngrave software is ready to install. Click Install and allow the computer time to run to the next step. 11. Extract Files. Click E xtract to unpack the files and launch the install process. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 29 28 12. Driver Installation. This is another necessary step in downloading the software. Click Next . Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 30 29 13. Finish. Y ou will now see a window telling you the drivers are successfully installed. Click Finish . 14. Open RetinaEngrave Software. Y ou are ready to launch the program. You can go directly to the software by Clicking F inish . You can also launch the program through your start menu or by clicking the desktop shortcut icon. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 31 30 ATTENTION! If the laser system does not find a DHCP server while booting, it will assign itself an IP address. This address is displayed on the screen after boot—the selfassigned IP does not change between power cycles. • The panel uses capacitive sensing which requires contact with skin to operate. • The panel is quite sensitive and can often sense changes through thin fabrics (a cotton shirt). Please take note of this and avoid leaning on the panel during maintenance. • The control panel interface is modebased, meaning that each button’s function depends on the currentlyselected mode. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at ...

-

Page 32: Focus Lens Adjustment

31 TESTS AND ADJUSTMENTS It is important that your laser is tested and adjusted (if needed) for proper use before you start your first job. The following will be on our list of tests and adjustments: 1. Focus Lens Adjustment 2. Laser Tube Test 3. Mirror Alignment 4. Focusing 5. Laser Head Adjustment 6. Belt Tension Focus Lens Adjustment The focus lens assembly is preinstalled at the factory, however it can sometimes become loose or out of adjustment during the shipping process. FOCUS LENS ADJUSTMENT STEPS: 1. Adjust Focus Lens. T he Focus Lens attaches to the focus head using one (1) M3 thumbscrew and two (2) M3 spring washers (G). Be sure all screws and washers are accounted for and properly placed and tightened (Figure 1). 2. Check the Air Assist. Be sure the air assist tube is attached to the pushtoconnect connector once the head has been secured (Figure 2). 3. Check for Interference . Run a job with the laser OFF to verify the air tube will not interfere with the beam path or rub against the X rail while engraving. Alternatively, this can be done manually by physically moving the laser head with your hand in a rectangular pattern within ... -

Page 33: Laser Tube Test

32 the work area. The laser will need to be “Unlocked” to proceed with a manual test. Use the touch screen and press the lock icon to toggle from “Locked” to “Unlocked”. Laser Tube Test In this test we are going to tape a piece of thermal paper between the laser tube aperture and the beam combiner aperture and then test fire the laser to ensure the laser is aligned. LASER TUBE TEST STEPS: 1. Check Assembly. B efore you get started with the tube test, be sure the machine is properly assembled with the water pump and air compressor working. This will be a live firing of the laser. 2. Open Safety Lid. Y ou will need to access the interior of the machine. 3. Place Thermal Paper. T ake a piece of thermal paper (I) and tape it between the Beam Combiner and Mirror #1 with the thermal sensitive side facing the laser tube output. Alignment of the thermal paper is not critical, but make sure that there is a large enough white space that can capture the beam output; the beam is approximately 5mm in diameter and will exit from the center of the tube. 4. Close Safety Lid. S afety measures should make it impossible to fire the laser with the safety lid open. Regardless, never attempt to fire the laser with safety lid open. 5. Set Laser To Test Mode. T his step will require using the Touch Screen Interface. This manual has a section fully describing the Touch Screen features, but for now we can ... -

Page 34: Mirror Alignment

33 Mirror Alignment Your laser was aligned during assembly and testing in Las Vegas—the CO2 beam and Alignment Laser beams were matched to follow the same path through the mirrors and fire down the center of the focusing head. However, shipping is a highvibration environment and it is sometimes necessary to realign mirrors. Before we go through a full realignment process, let’s check and see what the current alignment is: ALIGNMENT TEST STEPS: 1. Open Safety Lid. Y ou will need to access the interior of the machine. 2. Place Thermal Paper. T ake a piece of thermal paper (I) and place it above the lens on the focusing head, covering the aperture. Tape two edges so that the paper will stay relatively taut over the hole. Press your finger firmly along the edge of the aperture to make a mark on the thermal paper to show the aperture’s outline. 3. Position the Laser for Testing. U sing the Touch Screen Interface, push the arrow keys to position the laser in the uppermost left corner. 4. Close Safety Lid. S afety measures should make it impossible to fire the laser with the safety lid open. Regardless, never attempt to fire the laser with safety lid open. 5. Test Fire the Laser. P ress the Test Fire Button on the Touch Screen. ... - Page 35 34 The HSeries Hobby laser has an integrated beam combiner which greatly simplifies beam alignment. The general procedure is to first align the red beam with the invisible beam then use the red beam as the primary indicator for alignment. We recommend first aligning the invisible cutting beam with the visible Alignment Beam—this saves a great deal of time lost in opening and closing the lid for safe access while firing the laser. Follow this procedure: REALIGNMENT PROCEDURE (Mirror #1) STEPS: 1. Open Safety Lid. Y ou will need to access the interior of the machine. 2. Place Thermal Paper. T ake a piece of thermal paper and place it over Mirror 1 in the same matter as in the Alignment Test. 3. Unlock Laser to Manual Control. P ressing the Lock/Unlock button on the Touch Screen Interface locks or unlocks the drive motors. System cannot jog or test fire while unlocked, but laser head can be positioned by hand, which is what we want to do next. 4. Close Safety Lid. S afety measures should make it impossible to fire the laser with the safety lid open. Regardless, never intentionally fire the laser with safety lid open. 5. Test Fire the Laser. P ress the Test Fire Button on the Touch Screen. Observe and note the location of the new mark on the thermal paper. You may need to hit Test Fire more than once to create a visible black dot on the thermal paper. 6.

- Page 36 35 10. Retest Fire. Move the X gantry to the top Y position. Fire another black dot onto the thermal paper. You should now have two black dots (one from the upper Y position and one from lower Y position). Move the X gantry up and down and verify that the red dot tracks from one black dot to the other black dot. 11. Adjust Mirror #1. Move the X gantry to the lowest Y position. The red dot should now overlap with one of the black dots. Adjust mirror #1 until the red dot is in the middle of the . two black dots 12. Retestfire. Use a fresh piece of thermal paper and fire a test dot with the X gantry still in the lowest Y position. Move the X gantry to the top position and fire another test dot. Now the two black dots should be closer together. 13. Adjust. M ove the X gantry back to the lowest Y position. Now adjust the red dot until it moves to the center of the two black dots. 14. Repeat Until Aligned. Repeat the process of firing two black dots on the top and on the bottom Y positions and adjusting mirror #1 to move the red dot to the center of the two black dots until the two black dots from the top and bottom Y positions are centered on top of each other. ...

- Page 37 36 REALIGNMENT PROCEDURE (Mirror #2) 15. Adjust Mirror #1. With mirror #1 aligned, we will now adjust mirror #2. Put a piece of thermal paper on mirror #3. Using the red dot, adjust the mirror until the red laser is somewhere on the mirror. 16. Fire and Adjust . Move the laser head to the far right position. Fire a test dot here producing a black dot. The red and black dot may be off slightly because the distance travelled by the laser beams is longer so any small errors are amplified. Without touching any of the mirrors, adjust the red dot to overlap with the black dot through the screws on the red laser diode mount or twisting the red laser diode mount. 17. Second Test Fire. Put on a new piece of thermal paper. Move the laser head to the far left and fire a black dot. Move the laser head to the far right and fire a second black dot. 18. Track and Verify. N ow you should have two black dots on the thermal paper and the red dot. Verify as you move from the left side to the right side that the red pointer tracks between the two black dots. 19. Adjust Mirror #2. Move the laser head to the far right. The red laser dot should overlap with one of the black dots. Adjusting only mirror #2, move the red dot between the two Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com .

- Page 38 37 black dots. 20. Test Fire and Adjust. Replace with a new piece of thermal paper and fire dots in the far left and far right positions. Again move to the far right position then adjust the red dot between the two black dots. Repeat until the two black dots are exactly on top of each other. Mirror #2 is now aligned. PRO TIP! The idea is that when the laser is not aligned, you will have two black dots from the test fires in the top and bottom positions. The red laser pointer is aligned with the invisible laser pointer so gives you immediate feedback on the mirror adjustment. By adjusting it into the middle of the two black dots, you are splitting the error difference. Usually after 1 or 2 iterations, the black dots will be exactly on top and this axis is aligned. The goal is to have the two black dots overlap exactly. IT IS NOT NECESSARY THAT THE DOTS BE IN THE CENTER OF THE MIRROR BUT THEY SHOULD BE SOMEWHERE ON THE MIRROR. REALIGNMENT PROCEDURE (Mirror #3) 21. Adjust Mirror #3 . Once mirror #2 is aligned, put a piece of thermal paper on top of the lens. Adjust the screws on mirror #3 until the red dot is in the center of the lens. Fire a black dot into the thermal paper. 22. Fire and Adjust. M ove the laser head around and verify the red dot does not move away from the black dot anywhere on the laser bed. The closer you get the dots stationary, the better aligned the laser will be. You can fire black dots at the 4 corners of the laser bed and verify none of them are more than 2mm away from each other. Adjust mirror #3 until red dot centered. ...

-

Page 39: Focusing

38 For a video tutorial on the Mirror Alignment Procedure, goto https://www.youtube.com/watch?v=qLJsf2cvkE . Focusing Focusing the Hobby Advanced Laser is quick and easy. Your laser included a billet sized for the included 2inch focal length lens. STEPS: 1. Place Billet. P lace the billet on the top of the engraving plane. 2. Release Locking Mechanism. R elease the locking mechanism on the focus head until the air assist nozzle rests on top of the billet. 3. Retighten. R etighten the sliding head and remove the billet from the workpiece. Laser Head Adjustment Proper laser head adjustment is critical for high accuracy. The two upper wheels of the laser head have fixed axles and the two bottom wheels are mounted through eccentric spacers. When the eccentric spacers are turned, they tighten the bottom wheels against the underside of the black X axis rail. Too much tension and the wheels can bind up when doing high speed raster or rapid moves. Too little tension and you can see some slop in the cutting. Two special wrenches are included to adjust the wheels. ECCENTRIC SPACER ADJUSTMENT PROCEDURE STEPS: 1. Adjust the Eccentric Shafts. First loosen the locking nut which is pressed against the spring washer and the eccentric shaft. Use one of the included adjustment wrenches to hold the eccentric spacer in place while using the second to loosen the nut. With the locking ... - Page 40 39 3. Resecure. U se the two wrenches to again tighten the locking nut after you are happy with the eccentric nut position. PROPER WHEEL TENSION PROCEDURE STEPS: 1. Prep. U nlock the motors or turn off the machine’s power for at least an hour. 2. Assess Tightness. Grip the laser head with one hand. You should be able to turn each of the wheels relatively freely with the other hand even with the laser head held in one place. If you can’t turn each wheel without moving the laser head, likely the tension is too high and one or both eccentric wheels need to be loosened. 3. Test Laser Head Tension. T urn each of the wheels and the laser head should move. If the wheels are freewheeling then the tension is too low and the eccentrics should be tightened. 4. Assess For Further Adjustment. C heck if there is any front to back tolerance in the laser head assembly. This can be tested by gently twisting the laser head about the Z and X axes of the machine. There should be minimal wobble to ensure the laser head doesn’t move when the laser head rapidly changes direction. A small amount of looseness on the head is required for proper operation. PRO TIP! Ideally the wheels should be tight enough so if they rotate, they move the head but not tight enough that they introduce too much friction. The above wheel test is an excellent test of balance between these two. ...

-

Page 41: User Interfaces

40 USER INTERFACES HSeries Hobby Laser Touchscreen Interface The LCD touch panel allows you to control the basic functions of your laser without needing to connect to a computer. This is very convenient during alignment and testing procedures. DISPLAY PANEL The LCD screen has two lines and gives operations information in four fields: 1. Selection Field. L ocated on the top line, this field gives information on the current operation mode of the laser. 2. Mode Field. L ocated on the far left of the lower line, this field tells the operator the current mode. 3. Power Field. Displays the laser power on a scale of 0255. During a job you can adjust from 0255 on the fly using the up and down arrows. It is located to the right of the MODE field. Note that if the power is increased above the default power setting (180), the laser tube life will deteriorate more rapidly. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 42 41 4. Address Field. D isplays the last 3 digits of the IP address with a character prefix. A prefix of A means that the laser did not find a DHCP server on its network and selfassigned an IP address. The D prefix means the laser found a DHCP server. BUTTON FUNCTIONS Panel function buttons are numbered 1 through 6 starting from the left. Jog buttons (arrow pad) continue the numbering from 7 starting at 12 o’clock and counting up counterclockwise. Typically the icons on the top line are active during Fast XY Jog (Mode 0). The icons on the bottom are typically active during Alignment (Mode 2). 1. FS/Z (MODE SELECT). T oggles between modes: a. Fast XY Jog (Mode 0) b. Slow XY Jog (Mode 1) c. Alignment (Mode 2) d. Factory Reset (Mode 3) 2. LOCK/UNLOCK. L ocks or unlocks the drive motors. System cannot jog or test fire while unlocked, but laser head can be positioned by hand. a. Locked b. Unlocked 3. HOME. If in Fast XY (Mode 0) or Slow XY (Mode 1) pressing this button will cause the laser head to seek the home position. After homing, the laser will know the position of the head. Unlocking the motion system causes the unit to forget position (it must be rehomed). 4.

- Page 43 42 a. In Fast XY (Mode 0) or Slow XY (Mode 1) the laser will move to the previously saved job start position. b. In Alignment (Mode 2) this button fires a shortduration pulse designed to mark thermal paper. 5. RUN PERIMETER a. In Fast XY (Mode 0) the bounding perimeter of the job will be shown quickly (RetinaEngrave software must be started/loaded with a job for this function to be active). b. In Slow XY (Mode 1) the bounding perimeter of the job will be shown slowly. 6. START/CANCEL. I n any menu mode (File Select or Factory Reset) this button will select the option displayed in the SELECTION field. a. Cancels a move operation (homing, autofocus or a running job). b. In Fast/Slow XY, with the laser UNLOCKED, this fires a higherpower test pulse. c. In Fast XY, pressing this button after the laser homes will rapidly move the head to the upper left corner of the workspace. d. In Slow XY, pressing this button after running a job will allow you to rerun the same job. 710. JOG BUTTONS. F our green arrow keys pointing UP (7), DOWN (9), LEFT (8), and RIGHT (10). a. In Fast or Slow XY (Modes 0 and 1), the buttons move the laser head left/right and front/back. b. In File Select (Mode 3) the up and down buttons scroll through the loaded jobs. ...

-

Page 44: Validating Control Card

43 function is enabled while the motors are unlocked. The test pulse will not fire with the magnetic safety interlock open. FILE SELECT (MODE 3). N avigate through .bin job files that are loaded on a microSD card (not included). Use the up and down jog buttons to scroll through the list and press the Start button to load the job. Press the Start button a second time to run the job. FACTORY RESET MODE (MODE 4). U se this mode to reset the laser’s IP address settings to the factory defaults. Useful if you assign a static IP but can no longer connect. Attention! The Hobby Laser controller has 2 hard stops and 2 soft stops on the limits of the axes. Soft stops prevent the motion system from attempting to move beyond its mechanical limits, but require a reference in order to work: the laser must be homed in order for the soft stops to function properly. Validating Control Card RetinaEngrave 3d control cards are preinstalled in all Hobby Laser models. If you are a new customer, your laser’s control card is shipped with an 80hour temporary usage authorization. If you are an existing customer, this information will apply if you update your software—after the update you will have 80 hours to activate your card. The 80 hours are only counted while the laser is ON. During the temporary usage period you must connect your laser to your PC while it is connected to the internet and validate your card. Control card activation is a onetime process. This section will walk you through the validation process VALIDATION OF CONTROL CARD (New Customers Only) STEPS: 1. Connect Your Laser to Your Computer. E ither directly or over the network. You will need a working Internet connection to continue. Note that activation cannot be done via USB. 2. Turn On Your Laser. Y our machine must be ON to continue this process. ... - Page 45 44 clarification or updated information. Remember spaces with an asterisk (*) require input of valid information. The information requested is the following: a. Purchase Order Number (Optional). T h is will be either a three (3) digit number or a nine (9) digit number that was emailed to you from GoogleCheckout at the time you purchased your machine. b. Contact Person/Company (Required). E nter a first and last name. c. Contact Email (Required). U se an active email account that you regularly check. d. Comments(Optional). C omments can include any information that you want to be added to your customer account file. 6. Click Send. O nce all the required fields are filled in (and any optional fields you chose) click “ S end ” . The information will be sent to us for comparison against your order information. Once the information has been received by us, you will see a popup confirmation message. From there we will quickly verify your information and validate your authorization. The next time you launch RetinaEngrave software your control card should be validated and activated under your account. VALIDATION FOR EXISTING CUSTOMERS (SOFTWARE UPGRADE) 1. Follow Download Instructions. Download the latest version of RetinaEngrave and extract the .zip archive to a location on your computer. You may or may not be required to update ...

- Page 46 45 5. Save Profile. C hoose a location on your computer and save your laser’s profile. 6. Log In. C onnect your computer to the internet and log in to your email account you registered your purchase with (or the email you used to validate your control card). 7. Send Profile to Full Spectrum Laser. Attach the laser profile file to a new email and send to a ctivation@fullspectrumlaser.com . W e will verify that your information matches the purchase, or send you an email if we need more information. Once your profile has been verified, we will email you an activated profile. When you receive this email continue to the final steps below. 8. Download the Activated Profile. T his file will be attached to the email you received. 9. Start RetinaEngrave. Y ou can drag the activated profile into the workspace, or use the Help menu → “Open Profile From File”. Your laser is now activated. ...

- Page 47 46 Using RetinaEngrave Software RetinaEngrave is the combination control software, electronics and print driver that allows you to create jobs and download them to your laser system. The full control package for your laser has four parts: • RETINAENGRAVE PRINT DRIVER • RETINAENGRAVE JOB SOFTWARE • FSL LCD CAPACITIVE TOUCH CONTROL PANEL • RETINAENGRAVE PRO LASER CONTROLLER QUICK START CHECKLIST A typical job starts with the creation of a design in your favored software. You can also find designs online. Once you are satisfied with your design, follow these steps: 1. Open RetinaEngrave. D oubleClick the RetinaEngrave icon on the desktop of your computer. The program must be open at the time of printing from your design software in order to capture the print stream. You can also print to an XPS print file while RetinaEngrave is not running and open this XPS file at a later time to print. 2. Select Print Driver. Select the “Full Spectrum Engineering Print Driver”. M ake sure that the “Preflight Check” tab is not giving any warnings. 3. Print. C lick the “Print” button. Your job is parsed by RetinaEngrave and will appear in the RetinaEngrave software under the currently selected mode tab. Now you are able to review your design, make adjustments and choose the laser settings for running the job. 4. Options. Y ou can start the job immediately or download the job to the onboard memory of the RetinaEngrave controller. To run a downloaded job, there is an additional step of loading the job in the controller’s memory before pressing “Start”. This is done using the LCD touch panel. ...

-

Page 48: Retinaengrave Interface

47 RetinaEngrave Interface In this section you will be introduced to the major interface features of RetinaEngrave. WORK SPACE The workspace window shows a preview of your current job. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 49 48 TOP LINE MENUS (LEFT SIDE) FILE The File menu allows the user to open up files to engrave. RetinaEngrave supports drag and drop of .xps files for vector cutting and standard image file types (.bmp, .jpg, .png, .tiff) for raster engraving. Other file types must be printed to the Full Spectrum Engineering Driver or saved as .xps documents. The file menu also allows a user to load or save a project and settings. File submenus Save Project Open Project Settings Only Options Clear Workspace The File submenu allows you to save your workspace window setup, set the PC to audibly alert when a job is completed, enable or disable the keyboard shortcuts, load the lastsaved project on startup or log output for troubleshooting. Note that adjustments made to the designs scale or stroke color while in RE cannot be saved. Designs need to be at the desired scale and stroke color before being brought into RE. LASER The Laser menu provides options related to the laser unit configuration and communications. It will allow you to select the type of laser you are connected to, manually reconnect to the laser or manually set the connection IP address. Laser submenus: Change Laser Profile Firmware (Update) RetinaEngrave Card Commands Configure Static IP Address Specify IP Address for Connection Save Job as Binary File Send Binary to USB Save and Send Current Job to USB Material and Focus Tests The Laser submenu allows you to save the current job and settings as a .bin file onto a USB device (when the device is loaded onto the laser). CAUTION! The “RetinaEngrave Card Commands submenu option should only be accessed under supervision of Full Spectrum Laser support staff. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at ...

- Page 50 49 TABS The tabs menu allows you to show the 3D Engrave Tab or the Control Panel. Tabs submenus: Show 3D Engrave Tab Show Control Panel HELP The help menu offers options to inform you about the version of RetinaEngrave you are using, an Activation menu (future functionality), and Troubleshooting and Update fields which will open the FSL website in your default browser. Help submenus: Offline Activation Software Updates About TOP LINE MENUS (RIGHT SIDE) INCH/CM This tabs switches measurements from inches to the metric system. CURRENT POSITION Shows the laser’s current absolute position from the origin (home; upper right), it is reset to 0,0 when the laser is homed. The right field is the X coordinate, the left field the Y coordinate. MOVE TO The text fields show the saved position read from the controller. The fields are editable, allowing you to move to a manually entered location. Pressing the Move To button will first move the laser head to the home switches for reference then rapidly move to the position in the text boxes. Press the Home button to move the laser head to the origin. The laser will measure the distance it takes to reach the limit switches and enter the X and Y values into the Move To fields. It will then set the Current Position boxes to 0,0. MOVE RELATIVE These fields command a move by the specified amounts along X and Y using the current position as the origin. Combine with the Home button to move to, or between, fixture points. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com...

- Page 51 50 LINE TWO MENUS (LEFT) OPEN FILE [CTRL+O] Open compatible file types (.xps, .bmp, .set, .bin). SAVE PROJECT [CTRL+S] Save your current project and settings as a .set file. CLEAR WORKSPACE Clear the workspace of the current job. This feature only exists in prior versions of the software. ZOOM IN [+], ZOOM OUT [], 1:1 ZOOM The zoom buttons control the workspace view of the Engrave and Cut tabs. The 1:1 Zoom button restores the default zoom level. LINE TWO MENUS (MIDDLE) HOME [H] Move the laser head to the origin (upper right of the work area). The laser should be homed after startup or RetinaEngrave will present a bounds alarm when you attempt to run a job. RetinaEngrave has a builtin bounds checker to make sure that your design fits within the workspace. PERIMETER [J] The perimeter function will run the laser head in a box that bounds the limits of your design. PERIMETER STEPS [P] Each button press steps through one side of the perimeter bounding box. LASER HEAD POSITIONING (BETA) The default job origin is located at the upper left of your design (0,0 in the workspace) and referenced from the current location of the laser head in the work envelope. The Laser Head Positioning button opens a dialog box that allows you to change the default job origin between the Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 52 51 center of the job or the upper left (2 radio buttons in top menu division). The lower division of the Laser Head Positioning dialog box contains 9 radio buttons that allow you to preview job perimeter positions (you cannot set them as work origins). Keep in mind that the job origin setting is reset to default when RetinaEngrave is closed. TEST FIRE [F] AND TEST FIRE DURATION FIELD Pressing this button causes the tube to fire for the amount of time (in milliseconds) listed in the duration field. Default value is 5.0ms—this works well for marking thermal paper without burning through. Remember to close the lid or the tube will not fire. ROTARY ENGRAVE TAB The rotary tool, when selected, allows you to enable a rotary attachment, if installed, which allows the proper steps to be sent to the rotary to turn the item properly. See Appendix B: Rotary Attachment Installation for more information on the rotary attachment. LINE TWO MENUS (RIGHT) START JOB [G] Press the Start button to start the job with the current settings. The job origin is, by default, located at the upper left of your design and is indexed from the current location of the laser head. For example, if you are vector cutting a 3 inch square, the laser will fire and move 3 inches to the right, then 3 inches forward (down), then 3 inches left and finally 3 inches up back to the starting position of the laser head. The Start button will be grayed out and not selectable whenever the laser is disconnected. PAUSE [SPACEBAR] Pressing the space key will pause and unpause the inprogress job. CANCEL Immediately ends the inprogress job and returns to the job origin. MODESELECT MENU This dropdown menu allows you to select between several modes: Raster and Vector modes open their respective tabs, “Raster then Vector” mode will first run the job in the raster tab (black pixels) and then run the job in the vector tab. The Simulate Vector modes create a reddot overlay in the workspace that follows the path of your vector lines at some multiple of the currently selected speed (for example,100% speed at 0.5x runs at equivalent of 50% speed). Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at ...

- Page 53 52 RESOLUTION MENU Dropdown menu where you can select the dpi of the current job. Only used in Raster mode. CONTROL PANEL JOG “Jogging” allows you to move the laser head using either the buttons or the keyboard arrow keys. Selecting the slow jog checkbox jogs the motion system at half of normal speed. The Lock/Unlock button allows you to unlock the motors to move the laser head by hand—the motors must be locked in order to run a job or jog. RASTER PROPERTIES The Raster Properties section allows you to set the power and speed of a raster job, as well as the B/W threshold for a grayscale image (see Operations section for more information). IMPORT OPTIONS Import Options allow you to set conditions under which the print stream from Windows is captured. Ignoring raster data is useful if you are working with large or complex files and only causes RetinaEngrave to only render outlines of filled sections. Ignoring vector data is useful when engraving images. Ignoring thin vectors will ignore small lines within a factor set by the tolerance field. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 54 53 VECTOR LAYERS. The Vector Layers section controls the layer order, speed, power and number of repeats for each layer. As discussed in the General Usage subsection, vector layers are based on one of 7 colors. The Contained Objects First checkbox determines the order of cutting within a particular layer. CUSTOMIZING THE INTERFACE The user interface for RetinaEngrave is built around several tabs relating to functionality (Raster Engrave, Vector Cut, etc). These tabs can be dragged to change their order or location in the program window. You can organize your workspace using the autosize function or leave the tab dialog window floating. The autosize function will snap the dragged tab to a preset location in the program window. The default tab location is reached by dragging to the center of the autosize overlay. Keep in mind that the Start button will always start a job using the data in the active tab. ...

-

Page 55: Operations

54 OPERATIONS Engraving Your HSeries Hobby Laser System has several advanced functions that make it easy to bring your designs from your computer into the real world. Engraving is the process by which complex designs are etched into a work piece or a work piece is marked using an additive coating such as Thermark™. Engraving can range from a simple surface mark all the way through deep material removal. Engraving is differentiated from cutting in that cutting is the process of burning a closed contour completely through a workpiece. The most common type of engraving is known as “Raster Engraving” or “Rastering”, because the laser fires individual pulses corresponding to pixels in an image. When the laser is operating in raster mode the head moves rapidly from left to right and slowly top to bottom, engraving your image pixel by pixel and line by line. You can also engrave images in vector mode by setting the power such that you score the workpiece without cutting through. Engraving works with both vector and pixelbased source files, allowing you to engrave anything from a simple block logo all the way to highresolution photographs. The proceeding sections will introduce you to engraving with RetinaEngrave. RASTER ENGRAVE TAB (LEFT BUTTON PANEL TOP TO BOTTOM) Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 56 55 ROTATE IMAGE 90 DEGREES Each button press will rotate the image 90 degree clockwise . MIRROR IMAGE VERTICALLY Mirrors the current image about a vertical centerline. MIRROR IMAGE HORIZONTALLY Mirrors the current image about a vertical centerline. INVERT IMAGE Reverses the black and white pixels of the image. Useful for engraving on coated materials. SCALE Scales the image larger or smaller.. NO DITHER When No Dither is selected, RetinaEngrave will use the threshold slider value to compute a grayscale cutoff. Any grays below the threshold will be black and any above will be white. SIMPLE DITHER Dithering a color or grayscale image will produce a pattern of black pixels that approximates the original gradients. Dithering applies a computed dot density of on/off pixels to the image to create a grayscale effect. The quality of the dithered image preview in the workspace often looks poor—however, the actual output engrave quality will be much higher. Dithered images simulate true grayscale by averaging pixel density to achieve an optical effect closely approximating the original image. Selecting this button has no effect on images that are 1bit or black/white already. HALFTONE DITHER Like the Simple Dither button, this button dithers the image in the workspace but uses a different algorithm. Certain images and work materials will often respond better to one algorithm or another. REVERSE RASTER Selecting this feature will allow the job to begin from the bottom of the image and engraver bottom to top instead of top to bottom as standard. This requires the laser head to be jogged down the Y axis in the work area to start the raster job from the bottom left of the image instead of the top left.. ...

- Page 57 56 RASTER PROPERTIES (CONTROL PANEL) RASTER POWER % This field and slider allow you to set the firing current as a percentage of the maximum as set in the configuration file. Laser tubes have a minimum activation current; setting this value too low (below 10%) could result in the laser not firing as this is under the minimum activation current. Keep in mind that when setting the power below 10%, the tube may no longer fire as it has reached the minimum activation current. RASTER SPEED % Set the engraving speed as a percentage of the maximum. Maximum speed is set in the config.xml file. The raster routine in v4 is optimized so it only rasters nonwhitespace and minimizes the acceleration distance. If you set the speed % very low such as 1% then the laser head does not need much acceleration distance. Total time to engrave = (acceleration time + raster time). Since acceleration time is also lower the total time is not linearly related to the speed %. However, the energy/heat applied to the material is linear according to the speed %. For deeper engraving use a slower speed. BLACK/WHITE THRESHOLD Adjust this slider to fade in or fade out portions of any image that is not black/white. Your computer graphics card must be fast enough to use the slider in realtime to see the updates. This has no effect on 1bit bitmaps or black and white images. If you have a computer with a slow graphics card, set the threshold using the text box and enter the values manually. IGNORE ALL VECTOR Checking this box will only import raster data and ignore vector data. When processing a print job, RetinaEngrave attempts to sort all the vectors for the fastest cut times. A drawing containing millions of points or vectors will take up a large amount of memory and CPU which can cause a Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

- Page 58 57 major slowdown in performance. Ignoring the vector data will also allow faster print jobs if only raster is required. DPI SELECTION Full Spectrum Laser recommends default settings of 500x500dpi for most applications; text as small as 4pt can be engraved at 500 dpi with excellent readability. Typically, 1000 dpi is only used special cases. The dpi setting also affects the delivered power density, as higher dpi settings correspond to a higher number of pulses per square inch. It is also important to note that due to the focused beam spot size (0.0020.005 inches) there will be pixel overlap at higher dpi settings. This leads to a blending effect in the overlapped areas, which will lead to a darker engrave result on particular materials, such as wood. The dpi settings affect the print processing resolution. The maximum printing resolution is set in the configuration file and displayed in the control panel in the Source Image Info box. The final resolution is set to the maximum of the configuration file setting and the dpi selected from the dropdown menu. The default setting is 250 dpi. By selecting 1000 dpi before printing, the laser will import at 250 dpi then upscale the image using a bicubic interpolation to 1000 dpi. RetinaEngrave stores the source image in memory and converts it to grayscale before dithering. Due to the large number of pixels in a 1000 dpi image (1 million pixels per square inch) your computer may run out of memory. Computers with less available memory should select 250 dpi before printing because even at an input resolution of 500 dpi the memory requirements can be high. POSITIONING WHEN RASTER ENGRAVING When you raster an image, the laser head accelerates to the desired speed over some at the default job origin—if you are using a changed origin, such as a center origin, the laser head will still move to the upper left corner before beginning the job. Because of the acceleration and deceleration distances, some jobs will require a one (1) inch buffer on the left and right sides to avoid crashing the laser head. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com .

- Page 59 58 PRO TIPS! Getting Better Raster Results A laser has two states: on and off. Every black pixel or “laser dot” is the result of the laser turning on and firing at a particular location. This location is controlled by the input image, which can be thought of as a “map” of on and off pixels. The question is how do we give RetinaEngrave the best “map” of these laser dots to accurately represent the original image? Your source image is processed several times between sending it to the Windows XPS Image Writer (printer) and final laser processing of the workpiece. The first alteration of the source image occurs when the image is sent from the print stream into RetinaEngrave. If the printer DPI is set differently from the software DPI, the source image must be upsampled to the native DPI of the laser; upsampling is necessary to keep the output image dimensions (in inches) the same as the source image dimensions. This process generates new pixels; unfortunately there are mathematical constraints on the sampling process so it is imperfect. In order to avoid introduction of error through upsampling, the source image must be a 1bit image. 1bit images are an exact “map”; all pixels are either on (black) or off (white). The best results are achieved by creating/converting a source image in a dedicated editing program with DPI settings that match the native DPI of the laser (1000 dpi). In the case of non 1bit .bmp images (grayscale/color), dimensions are set on import using the page size in the print driver dialog box. Changing the DPI setting results in a different number of pixels in the same space, without changing the dimensions of the image. This procedure results in lower output quality that is not true to the source image. Multibit images that are not evenly divisible by the native laser DPI (250/500/1000) should always be direct printed instead of dragged and dropped, and should be rastered at the same resolution as they were printed. The case study in the following section examines the results of various import methods. SOURCE TYPE IMPORT METHOD BEST PRACTICE 1bit BMP Drag and Drop, FileOpe Pixels are divided by laser dpi (1000 for hobby). 1000=1 inch. DPI box changes DIMENSIONS of output by skipping lines. Output is always true to source. It is not recommended to Direct Print 1bit images Color/Grayscale BMP Direct Print ...

-

Page 60: Cutting

59 Cutting In Vector Cut mode, RetinaEngrave receives information from the print stream and interprets it as a series of paths for the laser head to follow. In order for the print stream to have vector information, the file being printed must be a vector file. RetinaEngrave is capable of following complex contour paths created in any vector drawing program, however certain programs and formats are more reliable than others. Full Spectrum Laser carries out unit testing using CorelDraw X7 and recommends that Hobby Laser owners use this program. If you use different design software and run into a problem with the print interface, we recommend printing to the XPS Document Image Writer or saving as a PDF. PDF files save vector information and are the best way to carry artwork from a noncompatible operating system (Mac or Linux) onto your Windows PC. Limited testing has been carried out with CorelDraw X6 and it appears to be a good choice, as well. Other popular packages include Adobe Illustrator, Inkscape and Google’s free online vector drawing application. Additionally, most CAD packages are able to output drawings in a vector format for printing; Autodesk 123D is particularly interesting for its cost (free) and builtin 3D slicing capabilities. PRO TIP! The Microsoft XPS Document Writer creates images so that they will print exactly as they appear on your screen. Any program that is vector based will have its information embedded as vector paths (CorelDraw, MS Word, CAD programs, etc) and should work with the Vector Cut functionality of RetinaEngrave3D. VECTOR CUT TAB (LEFT BUTTON PANEL TOP TO BOTTOM) Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 61 60 ROTATE VECTOR 90 DEGREES Each button press will rotate the design 90 degree clockwise. MIRROR VECTOR VERTICALLY Mirrors the current vector drawing about a vertical centerline. MIRROR VECTOR HORIZONTALLY Mirrors the current design about a horizontal centerline. RESIZE VECTOR ACCORDING TO INPUT VALUES This button will bring up a dialog box allowing you to change the size of the vector image in the workspace by setting specific X and Y dimensions. It does not preserve scale. HORIZONTAL VECTOR HATCHING This button and corresponding parameter box automatically fill closed contours with a horizontal hatch pattern, with the gap between horizontal scan lines (in inches) determined by the input in the parameter box. This is a useful function for engraving deeply into an object—with the proper settings it will remove material much more quickly than in Engraving mode. Be aware that due to the scan gap being nonzero the bottom surface might not be smooth. VECTOR LAYERS, VECTOR CURRENT % VECTOR LAYERS RetinaEngrave automatically separates vector drawings into layers by color. Each layer can specify different properties. The Reset Layer Properties button will reset the Vector Layers table to the default values. Order. L ayers are cut in order from one (1) to seven (7). Speed. S ets the speed of the layer as a percentage of the maximum value. Power %. S ets the PWM frequency. PWM power control is very fine. Setting it to 0.5% will mark but not cut through paper. Passes. N umber of repetitions. Polylines. ...

- Page 62 61 VECTOR CURRENT % Total power is determined by a combination of delivered current and voltage to the laser tube. The current is directly regulated while voltage is controlled by PWM (Pulse Width Modulation). PWM is a technique whereby an average voltage is delivered in a series of pulses per unit time. In Vector mode you can control both the PWM frequency (power) as well as the delivered current (Vector Current %). In Raster mode, the output is pulsed based on the speed and pixel pattern, so only current control is available (Raster Power %). VECTOR IMPORT OPTIONS IGNORE RASTER Select this option to speed up processing of large vector files on computers with limited memory. Raster data is memory intensive for large drawings at the highest resolutions and is unneeded if only vector cutting is required. IGNORE ALL VECTOR The existing documents in the Vector Cut is not replaced when loading new documents. IGNORE THIN VECTOR Disables vectorable content from Raster Tab and nonvectorable content from Vector Tab. Vectorable is defined as having linewidth set to hairline. All other objects, including images, are nonvectorable. This option is useful when importing projects with the intention of “Raster then Vector” (Combined Mode). TOLERANCE Override the Config File Import Tolerance Setting. This is used to determine the amount of points generated for objects on Vector Import. AUTOMATIC MODE Start jobs as soon as they are printed using default settings. Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ...

-

Page 63: Designating Layers

62 Designating Layers Designating a color to objects/ layers you want to vector cut enables you to take advantage of RetinaEngrave’s ability to specify cutting order, cut speed, laser power and number of repeats for each layer. RetinaEngrave supports up to seven standard color layers for maximum program compatibility: Black, B lue , R ed , M agenta , G reen , C yan , and Y ellow f rom the RGB color palette. PRO TIP! RetinaEngrave uses a “best guess color round off routine” when a color is not a standard RGB color. Avoid using black whenever possible because black is the default color RetinaEngrave uses whenever it cannot figure out what color it should be. By avoiding black, you will have more control. ... -

Page 64: Design Tab

63 Design Tab The Design Tab provides basic drawing tools for creating simple designs within RetinaEngrave. The tools allow you to draw open or closed contours, complex paths, shapes and text with a variety of fill options. The Design Tab is project based, with each project having one or more designs. Once you have a design, you select it and render it to one of the mode tabs. Attention! The Design Tab is not meant to replace a dedicated drawing/design package—it exists as an internal tool for quick tests and is released “as is”. If you are having a problem with the output of the design tab, please use a standard program such as CorelDraw to create your work and report any software issues to s upport@fslaser.com . DESIGN VIEW Technical Support is available from 8:00 am (PST) to 5:00 pm (PST) Monday through Friday at support@fslaser.com . ... - Page 65 64 DESIGN VIEW TOP LINE BUTTONS (LEFT SIDE) OPEN Open a new project.Opening a new project removes any unsaved data in the document design window. SAVE Save your current project. NEW PROJECT BUTTONS Opens a new project. EDIT SHAPE Select shapes or points and edit their information (color, thickness, fill, etc). NEW LINE Add a new point to point line. Drag the end handles to change length or use the Shape Properties box (bottom of Shape Properties Panel) to set start and end points. NEW RECTANGLE Draw a rectangle. Use the handles to change proportions or the properties panel to adjust width and height (units are inches) as well as corner radii. Use the Stroke properties to adjust corner joint type. NEW ELLIPSE Draw an ellipse. Use the properties panel to change the X and Y radii (units are pixels). NEW PATH Create a new spline path. Select one of the endpoints to bring up the Shape Properties box and add/remove points and adjust line tangency. NEW TEXT Place text in the design area. ...