Table of Contents

Advertisement

Models:

ART 55 A/AR

ART 60 A/AR

ART 80 A/AR

ART 100 A/AR

ART 120 A/AR

ART 150 A/AR

ART 200 A/AR

ART 250 A/AR

ART 300 A/AR

ART 360 A/AR

ART 420 A/AR

A4RT 60 A/AR

A4RT 80 A/AR

A4RT 100 A/AR

A4RT 120 A/AR

A4RT 150 A/AR

A4RT 200 A/AR

A4RT 250 A/AR

A4RT 300 A/AR

A4RT 360 A/AR

A4RT 420 A/A R

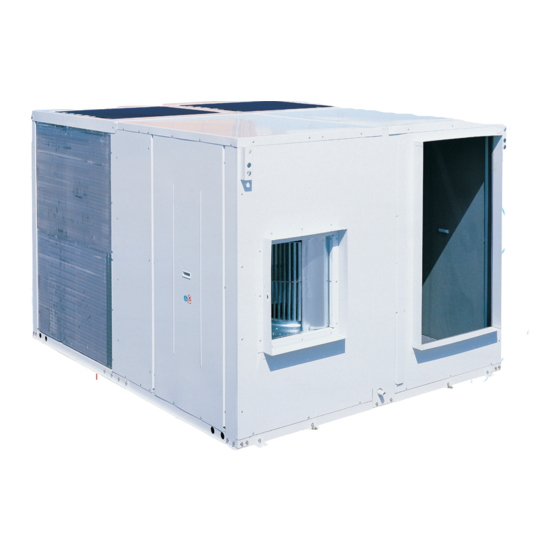

Rooftop Packaged

Air Conditioners

ART-A_(i)

Advertisement

Table of Contents

Summary of Contents for Acson ART 55 A

- Page 1 Models: ART 55 A/AR ART 60 A/AR ART 80 A/AR ART 100 A/AR ART 120 A/AR ART 150 A/AR ART 200 A/AR ART 250 A/AR ART 300 A/AR ART 360 A/AR ART 420 A/AR A4RT 60 A/AR A4RT 80 A/AR...

- Page 2 TABLE OF CONTENTS 1. NOMENCLATURE......................1 - PRODUCT LINE-UP 2. FEATURES........................4 3. APPLICATION INFORMATION..................5 - OPERATING RANGE - REFRIGERANT CIRCUIT DIAGRAMS - CONTROLLERS - PRECAUTION AND INSTALLATION 4. SOUND DATA....................... 43 5. SELECTION PROCESS....................49 - FAN PERFORMANCE CHART ENGINEERING &...

-

Page 3: Nomenclature

Production spec variation Type of ref. connection X: Not Applicable Electrical F: 380-415V/3Ph/50Hz Model Type R: Heatpump Blank: Cooling Only Series A: A series Capacity 100: 100,000 Btu/h Model Name RT: Rooftop Refrigerant 4: R407C Blank: R22 Brand A: Acson... - Page 4 Product Line-up A(4)RT Cooling Only Classification FXAB FXAD FXBA FXAA FXAC FXBC FXBA 100A FXAA 100A FXBC FXAC 120A FXBB FXAB 120A FXAC FXBC FXBA 150A FXAA A4RT FXBD 150A FXAD 200A FXBA FXAA FXBD 200A FXAD 250A FXAA 250A FXAC 300A FXAA...

- Page 5 A(4)RT Heat Pump Classification 60AR FXAC FXBC 80AR FXAC FXBC 100AR FXAC FXBC 120AR FXAC FXBC 150AR FXAC A4RT FXBC 200AR FXAC 250AR FXAC 300AR FXAC 360AR FXAC 420AR FXAC 55AR FXAI 60AR FXAH 60AR FXAI 80AR FXBC FXAC 80AR FXBH FXAH FXBN...

- Page 6 Refrigerant is factory pre-charged to ensure clean and efficient operation. Flexibility Of Air Supply Acson rooftop unit uses a belt driven fan such that the air volume and static required can be adjusted according to the requirement. This flexibility allows for wider application.

-

Page 7: Application Information

3. APPLICATION INFORMATION Operating Range Ensure the operating temperature is in allowable range. Cooling (R22) Cooling (R22) Cooling Mode For Heat Pump Model Cooling Only Unit Indoor temp. (°C WB) Indoor temp. (°C WB) Heat pump Cooling (R407C) Heat Pump Unit Only Cooling Only Unit &... - Page 8 Refrigerant Circuit Diagrams A(4)RT55/60A...

- Page 9 A(4)RT80/100A...

- Page 10 A(4)RT120A...

- Page 11 A(4)RT150/200A...

- Page 12 A(4)RT250/300A...

- Page 13 A(4)RT360/420A COMP1...

- Page 14 ART55AR COOLING OPERATION HEATING OPERATION HEAT EXCHANGER (OUTDOOR) ACCUMULATOR CHECK JOINT COMPRESSOR HEAT EXCHANGER (INDOOR)

- Page 15 A(4)RT60AR...

- Page 16 ART80/100AR...

- Page 17 A4RT80/100AR...

- Page 18 A(4)RT120AR...

- Page 19 ART150/200AR...

- Page 20 A4RT150/200AR...

- Page 21 A(4)RT250/300AR...

- Page 22 A(4)RT360/420AR COMP1...

- Page 23 Controllers SLM Wired Controller (Model: A(4)RT55/60/80/100/120A/AR) SENSOR ON/OFF ON/OFF AUTO COOL HIGH TEMP MODE TEMP HEAT SWING SLEEP TIMER SWING SLEEP TIMER MODE AC-5300 (OPTIONAL) 1. “ON/OFF” Switch 6. “SLEEP” Mode • Press to start the air conditioner unit. • Press button to activate the sleep function.

- Page 24 Sequential Controller (Model: A(4)RT150/200/250/300/360/420A/AR) Sequential Controller Functions 1) Sequential Controller LCD Display A : Time display B : Error indication C : Compressor running display (up to 4 compressors) D : Key lock display E : Heater display (up to 2 heaters) F : Energy saving mode display G : Compressor defrost cycle display (up to 4 compressors) H : Operation mode display...

- Page 25 7-days timer Press the ON TIMER key to activate auto-ON timer mode. Under this mode, press the respective MINUTE, HOUR and DAY key to select the time of the week when the air-conditioning unit is to automatically start running. Press the ON TIMER key again to save the setting. Press the OFF TIMER key to activate auto-OFF timer mode.

-

Page 26: Wiring Diagrams

b) Step-by-step guide i) First, open up the casing of the LCD remote controller into its top and bottom case using a screwdriver. To do this, insert the screwdriver into the lower slot and slide it in the outward direction. ii) Fix the bottom case onto the wall with the 2 wooden screws provided. -

Page 27: Safety Precautions

Precaution & Installation Safety Precautions Before installing the air conditioner unit, please read the following safety precautions carefully. WARNING • Installation and maintenance should be performed by qualified persons who are familiar with local code and regulation, and experienced with this type of appliance. •... - Page 28 Installation All series of air conditioners are designed for outdoor installations and are to be placed on a slab or rooftop. However, if the air conditioner is to be installed in a plant room, please contact your equipment supplier prior to installation for further advise.

- Page 29 A(4)RT60/80/100/120 A/AR A(4)RT150/200 A/AR Condenser inlet Evaporator (min clearance) coil, air filter Condenser service inlet Electrical control circuit Evaporator coil, & compressor air filter service service Condenser Evaporator inlet coil, air filter service (min clearance) condenser outlet Condenser outlet (unit : mm) (unit : mm) A(4)RT250/300 A/AR A(4)RT360/420 A/AR...

- Page 30 2. Duct Construction. (1) Series ART side flow units are equipped with horizontal supply and return air openings. Duct connection to the unit should be made with duct flanges and secured directly to the air openings with flexible duct connectors to avoid normal noise transmission. (2) For vertical air supply, a field supply plenum should be used.

- Page 31 3. Lifting Method. When the unit is to be lifted and moved, attach ropes to the hoisting hangers (4 pieces) provided on the top corners of the unit. When the unit is lifted, its center of gravity tends to shift the unit to one side.

- Page 32 6. Optional Features (Down Flow) - Site Modification Required. Reconstruction Method. (From Side Flow To Down Flow) (For A(4)RT80/100/120/150/200A/AR Only) Series ART side flow units are able to be modified to down flow in the field with the help of additional accessory items.

- Page 33 7. Special Precautions When Dealing With Refrigerant R407C Unit (1) What Is New Refrigerant R407C? R407C is a zeotropic refrigerant mixture which has Zero Ozone Depletion Potential (ODP = 0) and thus, conforms to the Montreal Protocol regulation. It requires Polyol-ester (POE) oil for its compressor’s lubricant.

- Page 34 c) Ensure that the compressor is not exposed to open air for more than the recommended time specified by its manufacturer (typically less than 10 minutes). Remove the seal-plugs only when the compressor is about to be brazed. d) The system should be thoroughly vacuumed to 1.0 Pa (-700mmHg) or lower. This vacuuming level is more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

- Page 35 8. Electric Wiring Construct The Earth Connection. All electrical work must be carried out by a suitable qualified electrical trades-person and in accordance with local supply authority requirements and associated regulators. The unit is to be wired directly from an electrical distribution board either by a circuit breaker (preferred) or HRC fuse.

- Page 36 Control Module Of Unit ART55A/AR connector for remote control Terminal Block for power supply wire Control Module Of Unit A(4)RT60A Connector For Terminal Block For Remote Control Wires Power Supply Wires Control Module Of Unit A(4)RT80/100A Connector For Remote Control Wires Terminal Block For Power Supply Wires...

- Page 37 Control Module Of Unit A(4)RT120A Connector For Remote Control Wires Terminal Block For Power Supply Wires Control Module Of Unit A(4)RT150/200A Connector For Remote Control Wires Terminal Block For Power Supply Wires...

- Page 38 Control Module Of Unit A(4)RT250/300A Connector For Remote Control Wires Terminal Block For Power Supply Wires Control Module Of Unit A(4)RT60AR Connector For Terminal Block For Remote Control Wires Power Supply Wires...

- Page 39 Control Module Of Unit ART80/100AR Connector For Remote Control Wires Terminal Block For Power Supply Wires Control Module Of Unit A4RT80/100AR Connector For Remote Control Wires Terminal Block For Power Supply Wires...

- Page 40 Control Module Of Unit A(4)RT120AR Connector For Remote Control Wires Terminal Block For Power Supply Wires Control Module Of Unit ART150/200AR Terminal Block For Connector For Remote Control Wires Power Supply Wires...

- Page 41 Control Module Of Unit A4RT150/200AR Terminal Block For Connector For Power Supply Wires Remote Control Wires Control Module Of Unit A(4)RT250/300AR Connector For Remote Control Wires Terminal Block For Power Supply Wires...

- Page 42 Control Module Of Unit A(4)RT360/420A/AR connector for remote control wires 52C1 52F2 52C2 51F1 52F3 51C1 51C2 TB2 & 3 Terminal Block for (4)RT-AR only power supply wires...

- Page 43 9. The Putting Condition Of The Belt 1. Set the parallel angle of the fan and the motor pulley as shown in table 1 and figure 1. 2. Set the tension of one belt when the flexion load is within the range as shown in figure 2 and table 2 at the proper flexion.

- Page 44 11. Before Operating The Unit 1. Check points for operation Check the following points before you operate your air conditioner. (1) Check that there is nothing blocking the flow of air from the air outlet into the air inlet. Indoor Side Outdoor Side Outlet grille Inlet grille...

-

Page 45: Sound Data

4. SOUND DATA 1/1 Octave Sound Pressure Level (dB, ref 20 µPa) Overall Noise Model 125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz (dBA) Criteria ART55A/AR A(4)RT60A/AR A(4)RT80A/AR A(4)RT100A/AR A(4)RT120A/AR A(4)RT150A/AR A(4)RT200A/AR A(4)RT250A/AR A(4)RT300A/AR A(4)RT360A/AR > 70* A(4)RT420A/AR > 70* * THE DATA DOES NOT APPLY TO INDOOR NOISE CRITERION. Note: 1. -

Page 46: Table Of Contents

A(4)RT60A/AR NC CURVES NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) A(4)RT80A/AR NC CURVES NC-65 NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) -

Page 47: Table Of Contents

A(4)RT100A/AR NC CURVES NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) A(4)RT120A/AR NC CURVES NC-65 NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) -

Page 48: Table Of Contents

A(4)RT150A/AR NC CURVES NC-70 NC-65 NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) A(4)RT 200A/AR NC CURVES NC-65 NC-60 NC-55 NC-50 NC-45 NC-40 NC-35 NC-30 NC-25 NC-20 1000 2000 4000 8000 Octave-band frequency (Hz) - Page 49 A(4)RT 360A/AR NC CURVES NC70 NC65 NC60 NC55 NC50 NC45 NC40 NC35 NC30 NC25 NC20 1000 2000 4000 8000 Octave-band frequency (Hz) A(4)RT 420A/AR NC CURVES NC70 NC65 NC60 NC55 NC50 NC45 NC40 NC35 NC30 NC25 NC20 1000 2000 4000 8000 Octave-band frequency (Hz)

- Page 50 A(4)RT 360A/AR NC CURVES NC70 NC65 NC60 NC55 NC50 NC45 NC40 NC35 NC30 NC25 NC20 1000 2000 4000 8000 Octave-band frequency (Hz) A(4)RT 420A/AR NC CURVES 1000 2000 4000 8000 Octave-band frequency (Hz)

-

Page 51: Operating Range

5. SELECTION PROCESS Drive Package The following are the design requirements for ART100A unit: Model: ART100A Supply Air Quantity 3800 External Static Pressure Step 1: From the blower curve (at 3800 CFM), Standard operating system; Internal Static Pressure Step 2: Therefore at 3800 CFM and 150 Pa external static pressure, Total Static Pressure 150 + 160... - Page 52 DIMENSIONAL DATA Below tables summarizes the pulley data, motor size used for the RT series, as manufactured. Blower Pulley, Db Motor Pulley, Dm V Belt Model Type Diameter (mm) Type Diameter (mm) Type Length (mm) ART 55A/AR SPZ 1 100 SPZ 1 63 SPZ 1000 A(4)RT 60A/AR SPZ 1 125 SPZ 1 ...

- Page 53 Blower Curve ART55A/AR Air Flow...

- Page 54 A(4)RT60A/AR Air Flow...

- Page 55 (4)RT080A/AR 1.5 kW 1300 1.1 kW 1200 Standard Point 1100 Internal Static Pressure 1000 2800 2900 3000 3100 3200 3300 CFM 1320 1400 1500 1560 Air Flow...

- Page 56 (4)RT100A/AR 2.2 kW 1.5 kW 1400 1.1 kW Standard Point 1300 Internal Static Pressure 1200 1100 1000 3100 3200 3300 3400 3500 3600 3700 3800 3900 4000 4100 CFM 1470 1500 1600 1700 1800 1900 1930 Air Flow...

- Page 57 (4)RT120A/AR 2.2 kW 1.5 kW 1400 1.1 kW Standard Point 1300 Internal Static Pressure 1200 1100 1000 3100 3200 3300 3400 3500 3600 3700 3800 3900 4000 4100 CFM 1470 1500 1600 1700 1800 1900 1930 Air Flow...

- Page 58 (4)RT150A/AR 3.0 kW 1000 2.2 kW Standard Point 1.5kW Internal Static Pressure 4600 4800 5000 5200 5400 5600 5800 6000 6200 CFM 2170 2200 2400 2600 2800 2926 L/S Air Flow...

- Page 59 (4)RT200A/AR 5.5 kW 1200 1100 3.7 kW 1000 Standard Point 3.0kW Internal Static Pressure 5600 5800 6000 6200 6400 6600 6800 7000 7200 CFM 2640 2800 3000 3200 3400 L/s Air Flow...

- Page 60 A(4)RT250A/AR Air Flow...

- Page 61 A(4)RT300A/AR Air Flow...

- Page 62 A(4)RT360A/AR 7.5kw 5.5kw Standard Point 4.0kw Internal Static Pressure 9000 9500 10000 10500 11000 11500 12000 12500 Air Flow (CFM)

- Page 63 A(4)RT420A/AR 1000 11.0kw 7.5kw Standard Point 5.5kw Internal Static Pressure 10500 11000 11500 12000 12500 13000 13500 14000 14500 15000 Air Flow (CFM)

- Page 64 6. ENGINEERING & PHYSICAL DATA Specifications General Data - Cooling Only (R22) MODEL ART55A Btu/h 54000 NOMINAL CAPACITY 15830 NOMINAL TOTAL INPUT POWER 6380 NOMINAL RUNNING CURRENT 11.0 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R22 / TXV 2.48 AIR DISCHARGE...

- Page 65 General Data - Cooling Only (R22) MODEL ART100A ART120A Btu/h 100000 116000 NOMINAL CAPACITY 29300 34000 NOMINAL TOTAL INPUT POWER 10500 11560 NOMINAL RUNNING CURRENT 18.2 22.1 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R22 / CAPILLARY TUBE R22 / TXV 2.94...

- Page 66 General Data - Cooling Only (R22) MODEL ART250A ART300A Btu/h 250000 300000 NOMINAL CAPACITY 73270 87930 NOMINAL TOTAL INPUT POWER 27560 35960 NOMINAL RUNNING CURRENT 49.6 62.7 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R22 / TXV 2.56 2.39...

- Page 67 General Data - Heat pump (R22) MODEL ART55AR Btu/h 55000 NOMINAL COOLING CAPACITY 16119 Btu/h 56500 NOMINAL HEATING CAPACITY 16559 NOMINAL TOTAL INPUT POWER (COOLING) 5778 NOMINAL TOTAL INPUT POWER (HEATING) 5128 NOMINAL RUNNING CURRENT (COOLING) 10.2 NOMINAL RUNNING CURRENT (HEATING) POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50...

- Page 68 General Data - Heat pump (R22) MODEL ART100AR ART120AR Btu/h 100000 105000 NOMINAL COOLING CAPACITY 29300 30770 Btu/h 105000 118000 NOMINAL HEATING CAPACITY 30800 32580 NOMINAL TOTAL INPUT POWER (COOLING) 11860 11600 NOMINAL TOTAL INPUT POWER (HEATING) 10050 10700 NOMINAL RUNNING CURRENT (COOLING) 20.5 21.6 NOMINAL RUNNING CURRENT (HEATING)

- Page 69 General Data - Heat pump (R22) MODEL ART250AR ART300AR Btu/h 235000 290000 NOMINAL COOLING CAPACITY 68880 84990 Btu/h 252000 295000 NOMINAL HEATING CAPACITY 73860 86460 NOMINAL TOTAL INPUT POWER (COOLING) 27660 37160 NOMINAL TOTAL INPUT POWER (HEATING) 26360 32660 NOMINAL RUNNING CURRENT (COOLING) 49.9 64.7 NOMINAL RUNNING CURRENT (HEATING)

- Page 70 General Data - Cooling Only (R407C) MODEL A4RT60A A4RT80A Btu/h 59000 72000 NOMINAL CAPACITY 17290 21100 NOMINAL TOTAL INPUT POWER 5890 8700 NOMINAL RUNNING CURRENT 10.9 16.3 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R407C / TXV R407C / CAPILLARY TUBE 2.94...

- Page 71 General Data - Cooling Only (R407C) MODEL A4RT150A A4RT200A Btu/h 140000 190000 NOMINAL CAPACITY 41030 55680 NOMINAL TOTAL INPUT POWER 17200 25100 NOMINAL RUNNING CURRENT 32.1 43.8 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R407C / CAPILLARY TUBE 2.34 2.18...

- Page 72 General Data - Cooling Only (R407C) MODEL A4RT360A A4RT420A Btu/h 331000 415000 NOMINAL CAPACITY 97010 121620 NOMINAL TOTAL INPUT POWER 41870 48800 NOMINAL RUNNING CURRENT 74.2 83.7 POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 REFRIGERANT TYPE / CONTROL R407C / TXV 2.32 2.49...

- Page 73 General Data - Heat pump (R407C) MODEL A4RT60AR A4RT80AR Btu/h 56000 72000 NOMINAL COOLING CAPACITY 16710 21100 Btu/h 69000 77000 NOMINAL HEATING CAPACITY 20220 22570 NOMINAL TOTAL INPUT POWER (COOLING) 6650 8410 NOMINAL TOTAL INPUT POWER (HEATING) 6580 7540 NOMINAL RUNNING CURRENT (COOLING) 13.2 16.0 NOMINAL RUNNING CURRENT (HEATING)

- Page 74 General Data - Heat pump (R407C) MODEL A4RT150AR A4RT200AR Btu/h 149000 190000 NOMINAL COOLING CAPACITY 43670 55680 Btu/h 160000 230000 NOMINAL HEATING CAPACITY 46890 67410 NOMINAL TOTAL INPUT POWER (COOLING) 16570 21160 NOMINAL TOTAL INPUT POWER (HEATING) 15710 20300 NOMINAL RUNNING CURRENT (COOLING) 32.2 39.9 NOMINAL RUNNING CURRENT (HEATING)

- Page 75 General Data - Heat pump (R407C) MODEL A4RT360AR A4RT420AR Btu/h 345000 374000 NOMINAL COOLING CAPACITY 101110 109610 Btu/h 349000 431000 NOMINAL HEATING CAPACITY 102290 126310 NOMINAL TOTAL INPUT POWER (COOLING) 43170 48200 NOMINAL TOTAL INPUT POWER (HEATING) 41670 46800 NOMINAL RUNNING CURRENT (COOLING) 74.2 82.9 NOMINAL RUNNING CURRENT (HEATING)

- Page 76 Components Data (R22) MODEL ART55A TYPE CENTRIFUGAL QUANTITY MATERIAL METAL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 203 / 8 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER QUANTITY...

- Page 77 Components Data (R22) MODEL ART60A ART80A TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR...

- Page 78 Components Data (R22) MODEL ART100A ART120A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE...

- Page 79 Components Data (R22) MODEL ART150A ART200A TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 384.5 / 15.1 LENGTH mm/in 374.0 / 14.7 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 80 Components Data (R22) MODEL ART250A ART300A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 457.2 / 18 LENGTH mm/in 480 / 18.9 481 / 18.9 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE...

- Page 81 Components Data (R22) MODEL ART360A ART420A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 560 / 22 LENGTH mm/in 457 / 18 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 82 Components Data (R22) MODEL ART55AR TYPE CENTRIFUGAL QUANTITY MATERIAL METAL EVAPORATOR * DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 203 / 8 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR * QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 83 Components Data (R22) MODEL ART60AR ART80AR TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 286.0 / 11.3 LENGTH mm/in 254 / 10 274.0 / 10.8 & 184.0 / 7.2 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR...

- Page 84 Components Data (R22) MODEL ART100AR ART120AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 286.0 / 11.3 254 / 10 LENGTH mm/in 274.0 / 10.8 & 184.0 / 7.2 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR*...

- Page 85 Components Data (R22) MODEL ART150AR ART200AR TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 384.5 / 15.1 LENGTH mm/in 374.0 / 14.7 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 86 Components Data (R22) MODEL ART250AR ART300AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 457.2 / 18 LENGTH mm/in 480 / 18.9 481 / 18.9 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP54 TYPE...

- Page 87 Components Data (R22) MODEL ART360AR ART420AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 560 / 22 LENGTH mm/in 457 / 18 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP44 TYPE PROPELLER...

- Page 88 Components Data (R407C) MODEL A4RT60A A4RT80A TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR...

- Page 89 Components Data (R407C) MODEL A4RT100A A4RT120A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE...

- Page 90 Components Data (R407C) MODEL A4RT150A A4RT200A TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 384.5 / 15.1 LENGTH mm/in 374.0 / 14.7 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 91 Components Data (R407C) MODEL A4RT250A A4RT300A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 457.2 / 18 LENGTH mm/in 480 / 18.9 481 / 18.9 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP54 TYPE...

- Page 92 Components Data (R407C) MODEL A4RT360A A4RT420A TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR DRIVE BELT DRIVE DIAMETER mm/in 560 / 22 LENGTH mm/in 457 / 18 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP44 TYPE PROPELLER...

- Page 93 Components Data (R407C) MODEL A4RT60AR A4RT80AR TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR...

- Page 94 Components Data (R407C) MODEL A4RT100AR A4RT120AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 254 / 10 LENGTH mm/in 254 / 10 & 203.2 / 8.0 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE...

- Page 95 Components Data (R407C) MODEL A4RT150AR A4RT200AR TYPE CENTRIFUGAL QUANTITY MATERIAL PLASTIC EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 384.5 / 15.1 LENGTH mm/in 374.0 / 14.7 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP22 TYPE PROPELLER...

- Page 96 Components Data (R407C) MODEL A4RT250AR A4RT300AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 457.2 / 18 LENGTH mm/in 480 / 18.9 481 / 18.9 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP54 TYPE...

- Page 97 Components Data (R407C) MODEL A4RT360AR A4RT420AR TYPE CENTRIFUGAL QUANTITY MATERIAL GALVANISED STEEL EVAPORATOR* DRIVE BELT DRIVE DIAMETER mm/in 560 / 22 LENGTH mm/in 457 / 18 TYPE THREE PHASE SQUIRREL CAGE INDUCTION MOTOR EVAPORATOR* QUANTITY FAN MOTOR INDEX OF PROTECTION (IP) IP44 TYPE PROPELLER...

- Page 98 Safety Devices (R22) MODEL ART55A TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER DISCHARGE THERMOSTAT SETTING °C / °F 125 / 257 MODEL ART60A ART80A...

- Page 99 Safety Devices (R22) MODEL ART250A ART300A TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER DISCHARGE THERMOSTAT SETTING °C / °F MODEL ART360A ART420A TYPE HIGH PRESSURE SWITCH...

- Page 100 Safety Devices (R22) MODEL ART55AR TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 2937 / 426 CLOSE kPa/psi 2413 / 350 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER 125 / 257 DISCHARGE THERMOSTAT SETTING °C / °F MODEL ART60AR ART80AR...

- Page 101 Safety Devices (R22) MODEL ART250AR ART300AR TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 2937 / 426 CLOSE kPa/psi 2413 / 350 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER DISCHARGE THERMOSTAT SETTING °C / °F MODEL ART360AR ART420AR TYPE HIGH PRESSURE SWITCH...

- Page 102 Safety Devices (R407C) MODEL A4RT60A A4RT80A TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER 125 / 257 DISCHARGE THERMOSTAT SETTING °C / °F MODEL A4RT100A A4RT120A...

- Page 103 Safety Devices (R407C) MODEL A4RT250A A4RT300A TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER DISCHARGE THERMOSTAT SETTING °C / °F MODEL A4RT360A A4RT420A TYPE HIGH PRESSURE SWITCH...

- Page 104 Safety Devices (R407C) MODEL A4RT60AR A4RT80AR TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER 125 / 257 DISCHARGE THERMOSTAT SETTING °C / °F MODEL A4RT100AR A4RT120AR...

- Page 105 Safety Devices (R407C) MODEL A4RT250AR A4RT300AR TYPE HIGH PRESSURE SWITCH OPEN kPa/psi 3241 / 470 CLOSE kPa/psi 2648 / 384 TYPE SAFETY DEVICE LOW PRESSURE SWITCH OPEN kPa/psi CLOSE kPa/psi PHASE SEQUENCER DISCHARGE THERMOSTAT SETTING °C / °F MODEL A4RT360AR A4RT420AR TYPE HIGH PRESSURE SWITCH...

-

Page 106: Performance Data

7. PERFORMANCE DATA Calculation Steps Interpolation method can be used to get the total capacity, TC and sensible capacity, SC and power input, PI at those temperatures which are not stated out in the table. Extrapolation method are not allowed to be used to get the TC, SC and PI. - Page 107 Details: Step: To obtain the Total capacity and Sensible capacity and Power input for (a) Indoor Condition: 25˚C DB, 16˚C WB Outdoor Condition: 35°C DB Outdoor DB, ˚C Indoor WB Indoor DB ˚C ˚C TC (kW) SHC (kW) PI (kW) 53.36 47.36 20.24...

- Page 108 (b) Indoor Condition: 25˚C DB, 16˚C WB Outdoor Condition: 40°C DB Outdoor DB, ˚C Indoor WB Indoor DB ˚C ˚C TC (kW) SHC (kW) PI (kW) 48.02 43.38 21.89 ....... 49.37 49.37 22.02 Total capacity, TC Interpolation Method: 27º C – 24º C 49.37kW –...

- Page 109 Step: To obtain the Total capacity, Sensible capacity and Power Input for (a) Indoor Condition: 25°C DB, 17°C WB Outdoor Condition: 35°C DB Outdoor DB,˚C Indoor WB Indoor DB ˚C ˚C TC (kW) SHC (kW) PI (kW) 53.72 49.65 20.27 ......

- Page 110 (b) Indoor Condition: 25°C DB, 17°C WB Outdoor Condition: 40°C DB Outdoor DB,˚C Indoor WB Indoor DB ˚C ˚C TC (kW) SHC (kW) PI (kW) 48.47 45.38 21.93 ......52.61 36.24 22.35 Total capacity, TC Interpolation Method: 19ºC – 16ºC 52.61kW –...

- Page 111 Step: To obtain the Total capacity and Sensible capacity for (a) Indoor Condition: 25°C DB, 17°C WB Outdoor Condition: 37°C DB Outdoor DB, ˚C Indoor WB Indoor DB ˚C ˚C (kW) (kW) (kW) (kW) (kW) (kW) (kW) (kW) (kW) ..55.29 46.30 20.41...

-

Page 112: Performance Table

Performance Table R22 Model (COOLING ONLY) Model: ART55A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 15.64 11.77 5.00 15.14 11.51 5.35 14.62 11.23 5.75 14.05 10.94 6.20 12.64 9.99 6.71 11.75 9.45 7.39 10.82 8.88 8.14 24°C 15.70... - Page 113 Model: ART80A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 23.17 16.35 6.35 22.44 15.98 6.79 21.66 15.60 7.30 20.82 15.20 7.87 18.74 13.87 8.52 17.40 13.12 9.38 16.03 12.34 10.34 24°C 23.26 19.47 6.36 22.53 19.06 6.80 21.75...

- Page 114 Model: ART120A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 33.60 22.75 9.07 32.53 22.25 9.69 31.40 21.72 10.41 30.19 21.15 11.24 27.17 19.31 12.16 25.24 18.27 13.39 23.25 17.18 14.75 24°C 33.73 27.10 9.08 32.67 26.54 9.70 31.54...

- Page 115 Model: ART200A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 57.91 40.85 16.24 56.07 39.94 17.35 54.12 38.99 18.65 52.03 37.98 20.12 46.82 34.67 21.77 43.49 32.80 23.97 40.07 30.84 26.41 24°C 58.13 48.65 16.25 56.30 47.64 17.37 54.35...

- Page 116 Model: ART300A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 86.89 62.10 28.21 84.14 60.73 30.15 81.21 59.28 32.40 78.07 57.74 34.96 70.25 52.71 37.82 65.26 49.87 41.65 60.11 46.89 45.88 24°C 87.22 73.97 28.24 84.47 72.43 30.18 81.55...

- Page 117 Model: ART420A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 52°C 21°C 117.01 85.84 36.71 113.31 83.94 39.23 109.36 81.94 42.16 105.14 79.81 45.50 94.61 72.86 49.23 87.89 68.92 54.20 80.96 64.81 59.72 24°C 117.47 102.24 36.75 113.76 100.11 39.28 109.83...

- Page 118 R22 Model (HEAT PUMP) Cooling Mode Model: ART55AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 15.93 11.98 4.53 15.42 11.72 4.84 14.89 11.44 5.21 14.31 11.14 5.62 12.88 10.17 6.08 11.96 9.62 6.69 24°C 15.99 14.27 4.54 15.49 13.98...

- Page 119 Model: ART80AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 23.17 17.43 7.37 22.44 17.05 7.88 21.66 16.64 8.47 20.82 16.21 9.14 18.74 14.80 9.89 17.40 14.00 10.89 24°C 23.26 20.77 7.38 22.53 20.33 7.89 21.75 19.88 8.48 20.92 19.39...

- Page 120 Model: ART120AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 30.41 22.88 9.10 29.44 22.37 9.72 28.42 21.84 10.45 27.32 21.27 11.28 24.59 19.42 12.20 22.84 18.37 13.43 24°C 30.52 27.25 9.11 29.56 26.68 9.74 28.54 26.08 10.46 27.45 25.45...

- Page 121 Model: ART200AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 57.91 38.12 18.43 56.07 37.28 19.70 54.12 36.39 21.17 52.03 35.44 22.85 46.82 32.36 24.72 43.49 30.61 27.22 24°C 58.13 45.41 18.45 56.30 44.46 19.72 54.35 43.47 21.19 52.28 42.41...

- Page 122 Model: ART300AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 83.90 61.54 29.15 81.24 60.19 31.15 78.41 58.75 33.48 75.38 57.22 36.12 67.84 52.24 39.09 63.01 49.42 43.04 24°C 84.22 73.31 29.18 81.57 71.78 31.19 78.75 70.17 33.51 75.74 68.46...

- Page 123 Model: ART420AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 111.21 86.81 36.40 107.69 84.90 38.90 103.94 82.87 41.80 99.92 80.71 45.11 89.92 73.68 48.81 83.53 69.70 53.74 24°C 111.64 103.40 36.43 108.12 101.25 38.94 104.38 98.98 41.85 100.39 96.57...

- Page 124 R22 Model (HEAT PUMP) Heating Mode Model: ART55AR Ind. DB Outdoor WB TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) 10.87 3.88 19.42 4.65 24.09 5.08 26.43 5.29 28.76 5.50 10.65...

- Page 125 Model: ART150AR Ind. DB Outdoor WB TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) 36.05 11.42 49.91 13.70 57.48 14.95 61.26 15.57 65.04 16.20 35.45 11.87 48.42 14.17 55.96 15.42 59.57...

- Page 126 R407C Model (COOLING ONLY) Model: A4RT60A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 17.09 11.25 4.62 16.55 11.00 4.94 15.97 10.74 5.31 15.35 10.46 5.73 13.82 9.55 6.20 12.83 9.03 6.82 24°C 17.15 13.40 4.62 16.61 13.12 4.94 16.04...

- Page 127 Model: A4RT100A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 27.51 19.67 9.10 26.64 19.23 9.72 25.72 18.77 10.45 24.72 18.28 11.28 22.25 16.69 12.20 20.66 15.79 13.43 24°C 27.62 23.42 9.11 26.75 22.94 9.74 25.82 22.42 10.46 24.84 21.88...

- Page 128 Model: A4RT150A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 40.55 27.84 13.49 39.26 27.22 14.42 37.90 26.57 15.50 36.43 25.88 16.72 32.78 23.63 18.09 30.45 22.35 19.92 24°C 40.70 33.16 13.51 39.42 32.47 14.43 38.06 31.74 15.51 36.60 30.96...

- Page 129 Model: A4RT300A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 81.96 60.12 31.50 79.36 58.80 33.67 76.60 57.39 36.18 73.64 55.90 39.04 66.27 51.03 42.24 61.56 48.28 46.51 24°C 82.28 71.61 31.53 79.68 70.12 33.70 76.93 68.55 36.22 73.99 66.88...

- Page 130 Model: A4RT420A Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 120.19 94.95 38.28 116.38 92.85 40.91 112.33 90.64 43.96 107.99 88.28 47.44 97.18 80.59 51.33 90.27 76.24 56.52 24°C 120.65 113.10 38.32 116.85 110.74 40.95 112.81 108.26 44.01 108.50 105.62...

- Page 131 R407C Model (HEAT PUMP) Cooling Mode Model: A4RT60AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 16.51 10.87 5.38 15.99 10.63 5.75 15.43 10.37 6.18 14.83 10.10 6.67 13.35 9.22 7.22 12.40 8.73 7.94 24°C 16.57 12.94 5.39 16.05 12.68...

- Page 132 Model: A4RT100AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 25.49 19.41 8.49 24.68 18.99 9.07 23.82 18.53 9.75 22.90 18.05 10.52 20.61 16.48 11.38 19.14 15.59 12.53 24°C 25.58 23.13 8.50 24.78 22.64 9.08 23.92 22.14 9.76 23.01 21.60...

- Page 133 Model: A4RT150AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 43.15 31.66 13.00 41.79 30.96 13.89 40.33 30.22 14.93 38.77 29.43 16.11 34.89 26.87 17.43 32.41 25.42 19.19 24°C 43.32 37.71 13.01 41.95 36.92 13.91 40.50 36.09 14.94 38.96 35.21...

- Page 134 Model: A4RT250AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 66.61 48.86 22.91 64.50 47.79 24.48 62.26 46.64 26.31 59.85 45.43 28.39 53.86 41.47 30.71 50.03 39.23 33.82 24°C 66.87 58.20 22.93 64.76 56.99 24.51 62.52 55.71 26.33 60.13 54.35...

- Page 135 Model: A4RT360AR Outdoor temperature AFR (CFM) 19°C 25°C 30°C 35°C 40°C 46°C 21°C 99.91 78.93 33.86 96.75 77.19 36.19 93.39 75.35 38.89 89.78 73.39 41.97 80.79 67.00 45.41 75.04 63.38 50.00 24°C 100.30 94.02 33.90 97.14 92.06 36.23 93.78 90.00 38.93 90.20 87.80...

- Page 136 R407C Model (HEAT PUMP) Heating Mode Model: A4RT80AR Ind. DB Outdoor WB TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) 15.78 5.70 23.16 6.84 27.19 7.47 29.20 7.78 31.21 8.09 15.51...

- Page 137 Model: A4RT250AR Ind. DB Outdoor WB TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) TC (KW) PI (KW) 51.44 19.83 75.04 23.80 87.91 25.96 94.35 27.04 100.78 28.12 50.56 20.61 74.94 24.60 85.57 26.78 91.74...

- Page 138 8. OUTLINE AND DIMENSION ART55A/AR (unit : mm) Except : Drain size. (unit : inch) 20.0...

- Page 139 A(4)RT60A/AR (unit : mm) Except : Drain size. (unit : inch) 1020 Return air duct flange Supply air duct flange 16- 3 Holes 16- 3 Holes 4-15X25 Mtg. holes 1000 B Detail Hanger (4 places) A Detail Supply Supply air Control box Condenser Air inlet...

- Page 140 A(4)RT150/200A/AR RT-A 1670 1200 RT-AR 1800 1330 Detail A (unit : mm) Except : Drain size. (unit : inch) 200 200 200 200 200 1744 Supply air & Return air Duct flange 26- 3 Hole s 4-15X25 Mtg. holes Detail B 1744 Hanger (4 places) Supply...

- Page 141 A(4)RT360/420A/AR (unit : mm) Except : Drain size. (unit : inch) 3148...

- Page 142 Optional Units (Down Flow) - Site Modification Required A(4)RT80/100/120A/AR (unit : mm) Except : Drain size. (unit : inch) Detail A Condenser Air inlet View C (Bottom view) 16- 3 Holes 4-15X25 Mtg. holes 19- 3 Holes 1000 Detail B Hanger (4 places) Drain R 1 Control box...

- Page 143 A(4)RT250/300A/AR (unit : mm) Except : Drain size. (unit : inch)

-

Page 144: Electrical Data

9. ELECTRICAL DATA Electrical Data - Cooling Only (R22) MODEL ART55A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER EVAPORATOR MOTOR RATED RUNNING CURRENT MOTOR OUTPUT POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 220 ~ 240 / 1 / 50 RATED INPUT POWER CONDENSER MOTOR RATED RUNNING CURRENT... - Page 145 Electrical Data - Cooling Only (R22) MODEL ART100A ART120A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 1900 1340 EVAPORATOR MOTOR RATED RUNNING CURRENT 2.70 2.59 MOTOR OUTPUT 1500 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER...

- Page 146 Electrical Data - Cooling Only (R22) MODEL ART250A ART300A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 4700 6700 EVAPORATOR MOTOR RATED RUNNING CURRENT 11.7 MOTOR OUTPUT 5500 7500 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 TOTAL RATED INPUT POWER...

- Page 147 Electrical Data - Heat pump (R22) ART55AR MODEL INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER EVAPORATOR* MOTOR RATED RUNNING CURRENT MOTOR OUTPUT POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 220 ~ 240 / 1 / 50 RATED INPUT POWER CONDENSER* RATED RUNNING CURRENT...

- Page 148 Electrical Data - Heat pump (R22) MODEL ART100AR ART120AR INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 1900 1340 EVAPORATOR* MOTOR RATED RUNNING CURRENT 2.70 2.59 MOTOR OUTPUT 1500 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER...

- Page 149 Electrical Data - Heat pump (R22) MODEL ART250AR ART300AR INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 4700 6700 EVAPORATOR* MOTOR RATED RUNNING CURRENT 9.10 11.7 MOTOR OUTPUT 5500 7500 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50...

- Page 150 Electrical Data - Cooling Only (R407C) MODEL A4RT60A A4RT80A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 1200 EVAPORATOR MOTOR RATED RUNNING CURRENT MOTOR OUTPUT 1100 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 220 ~ 240 / 1 / 50 380 ~ 415 / 3 / 50 RATED INPUT POWER CONDENSER...

- Page 151 Electrical Data - Cooling Only (R407C) MODEL A4RT150A A4RT200A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 2200 3500 EVAPORATOR MOTOR RATED RUNNING CURRENT 3.80 MOTOR OUTPUT 2200 3700 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER...

- Page 152 Electrical Data - Cooling Only (R407C) MODEL A4RT360A A4RT420A INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 5870 7500 EVAPORATOR MOTOR RATED RUNNING CURRENT 11.3 13.3 MOTOR OUTPUT 5107 6525 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50...

- Page 153 Electrical Data - Heat pump (R407C) MODEL A4RT60AR A4RT80AR INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER EVAPORATOR* MOTOR RATED RUNNING CURRENT 1.57 MOTOR OUTPUT 1100 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 220 ~ 240 / 1 / 50 380 ~ 415 / 3 / 50 RATED INPUT POWER CONDENSER*...

- Page 154 Electrical Data - Heat pump (R407C) MODEL A4RT150AR A4RT200AR INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 1650 2700 EVAPORATOR* MOTOR RATED RUNNING CURRENT 3.50 MOTOR OUTPUT 2200 3700 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER...

- Page 155 Electrical Data - Heat pump (R407C) MODEL A4RT360AR A4RT420AR INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50 RATED INPUT POWER 5870 7500 EVAPORATOR* MOTOR RATED RUNNING CURRENT 11.3 13.3 MOTOR OUTPUT 5107 6525 POLES INSULATION GRADE POWER SOURCE V/Ph/Hz 380 ~ 415 / 3 / 50...

- Page 156 10. WIRING DIAGRAMS Cooling Only ART 55A ARRANGEMENT...

- Page 157 A(4)RT 60A ARRANGEMENT...

- Page 158 A(4)RT 80/100/120A ARRANGEMENT...

- Page 159 A(4)RT 150/200A ARRANGEMENT...

- Page 160 A(4)RT 250/300A ARRANGEMENT...

- Page 161 A(4)RT 360/420A ARRANGEMENT...

- Page 162 Heat Pump ART 55AR ARRANGEMENT...

- Page 163 A(4)RT 60AR ARRANGEMENT...

- Page 164 ART 80/100AR ARRANGEMENT...

- Page 165 A4RT80/100AR ARRANGEMENT...

- Page 166 A(4)RT 120AR ARRANGEMENT...

- Page 167 ART 150/200AR ARRANGEMENT...

- Page 168 A4RT 150/200AR ARRANGEMENT...

- Page 169 A(4)RT 250/300AR ARRANGEMENT...

- Page 170 A(4)RT 360/420AR ARRANGEMENT...

- Page 171 11. SERVICING & MAINTENANCE For Superior Performance And Lasting Warning Durability, Please Do Not Forget To 1.Do not wash the unit with water. If washed with water, electrical shock may be caused. Conduct Proper And Regular 2.Turn off power source. Maintenance.

-

Page 172: Transferring Work And Construction

When The Air Conditioner Is Not To Be Used For A Long Time If the air conditioner is not to be used for a long time due to seasonal change, etc., Please do the following work. 1. The power supply switch is turned off. If the power supply is kept on, several watts or several tends of watts will be wasted. - Page 173 Consideration Of The Noise (1) Take sufficient measures against noise when installing the air conditioners at hospitals or communications related businesses. (2) If the air conditioner is used in any of the above-mentioned environments, frequent operational failure can be expected. It is advisable to avoid these type of installation sites. For further details, consult with your dealer.

-

Page 174: Troubleshooting

12. TROUBLESHOOTING When a malfunction of the air conditioner unit is detected, immediately switch off the main power supply before proceeding with the following troubleshooting procedures. The following are common fault conditions and simple troubleshooting tips. If any other fault conditions which are not listed occur, contact your nearest local dealer. - Page 175 By means of pressure readings: 1. Overcharged with refrigerant. 2. Non-condensable gases in refrigerant circuit (e.g. air) 3. Obstructed air-intake / discharge. 4. Hot air short circuiting in outdoor unit. 1. Poor compression / no compression (compressor defective) 2. Reversing valve leaking. 1.

- Page 176 By Means of Diagnostic Flow Chart: Generally, there are two kinds of problems, i.e. starting failure and insufficient cooling/heating. “Starting failure” is caused by electrical defect while improper application or defects in refrigerant circuit causes “Insufficient cooling / heating”. i) Diagnosis of Electric Circuit : Faulty : Check : Cause...

- Page 177 ii ) Diagnosis of Refrigerant Circuit / Application There might be some causes where the unit starts running but does not perform satisfactorily, i.e. insufficient cooling. Judgement could be made by measuring temperature difference of indoor unit’s intake and discharge air as well as running current.

- Page 178 Insufficient heating Indoor / outdoor coil dirty Clean the coil Restricted (clogged) circulation Clean the filter Indoor air filter dirty Fan motor malfunction Change or repair the motor Obstruction at air inlet / outlet of indoor / outdoor Remove the obstruction unit High heating Windows / doors wide...

- Page 179 While upmost care is taken in ensuring that all details in the publication are correct at time of going to press, we are constantly striving for improvement and therefore reserve the rights to alter model specifications and equipment without prior notice. Details of specifications and equipment are also subject to change to suit local conditions and requirements and not all models are available in every market.

- Page 180 Revision History List Manual Rooftop packaged Air Conditioners ART-A_(i) Amendment on Revision Subject Date Manual’s Page No. 1. Changes on Blower Curve 54 to 58 10.10.2011 2. Changes on Blower Flange Dimension 1. Changes on Blower Flange Dimension 28.11.2011 1. Update on Product Line Up 2, 3 2.

Need help?

Do you have a question about the ART 55 A and is the answer not in the manual?

Questions and answers