Summary of Contents for Contec AD12-64(PCI)

- Page 1 AD12-64(PCI) AD12-16(PCI) 64/16 Channel Analog to Digital Input Board for PCI User’s Guide...

-

Page 2: Trademarks

Copyright 1999 CONTEC Co., LTD. ALL RIGHTS RESERVED No part of this document may be copied or reproduced in any form by any means without prior written consent of CONTEC Co., LTD. CONTEC Co., LTD. makes no commitment to update or keep current the information contained in this document. -

Page 3: Product Configuration

Check the contents to make sure that you have everything listed above. If you do not have all the items, contact your distributor or CONTEC group office where you purchased. Note! Do not remove the board from its protective packaging until the computer case is open and ready for installation. -

Page 4: Table Of Contents

Table of Contents Copyright ................i Trademarks ................i Product Configuration ............. ii 1. Introduction .............1 Features.................1 Limited Three-Year Warranty........3 How to Obtain Service ..........3 Liability .................3 About this Manual ............4 2. Setup ............... 5 Setup Components of the Board........5 Names of Components ..........5 Setting on Board Jumpers and Switch ......6 Setting the Board ID.............6 Setting procedure............6... - Page 5 4. Functions and Operating Procedures ......31 Functional Overview............31 Description ..............31 Analog Input Function ..........31 Initialization process ..........33 Specifying sampling conditions........34 Specifying input range..........36 Setting internal sampling clock .........38 Starting sampling operation ........39 Feeding conversion data ..........40 Details of analog input status ........42 Digital input function ..........44 Digital output function ..........44 Interrupt function ............45...

- Page 6 List of Figures Figure 2.1. Names of Components..........5 Figure 2.2. Board ID Setting (SW1) ........... 6 Figure 3.1. AD12-64(PCI) CN1 Pin Assignments to Signals ..21 Figure 3.2. AD12-16(PCI) CN1 Pin Assignments to Signals ..23 Figure 3.3. Connection for the Single-ended Input (via a Flat Cable)..............

- Page 7 List of Tables Table 4.1. Input range and setting data ........36 Table 4.2. Example conversion data in a ±10 –volt range conversion.............. 40 Table 4.3. Output port list ............51 Table 4.4. Input port list ............52 Table 4.5. Command list............53 Table 6.1.

-

Page 8: Introduction

Introduction 1. Introduction Thank you for purchasing our non-insulated type analog input board. The product is a PCI-compliant analog input board, which is provided with analog input function for converting analog signals into digital signals, digital input/output function, and programmable timer function. - Page 9 Introduction - Digital input/output The board is capable of four TTL-level digital inputs and four TTL-level digital outputs. - Programmable timer function The board is provided with an independent programmable timer. The timer allows generating interrupts and outputting count-up signals at regular intervals. The timer can be monitored on the basis of status without using interrupt capability.

-

Page 10: Limited Three-Year Warranty

Please obtain a Return Merchandise Authorization Number (RMA) from the CONTEC group office where you purchased before returning any product. * No product will be accepted by CONTEC group without the RMA number. Liability The obligation of the warrantor is solely to repair or replace the product. -

Page 11: About This Manual

Introduction About this Manual This manual consists of the following chapters : Chapter 1 Introduction Chapter 2 Setup This chapter explains how to set up the board and to set its on-board switch before it can be used. Chapter 3 Connecting an External Device This chapter describes the interface connector of the board and provides precautions on the signal... -

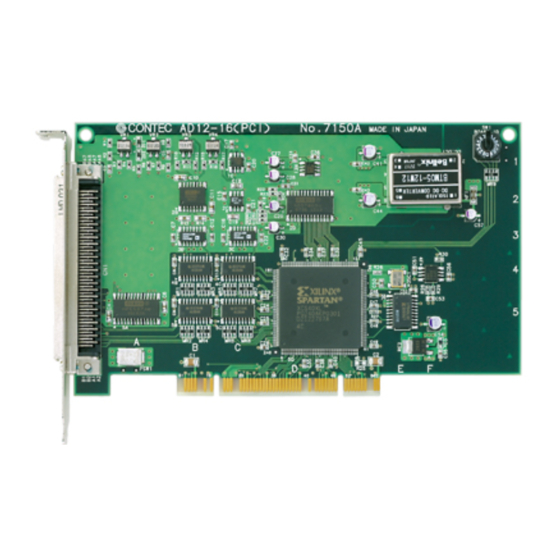

Page 12: Setup

Setup 2. Setup Setup Components of the Board Names of Components Board ID setting switch BOARD ID Analog input adjusting trimmers Signal connector Figure 2.1. Names of Components Note that the switch setting in the illustration is the factory default. AD12-64(PCI), AD12-16(PCI) -

Page 13: Setting On Board Jumpers And Switch

Setup Setting on Board Jumpers and Switch Setting the Board ID If you install two or more same type boards into one personal computer, set their respective board IDs to distinguish them. Assign a different value to each of the boards. The board IDs can be set from 0 to F to identify up to sixteen boards. -

Page 14: Setting Up The Board

Insert the attached FD into the disk drive, then select [Next>]. (7) In the [Windows driver file search for the device] dialog box, check that "CONTEC Co., Ltd. - AD12-x(PCI)" and "AIO_PI0.INF" in the [Location of driver] has been listed, then select [Next>]. - Page 15 (7) In the next dialog box, select a radio button of [Display a list of all the drivers in a specific location, so you can select the driver you want.], then select [Next>]. (8) In the next dialog box, select "CONTEC Co., Ltd. - AD12-x(PCI) " from [Models], then select [Next>]. AD12-64(PCI), AD12-16(PCI)

- Page 16 (9) In the [Windows driver file search for the device] dialog box, check that "CONTEC Co., Ltd. - AD12-x(PCI)" and "CONTEC~*.INF" in the [Location of driver] has been listed, then select [Next>]. (* is a number which the OS assigned.) (10) In the next dialog box, check the "Windows has finished...

- Page 17 (1) Select [System] from [Control Panel] and then open [Device Manager]. (2) Double-click on [Multi-function adapters] folder. (3) Double-click on [CONTEC Co., Ltd. - AD12-x(PCI)] folder to open "Property" screen. (4) Select [Resource]. Verify types and settings of resources, and there is no conflict.

-

Page 18: Installing For Windows 95

Setup Installing for Windows 95 Installing the board hardware Before the board can be used under the Windows 95 operation system (OS), the OS must recognize the assigned I/O address range and the interrupt level (IRQ) of this board and register these information into OS itself. - Page 19 Setup Procedure for use under Windows 95 version 4.00.950 or 4.00.950a : (1) Set the board ID. (2) Be sure to check that the personal computer is off, then plug the board into a PCI bus slot in the personal computer. (3) Turn the personal computer on to start up Windows 95.

- Page 20 Setup Procedure for use under Windows 95 version 4.00.950B or 4.00.950C : (1) Set the board ID. (2) Be sure to check that the personal computer is off, then plug the board into a PCI bus slot in the personal computer. (3) Turn the personal computer on to start up Windows 95.

- Page 21 (7) The [Select Hardware Type] dialog box will then appear. In [Select Hardware Type to Install], select [Other Devices]. (8) In the [Select Device] dialog box that appears, select [CONTEC] from [Manufacturers] and select [CONTEC Co., Ltd. - AD12-x(PCI)] from [Models]. (9) The [Change System Settings] dialog box appears. Follow the messages to restart the computer.

- Page 22 Setup For installing the third board and later, follow the same steps as those for installing the second one. Before you can install the third board or later, all of the already installed boards must be in the PCI bus slots. Notes! - The second board cannot be properly installed unless the resources (I/O addresses and interrupt level) for the board can...

- Page 23 Setup Method of installing two or more Boards (For use under Windows 95 version 4.00.950B or 4.00.950C) Follow the procedure below to install two boards for use under Windows 95 version 4.00.950B or 4.00.950C. (1) Check the board ID of the first board. Then plug it into a PCI bus slot.

- Page 24 (1) Select [System] from [Control Panel] and then open [Device Manager]. (2) Double-click on [Multi-function adapters] folder. (3) Double-click on [CONTEC Co., Ltd. - AD12-x(PCI)] folder to open "Property" screen. (4) Select [Resource]. Verify types and settings of resources, and there is no conflict.

-

Page 25: Installing For Windows Nt

Setup Installing for Windows NT Installing the board requires separately priced CONTEC driver software. Follow the procedure below to install the board. Verifying PC settings Be sure that [PnP OS] is either [disabled] or set to [not to use] in the PC's BIOS setup. -

Page 26: Installing For Other Os System

Setup Support software CONTEC provides following driver software for Windows NT. API-PAC(W32) Ver. Aug. 1999 or later. The above driver software supports simultaneous use of up to 16 boards. The API-PAC(W32) does not necessarily support all functions of the board. Make sure the specifications of the driver software before purchase. - Page 27 Setup Checking resources Before operating the board, be sure to check the personal computer resources (I/O addresses and interrupt level) assigned to the board. For PCI compatible (Plug and Play Compliant) board, free resources among the personal computer resources are assigned automatically upon activation of the personal computer.

-

Page 28: Connecting An External Device

Connecting an External Device 3. Connecting an External Device Interface Connector Connect the board to an external device using the on-board interface connector (96-pin half-pitch male connector designated as CN1). AD12-64(PCI) CN1 Pin Assignments to Signals [49] Analog Input63/31[-] Analog Input59/27[-] Analog Input55/31[+] Analog Input51/27[+] Analog Input62/30[-]... - Page 29 Connecting an External Device Analog Input0 ~ Analog Input63 indicate signals in single-ended input mode, while Analog Input0[+] ~ Analog input31[+] and Analog Input0[-] ~ Analog Input31[-] indicate signals in differential input mode. Reference Mounted connector: PCR-E96LMD (HONDA TSUSHIN KOGYO CO., LTD.) equivalent Applicable connector: PCR-E96FA (HONDA TSUSHIN KOGYO CO., LTD.)

-

Page 30: Ad12-16(Pci) Cn1 Pin Assignments To Signals

Connecting an External Device AD12-16(PCI) CN1 Pin Assignments to Signals [49] N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C. Analog Ground Analog Ground Analog Ground Analog Ground N.C. N.C. N.C. N.C. N.C. N.C. - Page 31 Connecting an External Device Reference Mounted connector: PCR-E96LMD (HONDA TSUSHIN KOGYO CO., LTD.) equivalent Applicable connector: PCR-E96FA (HONDA TSUSHIN KOGYO CO., LTD.) equivalent AD12-64(PCI), AD12-16(PCI)

-

Page 32: Connecting The Analog Input Signals

Connecting an External Device Connecting the Analog Input Signals The board allows input of analog signals in both single-ended mode and differential mode, and different connection systems to signals are employed for each input mode. This section gives examples of connecting the analog input signals to the board using a flat cable or a shielded cable. - Page 33 Connecting an External Device Notes! - Frequency components higher than 1MHz contained in a signal may cause crosstalk across channels. - Analog input signals may be interfered if a connection cable is susceptible to noises. Keep a connection cable away from potential sources of noises.

-

Page 34: Connection Example In Differential Input Mode

Connecting an External Device Connection example in differential input mode The following example uses a flat cable. Connect each analog input channel [+] of CN1's to a signal, and connect [-] input to ground of signal source. Then connect analog ground with ground of signal source. - Page 35 Connecting an External Device Notes! - Frequency components higher than 1MHz contained in a signal may cause crosstalk across channels. - Conversion data is indefinite when analog ground is unconnected. - Analog input signals may be interfered if a connection cable is susceptible to noises.

-

Page 36: Connecting The Digital Input/Output Signals And Control Signals

Connecting an External Device Connecting the Digital Input/Output Signals and Control Signals This section gives an example of connecting digital input/output signals and control signals between the board and an external device using a flat cable. To the control input signals (external sampling clock input and external trigger input), connect TTL-level signals. - Page 37 Connecting an External Device - Control input signals are TTL-level signals. Do not connect any signal outside the range from 0 to +5V; doing so can result in a fault in the board. - Do not plug or unplug the cable to/from the interface connector with the PC or external device powered on;...

-

Page 38: Ad12-64(Pci), Ad12-16(Pci)

Functions and Operating Procedures 4. Functions and Operating Procedures Functional Overview The AD12-16(PCI) or AD12-64(PCI) board consists of the following four independent function blocks: (1) Analog input function (2) Digital input function (3) Digital output function (4) Interrupt function Description Analog Input Function By outputting a sampling start command, the board converts an analog input signal into 12 bit digital data under specified sampling... -

Page 39: Figure 4.1. Basic Operation For Analog Input

Functions and Operating Procedures sampling start sampling start sampling clock input channel input channel a. Software mode - Single channel mode c. Clock mode - Single channel mode sampling start sampling start sampling clock input channel input channel b. Software mode - Multichannel mode d. -

Page 40: Initialization Process

Functions and Operating Procedures Initialization process The process initializes the analog input function. The initialization command clears all settings and statuses to intial values and sets the board to "initial status," as it is when the PC has been recycled or the reset button has been pressed. The following are control ports for initialization: Output Command... -

Page 41: Specifying Sampling Conditions

Functions and Operating Procedures Specifying sampling conditions Sampling conditions must be defined. Sampling conditions are specified by outputting a command for setting sampling conditions, followed by outputting setting data. Output Command (+08h) Setting data 0 (conditions) Channel Sampling Sampling Analog input (+0ch) Mode Clock Source... - Page 42 Functions and Operating Procedures Sampling mode [D0] Configure mode of sampling operation. Select "Software Command" for performing one sampling operation on specified channel or select "Clock" for performing periodical sampling using a clock signal. Sampling Mode [0] : Software Command *Initial status [1] : Clock The following are examples of initialization settings described in...

-

Page 43: Specifying Input Range

Functions and Operating Procedures Specifying input range "Input range" is the voltage range for inputting analog signals. Input ranges are specified for each channel. The voltages within the specified range are converted into a digital signal, in 12 bit resolution. Input ranges are specified for up to 64 channels. - Page 44 Functions and Operating Procedures The following are examples of initialization settings described in high-level languages: Microsoft C Microsoft QBASIC outp( ADR+8, 2 ); ADR+8, 2 for( i=0; i<64; i++ ){ I=0 TO 63 outp( ADR+12, i ); ADR+12, I outp( ADR+13, 0x04 ); ADR+13, &H04 NEXT Reference...

-

Page 45: Setting Internal Sampling Clock

Functions and Operating Procedures Setting internal sampling clock Specify sampling period (clock data) if "Clock mode" and "Internal sampling clock" have been selected as sampling conditions. Since clock data is indefinite under initial status, be sure to set up clock data when using internal sampling clock. -

Page 46: Starting Sampling Operation

Functions and Operating Procedures The following are examples of initialization settings described in high-level languages: The examples specify a range from 0 to 10 volts for all channels. Microsoft C Microsoft QBASIC outp( ADR+8, 3 ); OUT ADR+8, 3 outp( ADR+12, ClockData0 ); OUT ADR+12, ClockData0 outp( ADR+13, ClockDATA1 );... -

Page 47: Feeding Conversion Data

Functions and Operating Procedures Reference Sample software : AI1.C, AI2.C, AI3.C, AI4.C, AII.C, AII98.C Feeding conversion data Before feeding conversion data, verify that the conversion data is contained in a given register. Conversion data can be fed from the register even during conversion operation. The figure on the right shows the Start procedures for inputting conversion data. - Page 48 Functions and Operating Procedures The following shows control ports for feeding conversion data. Input Analog input status (+06h) Sampling Data Over Data Read Conversion Clock Error Write Error Busy Status Enable Analog input data (lower) (+00h) Conversion Conversion Conversion Conversion Conversion Conversion Conversion...

-

Page 49: Details Of Analog Input Status

Functions and Operating Procedures Details of analog input status Analog input status indicates a state of A/D conversion operation. Input Analog input status (+06h) Sampling Sampling Data Over Data Read Sampling Clock Error Clock Input Write Error Enable Busy Status Sampling busy status (BSY) [D0] Indicates that the board is currently sampling. -

Page 50: Figure 4.6. Timing For Setting/Resetting Data Overwrite Error Status

Functions and Operating Procedures Data overwrite error status (DOWE) [D2] Value "1" set to the status indicates that readable conversion data has been overwritten during clock-mode operation, because intervals of sampling clock are longer than data input intervals. If this status is detected, sampling clock interval must be expanded or reading intervals must be shortened. -

Page 51: Digital Input Function

Functions and Operating Procedures Digital input function The digital input function feeds activ-high 4-point TTL-level digital signals. The following shows control ports for digital input. "1" is input if digital input pints are unconnected. Input Digital input data (+05h) The following are examples of sampling start settings described in high-level languages: Microsoft C Microsoft QBASIC... -

Page 52: Interrupt Function

Functions and Operating Procedures Interrupt function The board is allowed to use hardware interrupt for a PC. An interrupt level specified by PCI BIOS is used for interrupt. When using the interrupt function, interrupt sources can be selected from the following statuses in advance. (Two or more statuses can be selected.) Status Description... - Page 53 Functions and Operating Procedures The following are examples of timer period settings described in high-level languages: Microsoft C outp( ADR+8, 4 ); outp( ADR+12, InterruptFactor0 ); outp( ADR+13, InterruptFactor1 ); Microsoft QBASIC ADR+4 ADR+12 InterruptFactor0 ADR+13 InterruptFactor1 Reference Sample software : AII.C, TI.C, EXTI.C, AII98.C, TI98.C, EXTI98.C AD12-64(PCI), AD12-16(PCI)

-

Page 54: External Trigger

Functions and Operating Procedures External trigger An interrupt request signal can be generated by a falling edge of an external TTL-level signal. Even if it is not specified as an interrupt source, feeding the status enables monitoring of the operation. An external trigger is allowed to enable and disable inputting of external signal by opening and closing an external trigger gate. -

Page 55: Timer

Functions and Operating Procedures Timer The timer generates interrupt signals periodically. The timer is completely independent of a sampling clock. Even if it is not specified as an interrupt source, feeding the status enables monitoring of the operation. Data specified upon initialization is indefinite. - Page 56 Functions and Operating Procedures The following shows control ports for starting timer: Output Command (+08h) The following shows control ports for stopping timer: Output Command (+08h) The following are examples of timer period settings described in high-level languages: Microsoft C outp( ADR+8, 5 );...

-

Page 57: Status Of External Trigger And Timer

Functions and Operating Procedures Status of external trigger and timer Input status for timer and external timer indicates status for timer counting up and input of external trigger. Input Timer/External trigger status Timer Timmer Ext. Trigger Ext. Trigger Ext. Trigger (+07h) O/R Status Status... -

Page 58: I/O Address Map List

Functions and Operating Procedures I/O address map list Output ports Table 4.3. Output port list AD12-64(PCI), AD12-16(PCI) -

Page 59: Table 4.4. Input Port List

Functions and Operating Procedures Input ports Table 4.4. Input port list AD12-64(PCI), AD12-16(PCI) -

Page 60: Command List

Functions and Operating Procedures Command list The following are commands to "Output port +8" on AD12-64(PCI)/AD12-16(PCI). Table 4.5. Command list Function Initialization Setup for sampling conditions Setup for input range Setup for internal sampling clock Setup for interrupt source Setup for timer period Start timer Stop timer Open external trigger gate... - Page 61 Functions and Operating Procedures AD12-64(PCI), AD12-16(PCI)

-

Page 62: Sample Program For Ms-Dos

Sample Program for MS-DOS 5. Sample Program for MS-DOS Sample programs are provided for introducing basic use of the board. The provided setup disk contains the following sample programs: AI1.C Analog input function sample program source file (Software - single channel mode) AI1.EXE Analog input function sample program (Software - single channel mode) -

Page 63: Preparation

Sample Program for MS-DOS TI.C Interrupt function sample program source file (Interrupt source : Timer Status) TII.EXE Interrupt function sample program (Interrupt source : Timer Status) EXTI.C Interrupt function sample program source file (Interrupt source : Ext. Trigger Input) EXTI.EXE Interrupt function sample program (Interrupt source : Ext. - Page 64 Sample Program for MS-DOS Analog input function This section describes programs AI1.EXE, AI2.EXE, AI3.EXE, and AI4.EXE. The program samples all channels in specified mode, and displays analog data on screen. (AI3.EXE samples channel 0 only.) A start-up command is the following (Exemplified by AI1.EXE): AI1 -B [board ID] - B: board ID ("0"...

- Page 65 Sample Program for MS-DOS Digital output function Outputs values of any of four digital outputs and displays output status. A start-up command is the following: DO -B [board ID] - B: board ID ("0" if omitted) If a board ID is not "0," enter board ID (decimal) following "-B". The following is an example startup command and display on screen.

-

Page 66: Calibration Procedures

Calibration Procedures 6. Calibration Procedures This program calibrates the analog input and analog output functions under MS-DOS. You must follow the instructions of this calibration program to calibration. Voltage standard Figure 6.1. Instruments for Calibration Connect the output from the standard voltage generator to the 1ch pin. - Page 67 Calibration Procedures AD12-64(PCI), AD12-16(PCI)

-

Page 68: System Reference

System Reference 7. System Reference Specifications Table 7.1. Specifications Item AD12-64(PCI) AD12-16(PCI) Analog input Number of input 64 single-ended input channels or 32 differential 16 single-ended input channels or 8 differential input channels (specified by software) input channels (specified by software) channels Input range Non-insulated bipolar ±10V, ±5V, ±2.5V, ±1.25V... -

Page 69: Block Diagram

System Reference External Dimensions 176.4 [mm] Figure 7.1. Board Dimensions Block Diagram 4 Digital Input / 4 Digital Output 64/16 single-end / External Sampling Clock Input / 32/8 differential External Trigger Input Analog Inputs Timer Output / Sampling Busy Output Multiplexer Instrument Amplifre... -

Page 70: External Sampling Clock Operation Timing

System Reference External Sampling Clock Operation Timing tSFS tHFS External Sampling Clock tDEC Conversion Start Figure 7.3. External Sampling Clock Operation Timing Diagram Table 7.2. Description for each portion Item Symbol Time (nsec) Falling setup time for external sampling clock siganl 100nsec Hold time for external sampling clock signal 100nsec... - Page 71 System Reference AD12-64(PCI), AD12-16(PCI)

-

Page 72: Index

Index 8. Index Analog Input, 31 Input ports, 52 Analog input mode, 34 input range, 36 interrupt sources, 45 Block Diagram, 62 Board ID, 6 Liability, 3 Calibration Procedures, 59 Multi-channel mode, 31 Channel mode, 34 clock data, 38 Names of Components, 5 Clock mode, 31 Command list, 53 Obtain Service, 3... - Page 73 Index Sample Program, 55 Sampling Clock, 63 Sampling clock source, 34 sampling conditions, 34 Sampling mode, 35 Setup, 1, 5 Single-channel mode, 31 single-ended input, 25 Software mode, 31 Specifications, 61 Support software, 10, 17, 19 SW1, 6 this Manual, 4 Timer, 48 Warranty, 3 AD12-64(PCI), AD12-16(PCI)

-

Page 74: Ad12-64(Pci), Ad12-16(Pci)

Index AD12-64(PCI), AD12-16(PCI) - Page 75 A-46-068 LZJ3711 021011 [991104]...

- Page 76 3-9-31, Himesato, Nishiyodogawa-ku, Osaka 555-0025, Japan : +81 (6) 6477-5219 Fax : +81 (6) 6477-1692 E-mail : intsales@osaka.contec.co.jp U.S.A. : CONTEC MICROELECTRONICS U.S.A. INC. 744 South Hillview Drive, Milpitas, CA 95035 U.S.A. : +1 (408) 719-8200 Fax : +1 (408) 719-6750 E-mail : tech_support@contecusa.com EUROPE : CONTEC MICROELECTRONICS EUROPE B.V.

Need help?

Do you have a question about the AD12-64(PCI) and is the answer not in the manual?

Questions and answers