Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for DeDietrich GT 430

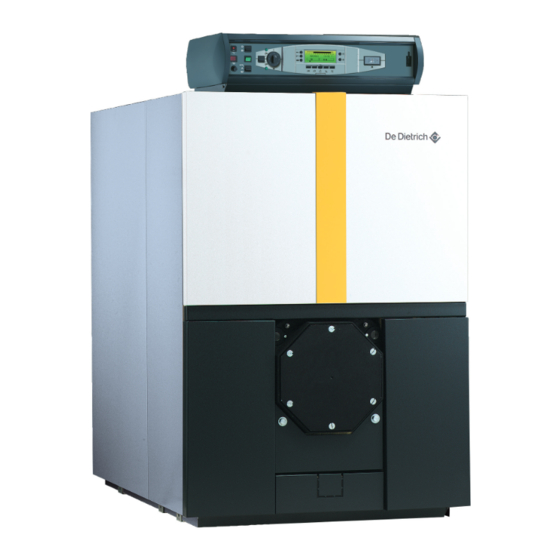

- Page 1 Fuel oil/gas boilers GT 430 Installation and Service Manual 300011893-001-02...

- Page 2 The appliance complies with the standard model described in declaration of compliance . It is manufactured and distributed pursuant to the requirements of european directives. The original of the declaration of compliance is available from the manufacturer. C002721-A GT 430 05/03/2013 - 300011893-001-02...

-

Page 3: Table Of Contents

Filling the system ..................25 05/03/2013 - 300011893-001-02 GT 430... - Page 4 Spare parts - GT 430 ........

-

Page 5: Introduction

Explain the installation to the user. If a maintenance is necessary, warn the user of the obligation to check the appliance and maintain it in good working order. Give all the instruction manuals to the user. 05/03/2013 - 300011893-001-02 GT 430... -

Page 6: User's Liability

The boilers and hot water tanks are designed and manufactured in accordance with the sound engineering practice, as requested in article 3.3 of the directive 97/23/EC, it is certified by compliance with the directives 90/396/EC, 92/42/EC, 2006/95/EC and 2004/108/EC. GT 430 05/03/2013 - 300011893-001-02... -

Page 7: Safety Instructions And Recommendations

The appliance should be on Summer or Antrifreeze mode rather than switched off to guarantee the following functions: - Anti blocking of pumps. - Antifreeze protection. - Protection against corrosion on domestic hot water tanks fitted with a titanium anode. 05/03/2013 - 300011893-001-02 GT 430... -

Page 8: Technical Description

3 Technical description 3.1 General description The boilers of the GT 430 range are pressurised hot water boilers - Heating body in cast iron. designed for connecting to a flue pipe which require a separate - S3, B3, K3 or DIEMATIC-m3 control panel. -

Page 9: Diematic-M3 Control Panel

A version of the B3 control panel with lateral attachment is also comprising the settings, control and safety devices allowing the boiler available. to operate autonomously. This panel makes it possible to give priority to DHW. 05/03/2013 - 300011893-001-02 GT 430... -

Page 10: Technical Specifications

Natural gas = 9.5% Maximum operating pressure: 6 bar ² Thermostat adjustable from 30 to 90°C Ambient temperature: 20 °C Safety thermostat: 110 °C Boiler GT 430-8 GT 430-9 GT 430-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 Useful output... -

Page 11: Boilers For Following Countries: Germany, Austria, Serbia, Slovenia

Natural gas = 9.5% Maximum operating pressure: 6 bar ² Thermostat adjustable from 30 to 90°C Ambient temperature: 20 °C Safety thermostat: 110 °C Boiler GT 430-8 GT 430-9 GT 410-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 Useful output... -

Page 12: Boilers For Following Countries: Switzerland

Natural gas = 9.5% Maximum operating pressure: 6 bar ² Thermostat adjustable from 30 to 90°C Ambient temperature: 20 °C Safety thermostat: 110 °C Boiler GT 430-8 GT 430-9 GT 410-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 Useful output... -

Page 13: Boilers For Following Countries: Russia

Natural gas = 9.5% Maximum operating pressure: 6 bar ² Thermostat adjustable from 30 to 90°C Ambient temperature: 20 °C Safety thermostat: 110 °C Boiler GT 430-8 GT 430-9 GT 410-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 Useful output... -

Page 14: Boilers For Following Countries: Algeria, Bulgaria, China, Cyprus, Denmark, Finland, Greece, Morocco, Norway, Romania, Sweden, Tunisia

Natural gas = 9.5% Maximum operating pressure: 6 bar ² Thermostat adjustable from 30 to 90°C Ambient temperature: 20 °C Safety thermostat: 110 °C Boiler GT 430-8 GT 430-9 GT 410-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 Useful output... -

Page 15: Installation

(hospitals, stores, etc.). liquefied hydrocarbon installations situated inside residential buildings and their annexes. Certificate of compliance (only concerns GT 430 - NF P 45-204 standards boilers fitted with a gas burner) Gas installation, (formerly DTU 61-1, gas installations: April 1982, In application of Article 25 of the Order of 27 April 2009 amending the addendum no 1: July 1984). -

Page 16: Choice Of The Location

- Front section: 455 - Intermediate section: 530 Rp 2" draining outlet Equivalent diameter (in mm): 573 Sludge removal hole Rp 2" 1/2 - plugged Boiler type GT 430-8 GT 430-9 GT 410-10 GT 430-11 GT 430-12 GT 430-13 GT 430-14 ø... -

Page 17: Position Of The Boiler

4.3.2 Position of the boiler For the assembly and because of their design, GT 430 boilers require The dimensions (in mm) correspond to the minimum recommended no special base. Their closed furnace system means that the floor dimensions needed to ensure adequate accessibility around the need not have refractory properties. -

Page 18: Ventilation

New establishment: Refer to the order of 25/06/1980 (installations of more than 20 kW and less than or equal to 70 kW). Existing establishment: Refer to the order of 25/06/1980 (installations less than 70 kW). GT 430 05/03/2013 - 300011893-001-02... -

Page 19: Example Of An Installation

The example of an installation shown below does not cover every possible configuration. Its sole aim is to draw your attention to the basic rules to be respected. GT 430 boiler with domestic hot water production using an independent tank. 20 9 8219N008C... -

Page 20: Hydraulic Connections

Install a sludge decanting pot on the Sludge removal leads to the draining of large quantities of water, so return pipe, very close to the boiler. remember to refill the system after the operation. GT 430 05/03/2013 - 300011893-001-02... -

Page 21: Hydraulic Connection Of The Heating Circuit

- The water temperature in the boiler is maintained at 50°C or more: The burner can modulate down to 30% of the nominal stage. - Operation at modulated low temperature (minimum outlet temperature: 40°C); The burner can modulate down to 50% of the nominal stage. 05/03/2013 - 300011893-001-02 GT 430... -

Page 22: Safety Valve

(a) = kW Minimum safety valve flowrate must be 700 kg/h. (b) = lb/h (c) = MBtu/h (d) = Kg/h 4.5.5 Connection of the water circuit for domestic use See: Domestic hot water calorifier instructions. GT 430 05/03/2013 - 300011893-001-02... -

Page 23: Chimney Connection

In order for the boiler to operate correctly, it is imperative to respect the draught at the nozzle (= 0). Please note that GT 430 boilers have pressurised and tight furnaces and that the pressure at the connection to the chimney must not exceed 0 mbar, unless special sealing precautions have been taken, for instance in order to connect a static condenser/regenerator. -

Page 24: Fuel-Oil Or Gas Connections

- Max øB = 290 mm Ø E - Max øB = 330 mm with 4 fastenings at 15° or 45° Ø M 4.8 Electrical connections Refer to the connection instructions supplied with the control panel.. GT 430 05/03/2013 - 300011893-001-02... -

Page 25: Filling The System

05/03/2013 - 300011893-001-02 GT 430... -

Page 26: Commissioning

6.2 Precautions required if the heating is stopped when there is a risk of freezing We recommend the use of a correctly dosed antifreeze agent to prevent to the heating circuit from freezing. If this cannot be done, drain the system completely. GT 430 05/03/2013 - 300011893-001-02... -

Page 27: Checking And Maintenance

The rating plate fixed on the side of the boiler during installation is used to identify the boiler correctly and also provides the main Boiler type specifications of the boiler. Manufacturing date Year of manufacture Week of manufacture Serial no. of the appliance 05/03/2013 - 300011893-001-02 GT 430... -

Page 28: Maintenance

- Unscrew the 4 closing nuts and open the furnace door. - Brush out the inside of the furnace. - Use a vacuum cleaner to remove any soot which has accumulated in the combustion chamber. - Close the door and replace the front panel. C003593-A GT 430 05/03/2013 - 300011893-001-02... -

Page 29: Positioning Of The Baffle Plates

Boilers for following countries: France, Germany, Austria, Belgium, Spain, Estonia, Luxemburg, Poland, Portugal, Czech Republic, Serbia, Slovenia, Switzerland Boiler GT 430-8 GT 430-9 - GT 430-10 GT 430-11 - GT 430-12 GT 430-13 - GT 430-14 Upper flue ways First 8229-0010 then 8229-... -

Page 30: Cleaning The Flue Gas Box

- 5 l spray with separate reservoir, nozzle and connecting tube. The nozzles enable easy application at the back of the combustion chamber. Manual pressurisation of the reservoir. - Motor-assisted pressurisation spray with reservoir, nozzle and connecting tube. These sprays are intended for intensive use. GT 430 05/03/2013 - 300011893-001-02... -

Page 31: Cleaning The Casing Material

7.4 Cleaning the casing material Use a soapy solution and a sponge only. Rinse with clean water and dry with chamois leather or a soft cloth. 7.5 Maintenance of the burner Refer to the instructions supplied with the burner. 05/03/2013 - 300011893-001-02 GT 430... -

Page 32: Spare Parts - Gt 430

8 Spare parts - GT 430 To order a spare part, quote the reference number next to the part required 300011893-002-B Boiler body + Miscellaneous DE DIETRICH THERMIQUE S.A.S. - Spare parts centre 4 rue d’Oberbronn - F-67110 REICHSHOFFEN -... - Page 33 Casing Insulating material for body 05/03/2013 - 300011893-001-02 GT 430...

-

Page 34: Control Panels

Package MD2 Side panel - Package MD139 Separate panel - DIEMATIC-m3 control panel Package MD1 Side panel - Package MD138 Separate panel - B3 control panel Package MD3 Side panel - Package MD140 Separate panel - GT 430 05/03/2013 - 300011893-001-02... - Page 35 9495-0050 Plug 1/4" 8802-4710 Flow controller GT 409 8229-0532 Plate for combustion chamber door, no opening 8802-4712 Flow controller GT 430-10 Plate for combustion chamber door with opening ø 8229-0546 8802-4722 Flow controller GT 430-11 8802-4725 Flow controller GT 412 Plate for combustion chamber door with opening ø...

- Page 36 8229-8820 Complete cable way, left, GT 409 8229-4018 Insulating material for body - Length 600 mm 8229-8821 Complete cable way, left, GT 430-10 8229-4009 Insulating material for body - Length 800 mm 8229-8822 Complete cable way, left, GT 430-11 8229-4012...

-

Page 37: Warranty Terms

Belgium The preceding dispositions about the contractual guarantee are not exclusive of profit if the need arises for the purchaser in Belgium of the applicable legal dispositions on hidden defects. 05/03/2013 - 300011893-001-02 GT 430... - Page 38 GT 430 05/03/2013 - 300011893-001-02...

- Page 39 05/03/2013 - 300011893-001-02 GT 430...

- Page 40 +49 (0)25 72 / 9161-0 +49 (0)25 72 / 9161-102 info@remeha.de +7 (495) 221-31-51 DE DIETRICH THERMIQUE Iberia S.L.U. DE DIETRICH SERVICE www.dedietrich-calefaccion.es www.dedietrich-heiztechnik.com Freecall 0800 / 201608 Av. Princep d’Astúries 43-45 08012 BARCELONA +34 932 920 520 +34 932 184 709 DUEDI S.r.l.

Need help?

Do you have a question about the GT 430 and is the answer not in the manual?

Questions and answers