Subscribe to Our Youtube Channel

Summary of Contents for Intelligent Weighing Technology intell-lab ph series

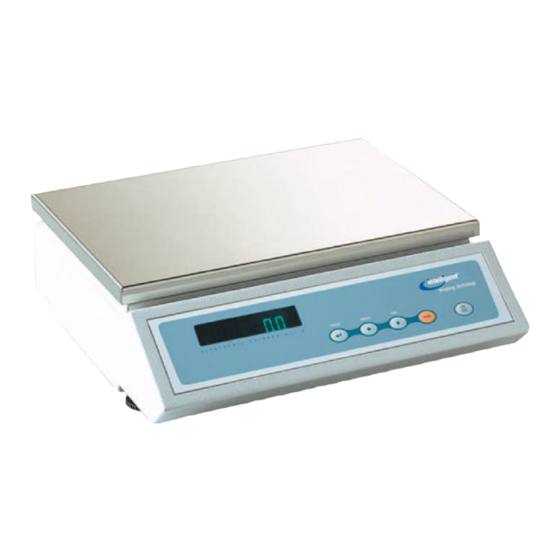

- Page 1 A Higher Level of Precision… A Higher Level of Performance ™ Intell-Lab Precision Toploading Balances PH Series User Operation Manual June, 2009...

-

Page 2: Table Of Contents

S U M M A R Y Summary ……………………………………………… ……………………. Installation instructions ..…………………………………………………… Weighing pan assembly ...………………………………………………... Keyboard and display ……………………………………………………… Inputs and outputs …………………………………………………………. Inputs and outputs balance Mod. K ………………………………… ……. Normal weighing ……………………………………………………………. Calibration ………………………………………………………………... 10-16 Tare function ……………………………………………………….…….…... -

Page 3: Installation Instructions

INSTALLATION INSTRUCTIONS Remove balance and accessories from the carton. Do not install the balance in a place with draughts, heavy thermic changes and vibrations. Place the weighing pan and the support pan on the balance (see page 4-5). ... -

Page 4: Weighing Pan Assembly

WEIGHING PAN ASSEMBLY June, 2009... - Page 5 WEIGHING PAN ASSEMBLY...

-

Page 6: Keyboard And Display

KEYBOARD AND DISPLAY Fig. 1 ELECTRONIC BALANCE Intell-Lab™ Intell-Lab™ ON/OFF key. It confirms selection from MENU key or it controls printing. It selects setup MENU’. CALIBRATION key. TARE key. Indicator of selected weight UNITS. - Page 7 9 Pin RS232 Interface Output for PC/keyboard and printer Hook for weighing under balance plan. P.S. remove hook cap. B1, B2 and B3 are screws for balance closing Fig. 2a - Bottom view...

- Page 8 ELECTRONIC BALANCE PH Series Weighing pan CONNECTOR 1 9 Pin RS232 Interface Output for PC/keyboard and printer Hook for weighing under balance plan. P.S. remove hook cap.

-

Page 9: Normal Weighing

STAND BY After having connected the balance to Intell-Lab™ AC outlet, it is now in “STAND BY” mode. To bring the balance to working conditions, press ON/OFF key. To bring it in “STAND BY” mode, press ON/OFF key again. NORMAL WEIGHING Load the good to weight on the pan and 92. -

Page 10: External Calibration

EXTERNAL CALIBRATION * * (For all models except Analytical balance). The electronic reading balance takes measurement of mass making use of B EL - - - - - - - - Intell-Lab™ ENGINEERING gravity (g). Difference in geographic area and altitude will vary gravity acceleration (g). - Page 11 will be displayed.

- Page 12 (*)Moreover, it is possible to calibrate the balance with a calibration weight higher than the one set. To perform this sort of calibration,press and keep CAL key pressed at empty pan Intell-Lab™ ENGINEERING until the acoustic alarm will be deactivated, then release the key and the following string "...

- Page 13 The balance is ready for weighing operations. NOTE: if there is an interference during calibration process, the message “ERROR” will be displayed. * (not for Analytical balances)

- Page 14 EXTERNAL CALIBRATION * * (Only for Analytical balances models). Press CAL key at empty pan. - - - - - - - - Intell-Lab™ Dashes are displayed. Intell-Lab™ As soon as calibration weight value starts to flash, load calibration weight on the pan.

- Page 15 starting from point “2”.

-

Page 16: Calibration Mode

CALIBRATION MODE * * These functions are available ONLY for models provided with servomotor and internal calibration mass. The balance effects mass measurements making use of gravity (g). Differences in geographical areas and in altitude will vary gravity acceleration (g). Therefore, in order to have precise measurements, the balance must be adjusted to local environment. - Page 17 CALIBRATION MODE SELECTION * * These functions are available ONLY for models provided with servomotor and internal calibration mass. From display zero condition, press MENU key until the message “CALIB” is C A L I B Intell-Lab™ displayed, then press key.

-

Page 18: Calibration

AUTOCALIBRATION *(AUT - CAL) / INTERNAL CALIBRATION * (I-CAL) * These functions are available ONLY for models provided with servomotor and internal calibration weight. Before effecting internal calibration, be Intell-Lab™ 0 . 0 0 sure no weight is loaded on the pan. Press CAL key at empty pan. - Page 19 ons or draughts.

-

Page 20: Tare Function

TECHNICAL CALIBRATION * * This function is available ONLY for models provided with servomotor and internal calibration mass. - - - - - - - - Intell-Lab™ Press CAL key at empty pan. Dashes are displayed. As soon as calibration weight value starts 2 0 0 G r Intell-Lab™... - Page 21 Load the container on the pan. 80. 16 MENU Press TARE key. Dashes will be displayed until stability is reached. B EL - - - - - - - - Intell-Lab™ ENGINEERING The value “0.00” will then be displayed when stability is reached. In case stability cannot be reached because of draughts, vibrations or other problems, dashes will keep on being...

- Page 22 OPTIONAL ALPHANUMERIC KEYBOARD If you have an alphanumeric keyboard, it TARE TARE A R C HELP is possible to perform tare pressing H I V . D E L E SELECT STAT. TARE/DELETE key too in the same way DOWN CLEA ESCA INSER...

-

Page 23: Alphanumeric Keyboard

MANUAL TARE FUNCTION * Having an optional alphanumeric keyboard, it is possible to insert a value of TARE TARE M. HELP DELETE ARCHIV. STAT. a known tare from the keyboard. SELECT DOWN CLEAR ESCAPE INSER FORMUL. Press TARE MAN key on the alphanumeric keyboard. -

Page 24: Weight Units

WEIGHT UNITS * From display zero condition, press MENU key until the message of unit “UNITS” is displayed. U N I T S Intell-Lab™ ENGINEERING Press key to confirm. G R A M Intell-Lab™ The unit “GRAM” will be ENGINEERING By pressing MENU key aga of unit “CARAT”... -

Page 25: Interface Selection

PC INTERFACE SELECTION Connect the balance to PC with proper cable (page 7). Intell-Lab™ ENGINEERING From display zero condition press MENU key until message “ PC-PRTR “ is displayed. Press key to confirm. Press MENU key until the message “PC” is Intell-Lab™... -

Page 26: Printer Interface Selection

PRINTER INTERFACE SELECTION Connect the balance to the printer with proper cable (page 7). Intell-Lab™ From display zero condition press MENU key until the message “ PC-PRTR “ is displayed. Press key to confirm. To select data printer mode press MENU key until the following messages will be B EL Intell-Lab™... -

Page 27: Baud Rate Selection

BAUD RATE SELECTION Press MENU key until the message ENGI NEERING “BAUD RT” is displayed. Intell-Lab™ Press key to confirm. 1 2 0 0 Intell -Lab™ ENGINEERING Select serial data baud rate (1200-2400- 4800-9600 baud) by pressing MENU key in sequence. - Page 28 Instructions 6K UK Rev 08.doc Page 23 of 46...

-

Page 29: Filters Settings

FILTERS SETTING It is possible to adapt the balance to the ambient conditions. Five settings are available: ENGINEERI NG FILTER 1 : proportion of ingredients F I L T E R conditions FILTRO 2 : very stable conditions FILTRO 3 : stable conditions FILTRO 4 : unstable conditions FILTRO 5 : very unstable conditions Press MENU key until the message... -

Page 30: Autozero Function

AUTOZERO FUNCTION Autozero is a drift automatic correction from zero. A U T O 0 Intell -Lab™ ENGINEERING Press MENU key until the message “AUTO 0” is displayed. Press Select by MENU key : A u 0 O F F Intell-Lab™... -

Page 31: Piececounting Function

PIECECOU NTING FUNCTION * From display zero condition, press MENU key until the message “ PCount “ is P C o u n t displayed. Intell-Lab™ E N G I N E E R I N G Press key to confirm. C A L Select the number of required pieces pressing MENU key repeatedly. - Page 32 If the pieces to count have a too smaller weight than balance readability, the Intell-Lab™ message “ERROR” will be displayed. It is necessary to use a balance at higher readability. If the sample weight is acceptable but not enough, the message “Add” will be Intell-Lab™...

- Page 33 AUTOMATIC UPDATING OF UNIT WEIGHT After having effected the sampling, it is possible to update the average unit weight as follows : Intell-Lab™ instead of loading all the pieces to count, load a number of pieces equal to the double of the one loaded on the pan. Wait for all the arrows to be displayed followed by a short acoustic message.

- Page 34 DISPLAY OF WEIGHT IN PIECECOUNTING CONDITION To display weight value during the counting of pieces, press MENU key. Intell-Lab™ This condition is indicated by lighting of all Intell-Lab™ display arrows. To return to piececounting condition and Intell -Lab™ proceed with counting, press MENU key again.

- Page 35 MANUAL INSERTION OF THE UNIT SAMPLE WEIGHT * It is possible to use the optional alphanumeric keyboard to insert weight of the unit sample, if it is known. M A N U A L Intell-Lab™ From zero condition on the display press ENGINEERING MENU key until the message “Pcount”...

-

Page 36: Range Function

V-RANGE FUNCTION * * This function is available ONLY for models double scale VR. 18 20. 2 Intell-Lab™ To activate V-RANGE function, press ENGINEERING ON/OFF key. Now a tare operation is automatically performed, and at the end it is possible to 0.0 0 Intell-Lab™... -

Page 37: Determination Of Solid Density For

DETERMINATION OF SOLID DENSITY FOR BALANCES WITH PROPER OPTIONAL SOFTWARE * Balance program allows to determine solid density through four steps: TARE IN AIR; TARE IN WATER; SOLID WEIGHING IN AIR; SOLID WEIGHING IN WATER. STORAGE OF TARE IN AIR Tare in air (weight of the small basket in air) is about zeroing of small basket weight in air. - Page 38 SERIAL INTERFACE RS 232 1) General characteristics The balance sends the value displayed in serial form RS232C, allowing to print weight on PC monitor or on a serial printer. In case of connection with PC, it is also able to get commands, always in RS232C format, that allow to effect all operations with balance keys through PC keyboard.

- Page 39 Possible non-meaningful zeroes are spaces.

- Page 40 ATTENTION When the balance is in over range condition, weight value transmitted is replaced by strings “over” and “under” (only if PC output has been selected). 5) Connecting balance to PC For connecting balance to PC, use connector 1 on the rear side of the balance as shown in the following figure : Balance Side...

- Page 41 alphanumeric keyboard.

- Page 42 Connectors located on the rear panel of the balance Connector 2 : Connector 1 : Supply Keyboard/PC/ connector Printer Fig. 2 Rear view panel of balance Mod. K...

- Page 43 WEIGHING PAN ASSEMBLY Fig. 3 CONNECTOR 1 FOR KEYBOARD OR PC OR PRINTER = +5v for keyboard pin 1 = Tx signal (PC) = pin 2 Rx signal (PC) = pin 3 June, 2009 busy signal pin 4 = Gnd pin 5 pin 4-6 = connected one with other by PC transmission...

-

Page 44: Warranty Conditions

WARRANTY CONDITIONS 1. Duration of warranty is of one (1) year from the date of purchase proved by invoice concerning the product or by delivery note. 2. Warranty covers all parts resulting defective at the origin. It does not cover mechanical or electronic parts damaged by wrong installation, tampering or incorrect use. - Page 45 © Intelligent Weighing Technology, Inc. All rights reserved worldwide. The information contained herein is the property of Intelligent Weighing Technology, Inc. and is supplied without liability for errors or omissions. No part may be reproduced or used escept as authorized by contract or other written permission. The copyright and the foregoing restriction on reproduction and use extend to all media in which the information may be...

Need help?

Do you have a question about the intell-lab ph series and is the answer not in the manual?

Questions and answers