GE Monogram ZBD6400 Series Technical Service Manual

Hide thumbs

Also See for Monogram ZBD6400 Series:

- Installation instructions manual (16 pages) ,

- Owner's manual (32 pages) ,

- Owner's manual (32 pages)

Summary of Contents for GE Monogram ZBD6400 Series

- Page 1 GE Consumer Home Services Training TECHNICAL SERVICE GUIDE Monogram Dishwasher MODEL SERIES: ZBD6400 ZBD6500 ZBD6600 ZBD6700 ZBD6900 ZBD7000 ZBD7100 PUB # 31-9087 12/01...

- Page 2 If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are removed for service, they must be returned to their original position and properly fastened. GE Consumer Home Services Training Technical Service Guide Copyright © 2001 All rights reserved.

-

Page 3: Table Of Contents

6000 & 7000 Series DISHWASHERS INDEX 5.2.28 Capacitor - Wash Motor 1.0 PRODUCT INFORMATION Page 2 5.2.29 Thermostat - Overtemperature 1.1 Description 5.2.30 Heating Element 1.2 Model Designation 5.2.31 Turbidity Sensor 1.3 Major Component Location 5.2.32 Air dome 1.4 Micro Filtration 5.2.33 Water Inlet Solenoid Valve 5.2.34 Drain Pump - Removal 2.0 SAFETY... -

Page 4: Product Information

6000 & 7000 Series DISHWASHERS 1.0 PRODUCT INFORMATION 1.1 DESCRIPTION 1.1.1 Electronic Control Panel Models Control Panel Electronic Model 6400 All white door, cabinet, and control panel, or all black door, cabinet, and control panel Electronic Model 6500 Stainless steel door, black cabinet and control panel Electronic Model 6700 All white door, control panel and cabinet, or all black door, control panel and cabinet... - Page 5 6000 & 7000 Series DISHWASHERS 1.1.3 Electronic Integrated Models Electronic Integrated Model 7000 Black cabinet, black door Electronic Integrated Model 7005 Black cabinet, black door, no turbidity sensor Electronic Integrated Model 7100 Black cabinet, stainless steel door Electronic Integrated Model 7105 Black cabinet, stainless steel door, no turbidity sensor Turbidity sensor PAGE 3...

- Page 6 6000 & 7000 Series DISHWASHERS 1.1.4 Interior, all Models Light - All Models except 6400 & 6500 Upper Basket Lower Basket Detergent and Rinse Aid Dispenser 1.1.5 General view beneath the cabinet Drain Pump Sump Air Dome Water Inlet Solenoid Valve Wash Motor / Pump Assembly Capacitor Heating Element...

-

Page 7: Model Designation

6000 & 7000 Series DISHWASHERS 1.2 Model Designation Model 6400 6700 6905 6600 6605 7000 7005 7100 7105 6500 6900 Control Panel Type Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Electronic Rotary Rotary Integrated Integrated Integrated Integrated Door Finish White 6400 6700... -

Page 8: Major Component Location

6000 & 7000 Series DISHWASHERS 1.3 Major Component Location The diagram below illustrate the location of the major components. Refer to Section 5.1 Water inlet solenoid valve Upper basket feed pipe Turbidity sensor (except 6905, 6605, 7005 & 7105) Drying assist fan Sump Door microswitch Drain pump... -

Page 9: Micro Filtration

6000 & 7000 Series DISHWASHERS 1.4 Micro-Filtration 1.4.1 Level 4 Micro-Filtration These models have a 4 level micro-filtration stainless steel filtering system. Lower Spray Arm Level 4 - Level 1 - Recuperative By-pass Filter Drain Cup Filter Level 2 - Perforated Stainless Steel Filters Level 3 - Micro-mesh Barrel Filter... - Page 10 6000 & 7000 Series DISHWASHERS 1.4.2 Water flow - 4 Level System The diagram below illustrates the water flow and identifies the main components in a 4 level micro-filtration system. Note: The sump is drawn in dotted lines for illustration purposes. Water solenoid inlet valve Various lower spray arm water jets Siphon break...

-

Page 11: Safety

6000 & 7000 Series DISHWASHERS 2.0 SAFETY 2.1 WARNING At the beginning and/or end of each service procedure, the appropriate icons below will appear as a reminder to All work on electrical or plumbing systems must be carried observe safe practices when servicing the unit. out by persons so qualified and in accordance with the Federal, State or local authority legislation which applies. -

Page 12: Specifications

6000 & 7000 Series DISHWASHERS 3.0 SPECIFICATIONS 3.1.1.4 6600 Model 3.1 GENERAL SPECIFICATIONS The controller has two large surface mounted rotary encod- 3.1.1 Control System ers for wash cycles and heat options and a smaller surface mounted switch for push button start. All control and interface boards operate at 120v. - Page 13 6000 & 7000 Series DISHWASHERS 3.1.2 Water Circulating System 3.1.2.1 Wash Motor Capacitor 370V AC, 60Hz, 15µF. Type - metallized Polypropylene. Electrical connection - 2 x 1/4" x 1/32" Quick Connect tabs. For usage 120V, 60Hz @ 185°F 3.1.2.2 Water Capacities The Water Solenoid Inlet Valve is rated at a nominal 1.25 US gallons per minute.

- Page 14 6000 & 7000 Series DISHWASHERS 3.1.2.5 Wash Motor/Pump Assembly 3.1.3 Switches/thermostats 120V AC, 60Hz, 1.7A. 3.1.3.1 Thermostat - Overtemp 110W, MCR CS&R, 3250 rpm. Identification - Blue Dot. Class F Mounting - Gasket in Tub base. Capacitor 15µF 370V Electrical connection -1/4" Quick Connect tabs. WARNING: Motor is fitted with internal auto reset overload 125V/250V.

- Page 15 6000 & 7000 Series DISHWASHERS 3.1.4 Miscellaneous 3.1.4.6 Dimensions 3.1.4.1 Detergent & Rinse Aid Dispenser The diagram below illustrates the cupboard space required. Single actuator type with gravity latch/lock mechanism. 110 - 240V AC, 60 Hz. Total capacity of detergent chamber - 1.4 fl.oz. Normal level detergent chamber - 0.9 fl.oz.

-

Page 16: Fault Indication

6000 & 7000 Series DISHWASHERS 4.0 FAULT INDICATION 4.1 Models 6400/6500, 6700/6900, 6905, 7000 Series. To assist with the diagnosis of dishwasher faults, any faults that are detected during a wash cycle are saved in nonvola- tile memory. These fault codes can then be accessed later on during a service call. - Page 17 6000 & 7000 Series DISHWASHERS 4.1.3 Identifying any faults that may have occurred: The fault codes (if any saved) are displayed by flashing the relevant LEDs, (at a rate of 0.5 second on, 0.5 second off, unless otherwise noted). Refer table below. Fault detected Condition Fault code LED...

- Page 18 6000 & 7000 Series DISHWASHERS 4.2.3 Identifying any faults that may have occurred: To check if a particular fault has been recorded, rotate the appropriate control knob to the corresponding Fault type to If a fault has been detected by the Field Test Cycle, or by the be checked for.

-

Page 19: Not Heating

6000 & 7000 Series DISHWASHERS NOT HEATING with the previous values and this represents one period of measurement. During a heating cycle, if the water temperature sensed has There are 4 failure modes: not been rising by greater than 9 deg F in 15 minutes, the heating element relay is to be de-energized and wash a. -

Page 20: Test Facilities

6000 & 7000 Series DISHWASHERS 4.10 TEST FACILITIES Several test functions are to be incorporated into the dishwasher control to facilitate fault finding. Access to these test functions is via the normal front panel control switches. Test functions incorporated are: 4.10.1 RELAY / TRIAC OUTPUT TEST 4.10.2... - Page 21 6000 & 7000 Series DISHWASHERS 4.10.1 RELAY / TRIAC OUTPUT TEST (LATCHING MODE) 4.10.1.1 Models 6400/6500, 6700/6900, 6905, 7000 By pressing the following button sequence the relay output test mode can be accessed. 6400/6500 6700/6900 6905 7000 Series #5 Heated Dry #5 Smart Dry #5 Smart Dry #6 Smart Dry...

- Page 22 6000 & 7000 Series DISHWASHERS 4.10.1.2 Models 6600 and 6605 Hold 3 seconds To access the output latching mode on Rotary Models 6600, 6605 align the wash cycles and heat options indicators on the knobs with the Start/Cancel button (both knobs horizontal and pointing towards start/cancel button, then press and hold for 3 seconds the Start/Cancel button when no program LEDs are on.

- Page 23 6000 & 7000 Series DISHWASHERS 4.10.2 TEMPERATURE CALIBRATION TEST 4.10.2.1 Models 6400/6500, 6700/6900, 6905. During the Relay/Triac output test (Refer 4.10.1) the program and option LEDs form a bar graph display indicating the tem- perature of the door thermistor. See table below. Note: A thermistor resistance of 1K7=113 °...

- Page 24 6000 & 7000 Series DISHWASHERS 4.10.4 TURBIDITY INPUT OPERATION Models 6400/6500, 6600, 6700/6900, 7000 Series. Note: There is no turbidity sensor on the 6605 and 6905 models. During the Relay/Triac output test (Refer 4.10.1) the SENSING LED, (POTS & PANS LED on 7000 series), (or the WASH CYCLES LED on Rotary machines, provided Turbidity Sensor monitoring was selected), will indicate if the turbidity sensor is operating correctly.

- Page 25 6000 & 7000 Series DISHWASHERS FIELD TEST CYCLE STEP ACTION TIME / Sec COMMENTS (Note 1) LED and Button TEST Unlimited For Push button models: The buzzer will sound for 0.5 seconds at the start of the step. Turn each Status LEDs on individually for a 1/2 second from top to bottom, (if fitted).

- Page 26 6000 & 7000 Series DISHWASHERS FIELD TEST CYCLE STEP ACTION TIME / Sec COMMENTS (Note 1) WASH + DISPENSE. The buzzer will sound for 0.5 seconds at the start of the step. The Smart or Heated Dry LED will be on. WASH + HEAT to 140°F.

- Page 27 6000 & 7000 Series DISHWASHERS 4.10.7 OVERFILL TEST 2. Press the Start/Cancel button to select fill time, as per chart (factory setting is 65 seconds). Continue to press the Start/ Models 6400/6500, 6600, 6605, 6700/6900, 6905, 7000 Cancel button until the desired indicator is illuminated. Series.

- Page 28 6000 & 7000 Series DISHWASHERS 4.10.10.2 Suspend Mode 4.10.10.3 Buzzer silencing Models 6600,6605 and 7000 have no suspend mode This feature is not available on Rotary models 6600 and indication 6605. The suspend mode is intended to prevent water being The buzzer can be silenced by pressing START/CANCEL pushed under the door, due to rapid expansion of the ambient and NORMAL WASH, (or POTS NORMAL on 6905), buttons...

-

Page 29: General Diagnostics

6000 & 7000 Series DISHWASHERS 4.11 GENERAL DIAGNOSTICS - All Models except 6600 & 6605 4.11.1 Overfill Mode - Drain Pump Operating • A circuit is connected to the Drain Pump. In this mode the Drain Pump will run continuously. Continuously •... - Page 30 6000 & 7000 Series DISHWASHERS The following malfunctions can cause the ‘Heated D ry’ or 4.11.2 Overfill Mode - Drain Pump Not Operating ‘Smart Dry’ LED to rapidly flash and terminate all outputs Symptom: Overfill mode indicated by Heated Dry or Smart of the electronic Power Control Board.

- Page 31 6000 & 7000 Series DISHWASHERS 4.11.3 Pressure Switch and Door Microswitch tion contact P1-11 to P1-14 (open circuit), senses water within the stainless steel tub. 120V AC neutral circuit • Switched Neutral: The switched neutral circuit from the N The Pressure Switch and Door Microswitch is in a series terminal of the Mains Terminal Block, is via the Door wiring configuration between the neutral N terminal of the Microswitch, to the SWITCHED NEUTRAL tab terminal of...

- Page 32 6000 & 7000 Series DISHWASHERS The following points are listed in relation to the Pressure Switch function and operation. • The Pressure Switch Level 1 is set at a level lower than the level required for the timed water fill. This is to ensure that water enters the dishwasher before the controller activates the heater circuit.

- Page 33 6000 & 7000 Series DISHWASHERS The “Switched Neutral” Circuit is designed to prevent operation of the following components, in the advent of the main door being left ajar to assist residual drying and/or a malfunction of the Power Control Board activating the Relay/Triac outputs: •...

-

Page 34: Service Procedures

6000 & 7000 Series DISHWASHERS 5.0 SERVICE PROCEDURES 5.1 GENERAL ACCESS These dishwashers have a removable Kick Panel fitted in 5.1.2.2 Remove the Mains Terminal Cover. front of an Electrical Access Panel. These panels require removal to access under sump components such as thermo- stats, drain pump, water inlet solenoid valve, turbidity sensor, pressure switch, wash motor capacitor, heating element, wash motor, sump, drying fan etc. -

Page 35: Procedures

6000 & 7000 Series DISHWASHERS 5.2 PROCEDURES 5.2.1 Door Latch CAUTION. Switch off electrical power supply Door Latch Phillips headed Remove 4 screws each side of door screw. 5.2.2.5 Reinstalling the Door Panel to the dishwasher re- quires the 4 Phillips headed stainless steel screws fitted to each side of the door to be replaced in reverse order as section 5.2.2.2 5.2.1.1 To remove the Door Latch, loosen then remove the... - Page 36 6000 & 7000 Series DISHWASHERS 5.2.3.2 Remove the 4 Phillips head stainless steel screws 5.2.4.3 Open the door to the horizontal position. Remove the fitted to each side of the door to enable the Door Panel to be remaining 13 Phillips head screws from the sides and top withdrawn from the stainless steel door liner.

- Page 37 6000 & 7000 Series DISHWASHERS 5.2.5 Control Panel Assembly - 6400, 6500,6600, 5.2.6 Power Control Board - All Models 6605 Models CAUTION. Switch off electrical power supply CAUTION. Switch off electrical power supply 5.2.5.1 Remove the six Phillips Head countersunk stainless 5.2.6.1 Remove relevant door and Control Panels.

- Page 38 6000 & 7000 Series DISHWASHERS 5.2.6.3 A drip sheet (black PVC material as shown below) 5.2.6.8 Starting at one end of the Power Control Board that covers the Power Control Board and must be reinstalled if a has been removed, remove each Quick Connect (Quick Power Control Board is removed/replaced.

- Page 39 6000 & 7000 Series DISHWASHERS 5.2.6.10 Fold the sides of the drip sheets inward and 5.2.7.3 Control Panel right hand side Dress-Panel: The fold the long wrap at the top of the Carrier Panel to the right hand side Dress Panel is attached and removed in a bottom of the Power Control Board.

-

Page 40: Cabinet Trims & Wrap Removal

6000 & 7000 Series DISHWASHERS 5.2.8 Cabinet trims and wrap removal, all models CAUTION. Switch off electrical power supply Cabinet wrap, 5.2.8.1 Open the dishwasher door. Remove the 4 Phillips lower rear head screws from the stainless steel trim in the left hand side flanges and right hand side of the top corners of the cabinet. -

Page 41: Door Hinge, Spring & Support Rods

6000 & 7000 Series DISHWASHERS 5.2.9 Door Hinge, Spring and Support Rods CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. Interior light switch Switch lever Door hinge Hinge slot Support rod 5.2.9.3 Operate and test dishwasher before leaving. Note: To replace the Door Hinges, the stainless steel door liner needs to be removed. -

Page 42: Remove Door Hinges

6000 & 7000 Series DISHWASHERS 5.2.10.3 Return the door to a partially closed position as 5.2.11.4 Reassemble the dishwasher in reverse order. shown in the photograph below to prevent damage to the spillway fixed to the front lip of the stainless steel tub. 5.2.11.5 Operate and test dishwasher before leaving. -

Page 43: Upper Venturi Assembly

6000 & 7000 Series DISHWASHERS 5.2.13 Upper Venturi Assembly The Upper Venturi Assembly consists of the Upper Venturi Housing, Upper Venturi Top and Upper Venturi Bottom. The Upper Venturi Housing is attached to the Upper Basket Assembly by integrally moulding retaining clamp and support lugs. -

Page 44: Upper Venturi Assembly - Dismantle

6000 & 7000 Series DISHWASHERS 5.2.14 Upper Venturi Assembly - Dismantle 5.2.16 Upper Venturi Assembly - Reinstall to Dishwasher In general practice, the Upper Venturi assembly will not need to be dismantled except to replace the teflon support washer Reinstallation of the Upper Venturi Assembly to the Upper after a considerable service life, or perhaps damage to the Basket Assembly is as follows: left hand thread of the Upper Venturi Bottom from misuse or... -

Page 45: Upper Basket Feed Pipe

6000 & 7000 Series DISHWASHERS 5.2.17.4 Slide the Rail Guides out and clear from the Wheel 5.2.18 Upper Basket Feed Pipe Guides. The Upper Basket Feed Pipe is a polyethylene blow mould- 5.2.17.5 Remove the Wheel Guide Axles as shown below. ing mounted on the top external surface of the stainless steel tub and is retained in position by the screwed Spray Nozzle which is located on the top internal surface of the stainless... - Page 46 6000 & 7000 Series DISHWASHERS 5.2.19.2 Grasp the hose and turn and remove from the Siphon Break spigot. 5.2.19.3 Open the dishwasher door to gain access to the CAUTION. Switch off electrical power supply Siphon Break Nut located on the internal right hand side and turn water supply off at main or isolating surface of the stainless steel tub as shown below.

-

Page 47: Drain Cup Filter

6000 & 7000 Series DISHWASHERS 5.2.20 Drain Cup Filter Note: The flat surface on the perforated Wash Filter aperture and the Barrel Wash Filter must be aligned. The Drain Cup Filter is located on the left hand side LH side perforated stainless steel Wash Filter perforated stainless steel Wash Filter, which is retained in the base of the stainless steel tub, by the locking action of the Drain Cup Filter. -

Page 48: Lower Spray Arm Support

6000 & 7000 Series DISHWASHERS the Lower Spray Arm Support through the 1 3/8" diameter 5.2.24 Lower Spray Arm Support recessed hole in the perforated face of the filter and tighten. The Lower Spray Arm Support positions and retains the Reassemble the dishwasher in reverse order. -

Page 49: General View Beneath The Cabinet

6000 & 7000 Series DISHWASHERS 5.2.26 General view beneath the cabinet Drain Pump Sump Air Dome Water Inlet Solenoid Valve Wash Motor / Pump Assembly Capacitor Heating Element Turbidity Sensor (not on 6905, 6605) Overtemperature Thermostat PAGE 47... -

Page 50: Pressure Switch

6000 & 7000 Series DISHWASHERS 5.2.27 Pressure Switch CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. 5.2.27.1 Refer to section 5.1 for access to the Pressure Switch. The pressure switch is located on a bracket that is mounted at the rear of the mains terminal compartment. -

Page 51: Thermostat - Overtemperature

6000 & 7000 Series DISHWASHERS 5.2.29 Thermostat - Overtemperature CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. 5.2.29.1 The overtemperature thermostat is located in the base of the tub alongside the wash motor capacitor. To release the thermostat grasp the plastic body and tilt it to one side, at the same time moving one lip of the rubber gasket it is mounted in to one side. -

Page 52: Heating Element

6000 & 7000 Series DISHWASHERS 5.2.30 Heating Element 5.2.30.9 Disengage the two stainless steel retainers from the Heating Element. Bend left rear Element retaining bracket. CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. -

Page 53: Turbidity Sensor

6000 & 7000 Series DISHWASHERS 5.2.31 Turbidity Sensor 5.2.32 Air dome All models except 6605, 6905, 7005 & 7105 CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. CAUTION. Switch off electrical power supply and turn off water supply at main or isolating valve. -

Page 54: Water Inlet Solenoid Valve

6000 & 7000 Series DISHWASHERS 5.2.33 Water Inlet Solenoid Valve 5.2.33.4 Compress the hose clamp which retains the con- necting hose and slide the clamp from the spigot. 5.2.33.5 Grasp the hose and remove it from the spigot of the CAUTION. -

Page 55: Wash Motor Pump Assembly Removal

6000 & 7000 Series DISHWASHERS 5.2.34.3 Remove the drain hose double coil hose clamp with 5.2.34.5 Grasp the Drain Pump and pull the complete motor a pair of pliers from the pump outlet as shown below and and pump assembly from the bore of the sump socket, withdraw the molded drain hose elbow from the pump outlet. - Page 56 6000 & 7000 Series DISHWASHERS 5.2.35.2 Disconnect the four pin wash motor/ pump recep- 5.2.35.5 Removal of the three outlet hoses now provides tacle from wiring harness/ plug as shown below. access to the centrally mounted induction/inlet spigot of the pump cover.

- Page 57 6000 & 7000 Series DISHWASHERS 5.2.35.7 The Wash Motor/Pump can then be withdrawn from the pump cover inlet hose, as shown below, and lifted clear as a complete assembly. 5.2.35.8 Reinstall the Wash Motor/Pump and reassemble the dishwasher in reverse order or refer to section 5.2.34 if the Wash Motor/Pump needs to be dismantled.

-

Page 58: Sump

6000 & 7000 Series DISHWASHERS 5.2.36 Sump 5.2.37 Sump Base Plate/Non-return Flap Valve 5.2.36.1 Refer to section 5.1 to gain access to sump. The Sump Base Plate incorporates the Non-return Flap Valve which can be removed and replaced as follows: 5.2.36.2 To remove the Sump, disconnect hoses attached to the Sump Spigots (4 Hoses). -

Page 59: Interior Light

6000 & 7000 Series DISHWASHERS 5.2.38 Interior Light - All models except 6400 and 5.2.38.5 Remove the two 3/16" Quick Connect terminals from the tab terminals of the light holder. 6500 5.2.38.6 To remove the reflector from the Light Body and Holder, simply prize the reflector retainer clips from the three relative cut outs of the Light Body and Holder. -

Page 60: Detergent And Rinse Aid Dispenser

6000 & 7000 Series DISHWASHERS 5.2.39 Detergent and Rinse Aid Dispenser 5.2.40 Drying Assist Fan CAUTION. Switch off electrical power supply. CAUTION. Switch off electrical power supply. 5.2.39.1. Remove the dishwasher outer Door Panel. 5.2.40.1 The drying assist fan is located in the top left hand corner of the stainless steel door liner. -

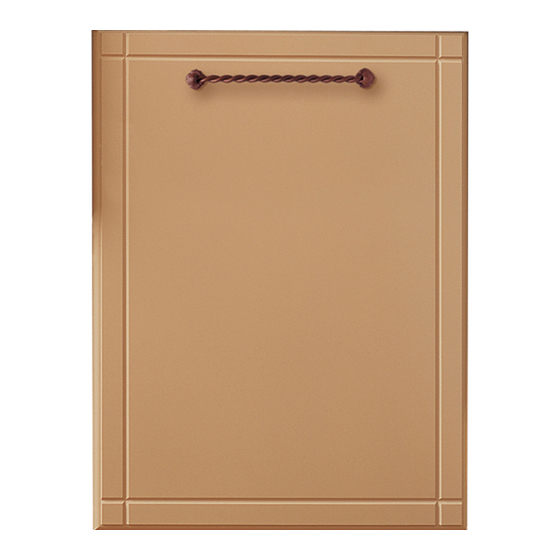

Page 61: Door Handle 6400, 6500, 6700, 6900, 6905

6000 & 7000 Series DISHWASHERS 5.2.41 Door Handle - 6400, 6500, 6700, 6900 & 6905 5.2.41.2 Compress the detent clip of the leaf spring on the end adjacent to the Door Lock Micro Switch. Models 5.2.41.3 Slide the leaf spring through two retaining slots formed in the Control Panel Carrier Frame. - Page 62 6000 & 7000 Series DISHWASHERS 5.2.42 Door Handle Cover Plate - 6400, 6500, 6700, 5.2.43 Door Lock Microswitch - 6400, 6500, 6700, 6900 & 6905 Models 6900, 6905, 6600 & 6605 Models CAUTION. Switch off electrical power supply. CAUTION. Switch off electrical power supply. 5.2.42.1 Remove the Door Handle.

- Page 63 6000 & 7000 Series DISHWASHERS 5.2.44 Door Lock Microswitch - 7000, 7005, 7100 & 5.2.45 Door Lock Microswitch Lever - 6400, 6500, 7105 Models 6700, 6900, 6905, 6600 & 6605 Models CAUTION. Switch off electrical power supply. CAUTION. Switch off electrical power supply. 5.2.44.1 Remove the outer door panel.

-

Page 64: Programs - 6400 & 6500 Models

6000 & 7000 Series DISHWASHERS 6.1.1 Programs - 6400 & 6500 Models Pots Normal 145 50 145 29 135 106 & Pans 11 145 50 145 29 128 93 High 155 50 155 29 135 100 11 155 50 155 29 128 93 Normal Normal AHAM... -

Page 65: Programs - 6600 Rotary Model

6000 & 7000 Series DISHWASHERS 6.1.2 Programs - 6600 Rotary Model Pots Normal 77 145 50 145 29 & Pans 711 145 50 145 29 HighTemp 155 50 155 29 711 155 50 155 29 Sani 171 50 171 29 711 171 50 171 29 Normal... -

Page 66: Programs - 6605 Pots Rotary Model

6000 & 7000 Series DISHWASHERS 6.1.3 Programs - 6605 Pots Rotary Model Heavy Normal 155 50 155 29 Duty High Temp 160 50 160 29 Sani 171 50 171 29 Normal Normal AHAM, DOE 135 50 135 29 Wash HighTemp CU 145 40 160 20 Sani... -

Page 67: Programs - 6700, 6900 & 7000 Models

6000 & 7000 Series DISHWASHERS 6.1.4 Programs - 6700, 6900 & 7000 Models Pots & Normal 7 145 50 145 29 6 135 Pans 11 145 50 145 29 6 128 High 7 155 50 155 29 6 135 11 155 50 155 29 6 128 Sani... -

Page 68: Programs - 6905 Model

6000 & 7000 Series DISHWASHERS 6.1.5 Programs - 6905 Model Heavy Normal 155 50 155 29 Duty High 160 50 160 29 Sani 171 50 171 29 Normal Normal AHAM, DOE 135 50 135 29 Wash High 145 40 160 20 Sani 160 50 171 29... -

Page 69: Circuit Diagram - Electronic Controller

6000 & 7000 Series DISHWASHERS 6.2 Circuit Diagram, Electronic Controller PAGE 67...