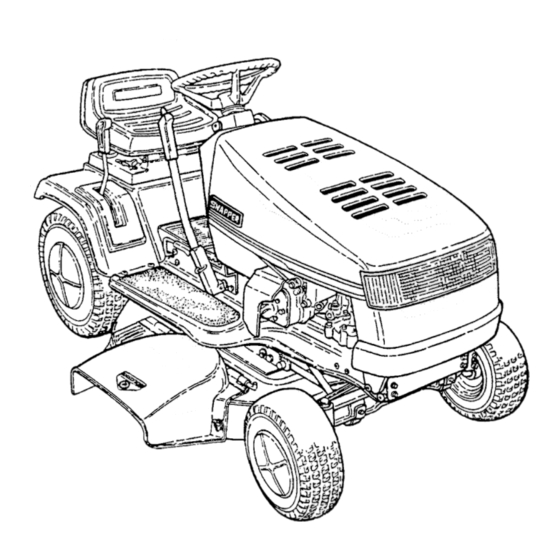

Snapper LT120G30DB Safety Instructions & Operator's Manual

Lawn tractor hydrostatic & gear drive series d

Hide thumbs

Also See for LT120G30DB:

- Parts manual (40 pages) ,

- Safety instructions & operator's manual (44 pages) ,

- Safety instructions and operator's manual (44 pages)

Table of Contents

Advertisement

Safety Instructions & Operator's Manual for

,SNAPPER,

LAWN

TRA CTOR

HYDROSTATIC

&

GEAR DRIVE

SERIES

D

MODELS

GEAR DRIVE

HYDROSTATIC

DRIVE

LT120G30DB

LT140H33DBV

NLT120G30DB

LT145H33DBV

LT125G38DB

LT145H38DBV

NLT145H38DBV

I

MODEL DESIGNATION

ENGINE HP

DRIVE SYSTEM TYPE

CUTTING WIDTH

MODEL NUMBER EXPLANATION

LT I 145I H 1381 O I B I V I

i

ENGINE TYPE

;

ENGINE MODEL

SERIES DESIGNATION

LT - Lawn Tractor

Model Designation

120 - 12.0 HP Engine Horse Power

125 - 12,5 HP Engine Horse Power

H - Hydrostatic

Transmission

30 - 30" Cutting Width

Mower

33 - 33" Cuttino Width

Mower

140 - 14.0 HP Engine Horse Power

145 - 14.5 HP Engine Horse Power

G - Gear Drive Transmission

38 - 38" Cutting Width Mower

D - Series Designation

B - Briggs & Stratton

Engine

V - Over Head Valve Type Engine

Thank

you

for buying

a SNAPPER

product!

Before

operating

the Lawn

Tractor,

read and

follow

the

"IMPORTANT

SAFETY INSTRUCTIONS"

on pages 2 & 2A, all other instructions

contained

in this manual and

the accompanying

booklet

"About

Power Mower Safety".

"Lawn mowers

and all power

equipment

can be

potentially

dangerous ff used improperly.

REMEMBER:

SAFETY REQUIRES CAREFULL

USE IN ACCORDANCE

WITH INSTRUCTIONS

AND COMMON SENSE/.

COPYRIGHT

© 1998

SNAPPER

NC

ALL RIGHTS

RESERVED

MANUAL No. 3-5576 (REV. 2, 6/98)

Advertisement

Chapters

Table of Contents

Summary of Contents for Snapper LT120G30DB

- Page 1 G - Gear Drive Transmission H - Hydrostatic Transmission 30 - 30" Cutting Width Mower 38 - 38" Cutting Width Mower 33 - 33" Cuttino Width Mower Thank for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

-

Page 2: Important Safety Instructions

If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN PROTECTION AGAINST TIPOVERS... - Page 3 BLADE is ON or machine is in motion. 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices.

-

Page 4: Table Of Contents

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ..2 & 2A MAINTENANCE INSTRUCTIONS (Continued) TABLE OF CONTENTS ........Battery Service ..........20-21 Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Charging ..........Serial & Model Number Location ......4 Controls ..............Components ............ -

Page 5: Familiarization

FAMILIARIZATION H_.'t::1 :! P"_I HE:I _v, (o] _] ::!mid _Ill L v,I :1:1:1 Ko]).]P',_In / (o]; • The serial and model number of the SNAPPER Series D REAR VIEW Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. -

Page 6: Controls

FAMILIARIZATION [_o] Lv, I ".,To] _, 1 :1_, b u_ The nomenclature drawings, Figures 2 & 3, illustrate the essential components of the SNAPPER Series D Lawn CHOKE Tractor. It is recommended that all operators of this equipment become thoroughly... -

Page 7: Operating Instructions

OPERATING INSTRUCTIONS I d :! =5.'t if:! :_iI It.,].-I :(H ;I ii [..1 ,i Make the followingchecks and perform service as re- quiredbeforeeach start-up. Check tires and add air as needed to bringpressure to 12psi in fronttires and 10 psi in rear tires. If guards are missingor damaged, Replace BEFORE usingmower. -

Page 8: Starting & Stopping Engine

OPERATING INSTRUCTIONS :,In #,I :_idI: [rl:_..'t liD] "J"JI: [tl =1 _[r] I: I =i STARTING ENGINE Take a comfortablepositionin seat of ridingmower,look ENGAGEMENT aroundto make sure that the area you are goingto mow LEVER is clear of people, children and pets. Take note of any stationaryobstacles! NOTE: The interlocksystemwillpreventthe engine from starting... - Page 9 OPERATING INSTRUCTIONS _._ net :_unlI: [_lr:l-_ n[o]"J"JI _[riYl: 1:1=1 nl ,] ;1 Lvi= HANDLE STARTING WHEEL DRIVE OF HYDRO MODELS Shift speed controllever to neutral. REVERSE Start engine. Release brake pedal. Slowlyshiftspeed controlleverforwardfor forwardmotion or to the rear for reverse motion.See Figure9. FORWARD SPEEDS STOPPING...

- Page 10 OPERATING INSTRUCTIONS _-'lmmr.1 :_m nlI _[rt::lE._m go] ..J..J I _[it L', [ olV,'J=1 :l :| mF_,l p]=l PULL BLADE ENGAGEMENT LEVER UP TO "ON" TO START MOWER BLADE(S) STARTING MOWER BLADE Start engine. Raise blade engagement lever to "ON". See Figure 12. STOPPING MOWER BLADE ENGAGEMENT LEVER...

-

Page 11: Raising Chute Deflector

OPERATING INSTRUCTIONS ROLLING GEAR DRIVE MODELS GEAR DRIVEMODELSHOWN With engine 'OFF', fullydepressclutcl_/brake pedal. Place speed controllever in the neutral (N) position.See Figure 15. Release clutch/brakepedal and movetractorto desired location. -SPEED CONTROL HANDLE Setparkbrake andplace speed controlleverintoa forward speed. FIGURE 15 1997 MODEL YEAR SHOWN m :_,_[_1 I: [rl_]: t,J= i =1,]=1 il _=[,, lo_ia= RAISING... -

Page 12: Accessories

V'_ltl'_1 ! W_.! : ] il =f;_*-[*4 =b'_._*] :! I $1 The SNAPPER Series D LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility. The accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for ordering any of the accessories desired. - Page 13 3. Electrical connections loose or corroded. 3. Clean end check connections for good contact.. 4. Defective ignition switch. 4. Contact authonzed SNAPPER dealer. ENGINE WILL NOT START 1. Blade engagement lever in the "ON" position. 1. Move blade engagement lever to "OFF"...

- Page 14 OIL LEAKING 1. Loose or missing oil filler cap. (Hydro Models Only) 1. Check oil level and replace oil cap. FROM TRANSMISSION 2. Leaking axle seals. 2. Contact authorized SNAPPER dealer. 3. Leaking at casing seal 3. Contact authorized SNAPPER dealer.

- Page 15 MAINTENANCE INSTRUCTIONS SERVICE SUBJECT REFERENCE EACH EACH TO BE PERFORMED PAGES HOURS HOURS HOURS HOURS SEASON Check Oil Level Engine Page 6 Initial Oil Change Engine Pages 15 & 16 Periodic Oil Change Engine page 15 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element &Page...

-

Page 16: Maintenance Instructions

MAINTENANCE INSTRUCTIONS SEAT ADJUSTING KNOBS The hydrostictransmission does not normally require maintainence, h owever, properoillevelshouldbeverified sfter everyseason. TO CHECK OIL LEVEL IN TRANSMISSION Remove seat by removing seat adjustment knobs, See Figure 18. Lay seat forward. Be careful not to pull seat switchwires from the switch. - Page 17 MAINTENANCE INSTRUCTIONS FILLER MODELS L T120G30DB, NL T120G30DB, TUBE LT125G33DB & LT125G38DB OIL DRAIN These models are equipped with 12 & 12 1/2 hp engines EXTENSION which are furnishes with extended oil drains. See Figure Raise tractorhood and tilt itforward. Disconnect s parkplugwire.

-

Page 18: Lubrication

MAINTENANCE INSTRUCTIONS The followinglubricationpoints shouldbe servicedafter each 25 operating hours to insure optimum performance of the Series D Lawn Tractor. FRONT WHEEL BEARINGS Lubricateeach front wheel bearing through the grease AXLE SPINDLE fitting on wheel hub. Using general purposegrease in a LUB RICATION FITTING greasegun, addgrease untilgreasepurgesfrom bearing. -

Page 19: Steering Drag Link

MAINTENANCE INSTRUCTIONS DRAG UNK LUBRICATION STEERING DRAG LINK Lubricateboth ends of steering drag link with a small amountof 30 wt. motoroilfrom anoilcan. See Figure26. STEERING TIE ROD Usingan oil can, filled with30wt. motoroil, lubricateboth ends of steeringtie rod. See Figure27. FIGURE 26 ::::C'o: BLADE ENGAGEMENT... -

Page 20: Engine Air Pre-Cleaner

MAINTENANCE INSTRUCTIONS The componentslistedshouldbe servicedon a regular AIR CLEANER basisto insurethattheyare intopworkingcondition. R efer to SERVICE SCHEDULE on Page 14 for recommended service intervals. ENGINE AIR PRE-CLEANER Theengineairpre-cleanershouldbe removedandcleaned every25 operatinghours.See Figure30. Referto Engine ENGINE AIR PRE.CLEANER Owner'sManual for specificcleaninginstructions. FIGURE 30 ENGINE AIR CLEANER The engine air cleaner element shouldbe removedand... -

Page 21: Engine Cooling System

MAINTENANCE INSTRUCTIONS ENGINE COOLING SYSTEM The engine coolingsystemconsists of an engine shroud and engine fins.These shouldbe kept clean and free of debris as needed or clean at least every 100 operating houm. REMOVE ADJUSTING KNOBS AND MOVE _ S ,TFO.WA.0, I / ,7 The batteryshouldbe servicedevery25 hours of opera- tion. -

Page 22: Maintenance Instructions (Continued)

MAINTENANCE INSTRUCTIONS Using distilledwater, fill cells as needed to 1/8" to 3/8" above cell plates. Replace cell covers. Charge battery if required. Install positive(+) cable first. Install negative(-) cable last. Install seat assembly over battery and secure in position with adjusting knobs. Leave knobs loose. Lower operator's seat and adjust to desired position. -

Page 23: Mower Deck Removal/Reinstallation

MAINTENANCE INSTRUCTIONS Should the tractiondrive belt show signs of excessive FRONT UFT ARM wear or damage, replace. MOWER DECK REMOVAL UFT ROD Placetractoron a firm,levelsurfacesuchas a drivewayor garage floor and engage park brake. Turn engine "OFF". HAIR PIN Raise hoodand removespark plugwire fromspark plug. Secure sparkplugwire away fromsparkplug.See Figure FIGURE 37 Lowerdeck to lowest setting. - Page 24 MAINTENANCE INSTRUCTIONS (30" & 33" BELT GUIDES SHOWN) Make note of hole used in sector plate. Slide sectorplates off of rear deck hanger brackets. Slide deck forward. Remove deck drive beItfrom engine pulley bottom groove. See Figure 40. Slide deck back and disconnect springfrom tension idler. Pull deck from under tractor from R.H.

- Page 25 MAINTENANCE INSTRUCTIONS Removetractiondrivebelt fromengine pulleytop groove. REMOVE See Figure44. FROM PULLEY Remove belt from center belt guide. Pullbelt untilitcan be removedfrom transmission pulley. TRACTION DRIVE BELT REPLACEMENT Place new traction drive belt over transmission pulley and span to engine pulley. Place belt intotop groove of engine pulley.

- Page 26 MAINTENANCE INSTRUCTIONS REMOVE SPINDLE PULLEY IDLER COVER 30" & 33" DECK DRIVE BELT REMOVAL AND REPLACEMENT Inspect deck drive belt for excessive wear and damage after every 25 operating hours. Replacement procedures are as follows: Place tractoron a firm, level surface. Turn engine "OFF".

-

Page 27: Standard Blade Wear Limits

MAINTENANCE INSTRUCTIONS " W.ARNING " Blades are extremely sharp and can cause severe injury. Wear heavy leather gloves when handling or I working around blades. DO NOT use a blade that is I excessively worn or damaged. WARNING I Never use a cutting blade that... - Page 28 MAINTENANCE INSTRUCTIONS Install blade mounting bolts, internal tooth lock washers and nuts. See Figure 53 Torque blade to 30 to 40 Ft, Lbs. 38" STANDARD MOWER BLADE REMOVAL REPLACEMENT Move tractor to a firm, level surface. Turn engine "OFF". (2- REQUIRED) Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

-

Page 29: Sharpening Standard Blade(S)

MAINTENANCE INSTRUCTIONS SHARPENING STANDARD BLADE(S) Blades should be kept sharp at all times. When the blade(s) are dull, cut grass will be ragged and lawn will usuallyturn brown.Sharpen standard bladesas follows: Move tractorto a firm, level surface. Tum engine "OFF'. Raise hood,remove spark plug wire from sparkplug and secure wire away from plug. - Page 30 MAINTENANCE INSTRUCTIONS BLADE Never use a blade that shows signs of excessive wear or damage. Refer to Figure 57 for NinJa blade wear limits. Sharpen allcuttingedges ofthe Ninja recycling blade at 27° (+3°, -2 °) for optimum performance. See Figure 58. Reinstall sharpened Ninja blade in reverse order of removal.

- Page 31 MAINTENANCE INSTRUCTIONS Secure stationaryidlerwith mountingbolt. Place sparkplug wire onto spark plug. Set park brake. Start Engine. Visuallyinspecttractiondrive belt for movement. When properlyadjusted,the tractiondrivebelt shouldnot have any movement or rotationwith the engine running and park brake engaged. Shouldmovement be present,readjusttractiondrive belt to releasebeittension asdescribedinprevious instructions.

- Page 32 MAINTENANCE INSTRUCTIONS To adjust tension, remove extension rod mountingbolt and nut. See Figure62. TEN SION/d -_LEAST MOSTTENSlON • Move extension rodto next hole towards rear of deck and "-_ secure with mountingbolt and nut. MOUNTING- NUT & BOLT Measure extension spring with blade engagement lever in FIGURE 62 the "ON"...

- Page 33 MAINTENANCE INSTRUCTIONS 33" DECK SHOWN Slidesectoroffof pinsand carefullylowerdeckontoangle iron. Rotate. b lade(s) until blade tips are at each side of deck. ANGLE IRON •Measuredistancefrom blade tip to flooron each side LMEASURE FROM deck. BLADE TIPS TO FLOOR Bladetips shouldbe within 1/8"ofeach otherfor thedeck FIGURE 66 to be consideredlevel.

- Page 34 MAINTENANCE INSTRUCTIONS NOTE: The deck shouldbe set sothat the rear ofthe deck is 1/4" 33" DECK SHOWN lowerthan the front. See Figure69. FRONT P'/////;! REAR X • 1/4" FRONT TO REAR LEVEL- FRONT LIFT ROD If the sector plates are in their lowest setting and proper L__ MEASUREFROM level cannot be obtained, adjust the front liftrod as follows: BLADETIPSTO FLOOR...

-

Page 35: Side To Side Level

MAINTENANCE INSTRUCTIONS FRONT OF TRACTOR NOTE: Before adjusting deck, bring tire pressureto proper psi. BLOCK Front 12 psi, Rear 10 psi. SIDE TO SIDE LEVEL Move tractor to a firm, level surface. Turn engine "OFF". Raise hood, remove spark plug wire from spark plug and secure wire away from plug. - Page 36 MAINTENANCE INSTRUCTIONS Attach the rear hanger plates to the hole that most closely aligns with the pin on the deck lift bracket. Secure with washer and hair pin. FRONT OF TRACTOR /h[ i !! !!ii! iiiii!i i ii! !i!!!i! !i Iiiiic i! !i ! Ni i ii!i Mii iii iii ii i i i i i i iiiiiiiiii Make certain sectorplates are mountedin the same I holes on each side for proper frontto rear level...

- Page 37 MAINTENANCE INSTRUCTIONS STEERING SECTOR Should excessive "PLAY" be present in the steering, adjustas follows: Tum Engine "OFF" and raise tractorhood. Remove spark plugwire from spark plug and securewire away from plug. From leftside of tractor, locate the steeringsector below fuel tank. See Figure 71. Looseneccentricmounting nut.

- Page 38 MAINTENANCE INSTRUCTIONS HYDRO DRIVE MODELS To be properlyadjusted,the brake shouldstopthe tractor in approximately 6 feet from top speed when the clutch/ brake pedal is fully depressed. BRAKE Adjustbrake when necessary as follows: Turn engine "OFF'. Raise hood, remove spark plugwire from spark plugand secure wire away from plug.

- Page 39 ELECTRICAL Figure 76 illustratestypical hamess muting on all the Series D Lawn Tractors. Use this when locatingvarious electricalcomponents. _---- O BATI1ERY NEGATIVE (-) -TO BATTERY PosmvF.(+) (UNDER SEAT) TERMINAL R,H° HEADLIGHT HEADUGHT SWITCH SWITCH BRAKE SWITCH 20 AMP- FUSE HEAD HARNESS HARNESS BLADE ENGAGEMENT...

- Page 40 ELECTRICAL The schematics below, Figure 77 & Figure 78 represent models with and without headlights. BRIGGS & STRA TTON WITHOUT LIGHTS BLACK PEDAL SWITCH INoj. "ED I SEAT SWITCH GREENI I N_ I II /-IGNITION ENGINE /GROUND I BLACK I" STARTER k '_--ALTERNATOR YELLOW...

- Page 41 McDonough, Georgia, to be defective in material or workmanship or both. For ninety (90) days from purchase date for the odginal purchaser's commercial, rental, or other non-residential use SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by th= factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 42 SERVICE NOTES...

- Page 43 SERVICE NOTES...

- Page 44 IA WARNING: The engine exhaust from this product contains chemicals known to the State I of Califomia to cause cancer, birth defects or other reproductive harm. COPYRIGHT © 1998 SNAPPER INC ALL RIGHTS RESERVED MANUAL No. 3-5576 (REV. 2, 6/98)

- Page 45 G - Gear Drive Transmission H - Hydrostatic Transmission 30 - 30" Cutting Width Mower 38 - 38" Cutting Width Mower 33 - 33" Cuttino Width Mower Thank for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

- Page 46 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN PROTECTION AGAINST TIPOVERS...

- Page 47 BLADE is ON or machine is in motion. 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices.

-

Page 48: Shifter Adj Ustment

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ..2 & 2A MAINTENANCE INSTRUCTIONS (Continued) TABLE OF CONTENTS ........Battery Service ..........20-21 Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Charging ..........Serial & Model Number Location ......4 Controls ..............Components ............ -

Page 49: Familiarization

FAMILIARIZATION H_.'t::1 :! P"_I HE:I _v, (o] _] ::!mid _Ill L v,I :1:1:1 Ko]).]P',_In / (o]; • The serial and model number of the SNAPPER Series D REAR VIEW Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. - Page 50 FAMILIARIZATION [_o] Lv, I ".,To] _, 1 :1_, b u_ The nomenclature drawings, Figures 2 & 3, illustrate the essential components of the SNAPPER Series D Lawn CHOKE Tractor. It is recommended that all operators of this equipment become thoroughly...

-

Page 51: Operating Instructions

OPERATING INSTRUCTIONS I d :! =5.'t if:! :_iI It.,].-I :(H ;I ii [..1 ,i Make the followingchecks and perform service as re- quiredbeforeeach start-up. Check tires and add air as needed to bringpressure to 12psi in fronttires and 10 psi in rear tires. If guards are missingor damaged, Replace BEFORE usingmower. -

Page 52: Starting & Stopping Engine

OPERATING INSTRUCTIONS :,In #,I :_idI: [rl:_..'t liD] "J"JI: [tl =1 _[r] I: I =i STARTING ENGINE Take a comfortablepositionin seat of ridingmower,look ENGAGEMENT aroundto make sure that the area you are goingto mow LEVER is clear of people, children and pets. Take note of any stationaryobstacles! NOTE: The interlocksystemwillpreventthe engine from starting... - Page 53 OPERATING INSTRUCTIONS _._ net :_unlI: [_lr:l-_ n[o]"J"JI _[riYl: 1:1=1 nl ,] ;1 Lvi= HANDLE STARTING WHEEL DRIVE OF HYDRO MODELS Shift speed controllever to neutral. REVERSE Start engine. Release brake pedal. Slowlyshiftspeed controlleverforwardfor forwardmotion or to the rear for reverse motion.See Figure9. FORWARD SPEEDS STOPPING...

- Page 54 OPERATING INSTRUCTIONS _-'lmmr.1 :_m nlI _[rt::lE._m go] ..J..J I _[it L', [ olV,'J=1 :l :| mF_,l p]=l PULL BLADE ENGAGEMENT LEVER UP TO "ON" TO START MOWER BLADE(S) STARTING MOWER BLADE Start engine. Raise blade engagement lever to "ON". See Figure 12. STOPPING MOWER BLADE ENGAGEMENT LEVER...

-

Page 55: Raising Chute Deflector

OPERATING INSTRUCTIONS ROLLING GEAR DRIVE MODELS GEAR DRIVEMODELSHOWN With engine 'OFF', fullydepressclutcl_/brake pedal. Place speed controllever in the neutral (N) position.See Figure 15. Release clutch/brakepedal and movetractorto desired location. -SPEED CONTROL HANDLE Setparkbrake andplace speed controlleverintoa forward speed. FIGURE 15 1997 MODEL YEAR SHOWN m :_,_[_1 I: [rl_]: t,J= i =1,]=1 il _=[,, lo_ia= RAISING... -

Page 56: Accessories

V'_ltl'_1 ! W_.! : ] il =f;_*-[*4 =b'_._*] :! I $1 The SNAPPER Series D LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility. The accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for ordering any of the accessories desired. - Page 57 3. Electrical connections loose or corroded. 3. Clean end check connections for good contact.. 4. Defective ignition switch. 4. Contact authonzed SNAPPER dealer. ENGINE WILL NOT START 1. Blade engagement lever in the "ON" position. 1. Move blade engagement lever to "OFF"...

- Page 58 OIL LEAKING 1. Loose or missing oil filler cap. (Hydro Models Only) 1. Check oil level and replace oil cap. FROM TRANSMISSION 2. Leaking axle seals. 2. Contact authorized SNAPPER dealer. 3. Leaking at casing seal 3. Contact authorized SNAPPER dealer.

- Page 59 MAINTENANCE INSTRUCTIONS SERVICE SUBJECT REFERENCE EACH EACH TO BE PERFORMED PAGES HOURS HOURS HOURS HOURS SEASON Check Oil Level Engine Page 6 Initial Oil Change Engine Pages 15 & 16 Periodic Oil Change Engine page 15 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element &Page...

-

Page 60: Maintenance Instructions

MAINTENANCE INSTRUCTIONS SEAT ADJUSTING KNOBS The hydrostictransmission does not normally require maintainence, h owever, properoillevelshouldbeverified sfter everyseason. TO CHECK OIL LEVEL IN TRANSMISSION Remove seat by removing seat adjustment knobs, See Figure 18. Lay seat forward. Be careful not to pull seat switchwires from the switch. - Page 61 MAINTENANCE INSTRUCTIONS FILLER MODELS L T120G30DB, NL T120G30DB, TUBE LT125G33DB & LT125G38DB OIL DRAIN These models are equipped with 12 & 12 1/2 hp engines EXTENSION which are furnishes with extended oil drains. See Figure Raise tractorhood and tilt itforward. Disconnect s parkplugwire.

-

Page 62: Lubrication

MAINTENANCE INSTRUCTIONS The followinglubricationpoints shouldbe servicedafter each 25 operating hours to insure optimum performance of the Series D Lawn Tractor. FRONT WHEEL BEARINGS Lubricateeach front wheel bearing through the grease AXLE SPINDLE fitting on wheel hub. Using general purposegrease in a LUB RICATION FITTING greasegun, addgrease untilgreasepurgesfrom bearing. -

Page 63: Steering Drag Link

MAINTENANCE INSTRUCTIONS DRAG UNK LUBRICATION STEERING DRAG LINK Lubricateboth ends of steering drag link with a small amountof 30 wt. motoroilfrom anoilcan. See Figure26. STEERING TIE ROD Usingan oil can, filled with30wt. motoroil, lubricateboth ends of steeringtie rod. See Figure27. FIGURE 26 ::::C'o: BLADE ENGAGEMENT... -

Page 64: Engine Air Pre-Cleaner

MAINTENANCE INSTRUCTIONS The componentslistedshouldbe servicedon a regular AIR CLEANER basisto insurethattheyare intopworkingcondition. R efer to SERVICE SCHEDULE on Page 14 for recommended service intervals. ENGINE AIR PRE-CLEANER Theengineairpre-cleanershouldbe removedandcleaned every25 operatinghours.See Figure30. Referto Engine ENGINE AIR PRE.CLEANER Owner'sManual for specificcleaninginstructions. FIGURE 30 ENGINE AIR CLEANER The engine air cleaner element shouldbe removedand... -

Page 65: Engine Cooling System

MAINTENANCE INSTRUCTIONS ENGINE COOLING SYSTEM The engine coolingsystemconsists of an engine shroud and engine fins.These shouldbe kept clean and free of debris as needed or clean at least every 100 operating houm. REMOVE ADJUSTING KNOBS AND MOVE _ S ,TFO.WA.0, I / ,7 The batteryshouldbe servicedevery25 hours of opera- tion. -

Page 66: Battery Charging

MAINTENANCE INSTRUCTIONS Using distilledwater, fill cells as needed to 1/8" to 3/8" above cell plates. Replace cell covers. Charge battery if required. Install positive(+) cable first. Install negative(-) cable last. Install seat assembly over battery and secure in position with adjusting knobs. Leave knobs loose. Lower operator's seat and adjust to desired position. -

Page 67: Mower Deck Removal/Reinstallation

MAINTENANCE INSTRUCTIONS Should the tractiondrive belt show signs of excessive FRONT UFT ARM wear or damage, replace. MOWER DECK REMOVAL UFT ROD Placetractoron a firm,levelsurfacesuchas a drivewayor garage floor and engage park brake. Turn engine "OFF". HAIR PIN Raise hoodand removespark plugwire fromspark plug. Secure sparkplugwire away fromsparkplug.See Figure FIGURE 37 Lowerdeck to lowest setting. - Page 68 MAINTENANCE INSTRUCTIONS (30" & 33" BELT GUIDES SHOWN) Make note of hole used in sector plate. Slide sectorplates off of rear deck hanger brackets. Slide deck forward. Remove deck drive beItfrom engine pulley bottom groove. See Figure 40. Slide deck back and disconnect springfrom tension idler. Pull deck from under tractor from R.H.

- Page 69 MAINTENANCE INSTRUCTIONS Removetractiondrivebelt fromengine pulleytop groove. REMOVE See Figure44. FROM PULLEY Remove belt from center belt guide. Pullbelt untilitcan be removedfrom transmission pulley. TRACTION DRIVE BELT REPLACEMENT Place new traction drive belt over transmission pulley and span to engine pulley. Place belt intotop groove of engine pulley.

- Page 70 MAINTENANCE INSTRUCTIONS REMOVE SPINDLE PULLEY IDLER COVER 30" & 33" DECK DRIVE BELT REMOVAL AND REPLACEMENT Inspect deck drive belt for excessive wear and damage after every 25 operating hours. Replacement procedures are as follows: Place tractoron a firm, level surface. Turn engine "OFF".

-

Page 71: Standard Blade Wear Limits

MAINTENANCE INSTRUCTIONS " W.ARNING " Blades are extremely sharp and can cause severe injury. Wear heavy leather gloves when handling or I working around blades. DO NOT use a blade that is I excessively worn or damaged. WARNING I Never use a cutting blade that... - Page 72 MAINTENANCE INSTRUCTIONS Install blade mounting bolts, internal tooth lock washers and nuts. See Figure 53 Torque blade to 30 to 40 Ft, Lbs. 38" STANDARD MOWER BLADE REMOVAL REPLACEMENT Move tractor to a firm, level surface. Turn engine "OFF". (2- REQUIRED) Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

-

Page 73: Sharpening Standard Blade(S)

MAINTENANCE INSTRUCTIONS SHARPENING STANDARD BLADE(S) Blades should be kept sharp at all times. When the blade(s) are dull, cut grass will be ragged and lawn will usuallyturn brown.Sharpen standard bladesas follows: Move tractorto a firm, level surface. Tum engine "OFF'. Raise hood,remove spark plug wire from sparkplug and secure wire away from plug. - Page 74 MAINTENANCE INSTRUCTIONS BLADE Never use a blade that shows signs of excessive wear or damage. Refer to Figure 57 for NinJa blade wear limits. Sharpen allcuttingedges ofthe Ninja recycling blade at 27° (+3°, -2 °) for optimum performance. See Figure 58. Reinstall sharpened Ninja blade in reverse order of removal.

- Page 75 MAINTENANCE INSTRUCTIONS Secure stationaryidlerwith mountingbolt. Place sparkplug wire onto spark plug. Set park brake. Start Engine. Visuallyinspecttractiondrive belt for movement. When properlyadjusted,the tractiondrivebelt shouldnot have any movement or rotationwith the engine running and park brake engaged. Shouldmovement be present,readjusttractiondrive belt to releasebeittension asdescribedinprevious instructions.

-

Page 76: Side To Side Level

MAINTENANCE INSTRUCTIONS To adjust tension, remove extension rod mountingbolt and nut. See Figure62. TEN SION/d -_LEAST MOSTTENSlON • Move extension rodto next hole towards rear of deck and "-_ secure with mountingbolt and nut. MOUNTING- NUT & BOLT Measure extension spring with blade engagement lever in FIGURE 62 the "ON"... -

Page 77: Sector Plates

MAINTENANCE INSTRUCTIONS 33" DECK SHOWN Slidesectoroffof pinsand carefullylowerdeckontoangle iron. Rotate. b lade(s) until blade tips are at each side of deck. ANGLE IRON •Measuredistancefrom blade tip to flooron each side LMEASURE FROM deck. BLADE TIPS TO FLOOR Bladetips shouldbe within 1/8"ofeach otherfor thedeck FIGURE 66 to be consideredlevel. -

Page 78: Front Liftrod

MAINTENANCE INSTRUCTIONS NOTE: The deck shouldbe set sothat the rear ofthe deck is 1/4" 33" DECK SHOWN lowerthan the front. See Figure69. FRONT P'/////;! REAR X • 1/4" FRONT TO REAR LEVEL- FRONT LIFT ROD If the sector plates are in their lowest setting and proper L__ MEASUREFROM level cannot be obtained, adjust the front liftrod as follows: BLADETIPSTO FLOOR... - Page 79 MAINTENANCE INSTRUCTIONS FRONT OF TRACTOR NOTE: Before adjusting deck, bring tire pressureto proper psi. BLOCK Front 12 psi, Rear 10 psi. SIDE TO SIDE LEVEL Move tractor to a firm, level surface. Turn engine "OFF". Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

- Page 80 MAINTENANCE INSTRUCTIONS Attach the rear hanger plates to the hole that most closely aligns with the pin on the deck lift bracket. Secure with washer and hair pin. FRONT OF TRACTOR /h[ i !! !!ii! iiiii!i i ii! !i!!!i! !i Iiiiic i! !i ! Ni i ii!i Mii iii iii ii i i i i i i iiiiiiiiii Make certain sectorplates are mountedin the same I holes on each side for proper frontto rear level...

- Page 81 MAINTENANCE INSTRUCTIONS STEERING SECTOR Should excessive "PLAY" be present in the steering, adjustas follows: Tum Engine "OFF" and raise tractorhood. Remove spark plugwire from spark plug and securewire away from plug. From leftside of tractor, locate the steeringsector below fuel tank. See Figure 71. Looseneccentricmounting nut.

- Page 82 MAINTENANCE INSTRUCTIONS HYDRO DRIVE MODELS To be properlyadjusted,the brake shouldstopthe tractor in approximately 6 feet from top speed when the clutch/ brake pedal is fully depressed. BRAKE Adjustbrake when necessary as follows: Turn engine "OFF'. Raise hood, remove spark plugwire from spark plugand secure wire away from plug.

- Page 83 ELECTRICAL Figure 76 illustratestypical hamess muting on all the Series D Lawn Tractors. Use this when locatingvarious electricalcomponents. _---- O BATI1ERY NEGATIVE (-) -TO BATTERY PosmvF.(+) (UNDER SEAT) TERMINAL R,H° HEADLIGHT HEADUGHT SWITCH SWITCH BRAKE SWITCH 20 AMP- FUSE HEAD HARNESS HARNESS BLADE ENGAGEMENT...

- Page 84 ELECTRICAL The schematics below, Figure 77 & Figure 78 represent models with and without headlights. BRIGGS & STRA TTON WITHOUT LIGHTS BLACK PEDAL SWITCH INoj. "ED I SEAT SWITCH GREENI I N_ I II /-IGNITION ENGINE /GROUND I BLACK I" STARTER k '_--ALTERNATOR YELLOW...

- Page 85 McDonough, Georgia, to be defective in material or workmanship or both. For ninety (90) days from purchase date for the odginal purchaser's commercial, rental, or other non-residential use SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by th= factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 86 SERVICE NOTES...

- Page 87 SERVICE NOTES...

- Page 88 IA WARNING: The engine exhaust from this product contains chemicals known to the State I of Califomia to cause cancer, birth defects or other reproductive harm. COPYRIGHT © 1998 SNAPPER INC ALL RIGHTS RESERVED MANUAL No. 3-5576 (REV. 2, 6/98)

- Page 89 G - Gear Drive Transmission H - Hydrostatic Transmission 30 - 30" Cutting Width Mower 38 - 38" Cutting Width Mower 33 - 33" Cuttino Width Mower Thank for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

- Page 90 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN PROTECTION AGAINST TIPOVERS...

- Page 91 BLADE is ON or machine is in motion. 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices.

-

Page 92: Steering Adjustment

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ..2 & 2A MAINTENANCE INSTRUCTIONS (Continued) TABLE OF CONTENTS ........Battery Service ..........20-21 Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Charging ..........Serial & Model Number Location ......4 Controls ..............Components ............ -

Page 93: Familiarization

FAMILIARIZATION H_.'t::1 :! P"_I HE:I _v, (o] _] ::!mid _Ill L v,I :1:1:1 Ko]).]P',_In / (o]; • The serial and model number of the SNAPPER Series D REAR VIEW Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. - Page 94 FAMILIARIZATION [_o] Lv, I ".,To] _, 1 :1_, b u_ The nomenclature drawings, Figures 2 & 3, illustrate the essential components of the SNAPPER Series D Lawn CHOKE Tractor. It is recommended that all operators of this equipment become thoroughly...

-

Page 95: Operating Instructions

OPERATING INSTRUCTIONS I d :! =5.'t if:! :_iI It.,].-I :(H ;I ii [..1 ,i Make the followingchecks and perform service as re- quiredbeforeeach start-up. Check tires and add air as needed to bringpressure to 12psi in fronttires and 10 psi in rear tires. If guards are missingor damaged, Replace BEFORE usingmower. -

Page 96: Starting & Stopping Engine

OPERATING INSTRUCTIONS :,In #,I :_idI: [rl:_..'t liD] "J"JI: [tl =1 _[r] I: I =i STARTING ENGINE Take a comfortablepositionin seat of ridingmower,look ENGAGEMENT aroundto make sure that the area you are goingto mow LEVER is clear of people, children and pets. Take note of any stationaryobstacles! NOTE: The interlocksystemwillpreventthe engine from starting... - Page 97 OPERATING INSTRUCTIONS _._ net :_unlI: [_lr:l-_ n[o]"J"JI _[riYl: 1:1=1 nl ,] ;1 Lvi= HANDLE STARTING WHEEL DRIVE OF HYDRO MODELS Shift speed controllever to neutral. REVERSE Start engine. Release brake pedal. Slowlyshiftspeed controlleverforwardfor forwardmotion or to the rear for reverse motion.See Figure9. FORWARD SPEEDS STOPPING...

- Page 98 OPERATING INSTRUCTIONS _-'lmmr.1 :_m nlI _[rt::lE._m go] ..J..J I _[it L', [ olV,'J=1 :l :| mF_,l p]=l PULL BLADE ENGAGEMENT LEVER UP TO "ON" TO START MOWER BLADE(S) STARTING MOWER BLADE Start engine. Raise blade engagement lever to "ON". See Figure 12. STOPPING MOWER BLADE ENGAGEMENT LEVER...

-

Page 99: Raising Chute Deflector

OPERATING INSTRUCTIONS ROLLING GEAR DRIVE MODELS GEAR DRIVEMODELSHOWN With engine 'OFF', fullydepressclutcl_/brake pedal. Place speed controllever in the neutral (N) position.See Figure 15. Release clutch/brakepedal and movetractorto desired location. -SPEED CONTROL HANDLE Setparkbrake andplace speed controlleverintoa forward speed. FIGURE 15 1997 MODEL YEAR SHOWN m :_,_[_1 I: [rl_]: t,J= i =1,]=1 il _=[,, lo_ia= RAISING... -

Page 100: Accessories

V'_ltl'_1 ! W_.! : ] il =f;_*-[*4 =b'_._*] :! I $1 The SNAPPER Series D LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility. The accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for ordering any of the accessories desired. - Page 101 3. Electrical connections loose or corroded. 3. Clean end check connections for good contact.. 4. Defective ignition switch. 4. Contact authonzed SNAPPER dealer. ENGINE WILL NOT START 1. Blade engagement lever in the "ON" position. 1. Move blade engagement lever to "OFF"...

- Page 102 OIL LEAKING 1. Loose or missing oil filler cap. (Hydro Models Only) 1. Check oil level and replace oil cap. FROM TRANSMISSION 2. Leaking axle seals. 2. Contact authorized SNAPPER dealer. 3. Leaking at casing seal 3. Contact authorized SNAPPER dealer.

- Page 103 MAINTENANCE INSTRUCTIONS SERVICE SUBJECT REFERENCE EACH EACH TO BE PERFORMED PAGES HOURS HOURS HOURS HOURS SEASON Check Oil Level Engine Page 6 Initial Oil Change Engine Pages 15 & 16 Periodic Oil Change Engine page 15 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element &Page...

-

Page 104: Maintenance Instructions

MAINTENANCE INSTRUCTIONS SEAT ADJUSTING KNOBS The hydrostictransmission does not normally require maintainence, h owever, properoillevelshouldbeverified sfter everyseason. TO CHECK OIL LEVEL IN TRANSMISSION Remove seat by removing seat adjustment knobs, See Figure 18. Lay seat forward. Be careful not to pull seat switchwires from the switch. - Page 105 MAINTENANCE INSTRUCTIONS FILLER MODELS L T120G30DB, NL T120G30DB, TUBE LT125G33DB & LT125G38DB OIL DRAIN These models are equipped with 12 & 12 1/2 hp engines EXTENSION which are furnishes with extended oil drains. See Figure Raise tractorhood and tilt itforward. Disconnect s parkplugwire.

-

Page 106: Lubrication

MAINTENANCE INSTRUCTIONS The followinglubricationpoints shouldbe servicedafter each 25 operating hours to insure optimum performance of the Series D Lawn Tractor. FRONT WHEEL BEARINGS Lubricateeach front wheel bearing through the grease AXLE SPINDLE fitting on wheel hub. Using general purposegrease in a LUB RICATION FITTING greasegun, addgrease untilgreasepurgesfrom bearing. -

Page 107: Steering Drag Link

MAINTENANCE INSTRUCTIONS DRAG UNK LUBRICATION STEERING DRAG LINK Lubricateboth ends of steering drag link with a small amountof 30 wt. motoroilfrom anoilcan. See Figure26. STEERING TIE ROD Usingan oil can, filled with30wt. motoroil, lubricateboth ends of steeringtie rod. See Figure27. FIGURE 26 ::::C'o: BLADE ENGAGEMENT... -

Page 108: Engine Air Pre-Cleaner

MAINTENANCE INSTRUCTIONS The componentslistedshouldbe servicedon a regular AIR CLEANER basisto insurethattheyare intopworkingcondition. R efer to SERVICE SCHEDULE on Page 14 for recommended service intervals. ENGINE AIR PRE-CLEANER Theengineairpre-cleanershouldbe removedandcleaned every25 operatinghours.See Figure30. Referto Engine ENGINE AIR PRE.CLEANER Owner'sManual for specificcleaninginstructions. FIGURE 30 ENGINE AIR CLEANER The engine air cleaner element shouldbe removedand... -

Page 109: Engine Cooling System

MAINTENANCE INSTRUCTIONS ENGINE COOLING SYSTEM The engine coolingsystemconsists of an engine shroud and engine fins.These shouldbe kept clean and free of debris as needed or clean at least every 100 operating houm. REMOVE ADJUSTING KNOBS AND MOVE _ S ,TFO.WA.0, I / ,7 The batteryshouldbe servicedevery25 hours of opera- tion. -

Page 110: Battery Charging

MAINTENANCE INSTRUCTIONS Using distilledwater, fill cells as needed to 1/8" to 3/8" above cell plates. Replace cell covers. Charge battery if required. Install positive(+) cable first. Install negative(-) cable last. Install seat assembly over battery and secure in position with adjusting knobs. Leave knobs loose. Lower operator's seat and adjust to desired position. -

Page 111: Mower Deck Removal/Reinstallation

MAINTENANCE INSTRUCTIONS Should the tractiondrive belt show signs of excessive FRONT UFT ARM wear or damage, replace. MOWER DECK REMOVAL UFT ROD Placetractoron a firm,levelsurfacesuchas a drivewayor garage floor and engage park brake. Turn engine "OFF". HAIR PIN Raise hoodand removespark plugwire fromspark plug. Secure sparkplugwire away fromsparkplug.See Figure FIGURE 37 Lowerdeck to lowest setting. - Page 112 MAINTENANCE INSTRUCTIONS (30" & 33" BELT GUIDES SHOWN) Make note of hole used in sector plate. Slide sectorplates off of rear deck hanger brackets. Slide deck forward. Remove deck drive beItfrom engine pulley bottom groove. See Figure 40. Slide deck back and disconnect springfrom tension idler. Pull deck from under tractor from R.H.

- Page 113 MAINTENANCE INSTRUCTIONS Removetractiondrivebelt fromengine pulleytop groove. REMOVE See Figure44. FROM PULLEY Remove belt from center belt guide. Pullbelt untilitcan be removedfrom transmission pulley. TRACTION DRIVE BELT REPLACEMENT Place new traction drive belt over transmission pulley and span to engine pulley. Place belt intotop groove of engine pulley.

- Page 114 MAINTENANCE INSTRUCTIONS REMOVE SPINDLE PULLEY IDLER COVER 30" & 33" DECK DRIVE BELT REMOVAL AND REPLACEMENT Inspect deck drive belt for excessive wear and damage after every 25 operating hours. Replacement procedures are as follows: Place tractoron a firm, level surface. Turn engine "OFF".

-

Page 115: Standard Blade Wear Limits

MAINTENANCE INSTRUCTIONS " W.ARNING " Blades are extremely sharp and can cause severe injury. Wear heavy leather gloves when handling or I working around blades. DO NOT use a blade that is I excessively worn or damaged. WARNING I Never use a cutting blade that... - Page 116 MAINTENANCE INSTRUCTIONS Install blade mounting bolts, internal tooth lock washers and nuts. See Figure 53 Torque blade to 30 to 40 Ft, Lbs. 38" STANDARD MOWER BLADE REMOVAL REPLACEMENT Move tractor to a firm, level surface. Turn engine "OFF". (2- REQUIRED) Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

-

Page 117: Sharpening Standard Blade(S)

MAINTENANCE INSTRUCTIONS SHARPENING STANDARD BLADE(S) Blades should be kept sharp at all times. When the blade(s) are dull, cut grass will be ragged and lawn will usuallyturn brown.Sharpen standard bladesas follows: Move tractorto a firm, level surface. Tum engine "OFF'. Raise hood,remove spark plug wire from sparkplug and secure wire away from plug. - Page 118 MAINTENANCE INSTRUCTIONS BLADE Never use a blade that shows signs of excessive wear or damage. Refer to Figure 57 for NinJa blade wear limits. Sharpen allcuttingedges ofthe Ninja recycling blade at 27° (+3°, -2 °) for optimum performance. See Figure 58. Reinstall sharpened Ninja blade in reverse order of removal.

- Page 119 MAINTENANCE INSTRUCTIONS Secure stationaryidlerwith mountingbolt. Place sparkplug wire onto spark plug. Set park brake. Start Engine. Visuallyinspecttractiondrive belt for movement. When properlyadjusted,the tractiondrivebelt shouldnot have any movement or rotationwith the engine running and park brake engaged. Shouldmovement be present,readjusttractiondrive belt to releasebeittension asdescribedinprevious instructions.

-

Page 120: Side To Side Level

MAINTENANCE INSTRUCTIONS To adjust tension, remove extension rod mountingbolt and nut. See Figure62. TEN SION/d -_LEAST MOSTTENSlON • Move extension rodto next hole towards rear of deck and "-_ secure with mountingbolt and nut. MOUNTING- NUT & BOLT Measure extension spring with blade engagement lever in FIGURE 62 the "ON"... -

Page 121: Sector Plates

MAINTENANCE INSTRUCTIONS 33" DECK SHOWN Slidesectoroffof pinsand carefullylowerdeckontoangle iron. Rotate. b lade(s) until blade tips are at each side of deck. ANGLE IRON •Measuredistancefrom blade tip to flooron each side LMEASURE FROM deck. BLADE TIPS TO FLOOR Bladetips shouldbe within 1/8"ofeach otherfor thedeck FIGURE 66 to be consideredlevel. -

Page 122: Front Liftrod

MAINTENANCE INSTRUCTIONS NOTE: The deck shouldbe set sothat the rear ofthe deck is 1/4" 33" DECK SHOWN lowerthan the front. See Figure69. FRONT P'/////;! REAR X • 1/4" FRONT TO REAR LEVEL- FRONT LIFT ROD If the sector plates are in their lowest setting and proper L__ MEASUREFROM level cannot be obtained, adjust the front liftrod as follows: BLADETIPSTO FLOOR... - Page 123 MAINTENANCE INSTRUCTIONS FRONT OF TRACTOR NOTE: Before adjusting deck, bring tire pressureto proper psi. BLOCK Front 12 psi, Rear 10 psi. SIDE TO SIDE LEVEL Move tractor to a firm, level surface. Turn engine "OFF". Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

- Page 124 MAINTENANCE INSTRUCTIONS Attach the rear hanger plates to the hole that most closely aligns with the pin on the deck lift bracket. Secure with washer and hair pin. FRONT OF TRACTOR /h[ i !! !!ii! iiiii!i i ii! !i!!!i! !i Iiiiic i! !i ! Ni i ii!i Mii iii iii ii i i i i i i iiiiiiiiii Make certain sectorplates are mountedin the same I holes on each side for proper frontto rear level...

- Page 125 MAINTENANCE INSTRUCTIONS STEERING SECTOR Should excessive "PLAY" be present in the steering, adjustas follows: Tum Engine "OFF" and raise tractorhood. Remove spark plugwire from spark plug and securewire away from plug. From leftside of tractor, locate the steeringsector below fuel tank. See Figure 71. Looseneccentricmounting nut.

- Page 126 MAINTENANCE INSTRUCTIONS HYDRO DRIVE MODELS To be properlyadjusted,the brake shouldstopthe tractor in approximately 6 feet from top speed when the clutch/ brake pedal is fully depressed. BRAKE Adjustbrake when necessary as follows: Turn engine "OFF'. Raise hood, remove spark plugwire from spark plugand secure wire away from plug.

- Page 127 ELECTRICAL Figure 76 illustratestypical hamess muting on all the Series D Lawn Tractors. Use this when locatingvarious electricalcomponents. _---- O BATI1ERY NEGATIVE (-) -TO BATTERY PosmvF.(+) (UNDER SEAT) TERMINAL R,H° HEADLIGHT HEADUGHT SWITCH SWITCH BRAKE SWITCH 20 AMP- FUSE HEAD HARNESS HARNESS BLADE ENGAGEMENT...

- Page 128 ELECTRICAL The schematics below, Figure 77 & Figure 78 represent models with and without headlights. BRIGGS & STRA TTON WITHOUT LIGHTS BLACK PEDAL SWITCH INoj. "ED I SEAT SWITCH GREENI I N_ I II /-IGNITION ENGINE /GROUND I BLACK I" STARTER k '_--ALTERNATOR YELLOW...

- Page 129 McDonough, Georgia, to be defective in material or workmanship or both. For ninety (90) days from purchase date for the odginal purchaser's commercial, rental, or other non-residential use SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by th= factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 130 SERVICE NOTES...

- Page 131 SERVICE NOTES...

- Page 132 IA WARNING: The engine exhaust from this product contains chemicals known to the State I of Califomia to cause cancer, birth defects or other reproductive harm. COPYRIGHT © 1998 SNAPPER INC ALL RIGHTS RESERVED MANUAL No. 3-5576 (REV. 2, 6/98)

- Page 133 G - Gear Drive Transmission H - Hydrostatic Transmission 30 - 30" Cutting Width Mower 38 - 38" Cutting Width Mower 33 - 33" Cuttino Width Mower Thank for buying a SNAPPER product! Before operating the Lawn Tractor, read and follow "IMPORTANT SAFETY INSTRUCTIONS"...

- Page 134 If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). PROTECTION FOR CHILDREN PROTECTION AGAINST TIPOVERS...

- Page 135 BLADE is ON or machine is in motion. 14. Have machine serviced authorized Deflector or entire grass catcher must be in place. SNAPPER dealer at least once a year and have the NEVER point discharge at people, passing cars, dealer install any new safety devices.

-

Page 136: Shifter Adj Ustment

TABLE OF CONTENTS IMPORTANT SAFETY INSTRUCTIONS ..2 & 2A MAINTENANCE INSTRUCTIONS (Continued) TABLE OF CONTENTS ........Battery Service ..........20-21 Battery Electrolyte Check ......FAMILIARIZATION ..........Battery Charging ..........Serial & Model Number Location ......4 Controls ..............Components ............ -

Page 137: Familiarization

FAMILIARIZATION H_.'t::1 :! P"_I HE:I _v, (o] _] ::!mid _Ill L v,I :1:1:1 Ko]).]P',_In / (o]; • The serial and model number of the SNAPPER Series D REAR VIEW Lawn Tractor are located on the rear face of the tractor frame as shown in Figure 1. -

Page 138: Controls

FAMILIARIZATION [_o] Lv, I ".,To] _, 1 :1_, b u_ The nomenclature drawings, Figures 2 & 3, illustrate the essential components of the SNAPPER Series D Lawn CHOKE Tractor. It is recommended that all operators of this equipment become thoroughly... -

Page 139: Operating Instructions

OPERATING INSTRUCTIONS I d :! =5.'t if:! :_iI It.,].-I :(H ;I ii [..1 ,i Make the followingchecks and perform service as re- quiredbeforeeach start-up. Check tires and add air as needed to bringpressure to 12psi in fronttires and 10 psi in rear tires. If guards are missingor damaged, Replace BEFORE usingmower. -

Page 140: Starting & Stopping Engine

OPERATING INSTRUCTIONS :,In #,I :_idI: [rl:_..'t liD] "J"JI: [tl =1 _[r] I: I =i STARTING ENGINE Take a comfortablepositionin seat of ridingmower,look ENGAGEMENT aroundto make sure that the area you are goingto mow LEVER is clear of people, children and pets. Take note of any stationaryobstacles! NOTE: The interlocksystemwillpreventthe engine from starting... - Page 141 OPERATING INSTRUCTIONS _._ net :_unlI: [_lr:l-_ n[o]"J"JI _[riYl: 1:1=1 nl ,] ;1 Lvi= HANDLE STARTING WHEEL DRIVE OF HYDRO MODELS Shift speed controllever to neutral. REVERSE Start engine. Release brake pedal. Slowlyshiftspeed controlleverforwardfor forwardmotion or to the rear for reverse motion.See Figure9. FORWARD SPEEDS STOPPING...

- Page 142 OPERATING INSTRUCTIONS _-'lmmr.1 :_m nlI _[rt::lE._m go] ..J..J I _[it L', [ olV,'J=1 :l :| mF_,l p]=l PULL BLADE ENGAGEMENT LEVER UP TO "ON" TO START MOWER BLADE(S) STARTING MOWER BLADE Start engine. Raise blade engagement lever to "ON". See Figure 12. STOPPING MOWER BLADE ENGAGEMENT LEVER...

-

Page 143: Raising Chute Deflector

OPERATING INSTRUCTIONS ROLLING GEAR DRIVE MODELS GEAR DRIVEMODELSHOWN With engine 'OFF', fullydepressclutcl_/brake pedal. Place speed controllever in the neutral (N) position.See Figure 15. Release clutch/brakepedal and movetractorto desired location. -SPEED CONTROL HANDLE Setparkbrake andplace speed controlleverintoa forward speed. FIGURE 15 1997 MODEL YEAR SHOWN m :_,_[_1 I: [rl_]: t,J= i =1,]=1 il _=[,, lo_ia= RAISING... -

Page 144: Accessories

V'_ltl'_1 ! W_.! : ] il =f;_*-[*4 =b'_._*] :! I $1 The SNAPPER Series D LAWN TRACTOR can be equipped with a variety of accessories that increase its versatility. The accessories available for each model are listed in the chart below. Contact an authorized SNAPPER dealer for ordering any of the accessories desired. - Page 145 3. Electrical connections loose or corroded. 3. Clean end check connections for good contact.. 4. Defective ignition switch. 4. Contact authonzed SNAPPER dealer. ENGINE WILL NOT START 1. Blade engagement lever in the "ON" position. 1. Move blade engagement lever to "OFF"...

- Page 146 OIL LEAKING 1. Loose or missing oil filler cap. (Hydro Models Only) 1. Check oil level and replace oil cap. FROM TRANSMISSION 2. Leaking axle seals. 2. Contact authorized SNAPPER dealer. 3. Leaking at casing seal 3. Contact authorized SNAPPER dealer.

- Page 147 MAINTENANCE INSTRUCTIONS SERVICE SUBJECT REFERENCE EACH EACH TO BE PERFORMED PAGES HOURS HOURS HOURS HOURS SEASON Check Oil Level Engine Page 6 Initial Oil Change Engine Pages 15 & 16 Periodic Oil Change Engine page 15 Air Pre-Cleaner Service Sponge Pre- Engine Manual Cleaner Element &Page...

-

Page 148: Maintenance Instructions

MAINTENANCE INSTRUCTIONS SEAT ADJUSTING KNOBS The hydrostictransmission does not normally require maintainence, h owever, properoillevelshouldbeverified sfter everyseason. TO CHECK OIL LEVEL IN TRANSMISSION Remove seat by removing seat adjustment knobs, See Figure 18. Lay seat forward. Be careful not to pull seat switchwires from the switch. - Page 149 MAINTENANCE INSTRUCTIONS FILLER MODELS L T120G30DB, NL T120G30DB, TUBE LT125G33DB & LT125G38DB OIL DRAIN These models are equipped with 12 & 12 1/2 hp engines EXTENSION which are furnishes with extended oil drains. See Figure Raise tractorhood and tilt itforward. Disconnect s parkplugwire.

-

Page 150: Lubrication

MAINTENANCE INSTRUCTIONS The followinglubricationpoints shouldbe servicedafter each 25 operating hours to insure optimum performance of the Series D Lawn Tractor. FRONT WHEEL BEARINGS Lubricateeach front wheel bearing through the grease AXLE SPINDLE fitting on wheel hub. Using general purposegrease in a LUB RICATION FITTING greasegun, addgrease untilgreasepurgesfrom bearing. -

Page 151: Steering Drag Link

MAINTENANCE INSTRUCTIONS DRAG UNK LUBRICATION STEERING DRAG LINK Lubricateboth ends of steering drag link with a small amountof 30 wt. motoroilfrom anoilcan. See Figure26. STEERING TIE ROD Usingan oil can, filled with30wt. motoroil, lubricateboth ends of steeringtie rod. See Figure27. FIGURE 26 ::::C'o: BLADE ENGAGEMENT... -

Page 152: Engine Air Pre-Cleaner

MAINTENANCE INSTRUCTIONS The componentslistedshouldbe servicedon a regular AIR CLEANER basisto insurethattheyare intopworkingcondition. R efer to SERVICE SCHEDULE on Page 14 for recommended service intervals. ENGINE AIR PRE-CLEANER Theengineairpre-cleanershouldbe removedandcleaned every25 operatinghours.See Figure30. Referto Engine ENGINE AIR PRE.CLEANER Owner'sManual for specificcleaninginstructions. FIGURE 30 ENGINE AIR CLEANER The engine air cleaner element shouldbe removedand... -

Page 153: Engine Cooling System

MAINTENANCE INSTRUCTIONS ENGINE COOLING SYSTEM The engine coolingsystemconsists of an engine shroud and engine fins.These shouldbe kept clean and free of debris as needed or clean at least every 100 operating houm. REMOVE ADJUSTING KNOBS AND MOVE _ S ,TFO.WA.0, I / ,7 The batteryshouldbe servicedevery25 hours of opera- tion. -

Page 154: Battery Charging

MAINTENANCE INSTRUCTIONS Using distilledwater, fill cells as needed to 1/8" to 3/8" above cell plates. Replace cell covers. Charge battery if required. Install positive(+) cable first. Install negative(-) cable last. Install seat assembly over battery and secure in position with adjusting knobs. Leave knobs loose. Lower operator's seat and adjust to desired position. -

Page 155: Mower Deck Removal/Reinstallation

MAINTENANCE INSTRUCTIONS Should the tractiondrive belt show signs of excessive FRONT UFT ARM wear or damage, replace. MOWER DECK REMOVAL UFT ROD Placetractoron a firm,levelsurfacesuchas a drivewayor garage floor and engage park brake. Turn engine "OFF". HAIR PIN Raise hoodand removespark plugwire fromspark plug. Secure sparkplugwire away fromsparkplug.See Figure FIGURE 37 Lowerdeck to lowest setting. - Page 156 MAINTENANCE INSTRUCTIONS (30" & 33" BELT GUIDES SHOWN) Make note of hole used in sector plate. Slide sectorplates off of rear deck hanger brackets. Slide deck forward. Remove deck drive beItfrom engine pulley bottom groove. See Figure 40. Slide deck back and disconnect springfrom tension idler. Pull deck from under tractor from R.H.

- Page 157 MAINTENANCE INSTRUCTIONS Removetractiondrivebelt fromengine pulleytop groove. REMOVE See Figure44. FROM PULLEY Remove belt from center belt guide. Pullbelt untilitcan be removedfrom transmission pulley. TRACTION DRIVE BELT REPLACEMENT Place new traction drive belt over transmission pulley and span to engine pulley. Place belt intotop groove of engine pulley.

- Page 158 MAINTENANCE INSTRUCTIONS REMOVE SPINDLE PULLEY IDLER COVER 30" & 33" DECK DRIVE BELT REMOVAL AND REPLACEMENT Inspect deck drive belt for excessive wear and damage after every 25 operating hours. Replacement procedures are as follows: Place tractoron a firm, level surface. Turn engine "OFF".

-

Page 159: Standard Blade Wear Limits

MAINTENANCE INSTRUCTIONS " W.ARNING " Blades are extremely sharp and can cause severe injury. Wear heavy leather gloves when handling or I working around blades. DO NOT use a blade that is I excessively worn or damaged. WARNING I Never use a cutting blade that... - Page 160 MAINTENANCE INSTRUCTIONS Install blade mounting bolts, internal tooth lock washers and nuts. See Figure 53 Torque blade to 30 to 40 Ft, Lbs. 38" STANDARD MOWER BLADE REMOVAL REPLACEMENT Move tractor to a firm, level surface. Turn engine "OFF". (2- REQUIRED) Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

-

Page 161: Sharpening Standard Blade(S)

MAINTENANCE INSTRUCTIONS SHARPENING STANDARD BLADE(S) Blades should be kept sharp at all times. When the blade(s) are dull, cut grass will be ragged and lawn will usuallyturn brown.Sharpen standard bladesas follows: Move tractorto a firm, level surface. Tum engine "OFF'. Raise hood,remove spark plug wire from sparkplug and secure wire away from plug. - Page 162 MAINTENANCE INSTRUCTIONS BLADE Never use a blade that shows signs of excessive wear or damage. Refer to Figure 57 for NinJa blade wear limits. Sharpen allcuttingedges ofthe Ninja recycling blade at 27° (+3°, -2 °) for optimum performance. See Figure 58. Reinstall sharpened Ninja blade in reverse order of removal.

- Page 163 MAINTENANCE INSTRUCTIONS Secure stationaryidlerwith mountingbolt. Place sparkplug wire onto spark plug. Set park brake. Start Engine. Visuallyinspecttractiondrive belt for movement. When properlyadjusted,the tractiondrivebelt shouldnot have any movement or rotationwith the engine running and park brake engaged. Shouldmovement be present,readjusttractiondrive belt to releasebeittension asdescribedinprevious instructions.

-

Page 164: Side To Side Level

MAINTENANCE INSTRUCTIONS To adjust tension, remove extension rod mountingbolt and nut. See Figure62. TEN SION/d -_LEAST MOSTTENSlON • Move extension rodto next hole towards rear of deck and "-_ secure with mountingbolt and nut. MOUNTING- NUT & BOLT Measure extension spring with blade engagement lever in FIGURE 62 the "ON"... -

Page 165: Sector Plates

MAINTENANCE INSTRUCTIONS 33" DECK SHOWN Slidesectoroffof pinsand carefullylowerdeckontoangle iron. Rotate. b lade(s) until blade tips are at each side of deck. ANGLE IRON •Measuredistancefrom blade tip to flooron each side LMEASURE FROM deck. BLADE TIPS TO FLOOR Bladetips shouldbe within 1/8"ofeach otherfor thedeck FIGURE 66 to be consideredlevel. -

Page 166: Front Liftrod

MAINTENANCE INSTRUCTIONS NOTE: The deck shouldbe set sothat the rear ofthe deck is 1/4" 33" DECK SHOWN lowerthan the front. See Figure69. FRONT P'/////;! REAR X • 1/4" FRONT TO REAR LEVEL- FRONT LIFT ROD If the sector plates are in their lowest setting and proper L__ MEASUREFROM level cannot be obtained, adjust the front liftrod as follows: BLADETIPSTO FLOOR... - Page 167 MAINTENANCE INSTRUCTIONS FRONT OF TRACTOR NOTE: Before adjusting deck, bring tire pressureto proper psi. BLOCK Front 12 psi, Rear 10 psi. SIDE TO SIDE LEVEL Move tractor to a firm, level surface. Turn engine "OFF". Raise hood, remove spark plug wire from spark plug and secure wire away from plug.

- Page 168 MAINTENANCE INSTRUCTIONS Attach the rear hanger plates to the hole that most closely aligns with the pin on the deck lift bracket. Secure with washer and hair pin. FRONT OF TRACTOR /h[ i !! !!ii! iiiii!i i ii! !i!!!i! !i Iiiiic i! !i ! Ni i ii!i Mii iii iii ii i i i i i i iiiiiiiiii Make certain sectorplates are mountedin the same I holes on each side for proper frontto rear level...

- Page 169 MAINTENANCE INSTRUCTIONS STEERING SECTOR Should excessive "PLAY" be present in the steering, adjustas follows: Tum Engine "OFF" and raise tractorhood. Remove spark plugwire from spark plug and securewire away from plug. From leftside of tractor, locate the steeringsector below fuel tank. See Figure 71. Looseneccentricmounting nut.

- Page 170 MAINTENANCE INSTRUCTIONS HYDRO DRIVE MODELS To be properlyadjusted,the brake shouldstopthe tractor in approximately 6 feet from top speed when the clutch/ brake pedal is fully depressed. BRAKE Adjustbrake when necessary as follows: Turn engine "OFF'. Raise hood, remove spark plugwire from spark plugand secure wire away from plug.

- Page 171 ELECTRICAL Figure 76 illustratestypical hamess muting on all the Series D Lawn Tractors. Use this when locatingvarious electricalcomponents. _---- O BATI1ERY NEGATIVE (-) -TO BATTERY PosmvF.(+) (UNDER SEAT) TERMINAL R,H° HEADLIGHT HEADUGHT SWITCH SWITCH BRAKE SWITCH 20 AMP- FUSE HEAD HARNESS HARNESS BLADE ENGAGEMENT...

- Page 172 ELECTRICAL The schematics below, Figure 77 & Figure 78 represent models with and without headlights. BRIGGS & STRA TTON WITHOUT LIGHTS BLACK PEDAL SWITCH INoj. "ED I SEAT SWITCH GREENI I N_ I II /-IGNITION ENGINE /GROUND I BLACK I" STARTER k '_--ALTERNATOR YELLOW...

- Page 173 McDonough, Georgia, to be defective in material or workmanship or both. For ninety (90) days from purchase date for the odginal purchaser's commercial, rental, or other non-residential use SNAPPER, through any SNAPPER dealer will replace, free of charge, any part or parts found upon examination by th= factory at McDonough, Georgia, to be defective in material or workmanship or both.

- Page 174 SERVICE NOTES...

- Page 175 SERVICE NOTES...

- Page 176 IA WARNING: The engine exhaust from this product contains chemicals known to the State I of Califomia to cause cancer, birth defects or other reproductive harm. COPYRIGHT © 1998 SNAPPER INC ALL RIGHTS RESERVED MANUAL No. 3-5576 (REV. 2, 6/98)