Summary of Contents for Canon imageRUNNER 1019J

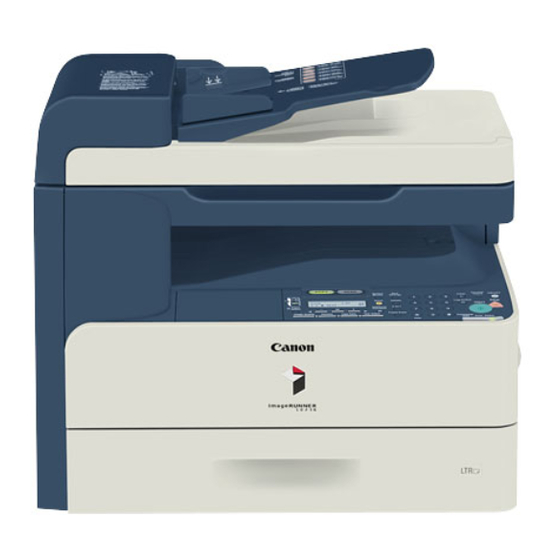

- Page 1 imageRUNNER imageRUNNER 1019J/1023/ 1019J/1023/ 1023N/1023iF 1023N/1023iF SERVICE SERVICE MANUAL MANUAL DU7-1207-000 DU7-1207-000...

- Page 2 Application Application This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance maintenance, and repair of products. This , and repair of products.

- Page 3 Introduction Introduction Symbols Used Symbols Used This documentation uses the following symbols to indicate special This documentation uses the following symbols to indicate special information: information: S S y y m m b b o o l l D D e e s s c c r r i i p p t t i i o o n n Indicates an item of a non-specific nature, possibly classified as Note, Caution, or ...

- Page 4 Introduction Introduction The following rules apply throughout this Service Manual: The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between elec- purpose of specific functions and the relationship between elec- trical and mechanical systems with reference to the trical and mechanical systems with reference to the timing of operation.

- Page 5 Contents Contents Contents Contents Chapter 1 Chapter 1 Introduction Introduction 1.1 System Construction System Construction ....................................1-1 1.1.1 System Configuration System Configuration ....................1-1 1.1.1 ....................1-1 1.2 Product Specifications Product Specifications .................................... 1-3 1.2.1 Names of Parts Names of Parts ......................1-3 1.2.1...

- Page 6 Contents Contents 1.2.7.1 1.2.7.1 Print Speed (iR1019J)) Print Speed (iR1019J)) ..........................................1-31 1-31 1.2.7.2 Print Speed (iR1023/1023N/1023iF) Print Speed (iR1023/1023N/1023iF) ... 1.2.7.2 ..............................1-32 1-32 1.2.7.3 Types of Paper ...

-

Page 7: Table Of Contents

Contents 4.2.2 Basic Sequence after Depression of Start Key (Book mode, One Sheet of original) 4.2.3 Basic Sequence after Depression of Start Key (ADF Mode, One Sheet of Original) 4.3 Various Control ....................4-6 4.3.1 Enlargement/Reduction ....................4-6 4.3.1.1 Magnification Change in Vertical Scan Direction ............4-6 4.3.1.2 Magnification Change in Horizontal Scan Direction ............ - Page 8 Contents 7.2 Detecting Jams ....................7-2 7.2.1 Jam Detection Outline ....................7-2 7.2.1.1 Outline ............................ 7-2 7.2.1.2 Types of Jams ........................7-3 7.3 Cassette Pick-Up Unit ..................7-4 7.3.1 Outline ......................... 7-4 7.3.2 Retry Pickup ....................... 7-4 7.3.3 Detecting the Size of Paper ...

- Page 9 Contents 8.4 Parts Replacement Procedure ................ 8-7 8.4.1 Fixing Unit ........................8-7 8.4.2 Pressure Roller ......................8-10 8.4.3 Fixing Film .........................8-11 8.4.4 Fixing Delivery Sensor ....................8-12 Chapter 9 External and Controls 9.1 Control Panel ..................... 9-1 9.1.1 Outline .......................... 9-1 9.2 Fans ........................9-1 9.2.1 Outline ..........................

- Page 10 Contents 10.2.3 Paper Pickup Operation ..................10-6 10.2.4 Reversal Operation ....................10-7 10.2.5 Delivery Operation ....................10-8 10.3 Detection Jams ....................10-9 10.3.1 Outline ........................10-9 10.4 Parts Replacement Procedure ..............10-11 10.4.1 ADF ........................10-11 10.4.2 External Covers ..........

- Page 11 Contents 12.3.2 Actions to Take before All Clearing (Backing up the User Data) ....12-3 12.4 ADF ......................... 12-4 12.4.1 Outline ........................12-4 12.4.1.1 Outline ..........................12-4 12.4.1.2 Preparing a Test Sheet for Adjustment ................. 12-4 12.4.2 Adjusting the Mechanical System ...............12-5 12.4.2.1 Adjusting the Perpendicularity ..................

- Page 12 Chapter 1 Noise Copying (A4/22cpm):66.7 dB or less (reference) (LTR/23cpm):67.05 dB or less (reference) (A4/18cpm):65.3dB dB or less (reference) (LTR/19cpm):65.65 dB or less (reference) Power supply rating 120V (50/60Hz), 230V (50/60Hz) Power consumption 120V: Approx. 748 kW (max.) (maximum) 230V: Approx. 954 kW (max.) Continuous printing: 120V/ approx.432 Wh, 230V/ approx.417 Power consumption Standby: 120V/ approx.18.2 Wh, 230V/ approx.19.7 Wh...

- Page 13 Chapter 1 Original size recognition Stamp Same as that of host machine. Operating environment 1.2.6.3 Fax Specifications 0013-1044 Applicable lines Subscriber telephone line (PSTN) G3 / ECM Transmission method Modulation method <G3 image signal> ITU-T V.27 ter (2.4Kbps, 4.8Kbps) ITU-T V.29 (7.2Kbps, 9.6Kbps) ITU-T V.17 (TC7.2Kbps, TC9.6Kbps, 12Kbps, 14.4Kbps) ITU-T V.34 (2.4Kbps, 4.8Kbps, 7.2Kbps, 9.6Kbps, 12Kbps, 14.4Kbps, 16.8Kbps, 19.2Kbps, 21.6Kbps, 24Kbps, 26.4Kbps,...

- Page 14 Chapter 1 Dual access Number of reservations: 64 max. Image memory type: SDRAM Image data backup Storage method: JBIG Backup battery: rechargeable capacitor Backup length: 1 hr (approx.) 1.2.7 Function List 1.2.7.1 Print Speed (iR1019J) 0013-1045 T-1-10 Type Single-sided Two-sided Cassette feed Manual feed Cassette feed...

- Page 15 Chapter 1 width paper. The slowdown is reduced with the following user mode. User Mode: Additional Functions > Adjust/Cleaning > Spesial Mode S> ON 1.2.7.2 Print Speed (iRiR1023/1023N/1023iF) 0013-7801 T-1-11 Type Single-sided Two-sided Cassette feed Manual feed Cassette feed Manual feed Plain paper, colored paper, recycled paper, heavy paper 1 13(8,3,2)

- Page 16 Chapter 1 1.2.7.3 Types of Paper 0013-1046 T-1-12 Cassette Manual feed tray Duplex Size (W X L) A4 (For JP/KOR/EU/ 76 x 127 to 216 x 356 A4, LTR, LGL ASIA/OCE) LGL/LTR/OFICIO/BOFI/ M-OFI/FOOLSCAP (for USA/CA/LA) 16K/A4(for CHN) Weight 64 to 90 g/m2 56 to 128 g/m2 64 to 90 g/m2 Quantity...

- Page 17 Chapter 2 2.1.3 Installation Procedure 0013-4622 1. Preparations for main body 1) Turn off the main power switch of the host machine and disconnect the power plug from the outlet. 2) To release the hooks at the back of the machine, move the machine backward until the hooks are about 10 cm away from the edge of the desk and so on.

- Page 18 Chapter 2 6) To release the hooks at the lower right of the machine, float the right side of the machine about 5 cm above the edge of the desk and so on. 7) Release the two claws [1] at the rear back of the right cover. 8) Using a flathead screwdriver, release the three claws [2] at the top of the right cover.

- Page 19 Chapter 2 9) Remove the claw [1] at the front, and then release the two hooks [2] using a flathead screwdriver. 10) Remove right cover [4] in the direction of the arrow, and then detach the righy cover [4] by releasing the three hooks [3] at the bottom.

- Page 20 Chapter 2 11) Using a nipper, remove the precut portion [1] of the right cover as shown below. F-2-6 Smooth the edges of the interface cable hole so that the canle is not damaged. 12) Attach the right cover.

- Page 21 Chapter 2 2. Installation of a card reader 1) Remove the screw [1] from the card reader. F-2-7 F-2-9 MEMO: The removed screw will be used later. MEMO: 2) Remove the screw [1] securing the ground cable, The removed card reader mount is no longer and then separate the card reader [3] from the card necessary.

- Page 22 Chapter 2 When mounting the LAN cover, take care so that the LAN port [1] will not damage the grounding plate [2]. Also, after mounting the LAN cover, check to be sure that the grounding plate [2] is in firm contact with the LAN port [1].

- Page 23 Chapter 2 2.2.2.3 Checking the Version 3) Using the [ ] or [ ] key, select [TYPE]; then, press [OK]. 0013-3988 1) Press the following keys in the indicated order to 4) Using [ ] or [ ], select the type to suit the start service mode: country/zone in question.

- Page 24 Chapter 2 2.3 Installing the Network Interface Adapter iN-E11 2.3.1 Checking the Contents 0013-2552 F-2-38 LAN cover 1 pc. Wire saddle 1 pc. LAN board 1 pc. Screw (TP; M3x6) 7 pc. IP-LAN cable 1 pc.

- Page 25 Chapter 2 2.3.2 Installation procedure 3) Mount the LAN board [1], and connect the IP- LAN cable [2]. - 4 screws [3] (TP; M3x6) 2.3.2.1 Mounting to the Host Machine 0013-2553 1) Turn off the main power switch, and disconnect the power plug from the power outlet.

- Page 26 Chapter 2 5) Mount the LAN cover [1]. - 3 screws [2] (TP; M3x6) F-2-42 F-2-43 When mounting the LAN cover , take care so that the LAN port [1] will not damage the grounding plate [2]. Also, after mounting the cover, check to be sure that 6) Push the 2 claws [3] of the rear cover [1] the grounding plate is in firm contact with the LAN (indicated in the figure) using a flat-blade...

- Page 27 Chapter 3 3.1 Construction 3.1.1 Functional Construction 0013-1074 The machine may be divided into the following 7 functional blocks. Printer communication Fax communication system system Modem PCB*2 Network PCB*1 Mojular jack PCB*2 Image reading/ NCU PCB*2 processing system Original Image processor PCB CS unit DC controller Control...

- Page 29 Chapter 3 the laser unit. Smoothing The 600 x 600-dpi image data from the PC is converted into image data equivalent of 1200 x 600 dpi. Sensor Detection It detects the state of each sensor of the reader unit and the ADF. ESS Control It controls the ESS function used to reduce the power consumption while the machine isin standby state.

- Page 30 Chapter 3 <with SEND functions, with printer functions> Image processor PCB DDR-SDRAM (256MB) Flash ROM (16MB) USB MEMORY (128MB) PCL ROM (16MB) <w/o SEND functions, with printer functions> Image processor PCB DDR-SDRAM (128MB) Flash ROM (16MB) <w/o SEND functions, w/o printer functions> Image processor PCB DDR-SDRAM (64MB) Flash ROM (12MB)

- Page 31 Chapter 3 3.1.4 DC Controller PCB 0013-1077 Fixing Heater Control Block The fixing heater control block monitors the temperature reading of the thermistor to ensure that the temperature of the heater reaches a specific level. If an error is detected in the temperature of the heater, it stops the power to the heater.

- Page 32 Chapter 3 Chapter 3 3.2 Basic Sequence 3.2 Basic Sequence 3.2.1 Basic Sequence 3.2.1 Basic Sequence 0013-1086 0013-1086 The machine's sequence of operation is controlled by The machine's sequence of operation is controlled by the CPU on the image processor PCB and the the CPU on the image processor PCB and the CPU on the CPU on the DC controller PCB.

- Page 33 Chapter Chapter ORIGINAL E ORIGINAL E X X POSURE SYSTEM POSURE SYSTEM...

-

Page 34: Basic Sequence After Depression Of Start Key (Book Mode, One Sheet Of Original)

Contents Contents Contents Contents 4.1 Construction Construction ..........................................4-1 4.1.1 Specifications, Control Methods, and Functions Specifications, Control Methods, and Functions ........... 4-1 4.1.1 ........... 4-1 4.1.2 4.1.2 Major Components Major Components ..................... 4-2 ..................... 4-2 4.2 Basic Sequence Basic Sequence ......... -

Page 35: Contact Sensor

Chapter 4 Chapter 4 4.1 Construction 4.1 Construction 4.1.1 Specifications, Control Methods, and Functions 4.1.1 Specifications, Control Methods, and Functions 0013-9589 0013-9589 T-4-1 T-4-1 I I t t e e m m F F u u n n c c t t i i o o n n / / M M e e t t h h o o d d E E x x p p o o s s u u r r e e l l i i g g h h t t s s o o u u r r c c e e L L E E D D... -

Page 36: Contact Sensor Hp Sensor

Chapter 4 Chapter 4 4.1.2 Major Components 4.1.2 Major Components 0013-1088 0013-1088 The original exposure system consists of the following major components: The original exposure system consists of the following major components: - contact sensor used to read originals - contact sensor used to read originals - reader motor, drive pulley, drive belt, carriage, - reader motor, drive pulley, drive belt, carriage, and carriage rail used to move and carriage rail used to move the contactsensor ... -

Page 37: Basic Sequence

Chapter 4 Chapter 4 4.2 Basic Sequence 4.2 Basic Sequence 4.2.1 Basic Sequence at Power-on 4.2.1 Basic Sequence at Power-on 0013-1089 0013-1089 Main power switch Main power switch Reader motor Reader motor (M401) (M401) CS HP sensor CS HP sensor (SR401) (SR401) Shading... -

Page 38: Basic Sequence After Depression Of Start Key

Chapter 4 4.2.2 Basic Sequence after Depression of Start Key (Book mode, One Sheet of original) 0013-1091 Black shading/White shading Start key STBY SCFW SCRW STBY Reader motor (M401) CS HP sensor (SR401) Trailing edge Leading edge Shading Shading of original of original position position... - Page 39 Chapter 4 4.2.3 Basic Sequence after Depression of Start Key (ADF Mode, One Sheet of Original) 0013-1092 Black shading/White shading Start key STBY SCRW SCFW STBY Reader motor (M401) CS HP sensor (SR401) Shading Shading Stream reading Trailing edge position position position of original...

-

Page 40: Various Control

Chapter 4 4.3 Various Control 4.3.1 Enlargement/Reduction 4.3.1.1 Magnification Change in Vertical Scan Direction 0013-1093 In the Book mode or when the ADF is used In the vertical scan direction, the image is read at 100%. Magnification is changed by processing data on the image processor PCB. -

Page 41: Contact Sensor Hp Sensor

Chapter 4 If presence of dust is detected at all points A, B, and C in this order at job end, the machine will indicate a reading glass cleaning message in the control panel. 0.5mm 0.5mm A B C Reading glass lens Platen guide Contact sensor... - Page 42 Chapter 5 Chapter 5 5.2 Parts Replacement Procedure 5.2 Parts Replacement Procedure MEMO: MEMO: 5.2.1 Laser Scanner Unit 5.2.1 Laser Scanner Unit When reinstalling the laser scanner unit, it is difficult When reinstalling the laser scanner unit, it is difficult to install the encircled screw if your stubby screw to install the encircled screw if your stubby screw driver is not magnetized.

- Page 43 Chapter Chapter IMAGE FORMATION IMAGE FORMATION...

-

Page 44: Construction

Contents Contents Contents Contents 6.1 Construction Construction ..........................................6-1 6.1.1 Specifications and Control Mechanism Specifications and Control Mechanism ..............6-1 6.1.1 ..............6-1 6.1.2 6.1.2 Outline Outline .......................... 6-2 .......................... 6-2 6.2 Image Formation Process Image Formation Process ....................... -

Page 45: Construction

Chapter 6 Chapter 6 6.1 Construction 6.1 Construction 6.1.1 Specifications and Control Mechanism 6.1.1 Specifications and Control Mechanism 0013-1101 0013-1101 T-6-1 T-6-1 Items Items Description Description Photosensitive e drum Photosensitiv drum D D r r u u m m t t y y p p e e O O P P C C d d r r u u m m D D r r u u m m d d i i a a m m e e t t e e r r 2 2 4 4 m m m m... -

Page 46: Outline

Chapter 6 Chapter 6 6.1.2 Outline 6.1.2 Outline 0013-1102 0013-1102 The following is below the construction of the image The following is below the construction of the image formation system. formation system. The main of image formation components consist of the drum unit (a photosensitive drum, a primary charging The main of image formation components consist of the drum unit (a photosensitive drum, a primary charging roller, a cleaner blade) and the developing unit (a developing cylinder). - Page 47 Chapter 6 Chapter 6 6.2 Image Formation Process 6.2 Image Formation Process 6.2.1 Reproduction Processes 6.2.1 Reproduction Processes 0013-1103 0013-1103 The machine uses an indirect electrostatic method, The machine uses an indirect electrostatic method, and is constructed as shown below and is constructed as shown below Copyboard glass Copyboard glass...

- Page 48 Chapter 6 4. Fixing block 6. fixing Delivery 5. Drum cleaning block 7.drum cleaning 1. primary charging 1. Latent image formation block 5. separation 3. Transfer block 2. laser beam exposure 4. transfer 2. Development block 3. development Registration Multifeeder Rotation of photosensitive drum flow of paper Cassette pickup...

- Page 49 Chapter 6 6.3.2 Transfer Charging Roller Parts Replacement Procedure 6.3.2.1 Removing the Transfer Charging Roller 6.3.1 Developing Assembly 0013-1217 1) Open the left cover, and remove the drum unit. 6.3.1.1 Removing the Developing Unit 2) Release the two hooks [1], and then remove the transfer charging roller [2].

-

Page 50: Waste Toner Full Sensor

Chapter 6 6.3.3 Waste Toner Full Sensor 6.3.3.1 Removing the Waste Toner Full Sensor 0013-7332 1) Detach the reader left cover, front-left cover, and internal cover. 2) Detach the right cover, control panel, and de livery tray. 3) Remove the cable from the clamp [1]. 4) Remove the waste toner full sensor [2], detach the connector [3]. - Page 51 Chapter 7 7) Make a note of the positions ([A] to [C]) of two 9) Remove the three screws [1], and slide the three springs [1]. Next, remove the two springs [1]. voltage cable guide (right). F-7-21 F-7-23 8) Remove the four high voltage contacts [1] and the 10) Remove the connector (J15) on the power ...

- Page 52 Chapter 7 13) Release the claw [1], and remove the bushing [2]. Slide the developing unit lever [3]. F-7-27 F-7-26 16) Remove one E-ring [1], two bearings [2], and left 14) Make a note of the positions ([A] to [C]) of two registration roller [3].

- Page 53 Chapter 7 When reinstalling the right registration roller, the grounding spring [2] must be in touch with the end [1] of this roller. It is recommended to use tweezers when reinstalling the E-ring [3]. F-7-29 F-7-30 7.6.9 Registration Sensor 2) Release the two hooks [1], and then detach the registration sensor cover [2].

- Page 54 Chapter 7 3) Remove the two bosses [1], disconnect the connector [2], and then slide the registration sensor unit [3] toward you to remove it. F-7-34 7.6.11 Feeding Roller F-7-32 7.6.11.1 Removing the Cassete Feed 4) Remove the registration sensor [1] by releasing Roller ...

- Page 55 Chapter 7 5) Remove the bushing [1] and shaft [2], and then remove the feed roller [3]. F-7-36 7.6.12 Duplex Pickup Solenoid F-7-38 7.6.12.1 Removing the Duplex Pickup Solenoid 0013-3319 1) Remove the left cover and rear-right cover. 7.6.13 Separation Roller 2) Remove the fan duct, main motor, relay PCB, registration clutch, pickup drive unit, main drive 7.6.13.1 Removing the Cassette...

- Page 56 Chapter 7 5) Remove the claw [1], and pull out the separation roller assembly [2]. 6) Remove the shaft [3] from the shaft hole to remove the separation roller assembly [4]. F-7-40 7) Remove the shaft [1], and remove the separation roller [2].

- Page 57 Chapter E XTERNALS & CONTROLS...

- Page 58 Contents Contents 9.1 Control Panel ..................... 9-1 9.1.1 Outline .......................... 9-1 9.2 Fans ........................9-1 9.2.1 Outline .......................... 9-1 9.3 Power Supply System ..................9-2 9.3.1 Power Supply ......................9-2 9.3.1.1 Outline ............................ 9-2 9.3.1.2 Rated Output of the Power Supply PCB ................9-4 9.3.2 Protection Function ....................9-4 9.3.2.1 Protective Functions ......................

-

Page 59: Control Panel

Chapter 9 9.1 Control Panel 9.1.1 Outline 0013-1186 The machine's control panel consists of the following PCBs, and is controlled by the ASIC of the image processor PCB. Image processor Control panel PCB Key SW ASIC F-9-1 9.2 Fans 9.2.1 Outline 0013-1187 ... -

Page 60: Rated Output Of The Power Supply Pcb

Chapter 9 9.3.1.2 Rated Output of the Power Supply PCB 0013-1189 T-9-2 Output 24VR 3.3V 3.3VR Rated output voltage 24V 5.1V 5.1V 3.4V 3.4V Output voltage +10%, -5% +3%, -4% +3%, -4% +3%, -3% +3%, -3% tolerance Rated output current 4.5A 0.3A 0.7A 2.4A... -

Page 61: Parts Replacement Procedure

Chapter 9 9.4 Parts Replacement Procedure 9.4.1 External Covers 9.4.1.1 External Covers 9.4.1.1.1 Detaching the Reader Rear Cover (Small) 0013-2399 1) Remove the screw [1], and then detach the reader rear cover (small). F-9-4 9.4.1.1.2 Detaching the Reader Rear Cover 0013-2400 ... - Page 62 Chapter 9 9.4.1.1.3 Detaching the Rear Cover 9.4.1.1.4 Detaching the Reader Left Cover 0013-2401 0013-2403 1) To release the hooks at the back of the machine, 1) Open the left door. move the machine backward until the hooks are 2) Remove the two screws [1], and then detach the about 5 cm away from the edge of the desk and so reader left cover [2] as shown.

- Page 63 Contents Contents Contents Contents 10.1 Basic Construcion Basic Construcion ......10.1 ..............................10-1 10-1 10.1.1 Outline Outline ........................10-1 10.1.1 ........................10-1 10.1.2 10.1.2 Drive Mechanism Drive Mechanism ....................10-2 ....................10-2 10.2 Basic Operation Basic Operation ........10.2 ..............

-

Page 64: Basic Construcion

Chapter 10 Chapter 10 10.1 Basic Construcion 10.1 Basic Construcion 10.1.1 Outline 10.1.1 Outline 0013-1191 0013-1191 The ADF is a feeding device used exclusively for stream reading, and The ADF is a feeding device used exclusively for stream reading, and its series of operations (original pickup, its series of operations (original pickup, feeding, delivery) is performed using the drive feeding, delivery) is performed using the drive of the ADF motor (M2001). -

Page 65: Basic Operation

Chapter 10 Chapter 10 10.1.2 Drive Mechanism 10.1.2 Drive Mechanism 0013-1192 0013-1192 M2001 M2001 2 2 1 1 3 3 0 0 0 0 0 0 0 0 0 0 0 0 2 2 2 2 2 2 L L L L L... - Page 66 Chapter 10 Chapter 10 T-10-2 T-10-2 O O p p e e r r a a t t i i o o n n m m o o d d e e n n a a m m e e O O u u t t l l i i n n e e o o f f o o p p e e r r a a t t i i o o n n A A s s s s o o c c i i a a t t e e d d p p r r i i n n t t m m o o d d e e [1] Fo...

- Page 67 Chapter 10 Chapter 10 [2] Forward Pickup/Reversal Delivery Operation [2] Forward Pickup/Reversal Delivery Operation The document flow is shown below. The document flow is shown below. MEMO: MEMO: This operation is performed for all double-sided documents irrespective of whether document widths are the This operation is performed for all double-sided documents irrespective of whether document widths are the same.

- Page 68 Chapter 10 Chapter 10 Reversal Reversal Delivery Delivery Feed Feed End of job End of job Idle feed Idle feed F-10-5 F-10-5 10.2.2 Document Size Detection 10.2.2 Document Size Detection 0013-1194 0013-1194 This machine detects the original size while feeding This machine detects the original size while feeding the original.

-

Page 69: Paper Pickup Operation

Chapter 10 10.2.3 Paper Pickup Operation 0013-1195 The pickup unit consists of pickup and transport rollers. When the Start Key signal or Original Feed signal is input, the ADF motor (M2001) turns in the normal direction and then the pickup solenoid (SL2001) turns on. The pickup unit lowers and the pickup and transport rollers rotate to feed the paper. -

Page 70: Reversal Operation

Chapter 10 10.2.4 Reversal Operation 0013-1196 There are two types of reversal operations, reversal from the top side to the reverse side and reversal from the reverse side to the top side. However, since their operating principles are the same, only reversal from the top side to the reverse side is described below. -

Page 71: Delivery Operation

Chapter 10 c. Reversal/Feed 2 The original is fed by the ADF motor (M2001), passing through the original scanning unit. Thus, the original has been reversed. After completion of re-pickup, the roller release solenoid (M2003) turns off at completion of scanning of the reverse side of the original. After this, re-reversal, feed, and delivery operations are performed. -

Page 72: Adf Motor Unit

Chapter 10 10.4.4 Feed Frame Unit 10.4.5 ADF Motor Unit 10.4.4.1 Removing the Feed Frame Unit 10.4.5.1 Removing the ADF Motor 0013-1443 0013-1252 1) Detach the front cover, the rear cover, the open/ 1) Remove the feed frame unit. close cover and the pickup tray. 2) Remove the two screws [1], and then remove the 2) Disconnect the five connectors [1]. -

Page 73: Pick-Up/Feed Roller Unit

Chapter 10 4) Remove the two gears [1] and three screws [2], and then remove the bracket [3]. 5) Remove the clamp and edge saddle from the motor frame. The remaining part is the ADF motor unit [4]. F-10-26 F-10-25 When reinstalling the pickup/feed roller unit, care should be taken to the following: 1. -

Page 74: Original Separation Pad

Chapter 10 10.4.8 Original Separation Pad 10.4.9 Feed Roller 10.4.8.1 Removing the Separation Pad 10.4.9.1 Removing the Feed Roller 0013-1256 0013-1445 1) Open the open/close cover. 1) Remove the pickup/feed roller unit. 2) Release the two claws [1], and then remove the 2) Remove the screw [1], and then remove the roller ... -

Page 75: Separation Rear Sensor

Chapter 10 10.4.11 Separation Rear Sensor 10.4.11.1 Removing the Separation Rear Sensor 0013-1450 1) Detach the rear cover. 2) Release the hook, remove the separation rear sensor [1], and then disconnect the connector [2]. F-10-34 4) Disconnect the connector [1], release the hook, and then remove the registration sensor [2]. -

Page 76: Pick-Up Solenoid

Chapter 10 F-10-38 F-10-36 3) Remove the screw [1], and then remove the pickup solenoid [2]. 3) Release the claw to remove the document edge sensor [1], and then disconnect the connector [2]. F-10-39 10.4.15 Registaration Solenoid 10.4.15.1 Removing the Registration F-10-37 Solenoid 10.4.14 Pick-up Solenoid... - Page 77 Contents Contents 12.1 Image Adjustments ..................12-1 12.1.1 Image parallelism adjustment ................12-1 12.2 Scanning System ..................12-2 12.2.1 Procedure after Replacing the CS ..............12-2 12.2.2 Procedure after Replacing the Copyboard Glass (if equipped with SEND functions) ........................12-2 12.3 Electrical Components .................

-

Page 78: Image Adjustments

Chapter 12 12.1 Image Adjustments MEMO: Parallelism varies depending on the difference in the spring pressure between the front and rear springs. 12.1.1 Image parallelism adjustment For example, the spring position "0"at the back of the host machine and the spring position "-1"at the front 0014-5881 of the host machine are not shown in this document 1) Create a test chart, load it in the ADF, and make a... -

Page 79: Procedure After Replacing The Copyboard Glass (If Equipped With Send Functions)

Chapter 12 12.2 Scanning System T-12-2 Settings Spring Spring 12.2.1 Procedure after Replacing the positions positions at at the the front of back of host host machine 0013-1269 After replacing the contact sensor (CS), go through machine the following steps to perform inter-channel output Correction of image A correction: (The A-side extends.) - Page 80 Chapter 13 13.2 Outline of Electrical Components 13.2.1 Clutch/Solenoid 13.2.1.1 List of Clutches/Solenoids/Motors/Fans 0013-1282 <Main body> T-13-1 Symbol Name Function Part No. Connection jack No. Error Registration clutch Drives the registration roller. FK2-1401 J205 (Relay PCB) Duplex pickup solenoid Drives the duplex pickup roller. FK2-1409 J204 (Relay PCB) Cassette pickup solenoid Drives the cassette pickup roller.

-

Page 81: Adf

Chapter 13 <ADF> T-13-2 Symbol Name Function Part No. Connection jack No. Error SL2001 Pickup solenoid Drives the pickup roller. FK2-1393 J411 (Analog processor PCB) SL2002 Registaration solenoid Drives the registration roller. FK2-1393 J411 (Analog processor PCB) SL2003 Roller release solenoid Releases the delivery roller. - Page 82 Chapter 13 13.2.2 Sensor 13.2.2.1 List of Sensors 0013-1283 <Main body> T-13-3 Symbol Name Function Part No. Connection jack No. Jam code SR401 CS HP sensor Detects the CS home position. WG8-5776 J412 (Analog processor PCB) Delivery sensor Detects delivery. WG8-5776 J107 (DC controller 010c, 0210,...

- Page 83 Contents Contents Contents Contents 15.1 Outline Outline ......... 15.1 ......................................15-1 15-1 15.1.1 Outline of Service Mode Outline of Service Mode ..................15-1 15.1.1 ..................15-1 15.1.2 15.1.2 Using the Mode Using the Mode ...................... 15-2 ...................... 15-2 15.2 Default settings Default settings ........

- Page 84 Contents Contents pattern OFF time length (short)><019: pseudo RBT signal pattern OFF time length pattern OFF time length (short)><019: pseudo RBT signal pattern OFF time length (long)> (long)> .................................................. 15-23 15-23 15.5.11 <020: pseudo CI signal pattern ON time length><021: pseudo CI signal pattern <020: pseudo CI signal pattern ON time length><021: pseudo CI signal pattern 15.5.11 OFF time length (short)><022: pseudo CI signal pattern OFF time length (long)>...

- Page 85 Contents Contents 15.7 Setting of Printer Functions (PRINTER) Setting of Printer Functions (PRINTER) ......15.7 ............... 15-34 15-34 15.7.1 Service Soft Switch Settings (PRINTER) Service Soft Switch Settings (PRINTER) ............15-34 15.7.1 ............15-34 15.7.2 Numerin Parameter Settings (Numeric Prama.) Numerin Parameter Settings (Numeric Prama.) ..........15-36 15.7.2 ..........15-36 15.7.2.1...

- Page 86 Contents Contents 15.15.3 15.15.3 Print Test ((3) PRINT TEST) Print Test ((3) PRINT TEST) ........................15-5 ........15-51 1 15.15.4 MODEM Test ((4) MODEM TEST) MODEM Test ((4) MODEM TEST) ........15.15.4 ..............15-5 ......15-51 1 15.15.5 FUNCTION TEST <(6) FUNCTION TEST>...

- Page 87 Chapter 15 Chapter 15 15.1 Outline 15.1 Outline 15.1.1 Outline of Service Mode 15.1.1 Outline of Service Mode 0013-1301 0013-1301 The items that follow may be checked/set using the machine's service mode, which is designed the way the The items that follow may be checked/set using the machine's service mode, which is designed the way the service mode used in fax machines is designed in terms of contents and operation.

- Page 88 Chapter 15 Chapter 15 #TEST MODE #TEST MODE Makes various status checks, such as contact sensor, sensor and print Makes various status checks, such as contact sensor, sensor and print status. status. 15.1.2 Using the Mode 15.1.2 Using the Mode 0013-1302 ...

- Page 89 Chapter 15 15.2 Default settings 15.2.1 Service Mode Menus 0013-1303 #SSSW Initial setting Function SW01 00100000 error/copy control SW02 not used SW03 00000000 echo remedy setting SW04 00000000 communication fault remedy setting SW05 00000000 standard function (DIS signal) setting SW06 - SW11 not used SW12 00000010...

- Page 90 Chapter 15 #MENU Initial setting Range of Function setting 0: 33.6kbs V.34 transmission speed 1: 31.2kbs 2: 28.8kbs 3: 26.4kbs 4: 24.0kbs 5: 21.6kbs 6: 19.2kbs 7: 16.8kbs 8: 14.4kbs 9: 12.0kbs 10: 9.6kbs 11: 7.2kbs 12: 4.8kbs 13: 2.4kbs 0: 50Hz pseudo CI signal frequency setting 1: 25Hz...

- Page 91 Chapter 15 #NUMERIC Param. Initial setting Range of setting Function 001: not used 002: 10 (10%) (1 - 99) RTN signal transmission condition (1) setting 003: 15 (15lines) (2 - 9) RTN signal transmission condition (2) setting 004: 12 (12times) (1 - 99) RTN signal transmission condition (3) setting 005:...

- Page 92 Chapter 15 #SCAN Initial setting Range setting Explanation #SCAN SW SW1 - SW50 Not used #SCAN 001: - 023: Not used NUMERIC 024: 300 to 450, one CS scan position during ADF scanning. unit=0.1mm 025: Not used 026: 6 to 48, one Distance from the standby position of CIS to the unit=0.1mm shading start point.

- Page 93 Chapter 15 #SCAN Initial setting Range setting Explanation #SCAN 195: 0: LTR_R ADF special paper, standardized size: LTR_R NUMERIC 1: FOOLSCAP misidentification-ready 2: OFFICIO 3: E_OFFICIO 4: G_LTR_R 5: A_LTR_R 196 - 212: Not used 213: 8273 1 to 9999 XYZ correction value of (X) of standard white plate (equipped with SEND functions) 214:...

- Page 94 Chapter 15 #PRINT Initial Range setting Explanation setting 43:-50: not used 0 to 6, 1 unit = 5 Target 2-sided temperature adjustment deg C not used 0 to 9999, one Adjustment of margin at leading edge of copy unit = 0.1 mm 0 to 9999, one Adjustment of margin at trailing edge of copy unit = 0.1 mm...

- Page 95 Chapter 15 Function Silent mode Enable Disable Not used Pre-rotation extension mode Enable Disable 15.7.1.2.2 Detailed Discussions of Bit 0 0013-1382 Select whether to enable or disable transfer bias pressure reduction mode. Select "Enable" to avoid image defects (black spots) produced by transfer bias leaks occurring in a low-pressure region, such as one at a high altitude.

-

Page 96: Numerin Parameter Settings (Numeric Prama.)

Chapter 15 Function Not used 15.7.1.3.2 Detailed Discussions of Bit 3 0013-1388 Select whether split recording is to be enabled when text data such as a header and body text is recorded. Selecting "Set" may split text data when a small paper size such as A5 is selected. In this case, a page may be split in the middle of a character string. -

Page 97: 034: Left-End Registration Adjustment (Manual Feed Tray)

Chapter 15 the top margin of the image becomes. 15.7.2.5 <034: Left-end registration adjustment (manual feed tray)> 0013-1397 Adjust the left-end registration margin of paper picked from a manual feed tray. The larger the adjustment value, the wider the left-end margin of the image becomes. 15.7.2.6 <035: Left-end registration adjustment (cassette 1)>... -

Page 98: Accessory Registration

Chapter 15 15.8 Registration of Accessories (ACC) 15.8.1 Accessory Registration 0013-7948 The table below gives summary description of the ac cessories available. Item Explanation #ACC CARD Card reader installation setting Enter a card number to use. (0 to 9999. One hundred cards are registered with the department ID beginning from the input card number in sequence.) *1:1,000 cards if option ROM is mounted. -

Page 99: Counters

Chapter 15 15.9 Display of Counter Information (COUNTER) 15.9.1 Counters 0013-1409 This copier is furnished with a maintenance/supplies counter set (DRBL-1), which can be used to gain rough measures of when to replace supplies. The counter set increments by one on counting each sheet of small-sized paper (up to A4/LTR) and by two on counting each sheet of large-sized paper (larger than A4/LTR). -

Page 100: Clearing Counters

Chapter 15 15.9.2 Clearing Counters 0013-1410 - Maintenance/parts counter all clear Execute service mode > CLEAR > COUNTER to clear all maintenance/parts counters. - Counter clear on parts replacement Press the numeric keypad key 0 after displaying the counter for a part just replaced, and the counter will be cleared individually. - Page 101 Chapter 15 Tonal signal reception test MODEM TEST OFF OFF OFF OFF OFF OFF changes from '0' to '1' in response to detection of a signal of 462 25 Hz. changes from '0' to '1' in response to detection of a signal of 1100 30 Hz.

- Page 102 Chapter 15 Left/right arrow key Transmission speed 31200bps 33600bps 15.15.5 FUNCTION TEST <(6) FUNCTION TEST> 0013-1426 Function test ((6) FUNCTION TEST) Press the numeric keypad key 6 on the test mode menu to select the function test. Press numeric keypad keys 1 and 3 to 9 during the function test to enter the menus listed below. T-15-24 Keypad Item...

- Page 103 Chapter 15 6-3:SENOR [1] - [8] Press numeric keypad key 1. Press numeric keypad key 0. Press numeric keypad key 0. SENSOR CHECK SENSOR NORMAL CAS 0 REG 0 0:NORMAL 1:LATCH [0] - [2] DEL 0 0 MULTI 0 Select a sensor mode. CAS:Cassette paper sensor (SR9): 0/Document presence, 1/Document absence 0: NORMAL REG:Registration sensor (SR11): 0/Document presence, 1/Document absence...

- Page 104 Chapter 15 Press numeric keypad key 4. REF xxx ANT xxx |ANT - LEF| xxx REF: Toner reference voltage (A/D value) ANT: Toner antenna voltage (A/D value) ANT - LEF: Differential voltage (A/D value) Press numeric keypad key 5. BSCT on BDOC[A3 ] BDSS3-0 [of of of of] BSCT: Not used...

- Page 105 Chapter 15 from the numeric keypad and verify the transfer speed. Select between the ON and OFF states with the left and right cursor keys to select between single-sided document feed (OFF) and double-sided document feed (ON). Book feed test (6-5: BOOK FEED TEST) Performs a book feed operation with a specified magnification and in a specified size.

- Page 106 Chapter 15 [N] [F] [P] [J] F-15-20 Operation key test (2) correspondence diagram 09: [I] 01: [A] 05: [E] 10: [J] 02: [B] 06: [F] 11: [K] 03: [C] 07: [G] 12: [L] 04: [D] 08: [H] F-15-21...

- Page 108 Cassette Feeding Module-N1 SERVICE MANUAL...

- Page 109 This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

- Page 110 Introduction Symbols Used This documentation uses the following symbols to indicate special information: Symbol Description Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to avoid combustion (fire). Indicates an item prohibiting disassembly to avoid elec tric shocks or problems.

- Page 111 Introduction The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between elec- trical and mechanical systems with reference to the timing of operation. In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow indicates the direction of the electric signal.

- Page 112 Contents Contents Chapter 1 Specifications 1.1 Product Specifications ..................1-1 1.1.1 Product Specifications ....................1-1 1.2 Names of Parts ....................1-1 1.2.1 External View ......................1-1 1.2.2 Cross-Section ......................1-2 Chapter 2 Functions 2.1 Basic Construction .................... 2-1 2.1.1 Outline .......................... 2-1 2.1.2 Retry Pickup ........................

- Page 113 Contents Contents 3.1 Document Feeding System ................3-1 3.1.1 Pickup Rollor .......................3-1 3.1.2 Separation Rollor .......................3-1 3.1.3 Feed Rollor ........................3-2 3.2 Electrical System ....................3-3 3.2.1 Sensor ..........................3-3 3.2.2 Solenoid ........................3-3...

-

Page 114: Pickup Rollor

Chapter 3 3.1 Document Feeding System 3.1.2 Separation Rollor 3.1.2.1 Removing the Cassette Separation 3.1.1 Pickup Rollor Roller 3.1.1.1 Removing the Cassette Pickup 0012-7748 1) Remove the cassette. Roller 2) Place the machine with the rear side down. 3) While pressing the separation roller [1] to release 0012-7745 ... -

Page 115: Feed Rollor

Chapter 3 3.1.3 Feed Rollor 3.1.3.1 Removing the Cassete Feed Roller 0012-7751 1) Remove the cassette. 2) Place the machine with the rear side down. 3) While pressing the separation roller [1] to rele ase the pressure, remove the boss [2] and slide the feed roller upward until the shafts [3] are separated. -

Page 116: Electrical System

Chapter 3 3.2 Electrical System 3.2.1 Sensor 3.2.1.1 Removing the Cassette Paper Sensor 0012-7744 1) Release the two claws [1], and then detach the sensor cover [2]. F-3-10 2) Remove the four screws [1], and then remove the pickup drive unit [2]. F-3-8 2) Disconnect the connector [1], release the claw, and then remove the cassette paper sensor [2]. -

Page 117: Chapter 4 Maintenance

Chapter MAINTENANCE... - Page 118 Contents Contents 4.1 Maintenance and Inspection ................4-1 4.1.1 Periodically Replaced Parts ..................4-1 4.1.2 Durables ........................4-1 4.1.3 Periodical Servicing ....................4-1 4.2 Outline of Electrical Components ..............4-1 4.2.1 Sensor/Solenoid ......................4-1...

-

Page 119: Maintenance And Inspection

Chapter 4 4.1 Maintenance and Inspection 4.1.1 Periodically Replaced Parts 4.1.1.1 Periodically Replaced Parts The machine does not have parts that require periodical replacement. 4.1.2 Durables 4.1.2.1 Durables The machine does not have durables. 4.1.3 Periodical Servicing 4.1.3.1 Periodeical Service Items The machine does not have periodecal service items.