Endress+Hauser Micropilot M FMR250 Operating Instructions Manual

Level radar

Hide thumbs

Also See for Micropilot M FMR250:

- Operating instructions manual (120 pages) ,

- Technical information (56 pages) ,

- Brief operating instructions (36 pages)

Summary of Contents for Endress+Hauser Micropilot M FMR250

- Page 1 Operating Instructions Micropilot M FMR250 Level-Radar BA284F/00/en/08.06 71030747 Valid as of software version: 01.05.00...

- Page 2 Micropilot M FMR250 with HART/4...20 mA Brief overview For quick and simple commissioning: Safety Instructions → Page 6 ff. Explanation of the warning symbols You can find special instructions at the appropriate position in the chapter in question. The positions are indicated with the icons Warning #, Caution " and Note !.

- Page 3 Micropilot M FMR250 with HART/4...20 mA Brief operating instructions Micropilot M FMR240/244/245/250 - Brief operating instructions KA235F/00/a2/08.06 52025245 Contrast: measured dist./ value meas value Group selection media tank tank medium process empty full pipe dist./ check range of start type...

- Page 4 Micropilot M FMR250 with HART/4...20 mA Endress+Hauser...

-

Page 5: Table Of Contents

Operational safety ......6 9.10 Contact addresses of Endress+Hauser ... 84 Notes on safety conventions and symbols . -

Page 6: Safety Instructions

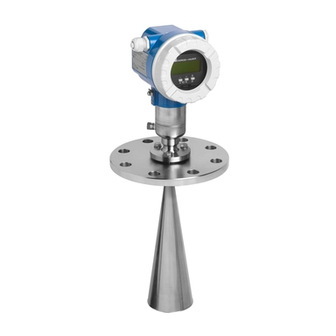

Safety instructions Designated use The Micropilot M FMR250 is a compact level radar for the continuous, contactless measurement of predominantly solids. The device can also be freely mounted outside closed metal vessels because of its operating frequency of about 26 GHz and a maximum radiated pulsed energy of 1mW (average power output 1 µW). -

Page 7: Notes On Safety Conventions And Symbols

Micropilot M FMR250 with HART/4...20 mA Safety instructions Notes on safety conventions and symbols In order to highlight safety-relevant or alternative operating procedures in the manual, the following conventions have been used, each indicated by a corresponding symbol in the margin. -

Page 8: Identification

Identification Micropilot M FMR250 with HART/4...20 mA Identification Device designation 2.1.1 Nameplate The following technical data are given on the instrument nameplate: L00-FMR2xxxx-18-00-00-en-001 Fig. 1: Information on the nameplate of the Micropilot M (example) 2.1.2 Ordering structure Ordering structure Micropilot M FMR250... - Page 9 Micropilot M FMR250 with HART/4...20 mA Identification Ordering structure Micropilot M FMR250 (continued) Antenna seal; Temperature: FKM Viton GLT; -40...200°C/-40...392 °F Special version Antenna extension: Not selected 250mm/10" 450mm/18" Special version Process connection: Thread DIN2999 R1-1/2, 316L Thread ANSI NPT1-1/2, 316L UNI flange DN200/8"/200A, 316L...

-

Page 10: Scope Of Delivery

The device complies with the applicable standards and regulations as listed in the EC declaration of conformity and thus complies with the statutory requirements of the EG directives. Endress+Hauser confirms the successful testing of the device by affixing to it the CE mark. -

Page 11: Installation

Micropilot M FMR250 with HART/4...20 mA Installation Installation Quick installation guide At mounting adjust the marking at the instrument flange! Installation in vessel (free space): Mark on process connector facing the nearest vessel wall! Turn housing The housing can be turned 350° in order to simplify access to the... -

Page 12: Installation Conditions

Installation Micropilot M FMR250 with HART/4...20 mA Installation conditions 3.3.1 Dimensions Housing dimensions max. 110 ENDRESS+HAUSER F12 housing (Aluminium) L00-F12xxxx-06-00-00-en-001 max. 100 ENDRESS+HAUSER T12 housing (Aluminium) L00-T12xxxx-06-00-00-en-001 max. 94 F23 housing (316L) L00-F23xxxx-06-00-00-en-001 Endress+Hauser... - Page 13 Micropilot M FMR250 with HART/4...20 mA Installation Micropilot M FMR250 - process connection, type of antenna F12 / T12 / F23 housing Threaded connection Flange DN80…100 E+H UNI flange DN 200 Alignment unit with 1 ½” BSPT (R 1 ½”)

- Page 14 Installation Micropilot M FMR250 with HART/4...20 mA E+H UNI flange The number of bolts has sometimes been reduced. The bolt-holes have been enlarged for adaption of dimensions, therefore, the flange needs to be properly aligned to the counterflange before the bolts are tightened.

- Page 15 Micropilot M FMR250 with HART/4...20 mA Installation 3.3.2 Engineering hints Orientation • Recommended distance (1) wall – outer edge of nozzle: ~1/6 of vessel diameter. However, the device should not, under any circumstances, be mounted less than 20 cm/ 8“ from the vessel wall.

- Page 16 Installation Micropilot M FMR250 with HART/4...20 mA Measurement in a plastic tank If the outer wall of the tank is made of a non-conductive material (e.g. GRP), microwaves can also be reflected off interfering installations outside the signal beam (e.g. metallic pipes (1), ladders (2), grates (3), …).

- Page 17 Micropilot M FMR250 with HART/4...20 mA Installation Measuring conditions • The measuring range begins, where the beam hits the vessel bottom. Particularly with dish bottoms or conical outlets the level cannot be detected below this point. The maximum measuring range can be increased in such applications by using an alignment unit (see Page 15).

- Page 18 Installation Micropilot M FMR250 with HART/4...20 mA Measuring range The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the mounting location and eventual interference reflections. The maximum configurable range is 70 m (229 ft) for Micropilot M FMR250.

-

Page 19: Installation Instructions

Micropilot M FMR250 with HART/4...20 mA Installation Installation instructions 3.4.1 Mounting kit For the mounting , you will require the following tool: • The tool for flange mounting or • a key AF60 for threaded boss and • 4 mm/0.1" Allen wrench for turning the housing. - Page 20 Installation Micropilot M FMR250 with HART/4...20 mA Standard installation FMR250 with horn antenna • Observe installation instructions on Page 15. • Marker is aligned towards vessel wall. • The marker is always exactly in the middle between two bolt-holes in the flange.

- Page 21 Micropilot M FMR250 with HART/4...20 mA Installation Standard installation FMR250 with parabolic antenna • Observe installation instructions on Page 15. • Marker is aligned towards vessel wall. • The marker is always exactly in the middle between two bolt-holes in the flange.

- Page 22 Installation Micropilot M FMR250 with HART/4...20 mA Examples for installation with small flange (< parabolic reflector) standard installation nozzle for installation in nozzle you can dismantle the parabolic reflector Antenna size 200mm/8” D [mm] H [mm] < 50 without antenna extension...

- Page 23 Micropilot M FMR250 with HART/4...20 mA Installation FMR250 with top target positioner Using top target positioner it is possible to tilt the antenna axis by up to 15° in all directions. The top target positioner is used for the optimum alignment of the radar beam with the bulk solids surface.

-

Page 24: Post-Installation Check

Installation Micropilot M FMR250 with HART/4...20 mA 3.4.3 Turn housing After mounting, the housing can be turned 350° in order to simplify access to the display and the terminal compartment. Proceed as follows to turn the housing to the required position: •... -

Page 25: Wiring

Micropilot M FMR250 with HART/4...20 mA Wiring Wiring Quick wiring guide Wiring in F12/F23 housing " Before connection please note the following: ● The power supply must be identical to the data on the Caution! ENDRESS+HAUSER nameplate (1). MICROPILOT M ●... - Page 26 Wiring Micropilot M FMR250 with HART/4...20 mA Wiring in T12 housing " Before connection please note the following: ● The power supply must be identical to the data on the nameplate (1). Caution! ENDRESS+HAUSER MICROPILOT M ● Switch off power supply before connecting up the device.

-

Page 27: Connecting The Measuring Unit

Micropilot M FMR250 with HART/4...20 mA Wiring Connecting the measuring unit Terminal compartment Three housings are available: • Aluminium housing F12 with additionally sealed terminal compartment for: – standard, – EEx ia, – EEx ia with dust Ex. • Aluminium housing T12 with separate terminal compartment for: –... - Page 28 Wiring Micropilot M FMR250 with HART/4...20 mA Supply voltage The following values are the voltages across the terminals directly at the instrument: Terminal voltage Current Communication consumption minimal maximal HART 4 mA 16 V 36 V standard 20 mA 7.5 V...

- Page 29 Micropilot M FMR250 with HART/4...20 mA Wiring 4.2.1 HART connection with E+H RMA422 / RN221N - ToF Tool - Fieldtool Package - FieldCare FXA193 4...20 mA RMA422 ENDRESS + HAUSER RMA 422 RN221N 1 2 3 4 - ToF Tool - dsdmdm df das.

-

Page 30: Recommended Connection

Wiring Micropilot M FMR250 with HART/4...20 mA Recommended connection 4.3.1 Equipotential bonding Connect the equipotential bonding to the external ground terminal of the transmitter. 4.3.2 Wiring screened cable " Caution! In Ex applications, the screen must only be grounded on the sensor side. Further safety instructions are given in the separate documentation for applications in explosion hazardous areas. -

Page 31: Operation

Micropilot M FMR250 with HART/4...20 mA Operation Operation Quick operation guide ENDRESS + HAUSER – >3 s media type basic setup Return to liquids tank shape medium property safety settings Group Selection solids dome ceiling unknown linearisation horizontal cyl DC: < 1.9 extended calibr. - Page 32 Operation Micropilot M FMR250 with HART/4...20 mA 5.1.1 General structure of the operating menu The operating menu is made up of two levels: • Function groups (00, 01, 03, …, 0C, 0D): The individual operating options of the instrument are split up roughly into different function groups. The function groups that are available include, e.g.: "basic setup", "safety settings", "output", "display", etc.

-

Page 33: Display And Operating Elements

Micropilot M FMR250 with HART/4...20 mA Operation Display and operating elements (liquid crystal display) Orde Orde Ser.- Ser.- r Cod r Cod No.: No.: sber surin sber surin eich eich g rang g rang U 16... U 16..20 . - Page 34 Operation Micropilot M FMR250 with HART/4...20 mA 5.2.1 Display Liquid crystal display (LCD): Four lines with 20 characters each. Display contrast adjustable through key combination. Headline Position indicator ENDRESS + HAUSER Symbol Main value Bargraph Unit – Selection list Function groups -> Functions HOME F000 F001 F002 F003 F004 ...

- Page 35 Micropilot M FMR250 with HART/4...20 mA Operation 5.2.2 Display symbols The following table describes the symbols that appear on the liquid crystal display: Sybmol Meaning ALARM_SYMBOL This alarm symbol appears when the instrument is in an alarm state. If the symbol flashes, this indicates a warning.

-

Page 36: Local Operation

Operation Micropilot M FMR250 with HART/4...20 mA Local operation 5.3.1 Locking of the configuration mode The Micropilot can be protected in two ways against unauthorised changing of instrument data, numerical values or factory settings: "unlock parameter" (0A4): A value <> 100 (e.g. 99) must be entered in "unlock parameter" (0A4) in the "diagnostics"... - Page 37 There is no need to change these parameters under normal circumstances and consequently, they are protected by a special code known only to the E+H service organization. Please contact Endress+Hauser if you have any questions.

- Page 38 Operation Micropilot M FMR250 with HART/4...20 mA 5.3.3 Factory settings (Reset) " Caution! A reset sets the instrument back to the factory settings. This can lead to an impairment of the measurement. Generally, you should perform a basic setup again following a reset.

-

Page 39: Display And Acknowledging Error Messages

Micropilot M FMR250 with HART/4...20 mA Operation Display and acknowledging error messages Type of error Errors that occur during commissioning or measuring are displayed immediately on the local display. If two or more system or process errors occur, the error with the highest priority is the one shown on the display. -

Page 40: Hart Communication

ToF Tool – Fieldtool Package The ToF Tool is a graphic and menu-guided operating program for measuring devices from Endress+Hauser. It is used for the commissioning, data storage, signal analysis and documentation of the devices. The following operating systems are supported: WinNT4.0, Win2000 and Windows XP. - Page 41 • FOUNDATION Fieldbus, PROFIBUS PA and HART via the FXA193/FXA291 service interface Note! You can use the ToF Tool to configure the Endress+Hauser parameters for devices with "FOUNDATION Fieldbus signal". You need an FF configuration program to be able to configure all the FF-specific parameters and to integrate the device into an FF network.

- Page 42 Operation Micropilot M FMR250 with HART/4...20 mA Signal analysis via envelope curve MicropilotM-en-306 Tank linearisation MicropilotM-en-307 Endress+Hauser...

-

Page 43: Commissioning

Micropilot M FMR250 with HART/4...20 mA Commissioning Commissioning Function check Make sure that all final checks have been completed before you start up your measuring point: • Checklist “Post installation check” (see Page 24). • Checklist “Post connection check” (see Page 30). -

Page 44: Basic Setup

Commissioning Micropilot M FMR250 with HART/4...20 mA Basic Setup level measurement in liquids media type media type flange: liquid solid reference point of measurement tank shape vessel / silo dome ceiling metal silo measuring cond. measuring cond. Unknown Unknown measuring cond. - Page 45 Micropilot M FMR250 with HART/4...20 mA Commissioning The basic setup is sufficient for successful commissioning in most applications. Complex measuring operations necessitate additional functions that the user can use to customise the Micropilot as necessary to suit his specific requirements. The functions available to do this are described in detail in the BA291F.

-

Page 46: Basic Setup With The Vu331

Commissioning Micropilot M FMR250 with HART/4...20 mA Basic Setup with the VU331 Function "measured value" (000) ⇒ ENDRESS + HAUSER – This function displays the current measured value in the selected unit (see "customer unit" (042) function). The number of digits after decimal point can be selected in the "no.of decimals"... - Page 47 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "tank shape" (002), liquids only ⇒ ENDRESS + HAUSER – This function is used to select the tank shape. Selection: • dome ceiling • horizontal cyl • bypass • stilling well • flat ceiling •...

- Page 48 Commissioning Micropilot M FMR250 with HART/4...20 mA Function "medium property" (003), liquids only ⇒ ENDRESS + HAUSER – This function is used to select the dielectric constant. Selection: • unknown • DC: < 1.9 • DC: 1.9 ... 4 • DC: 4 ... 10 •...

- Page 49 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "process cond." (004) , liquids only ⇒ ENDRESS + HAUSER – This function is used to select the process conditions. Selection: • standard • calm surface • turb. surface • agitator • fast change •...

- Page 50 Commissioning Micropilot M FMR250 with HART/4...20 mA Function "vessel / silo" (00A), solids only ⇒ ENDRESS + HAUSER – This function is used to select the vessel / silo. Selection: • unknown • metal silo • concrete silo • bin / bunker •...

- Page 51 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "process cond." (00C), solids only ⇒ ENDRESS + HAUSER – This function is used to select the process conditions. Selection: • standard • fast change • slow change • test:no filter Endress+Hauser...

- Page 52 Commissioning Micropilot M FMR250 with HART/4...20 mA Function "empty calibr." (005) ⇒ ENDRESS + HAUSER – This function is used to enter the distance from the flange (reference point of the measurement) to the minimum level (=zero). L00-FMR2xxxx-14-00-06-en-008 " Caution! For dish bottoms or conical outlets, the zero point should be no lower than the point at which the radar beam hits the bottom of the vessel.

- Page 53 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "full calibr." (006) ⇒ ENDRESS + HAUSER – This function is used to enter the distance from the minimum level to the maximum level (=span). L00-FMR2xxxx-14-00-06-en-009 In principle, it is possible to measure up to the tip of the antenna. However, due to considerations regarding corrosion and build-up, the end of the measuring range should not be chosen any closer than 50 mm (2") to the tip of the antenna.

- Page 54 Commissioning Micropilot M FMR250 with HART/4...20 mA Function "pipe diameter" (007) ⇒ ENDRESS + HAUSER – This function is used to enter the pipe diameter of the stilling well or bypass pipe. 100% 100% ø ø L00-FMR2xxxx-14-00-00-en-011 Microwaves propagate more slowly in pipes than in free space. This effect depends on the inside diameter of the pipe and is automatically taken into account by the Micropilot.

- Page 55 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "check distance" (051) ⇒ ENDRESS + HAUSER – This function triggers the mapping of interference echoes. To do so, the measured distance must be compared with the actual distance to the product surface. The following options are available for...

- Page 56 Commissioning Micropilot M FMR250 with HART/4...20 mA Function "range of mapping" (052) ⇒ ENDRESS + HAUSER – This function displays the suggested range of mapping. The reference point is always the reference point of the measurement (see Page 44 ff.). This value can be edited by the operator.

- Page 57 Micropilot M FMR250 with HART/4...20 mA Commissioning display (008) ⇒ ENDRESS + HAUSER – The distance measured from the reference point to the product surface and the level calculated with the aid of the empty adjustment are displayed. Check whether the values correspond to the actual level or the actual distance.

- Page 58 Commissioning Micropilot M FMR250 with HART/4...20 mA 6.4.2 Envelope curve with VU331 After the basic setup, an evaluation of the measurement with the aid of the envelope curve ("envelope curve" (0E) function group) is recommended. Function "plot settings" (0E1) ⇒...

- Page 59 Micropilot M FMR250 with HART/4...20 mA Commissioning Function "envelope curve display" (0E3) The envelope curve is displayed in this function. You can use it to obtain the following information: quality of evaluated echo full calibr. evaluated echo is marked empty calibr.

- Page 60 Commissioning Micropilot M FMR250 with HART/4...20 mA Move mode Then press to switch to Move mode. Either is displayed. • shifts the curve to the right. • shifts the curve to the left. L00-FMxxxxxx-07-00-00-yy-008 Vertical Zoom mode Press once more to switch to Vertical Zoom mode.

-

Page 61: Basic Setup With The Endress+Hauser Oprating Program

Micropilot M FMR250 with HART/4...20 mA Commissioning Basic Setup with the Endress+Hauser oprating program To carry out the basic setup with the operating program, proceed as follows: • Start the operating program and establish a connection. • Select the "basic setup" function group in the navigation window. - Page 62 Commissioning Micropilot M FMR250 with HART/4...20 mA Basic Setup step 2/4: • Enter the application parameters: – vessel / silo – medium property – process cond. MicropilotM-en-412 Basic Setup step 3/4: If "metal silo", "concrete silo", "..." is selected in the "vessel / silo" function, the following display appears on the screen: •...

- Page 63 Micropilot M FMR250 with HART/4...20 mA Commissioning Basic Setup step 4/4: • This step starts the tank mapping • The measured distance and the current measured value are always displayed in the header MicropilotM-en-404 6.5.1 Signal analysis via envelope curve After the basic setup, an evaluation of the measurement using the envelope curve is recommended.

- Page 64 Commissioning Micropilot M FMR250 with HART/4...20 mA 6.5.2 User-specific applications (operation) For details of setting the parameters of user-specific applications, see separate documentation BA291F/00/en "Description of the instrument functions for Micropilot M" on the enclosed CD- ROM. Endress+Hauser...

-

Page 65: Maintenance

They contain the related replacement instructions. All the spare parts kits which you can order from Endress+Hauser for repairs to the Micropilot M are listed with their order numbers on and . Please contact Endress+Hauser Service for further information on service and spare parts. -

Page 66: Accessories

L00-FMR2xxxx-00-00-06-en-001 Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (= Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a notebook. For details refer to TI405C/07/en. Note! For the following Endress+Hauser instruments you need the "ToF Adapter FXA291" as an additional accessory: •... - Page 67 Accessories ToF Adapter FXA291 The ToF Adapter FXA291 connects the Commubox FXA291 via the USB interface of a personal computer or a notebook to the following Endress+Hauser instruments: • Cerabar S PMC71, PMP7x • Deltabar S PMD7x, FMD7x • Deltapilot S FMB70 •...

- Page 68 Accessories Micropilot M FMR250 with HART/4...20 mA Approval: Nn-hazardous area ATEX II 2 G EEx ia IIC T6, ATEX II 3D FM IS Cl.I Div.1 Gr.A-D CSA IS Cl.I Div.1 Gr.A-D CSA General Purpose TIIS ia IIC T6 (in preparation) Cable: 20m/65ft;...

-

Page 69: Trouble-Shooting

Micropilot M FMR250 with HART/4...20 mA Trouble-shooting Trouble-shooting Trouble-shooting instructions Micropilot M FMR 250 -Trouble Shooting Check voltage and Not ok compare it with the Instrument does Connect the Instrument works? Ready specifications on the not respond correct voltage nameplate. -

Page 70: System Error Messages

Trouble-shooting Micropilot M FMR250 with HART/4...20 mA System error messages Code Description Possible cause Remedy A102 checksum error device has been powered off before data reset; general reset & new could be stored; avoid emc problem; calibr.required emc problem; if alarm prevails after reset,... - Page 71 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting Code Description Possible cause Remedy E641 no usable echo echo lost due to application conditions or check installation; channel 1 built up on antenna optimize orientation of antenna; check calibr. clean antenna (cf. OM)

-

Page 72: Application Errors In Liquids

Trouble-shooting Micropilot M FMR250 with HART/4...20 mA Application errors in liquids Error Output Possible cause Remedy A warning or alarm Depending on the configuration See table of error 1. See table of error messages has occurred. messages (see Page 70) (see Page 70) →... - Page 73 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting Error Output Possible cause Remedy → If the surface is not Signal is weakened by 1. Carry out tank mapping basic calm (e.g. filling, the rough surface – the setup emptying, agitator 100% interference echoes are 2.

-

Page 74: Application Errors In Solids

Trouble-shooting Micropilot M FMR250 with HART/4...20 mA Application errors in solids Error Output Possible cause Remedy A warning or alarm Depending on the configuration See table of error 1. See table of error messages has occurred. messages (see Page 70) (see Page 70) →... - Page 75 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting Error Output Possible cause Remedy → During filling or Signal is weakened (e.g. 1. Carry out tank mapping basic emptying the by fluidisation of the setup 100% measured value surface, extreme dust 2. Increase the output damping...

-

Page 76: Orientation Of The Micropilot

Trouble-shooting Micropilot M FMR250 with HART/4...20 mA Orientation of the Micropilot For orientation a marker is found on the flange or threaded boss of the Micropilot. During installation this must be oriented as follows (see Page 11): • In tanks: to the vessel wall •... -

Page 77: Endress+Hauser

Micropilot M FMR250 with HART/4...20 mA Trouble-shooting L00-FMRxxxxx-19-00-00-en-004 Fig. 7: Vessel empty, no interference echo L00-FMRxxxxx-19-00-00-en-005 Fig. 8: Vessel empty, interference echo obtained Fix the flange or threaded boss in this position. If necessary, replace the seal. Carry out tank mapping, see Page 55. -

Page 78: Spare Parts

(see Page 8s. Seite 8 ff.). The corresponding spare part number also appears on each spare part. Installation instructions are given on the instruction card that is also delivered. Spare parts Micropilot M FMR250, F12 housing with combined wiring and electronics compartment O r d d e : r. - Page 79 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting 11 Hood for terminal compartment 52006026 Cover terminal compartment F12 52019062 Hood terminal compartment F12, FHX40 12 Screw set 535720-9020 Set of screws housing F12/T12 20 Cover 52005936 Cover F12/T12 Aluminium, window, gasket...

- Page 80 Trouble-shooting Micropilot M FMR250 with HART/4...20 mA Spare parts Micropilot M FMR250, T12 housing with separate wiring and electronics compartment O rd d e : r. -N I L O o .: s s b e re a s u...

- Page 81 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting 20 Cover 52005936 Cover F12/T12 Aluminium, window, gasket 517391-0011 Cover F12/T12 Aluminium, coated, gasket 25 Cover for terminal compartment 518710-0020 Cover T3/T12, Aluminium, coated, gasket 30 Electronics 71026754 Electronics FMR24x/FMR250, Ex, HART, v5.0 71026819 Electronics FMR24x/FMR250, Ex, PA, v5.0...

- Page 82 Trouble-shooting Micropilot M FMR250 with HART/4...20 mA Spare parts Micropilot M FMR250, F23 housing with combined wiring and electrinics compartment in a L00-FMR250xx-00-00-06-xx-003 Stainless steel housing on request! 20 Cover 52018670 Cover F23, 316L, sight glass, gasket 52018671 DeCoverckel F23, 316L, gasket...

- Page 83 Micropilot M FMR250 with HART/4...20 mA Trouble-shooting Spare parts Micropilot M FMR250, horn/parabolic antenna M IC O rd M IC O rd C od S er P IL C od S er P IL o. : o. : M es...

-

Page 84: Return

BA291F/00/en/08.06 71030727 • Communication: FOUNDATION Fieldbus 9.10 Contact addresses of Endress+Hauser The addresses of Endress+Hauser are given on the back cover of this operating manual. If you have any questions, please do not hesitate to contact your E+H representative. Endress+Hauser... -

Page 85: Technical Data

Micropilot M FMR250 with HART/4...20 mA Technical data Technical data 10.1 Additional technical data 10.1.1 Input Measured variable The measured variable is the distance between a reference point and a reflective surface (i.e. medium surface). The level is calculated based on the tank height entered. - Page 86 Technical data Micropilot M FMR250 with HART/4...20 mA Influence of ambiente The measurements are carried out in accordance with EN 61298-3: temperature • digital output (HART, PROFIBUS PA): – FMR250 average T : 5 mm/10 K, max. 15 mm over the entire temperature range -40 °C...+80 °C •...

- Page 87 • F23 housing: approx 9.4 kg + weight of flange 10.1.8 Certificates and approvals CE approval The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms the instrument passing the required tests by attaching the CE-mark. RF approvals R&TTE, FCC...

- Page 88 Technical data Micropilot M FMR250 with HART/4...20 mA Ex approval Correlation of safety instructions (XA) and certificates (ZE) to the instrument: Instrument Certificate Explosion protection Output Communication Housing PTB 04 ATEX FMR250 Non-hazardous area A, B, C, HART, — —...

- Page 89 Micropilot M FMR250 with HART/4...20 mA Technical data 10.1.9 Supplementary Documentation Supplementary • Technical Information (TI390F/00/en) Documentation • Operating Instructions "Description of instrument functions" (BA291F/00/en) Endress+Hauser...

-

Page 90: Appendix

Appendix Micropilot M FMR250 with HART/4...20 mA Appendix 11.1 Operating menu HART (display modul), ToF Tool basic setup media type tank shape medium cond. process cond. empty calibr. full calibr. liquid dome ceiling unknown standard enter value enter value horizontal cyl. - Page 91 Micropilot M FMR250 with HART/4...20 mA Appendix dist./meas.value check distance range of mapping start mapping dist./meas.value distance = ok input of D and L dist. too small mapping range are displayed manual D and L are displayed pipe diameter dist. unknown enter value dist.

-

Page 92: Description Of Functions

Appendix Micropilot M FMR250 with HART/4...20 mA 11.2 Description of functions Note! A detailed description of the function groups, functions and parameters is given in the documentation BA291F/00/en "Description of the instrument functions of the Micropilot M" on the enclosed CD-ROM. -

Page 93: Function And System Design

Micropilot M FMR250 with HART/4...20 mA Appendix 11.3 Function and system design 11.3.1 Function (Measuring principle) The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight method. It measures the distance from the reference point (process connection) to the product surface. - Page 94 Appendix Micropilot M FMR250 with HART/4...20 mA Output The Micropilot is commissioned by entering an empty distance E (=zero), a full distance F (=span) and an application parameter. The application parameter automatically adapts the instrument to the process cond.. The data points “E” and “F” correspond with 4mA and 20mA for instruments with current output.

- Page 95 • with a Personal Computer, FXA193 and the operating software "ToF Tool - FieldTool Package" respectively "FieldCare". The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on the time-of-flight principle (radar, ultrasonic, guided micro-impulse). It assists with commissioning, securing data, signal analysis and documentation of the measuring point.

-

Page 96: Index

Micropilot M FMR250 with HART/4...20 mA Index Index accessories ........66 installation . - Page 97 Micropilot M FMR250 with HART/4...20 mA Index Service Interface FXA291 ..... . 66–67 software history....... . . 84 spare parts.

- Page 98 Micropilot M FMR250 with HART/4...20 mA Index Endress+Hauser...

- Page 99 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 100 www.endress.com/worldwide BA284F/00/en/08.06 71030747 CCS/FM+SGML 6.0 71030747...